Medical PCB assembly‚Äč is the critical, life-supporting backbone of modern healthcare electronics, where precision and reliability are non-negotiable. This article explores the stringent requirements, key standards, and best practices for partnering with a manufacturer that delivers both speed and accuracy for mission-critical medical devices.

Navigating the world of medical PCB assembly services‚Äč can be fraught with challenges. Are you struggling to find a partner who truly understands the stakes of PCB assembly for medical devices? Common pain points include:

- Balancing uncompromising quality with the need for cost efficiency and faster time-to-market.

- Navigating the complex web of medical industry regulations and standards without expert guidance.

- Sourcing a manufacturer capable of handling specialized needs like best rigid-flex PCB assembly services for medical devicesfor compact, durable designs.

- Experiencing frustrating delays or quality inconsistencies with overseas suppliers, despite lower china medical PCB assembly quotes.

- Finding a true partner for customized medical devices PCB assemblythat offers proactive support, not just a transactional service.

The solution lies in selecting a specialized, experienced partner. A trusted medical PCB assembly manufacturer‚Äč directly addresses these challenges by providing:

- Advanced manufacturing protocols and supply chain management to ensure high-quality, reliable medical PCB assembliesat competitive value.

- In-depth regulatory expertise and a quality system designed for compliance, making certification smoother.

- Specialized engineering and production capabilities for complex technologies like rigid-flex boards.

- A transparent, managed global supply chain that leverages efficiency without sacrificing the accountability expected in USA PCB manufacturing.

- A collaborative approach, treating your project as a partnership from the medical PCB assembly quotesstage through to full-scale production and support.

