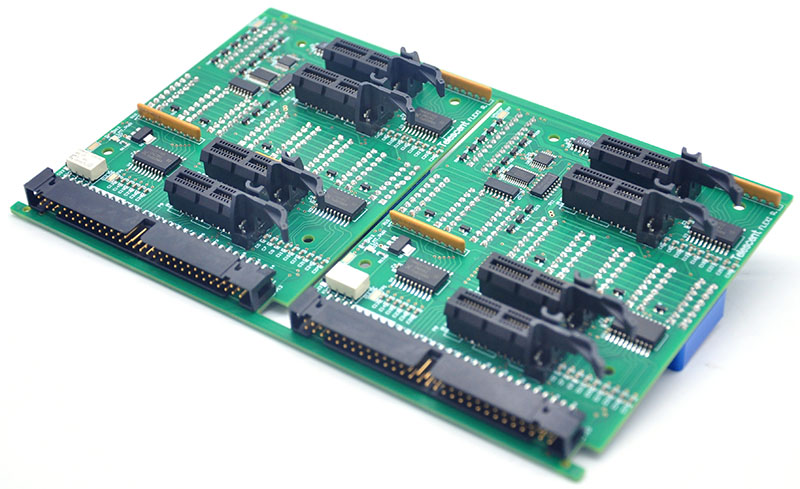

The demand for high-quality PCB Prototyping in Philippines continues to grow with the expansion of the local electronics manufacturing sector. Businesses and projects rely on precise prototyping to validate designs and accelerate production cycles, making PCB prototyping in Philippines a critical link in the supply chain. Our 20-year expertise enables us to deliver tailored PCB prototyping service Philippines, addressing local market needs with rigorous quality control and technical proficiency that outperforms many regional providers. We integrate seamlessly with Philippines PCB prototype requirements, ensuring each project meets international standards while adapting to local production conditions.

Top 10 PCB Prototype Manufacturer in Philippines

| Company Name | Main Business | Core Advantages | Process Capability | Lead Time |

| EBest Circuit Co., Limited (Best Technology Circuit Co., Limited) | PCB prototyping, mass production, bus bar PCB, one-stop PCB assembly | ISO 9001/13485/IATF 16949 certified, 18+ years experience, global supply chain, lifetime warranty | Copper thickness 1.0-3.0mm, line width 0.8-1.0mm, ENIG/immersion silver/gold plating, rigid/flexible PCBs | 4-7 working days for prototypes, 10-15 days for mass production |

| Antech-Enviro | PCB design, fabrication, repair, thermal monitoring tools supply | Precision surface preparation, high-end electronics testing, local technical support | Rigid PCBs, up to 54 layers, FR-4 material, precision etching | 5-8 working days for prototypes, 12-18 days for custom orders |

| Global Circuits Sourcing Solutions (GCSS) | PCB fabrication/assembly, quick-turn probe boards for semiconductors | High-mix low-volume production, global manufacturer partnerships, cost-effective solutions | Rigid/flexible/rigid-flex HDI PCBs, up to 32 layers, FR-4/Al/Cu materials | 3-6 working days for quick-turn prototypes, 8-14 days for standard orders |

| MDS Circuit Technology | PCB/PWB design, fast-delivery prototyping, small-batch production | Design optimization, responsive service, industrial electronics focus | Rigid/flexible/rigid-flex PCBs, up to 10 layers, FR-4 material | 4-7 working days for prototypes, 9-16 days for mass production |

| Pythos Technology Philippines Incorporated | Medical-grade PCB fabrication, custom prototype development | Medical industry compliance, strict quality control, cleanroom production | Rigid PCBs, FR-4 material, biocompatible surface treatment | 6-9 working days for prototypes, 14-20 days for medical orders |

| Thermozone Philippines Corporation | Specialty PCB fabrication, high-temperature resistant boards | Polyimide/copper material expertise, thermal management solutions | Rigid PCBs, FR-4/polyimide materials, high-temperature soldermask | 5-8 working days for prototypes, 11-17 days for specialty orders |

| A1 Printed Circuit Boards | Turn-key PCB solutions, design/fabrication/assembly/maintenance | Automotive/commercial industry focus, local logistics, preventive maintenance | Rigid/flexible/rigid-flex PCBs, burn-in testing capability, FR-4 material | 4-7 working days for prototypes, 10-15 days for automotive orders |

