Vietnamâs PCB industry has emerged as a key player in global electronics manufacturing, with exports reaching $1.52 billion in 2022 and continuous growth driven by foreign investments like Foxconnâs $383 million plant in Bac Ninh. For businesses seeking reliable partners, exploring the top 10 pcb manufacturers in Vietnam is critical to accessing high-quality production capabilities. These leading firms combine international certifications, advanced technologies, and strategic locations to serve sectors ranging from automotive to medical devices. Whether you need rapid Vietnam PCB prototyping, high-volume production, or complex HDI boards, the top 10 pcb manufacturers in Vietnam offer diverse solutions tailored to global standards, making Vietnam a competitive hub for PCB sourcing.

Are You Facing These Challenges?

- Inconsistent prototype quality leading to delayed product development cycles

- Difficulty finding manufacturers capable of handling complex designs (e.g., blind/buried vias, impedance control)

- Unreliable delivery times due to supply chain disruptions or production bottlenecks

- Lack of transparent pricing and hidden costs in PCB manufacturing quotes

- Insufficient technical support for design optimization and manufacturability reviews

- Quality control gaps resulting in high defect rates for mass-produced PCBs

End-to-End Assurance from Requirement to Delivery

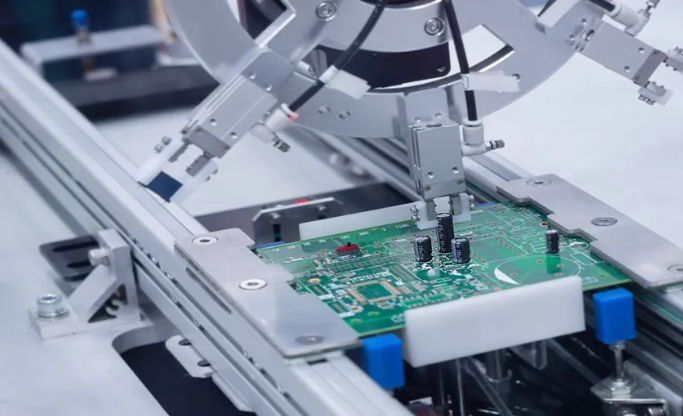

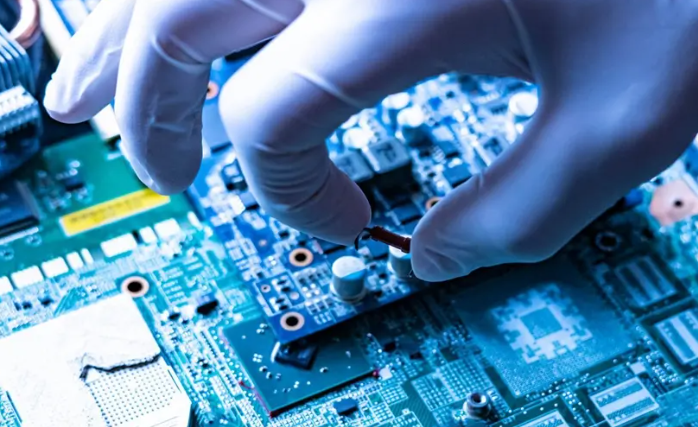

At our Vietnam PCB manufacturing company, we address these pain points with a comprehensive, customer-centric solution designed to deliver reliability, precision, and efficiency. Our process begins with a dedicated technical team that conducts free DFM (Design for Manufacturability) reviews to optimize your PCB design, eliminating potential production issues before manufacturing starts. For Vietnam PCB prototyping, we offer 48-hour rapid turnaround with 99.9% accuracy, using AI-powered AOI and X-ray inspection to ensure flawless samples. For mass production, our ISO 9001, IATF 16949, and ISO 13485 certified facilities leverage advanced SMT lines (35k components/hour) and automated Vietnam PCB quality control systems to maintain consistent quality, with a DPPM (Defects Per Million Parts) rate below industry averages. We provide transparent pricing with detailed cost breakdowns and real-time production tracking via our customer portal, so you always know the status of your order. Our supply chain is fortified with dual sourcing for critical materials and 3-6 months of strategic inventory, ensuring on-time Vietnam PCB manufacturer delivery time even during market fluctuations. From initial design consultation to final shipment, we stand by your project with 24/7 technical support and a 100% satisfaction guaranteeâbecause your success is our priority.

Why Choose Us?

- Certified Quality Excellence: Hold NADCAP, ISO 9001, IATF 16949, and ISO 13485 certifications, meeting the strictest standards for automotive, medical, and aerospace industries.