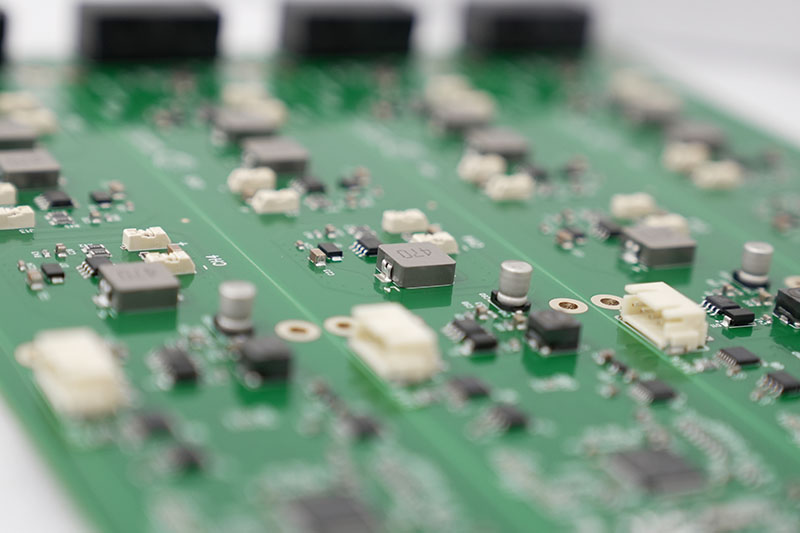

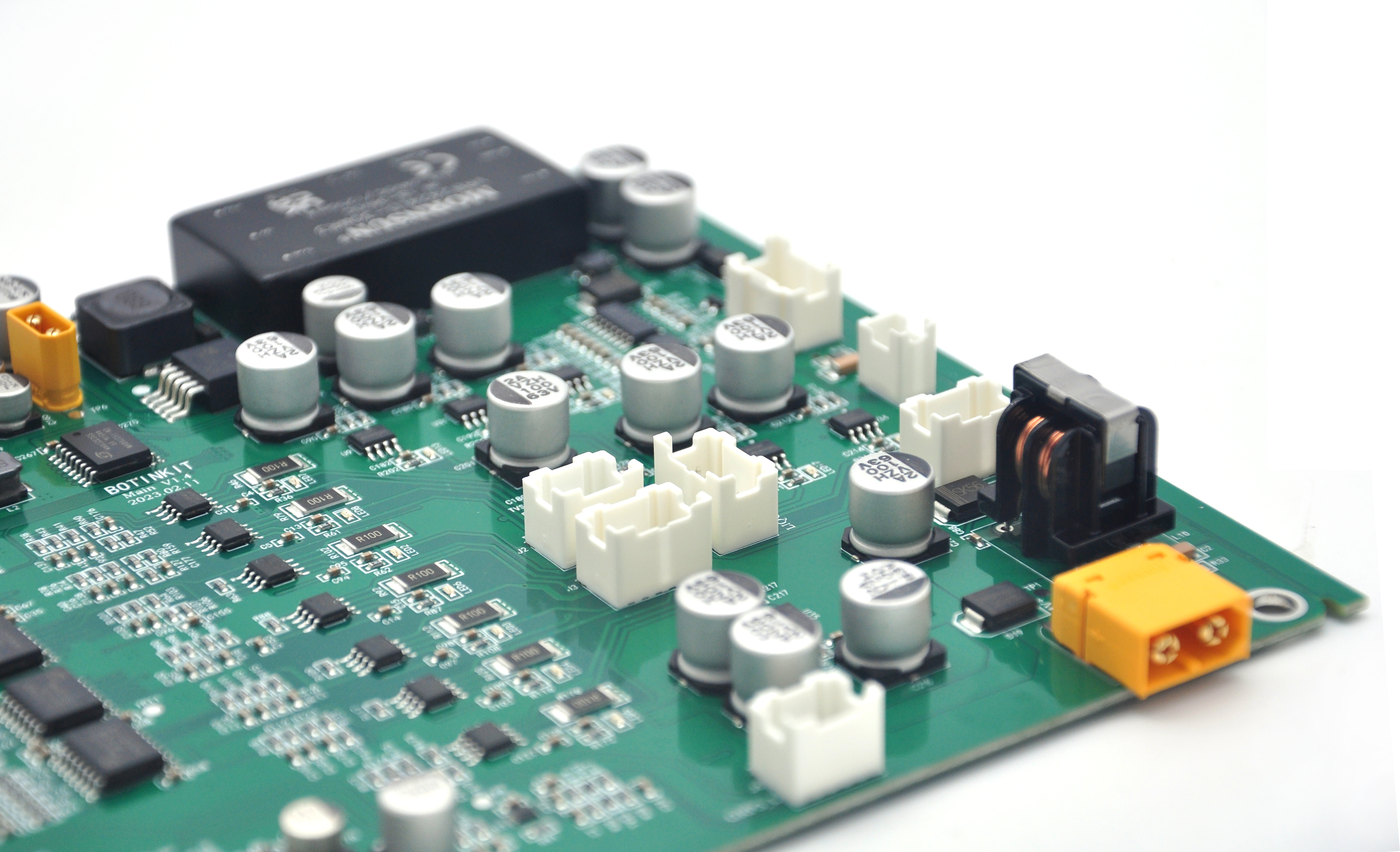

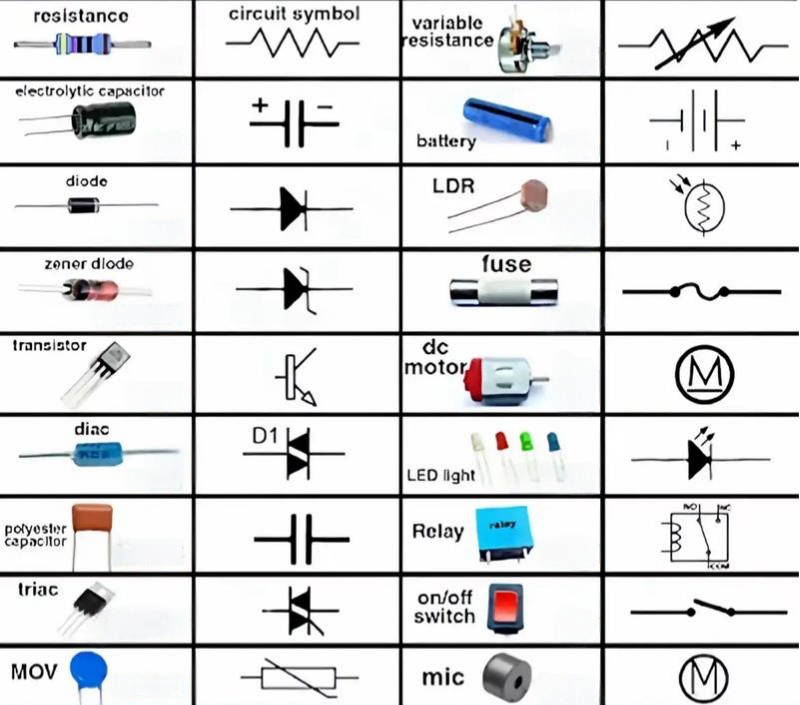

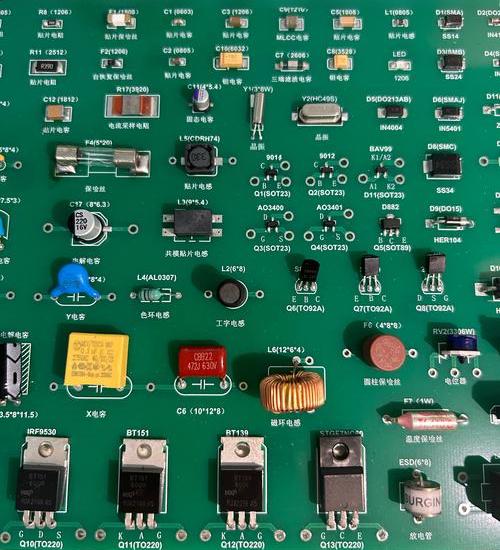

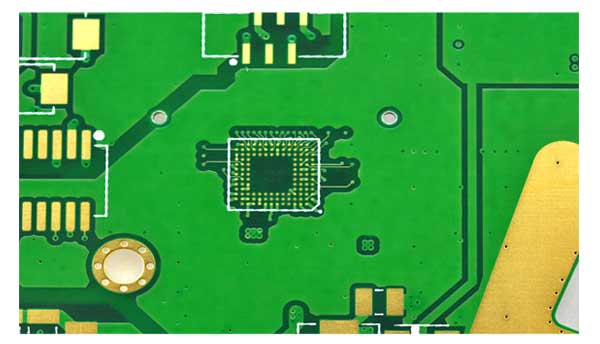

At BEST Technology, we are a specialized medical PCB assembly factory‚Äč with over 19 years of dedicated experience in PCB assembly for the medical industry. We combine state-of-the-art manufacturing with an unwavering commitment to the rigorous standards of healthcare electronics. All our medical PCB production complies with ISO 13485. The most common PCB types used in medical electronics include HDI PCBs, flexible PCBs, rigid-flex PCBs, heavy-copper PCBs, ultra-thin PCBs, high-frequency, microwave RF PCBs, and high-reliability PCBs. Our real expertise ensures your devices are built for reliability. Pls feel free to contact us at sales@bestpcbs.com‚Äč to discuss your project.

Medical PCB Assembly Requirements and Design Considerations

Designing PCBs for medical devices extends far beyond standard electronic assembly. It requires a foundational understanding of the device’s application, risk class, and operational environment to ensure patient safety and device efficacy.

- Biocompatibility & Cleanliness:‚Äč Assemblies must use materials that are non-toxic and processes that prevent ionic contamination, crucial for implants or devices contacting bodily fluids.

- High Reliability & Longevity:‚Äč Devices often require 10-15+ years of operational life. This demands careful component selection (e.g., long-life capacitors), conservative derating, and robust design for thermal management.