| Asian Provider | Multi-layer PCB prototyping, custom rigid-flex boards | High-layer count expertise, material versatility, competitive pricing | Rigid/flexible/rigid-flex PCBs, up to 60 layers, FR-4/Kapton materials | 7-10 working days for high-layer prototypes, 13-19 days for complex orders |

| Electronics Product Development Center | Low-volume PCB prototyping, R&D support, small-batch production | R&D collaboration, quick design iterations, local testing facilities | Rigid PCBs, up to 4 layers, FR-4 material, basic surface treatment | 3-5 working days for simple prototypes, 8-12 days for R&D orders |

| Mass Power Philippines Electronics Incorporated | Power electronics PCB prototyping, high-current board fabrication | High-current handling expertise, power industry compliance, durable designs | Rigid PCBs, thick copper traces, FR-4 material, anti-corrosion treatment | 5-8 working days for prototypes, 12-18 days for power boards |

Pain Points of PCB Prototyping in Philippines

- High raw material costs due to over-reliance on imports from China, Japan and Thailand, affecting PCB prototyping Philippines profitability.‚Äč

- Limited advanced equipment access leading to inability to meet high-precision requirements for Philippines PCB prototype with line width below 0.1mm.‚Äč

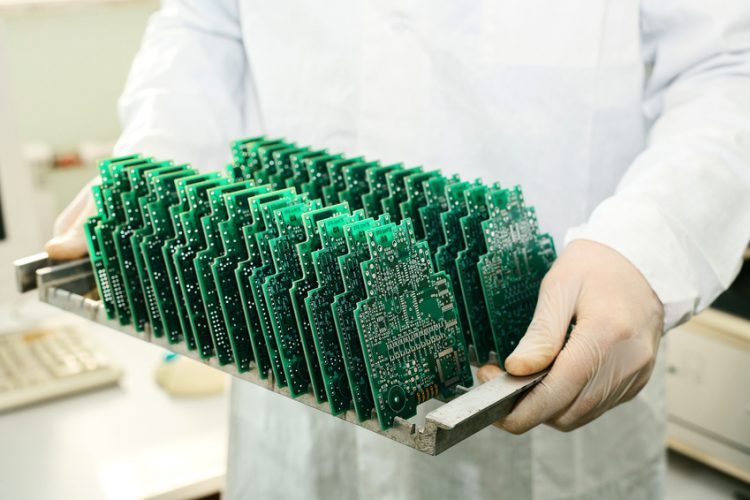

- Small-batch order inefficiency causes higher per-unit costs for PCB prototype service Philippines compared to large-scale production.‚Äč

- Inconsistent process control results in unstable product quality, with defect rates averaging 3-5% for local prototyping.‚Äč

- Environmental regulation compliance pressure increases production costs, especially for chemical treatment in PCB factory in Philippines.‚Äč

- Skilled labor shortage slows down production speed and extends lead time for complex PCB prototype in Philippines.‚Äč

- Weak local supply chain leads to delays in material replenishment, affecting on-time delivery of prototype PCB Philippines.

How to Choose a PCB Prototyping Service in Philippines?

Selection Guide to PCB Prototype Service in Philippines:

- Start by verifying core certifications such as ISO9001 and UL: Go beyond mere certificate checks to review internal audit records and CAPA (Corrective and Preventive Action) cases, ensuring compliance with IPC-A-600 standards. These standards cover 95% of high-quality PCB Prototype in Philippines requirements, so confirming their effective implementation is key to quality assurance.‚Äč

- Focus on verifiable process capabilities: including layer count (1-32 layers for most applications) and minimum line width. Prioritize manufacturers that stably achieve 0.1mm line width/spacing for complex designs, and request process verification reports (IQ/OQ/PQ) for key procedures like lamination to validate their technical reliability.‚Äč

- Don‚Äôt rely solely on delivery commitments: review historical data instead. Reliable providers maintain a 98%+ on-time delivery rate for PCB prototype service Philippines, with separate records for regular and urgent orders over the past six months to reflect real performance.‚Äč

- Assess full-process quality control systems: Confirm 100% AOI inspection for all boards, cross-check defect rates (target below 1% for precision prototyping) with actual inspection reports, and verify supporting equipment like SPI and X-Ray to ensure comprehensive defect detection.‚Äč

- Evaluate material sourcing stability for Philippines PCB prototype: Prioritize partners with global supplier networks, check that common materials have 30%+ safety stock, and confirm they have alternative material plans to avoid delays caused by supply chain disruptions.‚Äč

- Compare transparent cost structures when evaluating options: Reasonable PCB prototyping Philippines pricing balances quality and speed, with detailed quotes covering design optimization, testing and surface treatment, no hidden fees should be included.