- Advanced Technological Capabilities: Equipped with LDI laser imaging, 3D SPI, and 3D X-ray inspection for precision manufacturing of Vietnam HDI PCB manufacturing, rigid-flex, and thick-copper PCBs (down to 3mil/3mil line width/space).

- Rapid Turnaround & Scalability: Seamlessly scale from 10-piece prototypes to 100k+ unit mass production with 98%+ on-time delivery rate, supported by flexible manufacturing systems.

- Transparent & Competitive Pricing: No hidden feesâwe provide detailed quotes with material, engineering, and testing costs, plus volume discounts for long-term partnerships.

- Global Supply Chain Resilience: Dual-sourced critical components and strategic inventory management minimize risks of material shortages and production delays.

- 24/7 Expert Support: Our team of engineers with 10+ years of experience offers round-the-clock assistance for design optimization, technical troubleshooting, and post-delivery support.

Top 10 PCB Manufacturers in Vietnam

| Company Name | Process Capabilities | Core Advantages | Address |

|---|---|---|---|

| Meiko Electronics Vietnam | HDI PCBs, rigid PCBs, flexible PCBs, rigid-flex PCBs; up to 16-layer boards | ISO 9001/14001/IATF 16949 certified; 3,000 employees; serves automotive/communication sectors | Lot K1-K4, Thang Long Industrial Park, Kim Chung Commune, Dong Anh District, Hanoi |

| Young Poong Electronics Vietnam | Standard PCBs, electronic component assemblies | South Korean subsidiary; high-quality production for diverse industries | Lot CN06, Binh Xuyen II Industrial Park, Ba Hien Town, Binh Xuyen District, Vinh Phuc Province |

| Simmtech Vietnam | High-precision PCB assemblies, HDI boards | Advanced manufacturing for semiconductor and electronics sectors | Industrial Park, Ho Chi Minh City (specific address undisclosed) |

| Daeduck Vietnam | Rigid PCBs, flexible PCBs, PCB assemblies | Proven track record in consumer electronics and industrial applications | Vietnam-Singapore Industrial Park, Binh Duong Province |

| KCE Electronics Vietnam | SMT assembly, through-hole technology (THT), PCB manufacturing | Specializes in high-volume production with strict quality control | Industrial Zone, Dong Nai Province |

| Semco Electronics Vietnam | Custom PCB design, prototyping, mass production | Fast turnaround for consumer and automotive electronics | Long An Industrial Park, Long An Province |

| Unimicron Technology Vietnam | HDI PCBs, rigid-flex PCBs, advanced packaging substrates | Global technical expertise; serves high-tech industries | Bac Ninh Industrial Park, Bac Ninh Province |

| Tripod Vietnam | PCB manufacturing, PCBA assembly | Cost-effective solutions for small to medium batches | Tay Ninh Industrial Park, Tay Ninh Province |

| Vector Fabrication Vietnam | Precision PCB production, custom assemblies | Focus on medical and industrial electronics; ISO 13485 certified | Ho Chi Minh City Industrial Park, Ho Chi Minh City |

| Spartronics Vietnam | PCB assembly, conformal coating, non-destructive testing | NADCAP certified; serves aerospace and defense industries | Ho Chi Minh City Manufacturing Facility, Ho Chi Minh City |

How to Choose a PCB Manufacturer in Vietnam

- Verify international certifications (ISO 9001, IATF 16949, ISO 13485, UL) to ensure Vietnam PCB quality control compliance.

- Evaluate process capabilities against your needs (e.g., HDI, rigid-flex, minimum line width/space).

- Check the manufacturerâs industry experience and client portfolio, especially in your sector (automotive, medical, etc.).

- Assess production equipment quality (e.g., LDI, AOI, X-ray inspection) and technological upgrades.

- Request Vietnam PCB manufacturer delivery time data from the past 12 months (target â„98%).

- Review quality control processes, including DPPM rates and inspection protocols (IPC-A-600 standards).

- Ensure transparent pricing with detailed cost breakdowns (materials, engineering, testing, shipping).

- Confirm availability of DFM services and technical support for design optimization.

- Investigate supply chain resilience (dual sourcing, inventory management) to avoid delays.

- Seek customer references or case studies to validate performance and reliability.

Core Pain Points of PCB Manufacturers in Vietnam

- Weak heavy industry foundation limiting local supply of high-quality raw materials (e.g., advanced copper clad laminates).

- Unstable power supply and infrastructure gaps affecting production consistency.

- Shortage of skilled engineers and technical personnel for complex PCB design and manufacturing.

- Dependence on imported core technologies, leading to higher production costs and limited innovation.