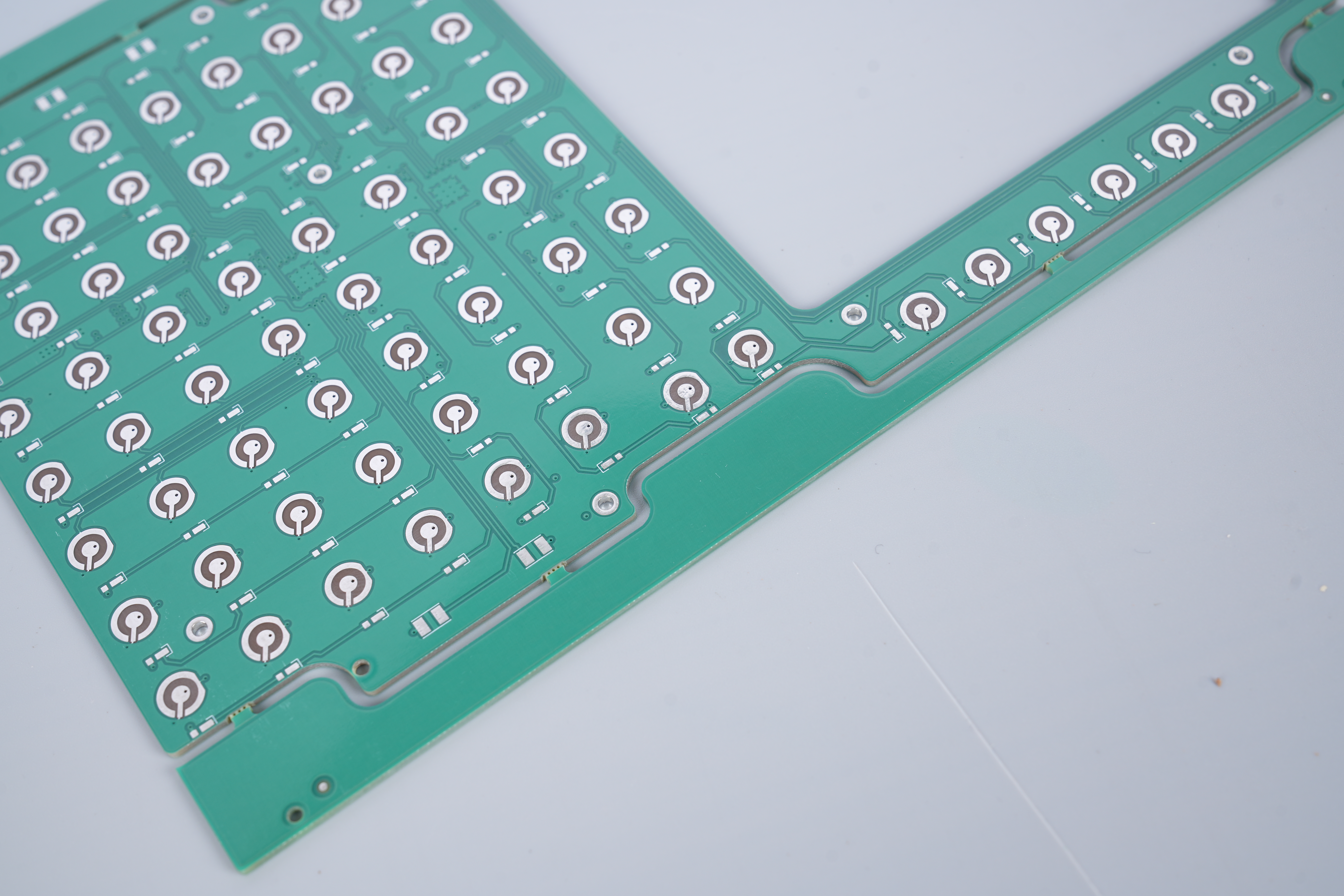

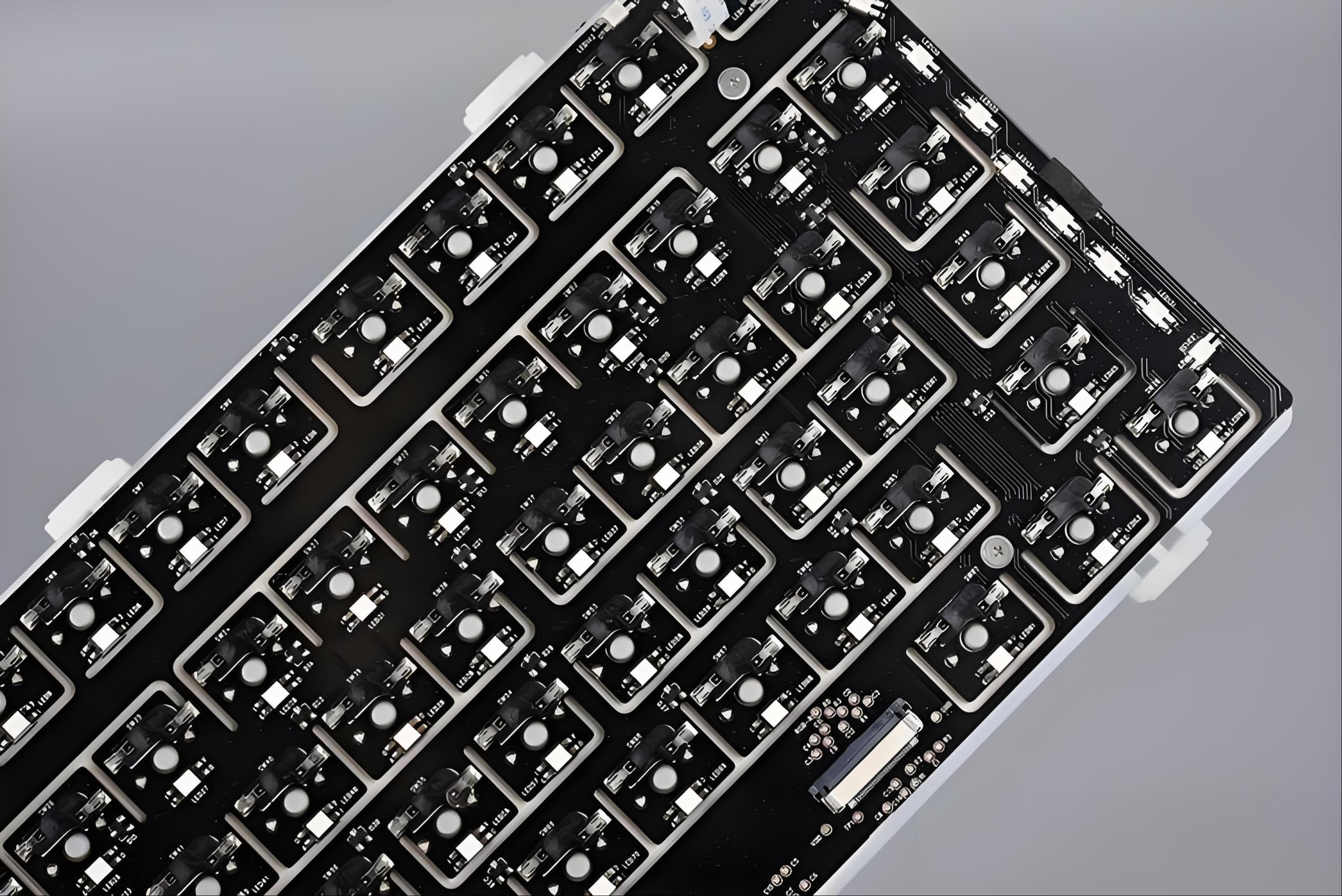

- Miniaturization:‚Äč Wearables, implants, and portable monitors demand ultra-dense, often multilayer or rigid-flex PCB assembly‚Äč designs to save space while maintaining functionality.

- Signal Integrity & Low Noise:‚Äč Diagnostic equipment (e.g., ECG, EEG) requires designs that minimize electromagnetic interference (EMI) and crosstalk to ensure accurate signal acquisition.

- Power Integrity & Safety:‚Äč Designs must ensure stable, clean power delivery, incorporate fail-safes, and meet stringent leakage current and isolation requirements (e.g., IEC 60601-1).

In summary, successful medical device PCB assembly‚Äč starts with a design philosophy that prioritizes safety, reliability, and manufacturability within the regulatory framework.

| PCB Type | Core Requirement | Typical Medical Device Examples |

|---|---|---|

| HDI PCB | High-density integration, miniaturization | Pacemakers, portable monitors, ultrasound probes |

| Flex / Rigid-Flex PCB | Bendability, 3D assembly, high reliability | Endoscopes, wearable patches, hearing aids |

| Heavy-Copper PCB | High current, high power capability | Electrosurgical units, laser therapy devices, medical power supplies |

| Ultra-Thin PCB | Ultra-lightweight, ultra-thin construction | Implantable sensors, capsule endoscopy devices |

| High-Frequency PCB | High-frequency / RF signal integrity | Wireless monitoring systems, MRI RF coils |

Key Standards for PCB Assembly for Medical Devices

Compliance with international standards is not optional; it’s the bedrock of medical device manufacturing. Adherence demonstrates a commitment to quality and safety throughout the product lifecycle.

The following table outlines the most critical standards:

| Standard | Focus Area | Relevance to PCB Assembly |

|---|---|---|

| ISO 13485:2016‚Äč | Quality Management System (QMS) | Mandates a full, documented QMS for design, production, and servicing. The cornerstone of regulatory trust. |