How to Evaluate the Technical Capabilities of PCB Factory in Philippines?

Evaluation Guide to the Technical Capabilities of PCB Factory in Philippines:

- Check factory experience and project track record in the PCB prototype manufacturer Philippines sector. Prioritize manufacturers with over 10 years of operation, and verify their delivery cases for complex boards to confirm mature technical capabilities.‚Äč

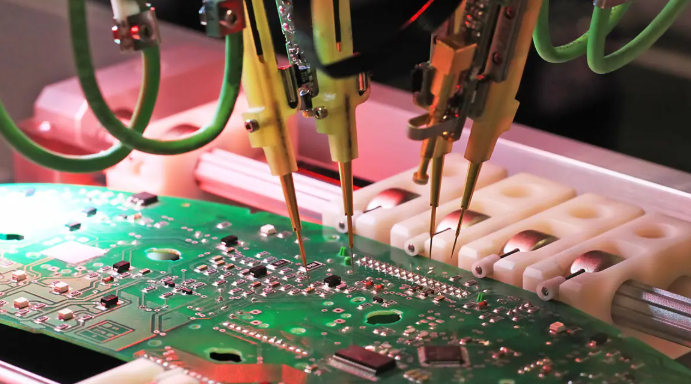

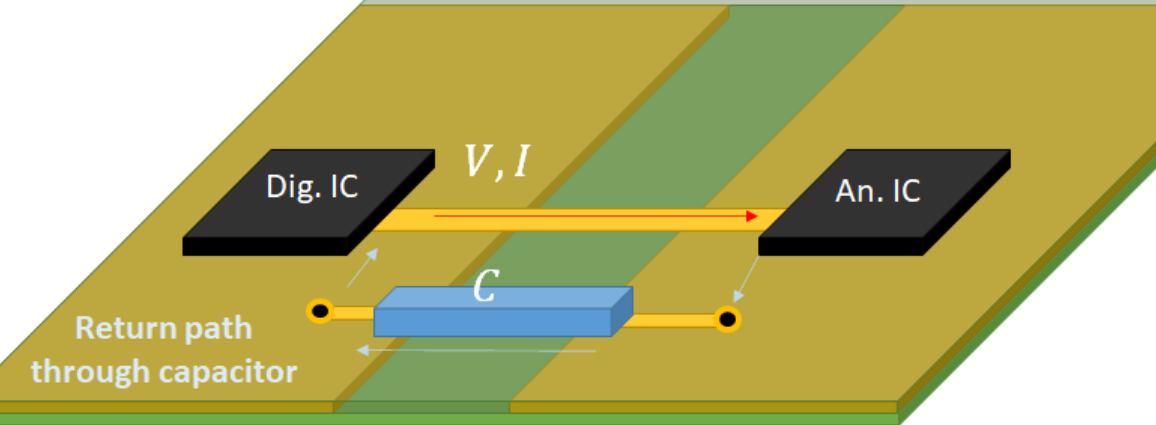

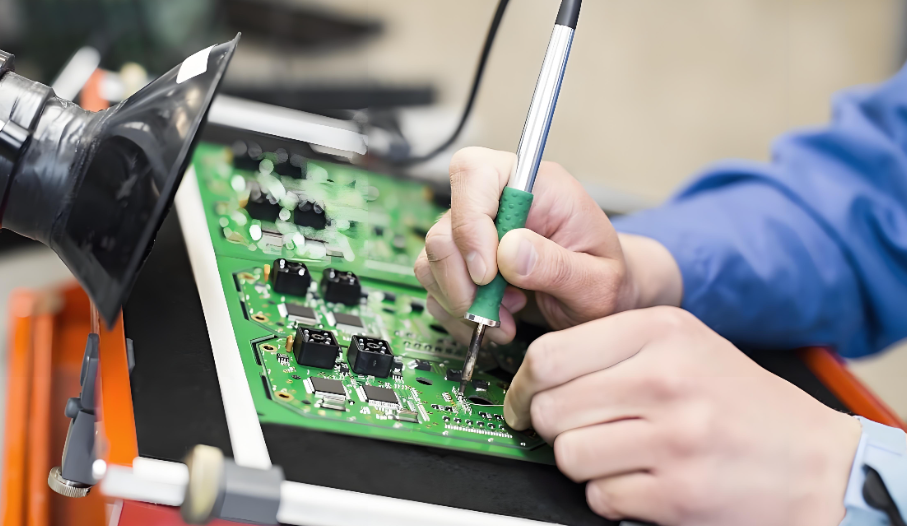

- Inspect production equipment brands and calibration records. Focus on automated etching and drilling machines, ensuring monthly calibration of key equipment with Z-axis pressure fluctuation ‚ȧ¬Ī5% and reflow oven temperature difference ‚ȧ¬Ī1‚ĄÉ for precision control.‚Äč

- Evaluate material testing capabilities for PCB Prototype in Philippines. Confirm they conduct thermal stability tests (-40‚ĄÉ to 125‚ĄÉ) and electrical performance verification, with ICT testing to detect circuit continuity and voltage fluctuations.‚Äč

- Verify compliance with international standards. Ensure alignment with IPC-A-610 for assembly (requiring solder joint tin penetration rate ‚Č•75%) and IPC-6012 for PCB qualification to guarantee consistent product quality.‚Äč

- Assess R&D capacity by reviewing past custom prototype PCB Philippines projects. Focus on their ability to handle HDI and rigid-flex designs, and whether they provide DFM optimization suggestions to avoid production defects.‚Äč

- Check quality control documentation. Request batch-specific inspection reports and defect analysis, confirming AOI/X-Ray inspection records and defect root-cause improvement measures for full-process traceability.‚Äč

- Evaluate surface treatment technologies. Confirm they offer HASL, ENIG, and OSP options, and match the technology to application scenarios‚ÄĒENIG for high-reliability needs, OSP for cost-sensitive PCB prototyping Philippines orders.‚Äč

- Inquire about environmental management systems. Ensure compliance with Philippine PCB-free standards (‚ȧ2 ppm) and verify waste treatment processes, avoiding production delays due to non-compliance.

How to Evaluate the Delivery Capabilities of PCB Factory in Philippines?

Evaluation Guide to the Delivery Capabilities of PCB Factory in Philippines:

- Request lead time data of the past 6 months, categorized by prototype layers (1-6/8-12/12+ layers) and processes. Confirm average delivery days and maximum delay cases for PCB Prototype in Philippines, and cross-verify with order contracts and delivery receipts to ensure data authenticity.‚Äč

- Assess order processing efficiency. Ensure standard projects complete initial design review within 24 hours, including DFM compliance check and process feasibility confirmation, to avoid subsequent adjustments that extend the cycle.‚Äč

- Evaluate raw material inventory management. Focus on safety stock of common materials like FR-4 and Polyimide, factories with over 30% safety stock can shorten production cycles by 2-3 days through on-demand material allocation, reducing import wait time.‚Äč

- Verify production scheduling flexibility for PCB prototype service Philippines. Confirm the capacity to handle urgent orders, such as 24-48 hour quick-turn prototypes, and whether there is a dedicated production line to avoid queueing with regular orders.‚Äč

- Review quality rework rates. Target monthly rework rate below 2% for single batches, and require analysis of rework causes (etching errors, solder joint defects, etc.) to ensure rework does not unnecessarily extend the production cycle.‚Äč

- Inquire about local logistics partnerships. Confirm cooperation with reliable couriers to cover major cities like Manila and Cebu, ensuring 24-72 hour delivery after prototype completion, with overseas warehouse support for faster local distribution.‚Äč

- Assess production progress communication efficiency. Require daily synchronous updates via professional systems, with instant notifications for key nodes (material arrival, etching completion, final inspection), to avoid information lag affecting cycle control.

Future Challenges of PCB Prototyping in Philippines

- Escalating global material prices will further squeeze profit margins for PCB Prototype in Philippines manufacturers.

- Rising environmental regulations require upgrades to waste treatment systems, increasing operational costs for PCB Factory in Philippines.

- Technological upgrades demand investment in HDI and flexible PCB equipment to compete in PCB prototyping Philippines market.

- Geopolitical tensions may disrupt supply chains, affecting material imports for Philippines PCB prototype.

- Talent gap expansion as advanced technologies require more skilled workers for precision prototyping.

- Increasing competition from neighboring countries like Vietnam and Thailand for PCB prototype manufacturer Philippines market share.

