We are elated to announce that Best Technology has recently completed 14 years of its glorious journey. Every small step has been worth celebrating. On June 26, 2020, our founder, Peter, Emily, group leaders and all the employees spent this unforgettable festival together.

On Best Technology successful journey, Peter opines- “These past 14 years have been a period of growth and a learning experience for us as we went through several trials and errors till we deliver successful business. Today we are proud of the fact that our employees can make great progress day by day after training with us and feel confident taking on tough project-related challenges,thanks for all the endeavour from employees and thanks for the great support from our suppliers and customers. Best Technology’s continuous development can not do without them.â€

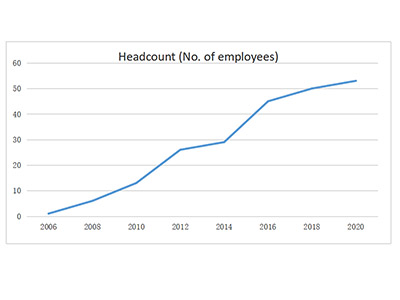

We have come a long way from 2006 when we started off with just 1 people(Peter). Today we are proud to announce that we have nearly 100 employees and many sister companies spread all over China mainland and also have customers in over 150 countries around the world.

From above, it is evident that there has been a staggering growth in the number of employees in the span of 14 years. This enhanced employee strength has built the roadmap to Best Technology’s success.

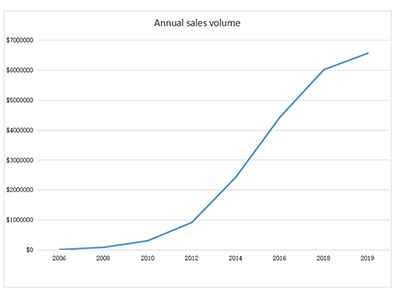

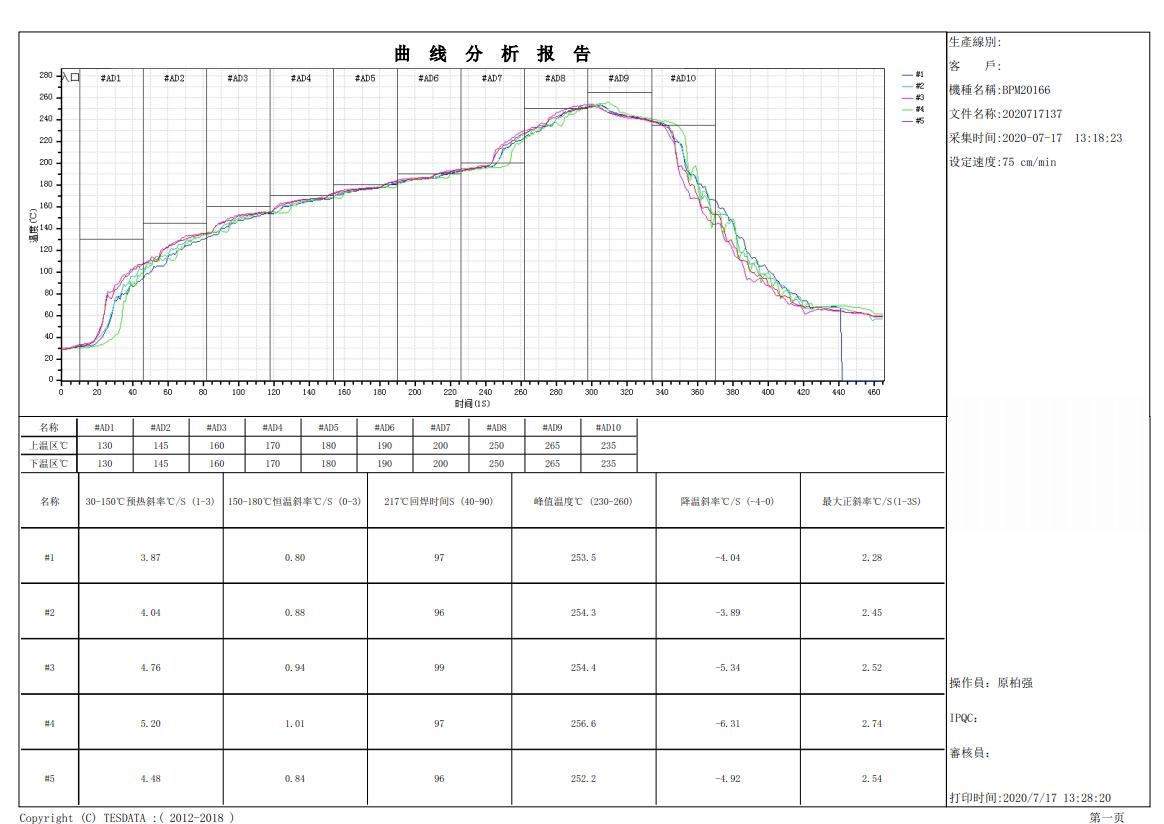

The above graph presents our company’s growth against the years 2006 to 2020. It can be seen that the growth rate is very high from 2006($8000) to 2019($6560,000). At this year 2020, Best Technology still keeps growing with increasing sales volume in spite of COVID-19 outbreak.