| IEC 60601-1‚Äč | Electrical Safety & Essential Performance | Sets requirements for basic safety and performance of medical electrical equipment, governing insulation, grounding, and testing. |

| IEC 61000-6‚Äč | EMC (Electromagnetic Compatibility) | Ensures the device does not emit harmful interference and is immune to interference from other sources, critical for PCB assembly for medical‚Äč equipment. |

| IPC-A-610 (Class 3)‚Äč | Acceptability of Electronic Assemblies | The definitive standard for high-reliability electronic assembly workmanship. Class 3 is for life-critical products. |

| FDA 21 CFR Part 820‚Äč | Quality System Regulation (USA) | The U.S. FDA’s requirements for the methods, facilities, and controls used in medical device manufacturing. |

Partnering with a medical PCB assembly manufacturer‚Äč fluent in these standards mitigates compliance risk and streamlines the path to market.

Why Best Rigid-Flex PCB Assembly Services for Medical Devices Are Important?

Rigid-flex PCBs, which combine rigid and flexible substrates into a single unit, are uniquely suited to solve critical design challenges in modern medical electronics, making specialized assembly services vital.

- Space and Weight Savings:‚Äč Eliminates connectors and cables between rigid boards, enabling ultra-compact designs for implants, hearing aids, and advanced portables.

- Enhanced Reliability:‚Äč By removing the most common failure points‚ÄĒconnectors and solder joints for inter-board wiring‚ÄĒrigid-flex designs offer superior mechanical stability and longevity.

- Dynamic Flexibility:‚Äč Can withstand hundreds of thousands of bend cycles, ideal for devices with moving parts like articulating surgical arms or wearable monitors.

- Improved Signal Integrity:‚Äč The continuous conductors between rigid sections reduce signal loss, reflection, and susceptibility to EMI, boosting performance in sensitive diagnostic tools.

- Streamlined Assembly:‚Äč A single, integrated rigid-flex board simplifies the final product assembly, reducing labor and potential assembly errors.