- Intense market competition from domestic and international manufacturers, pressuring profit margins.

- Challenges in meeting strict environmental regulations for waste disposal and emissions.

- Supply chain disruptions due to reliance on single-source materials or logistics bottlenecks.

- Inconsistent Vietnam PCB quality control standards across small to medium-sized manufacturers.

- Slow adoption of advanced automation technologies, resulting in lower production efficiency.

- Limited capacity for rapid Vietnam PCB prototyping and flexible production for custom orders.

How to Evaluate Production Capacity of PCB Manufacturers in Vietnam

- Review annual production volume and capacity utilization rate (ideal range: 70%-85%).

- Assess number of production lines (SMT/THT) and their throughput (components per hour).

- Verify capability to handle your specific PCB requirements (layers, line width/space, materials).

- Check availability of advanced equipment (LDI, AOI, X-ray, flying probe testers) for Vietnam HDI PCB manufacturing.

- Evaluate factory size, number of employees, and shift operations (24/7 production capability).

- Review past project portfolios for similar product types and volume scales.

- Confirm ISO certifications and quality management system documentation.

- Assess R&D investment and frequency of technological upgrades.

- Inquire about emergency production capacity for rush orders.

- Request on-site factory tours to observe 5S management and production workflows.

How to Evaluate Delivery Time of PCB Manufacturers in Vietnam

- Request historical on-time delivery (OTD) data for the past 12 months (target â„98%) to validate Vietnam PCB manufacturer delivery time reliability.

- Inquire about standard lead times for Vietnam PCB prototyping (ideal: 1-3 days) and mass production (2-4 weeks).

- Assess supply chain management practices (dual sourcing, material inventory levels).

- Verify proximity to major ports (Ho Chi Minh City, Haiphong) for efficient shipping.

- Evaluate production scheduling flexibility for design changes or order adjustments.

- Inquire about emergency delivery options and associated costs.

- Check for integration of ERP/MES systems for real-time production tracking.

- Review logistics partnerships and shipping carrier reliability.

- Ask about contingency plans for power outages or supply chain disruptions.

- Request customer references to confirm delivery time consistency.

Common Questions & Solutions for PCB Manufacturers in Vietnam

Q: How to resolve inconsistent PCB quality across batches?

A: Choose manufacturers with IPQC (In-Process Quality Control) systems with 20+ checkpoints and IPC-A-600G Class 2/3 compliance. Our facility uses automated inspection at every production stage and provides detailed Vietnam PCB quality control reports for each batch.

Q: What if my PCB design requires complex processes (e.g., blind/buried vias, impedance control)?

A: Partner with manufacturers specializing in Vietnam HDI PCB manufacturing and equipped with impedance testers. We offer free DFM reviews to optimize complex designs and ensure process compatibility.

Q: How to avoid hidden costs in PCB manufacturing quotes?

A: Request detailed breakdowns including material costs, engineering fees, testing charges, and shipping. We provide transparent quotes with no hidden fees and honor price commitments for the entire project lifecycle.

Q: What if production is delayed due to material shortages?

A: Select manufacturers with dual-sourced critical materials and strategic inventory. Our 3-6 month stock of key components ensures uninterrupted production even during supply chain disruptions, maintaining reliable Vietnam PCB manufacturer delivery time.

Q: How to get technical support for design optimization?

A: Choose manufacturers with dedicated engineering teams. Our experts offer 24/7 support for DFM reviews, design adjustments, and technical troubleshooting to improve manufacturability and reduce costs.

Q: What certifications are essential for automotive PCB applications?

A: IATF 16949 certification is mandatory. Our facility holds IATF 16949, ISO 9001, and UL certifications, ensuring compliance with automotive industry reliability and safety standards for Vietnam PCB manufacturing company solutions.

Q: How to verify a manufacturerâs production capacity?

A: Request factory audits, production line details, and past project case studies. We welcome on-site visits and provide comprehensive capacity reports to validate our manufacturing capabilities.

Q: What is the typical turnaround time for PCB prototyping in Vietnam?

A: Leading manufacturers offer 1-3 day turnaround. We provide 48-hour rapid Vietnam PCB prototyping with expedited options for urgent projects, without compromising quality.

Exploring the top 10 pcb manufacturers in Vietnam reveals a dynamic ecosystem of certified, technologically advanced firms, and partnering with a trusted Vietnam PCB manufacturing company from the top 10 pcb manufacturers in Vietnam ensures access to end-to-end quality assurance, rapid delivery, and expert support for all your PCB prototyping, design, and manufacturing needs.