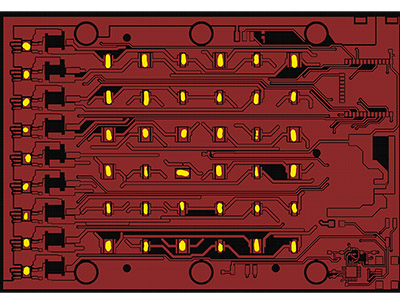

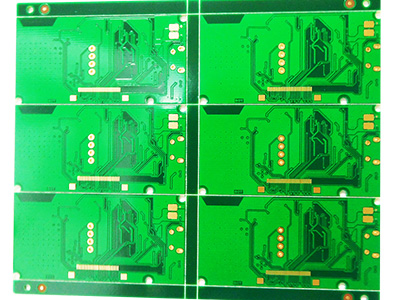

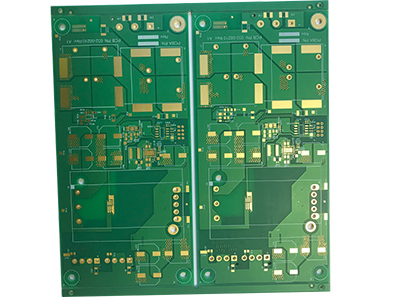

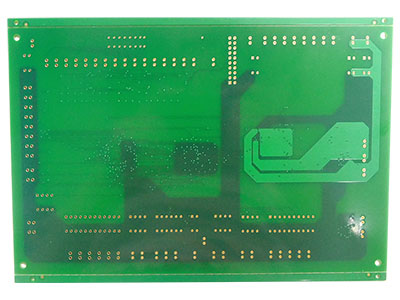

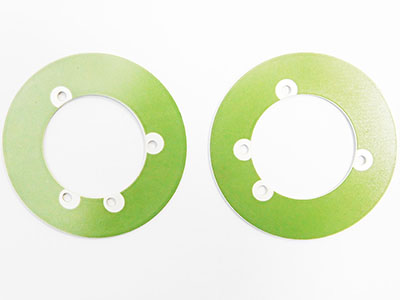

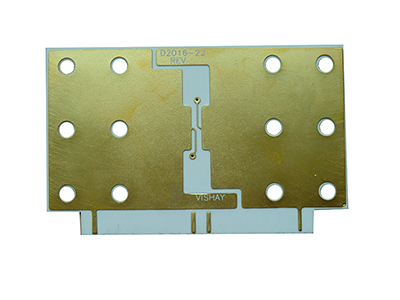

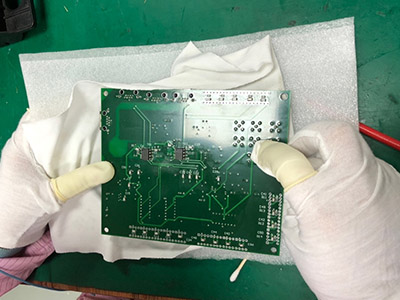

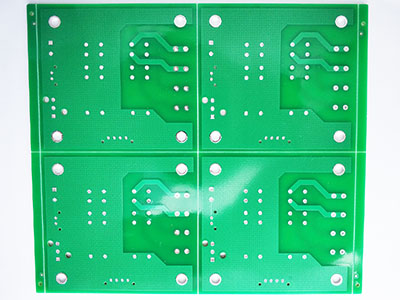

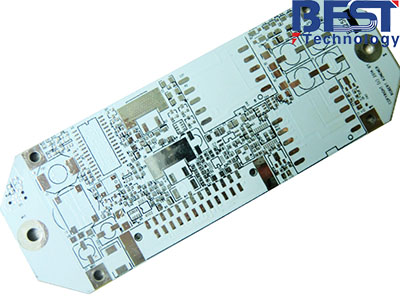

Best Technology’s unique journey has been a brick-by-brick progress and has entailed years of efforts. Our company’s commitment in becoming world class distinctive solution of printed circuit board and metal domes in 2025 has paved the way to the series of milestones achieved. These are equally appreciated by the correct leadership of our chairman, Peter.

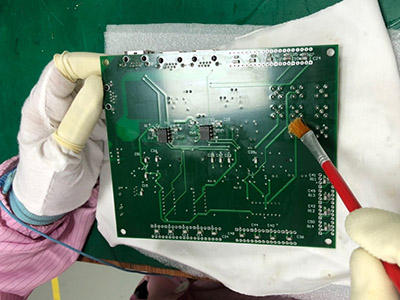

The primary aim of our company has been to equip the professionals with all possible accoutrements to tackle on-job challenges. Today’s ever changing face of businesses demands deeper knowledge, quality, and on-time delivery. Customers are always looking out for continuous and improved delivery. The best means to achieve the same is to keep improving.

We will continue our journey towards innovating the new ways of learning, delivering excellence to the customers and lending a hand to achieve professional goals.

What’s more, Best Technology’s 14th-year anniversary celebration is a solemn procession of efforts and dedication of the trainers and staffs who have spent their quality time to provide the best services and meet more expectations of the ever evolving PCB world.