Therefore, accessing best rigid-flex PCB assembly services for medical devices‚Äč is crucial for innovating next-generation, reliable, and miniaturized healthcare solutions.

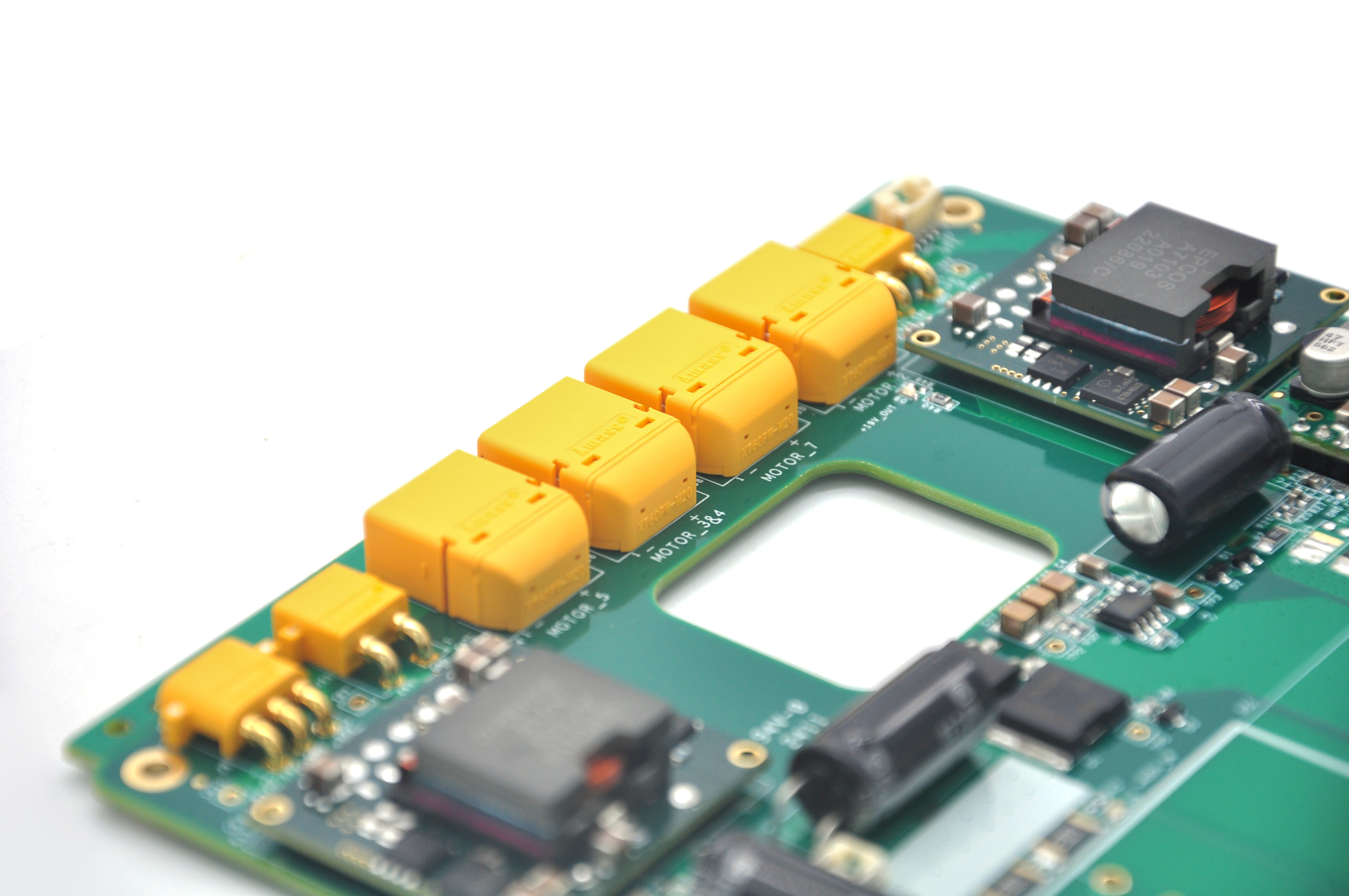

How Medical PCB Assemblies Support High-Reliability Healthcare Equipment?