- Demand for faster turnarounds (under 24 hours) pushes factories to optimize production workflows.

- Strict quality requirements from automotive and medical sectors raise entry barriers for local prototyping services.

FAQs of PCB Prototyping in Philippines

Q1: What causes delamination in Philippine PCB prototype boards? How can it be solved?

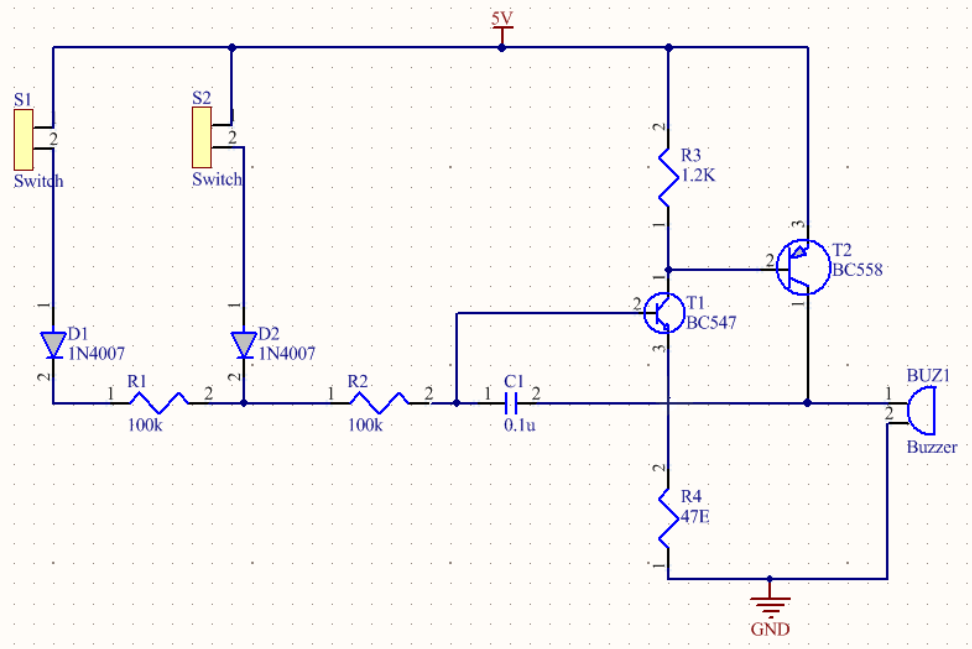

A1: Delamination is caused by low-quality materials, incorrect lamination temperature, or moisture in the substrate. We use high-quality FR-4 material and conduct 100% pre-inspection, pre-baking the substrate at 120‚ĄÉ for 2 hours, and controlling the lamination temperature within ¬Ī2‚ĄÉ. This reduces the delamination rate of our Philippine PCB prototype boards to below 0.5%.

Q2: Why do solder joints on Philippine local PCB prototype boards turn golden yellow?

A2: Excessive soldering temperature or unstable solder bath conditions can cause this problem. Our automatic reflow soldering furnace has real-time temperature monitoring to maintain the soldering temperature at 245¬Ī5‚ĄÉ. Pre-production design checks and regular solder bath maintenance further optimize the solder joint quality of Philippine PCB prototype boards.

Q3: How to avoid short circuits in high-density Philippine PCB prototype boards?

A3: Short circuits are caused by insufficient trace spacing, poor pad design, or solder mask failure. We conduct strict DRC checks before production to ensure a minimum trace spacing of 0.1mm, use oval pads for high-density designs, and perform 100% AOI inspection to eliminate the risk of short circuits in Philippine PCB prototype boards.

Q4: What causes uneven plating thickness in Philippine local PCB factories?

A4: Uneven current distribution, plating solution contamination, or insufficient stirring can lead to unevenness. We use automated plating equipment with ¬Ī0.1A current regulation, test solution purity every 4 hours, and optimize stirring parameters. This controls the plating thickness variation of our Philippine prototype PCBs to within ¬Ī0.005mm.

Q5: How to solve open circuit problems in the production of Philippine PCB prototype board manufacturers?

A5: Open circuits are caused by broken traces, poor solder adhesion, or surface contamination. We implement double-layer etching inspection, ultrasonic cleaning before soldering, and X-ray inspection of hidden solder joints. This ensures 100% connectivity of complex Philippine PCB prototype boards.