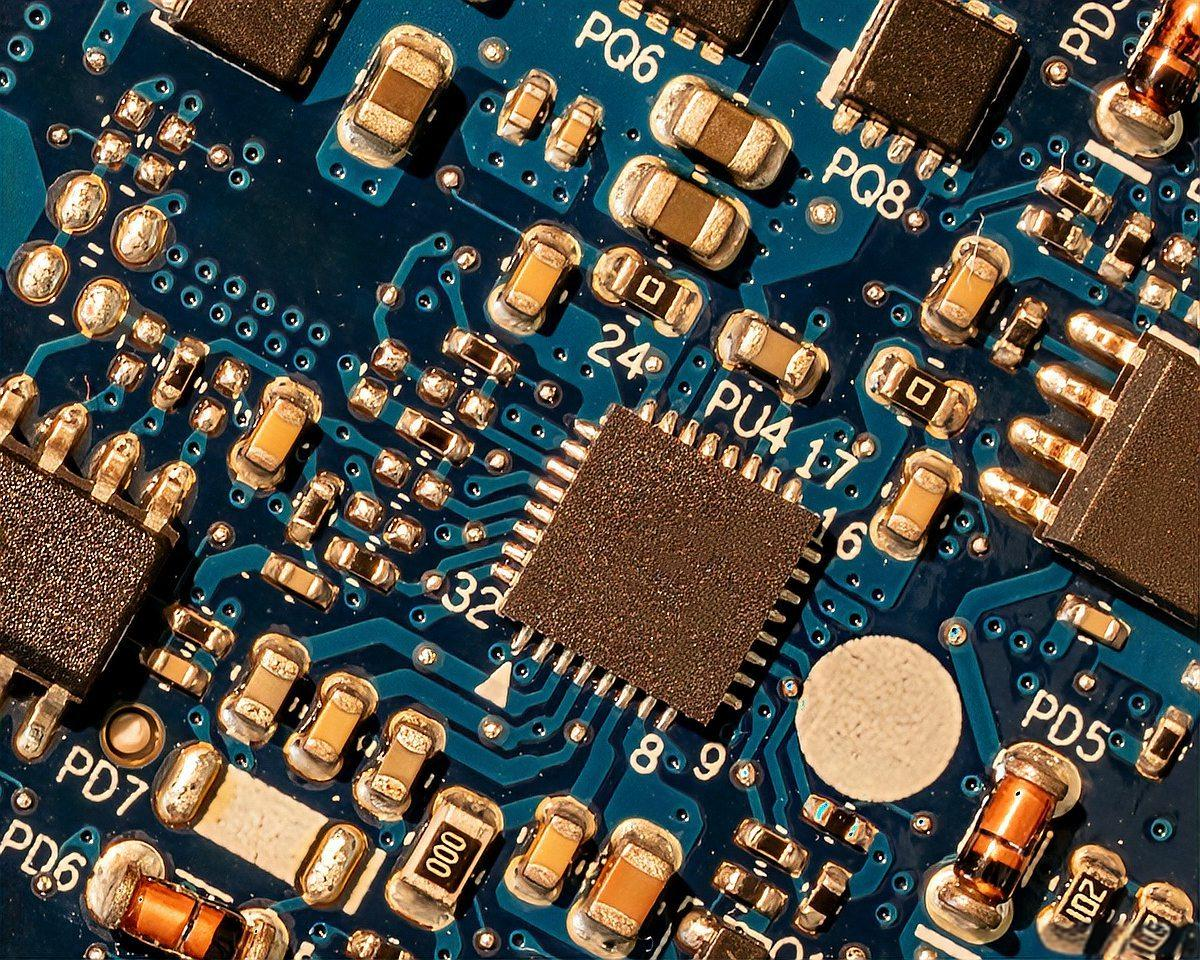

Medical PCB assemblies‚Äč are the operational core that translates design intent into reliable, life-sustaining function. Their support for high reliability is engineered through every material and process step.

- Component-Level Rigor:‚Äč Use of automotive- or medical-grade components with extended temperature ranges and longer lifespans, sourced from approved vendors.

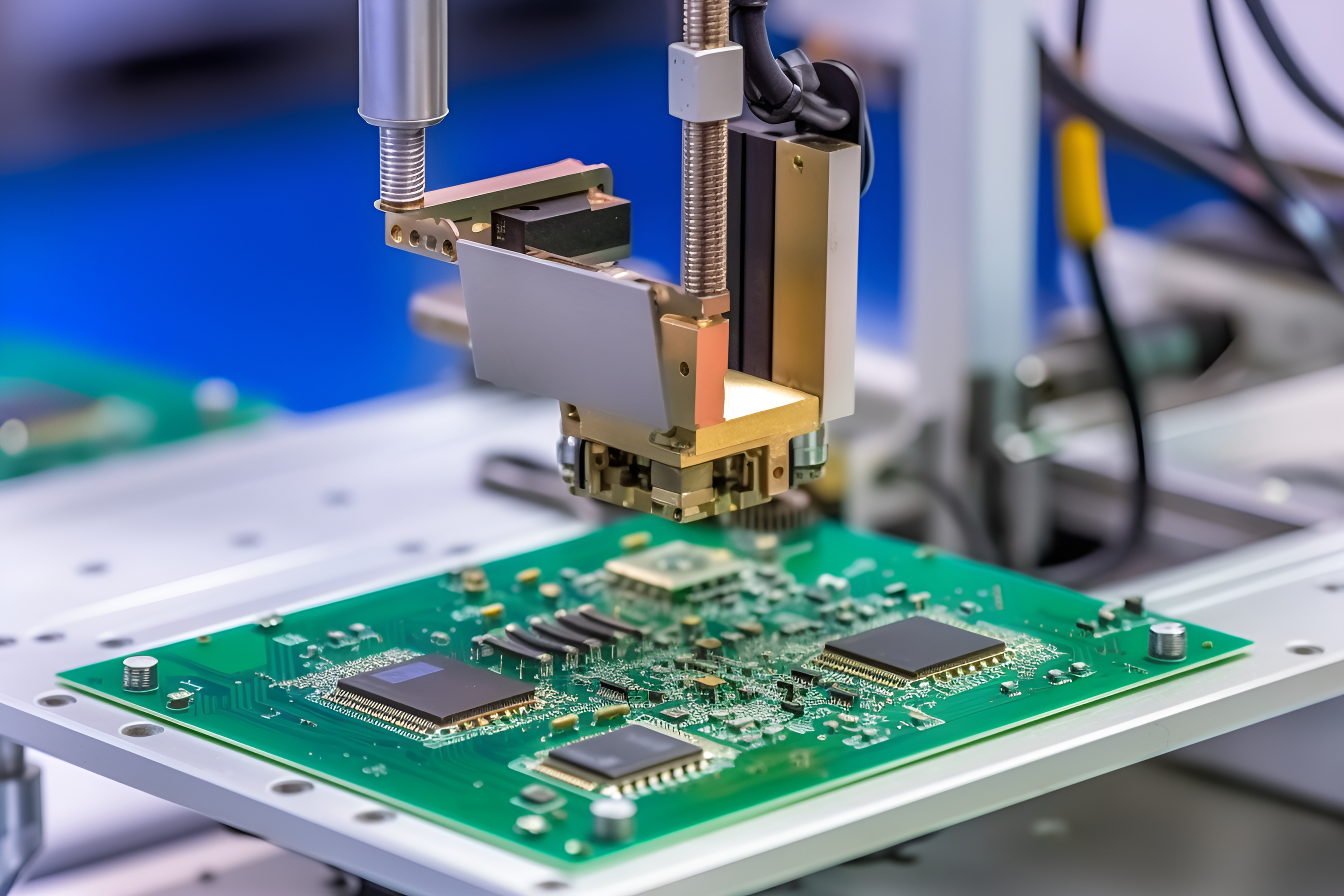

- Stringent Process Controls:‚Äč Adherence to IPC Class 3 standards ensures perfect solder joints, proper cleanliness, and no physical defects. This is enforced through automated optical inspection (AOI) and X-ray inspection.

- Comprehensive Testing Regime:‚Äč Beyond standard PCB medical test, assemblies undergo in-circuit test (ICT), functional testing, and often environmental stress screening (ESS) like thermal cycling to precipitate early failures.

- Traceability and Documentation:‚Äč Full material and component traceability, along with detailed Device History Records (DHRs), are maintained for every batch, supporting recalls and regulatory audits.

- Controlled Environment:‚Äč Assembly is performed in controlled ESD-safe and cleanroom environments to prevent contamination and electrostatic damage.

This multi-layered approach to quality ensures that every medical PCB board assembly‚Äč will perform consistently under demanding conditions throughout its service life.

How to Evaluate Accurate Medical PCB Assembly Quotes?

An accurate quote reflects a manufacturer’s understanding of your project’s true complexity and risks. It should be a transparent blueprint of cost, not just a bottom-line number.

- Detail of Requirements:‚Äč A serious manufacturer will ask for Gerber files, BOM, assembly drawings, and test specifications beforequoting. Vague quotes based on limited info are a red flag.

- Breakdown of Costs:‚Äč Look for a clear line-item breakdown: PCB fabrication, component sourcing (consigned or turnkey), assembly labor, testing fees, and compliance/certification support.

- Assumptions Stated:‚Äč The quote should list assumptions about standards (IPC Class, ISO 13485), testing level, and packaging. This prevents costly change orders later.

- Supply Chain Clarity:‚Äč For turnkey medical PCB assembly services, the quote should address component availability, longevity, and strategies for managing obsolescence.

- Value vs. Price:‚Äč Compare what‚Äôs included. A slightly higher quote that includes full testing, documentation, and regulatory support offers far greater value than a bare-bones cheap medical PCB assembly‚Äč option.

Evaluating quotes this way helps you find a true partner for fast PCB prototype assembly supplier for medical devices and equipment‚Äč and volume production.

What to Expect From Professional Medical PCB Assembly Services?

Professional service is defined by partnership, expertise, and proactive communication throughout the product lifecycle, not just during production.

- DFM/DFT Analysis:‚Äč Expect a formal Design for Manufacturability/Testability review. A good partner will identify potential assembly or test issues early, saving time and cost.

- Proactive Component Engineering:‚Äč They should advise on part alternatives, second sources, and lifecycle status to de-risk your supply chain.

- Transparent Communication:‚Äč Regular updates on production status, coupled with clear channels for addressing engineering change orders (ECOs) or issues.

- Comprehensive Documentation:‚Äč Delivery of all required certifications, test reports, and traceability documents as a standard deliverable.

- Scalability and Support:‚Äč Ability to seamlessly scale from prototype (quick turn medical PCB assembly) to high-volume production, with ongoing technical support.

This level of service transforms a supplier into an extension of your engineering team, crucial for complex medical devices PCB assembly.

How China Medical PCB Assembly Enhances Cost and Lead Time Efficiency?

Leveraging a high-quality China medical PCB assembly‚Äč ecosystem, when managed correctly, offers significant strategic advantages for the medical device industry.

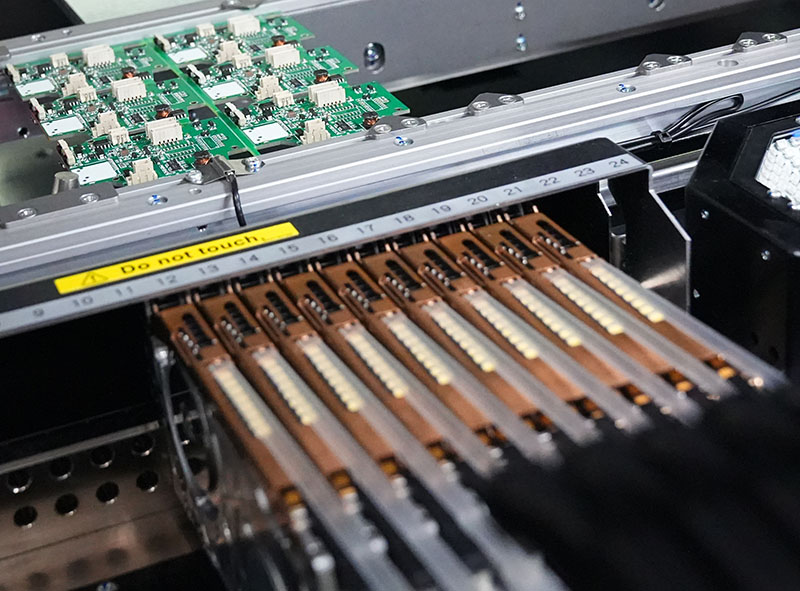

- Integrated Supply Chain:‚Äč Proximity to a vast network of component suppliers and PCB fabrication and assembly‚Äč facilities reduces material logistics time and cost.

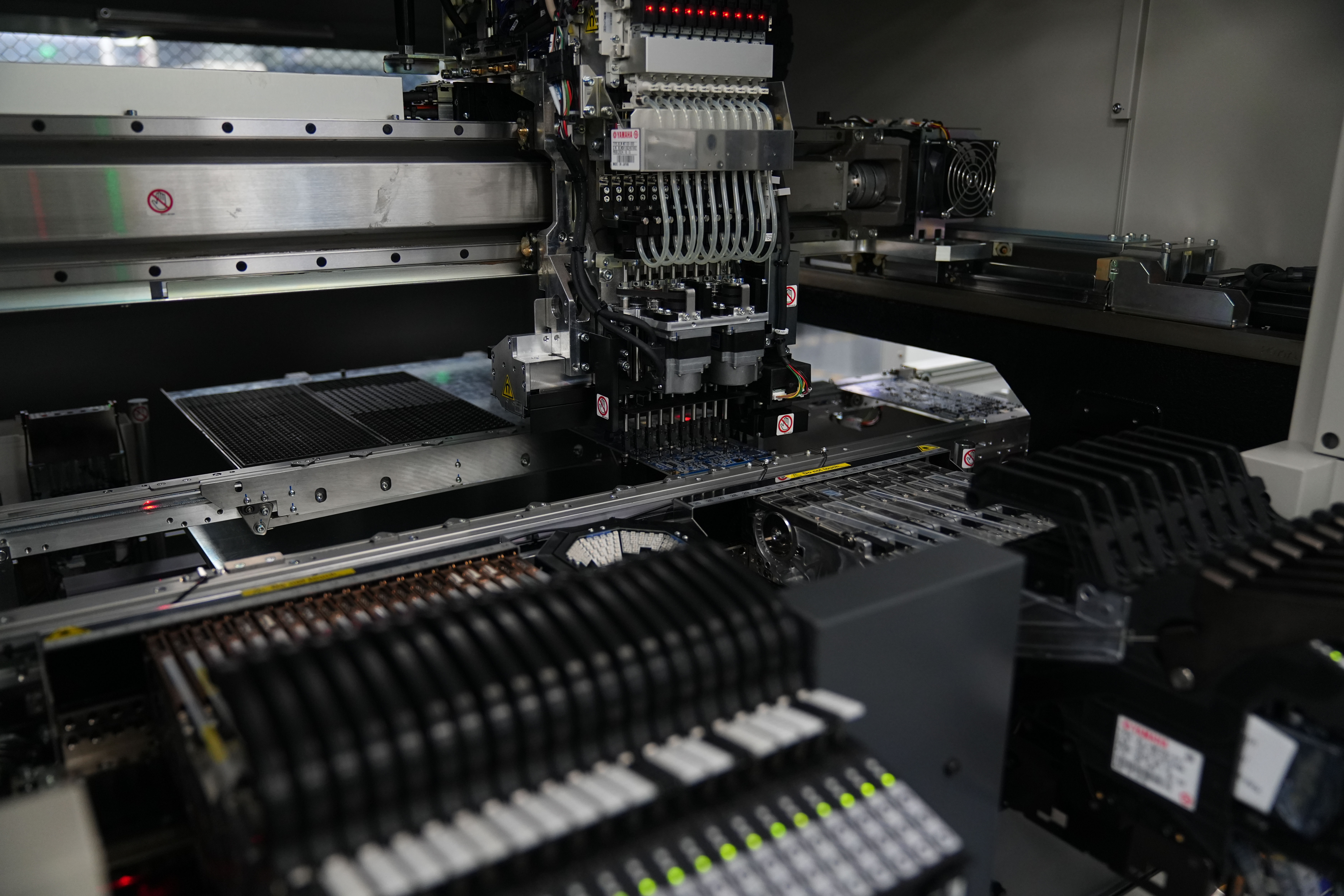

- Manufacturing Scale and Expertise:‚Äč Access to large-scale, technologically advanced factories with extensive experience in high-mix, high-complexity production.

- Cost Efficiency:‚Äč Competitive operational and labor costs can be passed on as savings, allowing for greater investment in higher-grade materials or more extensive testing without bloating the budget.

- Dedicated Medical Focus:‚Äč Leading China medical PCB assembly manufacturers‚Äč now operate state-of-the-art, certified facilities (ISO 13485, ISO 14644 cleanrooms) specifically for medical and aerospace work, aligning with global standards.

The key is partnering with a China medical PCB assembly supplier‚Äč that provides Western-standard project management, quality control, and transparency, turning geographic advantage into reliable value.

Why Choose EBest Circuit (Best Technology) as Your Trusted Medical PCB Assembly Manufacturer?

Selecting BEST Technology means choosing a partner dedicated to the success and safety of your medical device. We bridge the gap between high-quality standards and operational efficiency.

- Proven Medical Expertise:‚Äč With over 19 years of PCBA experience medical devices electronic PCB assembly, our team understands the unique demands of the healthcare sector.

- End-to-End Control:‚Äč As a integrated factory, we manage everything from advanced PCB fabrication and assembly‚Äč in-house, ensuring quality at every step and faster turnaround.

- Uncompromising Compliance:‚Äč Our facility is certified to ISO 13485 and IEC 60601-1 standards, and we build every board to IPC-A-610 Class 3 requirements. We provide full documentation packs.

- True Partnership Model:‚Äč We act as an extension of your team, offering expert PCB assembly for medical industry‚Äč guidance from design review through to volume manufacturing and lifecycle management.

- Optimal Value Proposition:‚Äč We combine the advanced capabilities and cost efficiency of a top-tier China medical PCB assembly factory‚Äč with the accountability, communication, and quality ethos demanded by global medical device companies.

To conclude, medical PCB assembly‚Äč is the essential discipline that transforms circuit designs into safe, effective, and reliable healthcare electronics. This article has detailed the critical requirements, standards, and partner selection criteria necessary for success in this demanding field.

For fast and accurate medical PCB assembly‚Äč that meets the highest benchmarks of quality and reliability, partnering with an expert is paramount. BEST Technology stands as your dedicated specialist, offering over two decades of focused experience, end-to-end manufacturing control, and an unwavering commitment to medical standards. Pls feel free to contact us for a detailed consultation and quote via sales@bestpcbs.com.