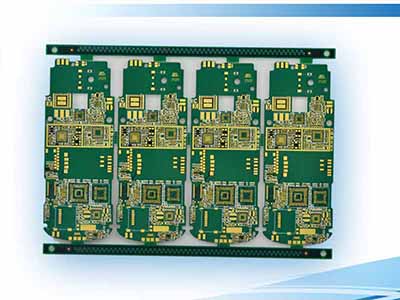

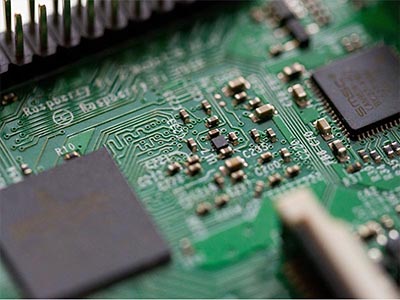

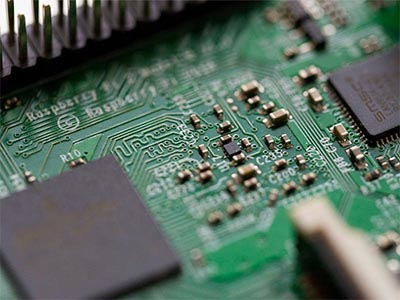

At the first sight, you will see that there is a layer of green oil on the PCB. It is called√ā¬†solder mask which is comprised of resin, talc and pigment. Of course, solder mask also has other colors,√ā¬†including√ā¬†red, yellow, black and so on, but green is the one that used the most widely.

When it comes to the question like that √Ę‚ā¨ŇďWhy are the most of printed circuit boards are green?√Ę‚ā¨¬Ě, the engineers from EBest Circuit (Best Technology) with rich experience gave 5 points to explain it:

1.√ā¬†There PCB is required to go through the exposure room with yellow light in some processes of fabrication and the visual effective in exposure room is better than the solder mask with other colors.

What√Ę‚ā¨‚ĄĘs more, the PCB needs to coat tin, SMT and AOI testing during SMT soldering. All of these processes require optical position alignment and the green solder mask is better for the recognition of instruments.

2.√ā¬†Before the flying probe testing is applied widely, most of the wires on the PCB are relied on the naked eyes to inspect.It is very tired to detect the boards in strong light. If the rigid board is green, it will not do a lot harms to eyes.

3.√ā¬†There are cobalt and carbon in √ā¬†blue and black solder mask,which have a certain conductivity, so there is a risk of short circuit. However, the PCB with green oil will be more friendly to the environment. Because it will not release poisonous gases when use the printed circuit board in a high temperature environment.

4.√ā¬†Since some famous brands began to use black solder mask in 2007, such as ASUS and Micro-Star and then people kept an eye on the colors of PCB.In this way, people gradually believe that PCBs with black solder mask means that the boards have high quality.After that, more and more PCB manufacturers started to apply black solder mask. NO one said that printed circuit boards with black solder mask are better than those with green solder mask.It is entirely due to the misleading caused by the famous brands using black solder mask to identify product positioning.

5.√ā¬†There is no reason, just because of habit, so it has been used all the time.

EBest Circuit (Best Technology) is the premier expert in PCB manufacture of electronics, brings a unique combination of technology and quality that offers a competitive supply of√ā¬†printed circuit board√ā¬†and PCBA. With high qualified engineers, we are able to help you find a PCB with high quality. To find out more, contact EBest Circuit (Best Technology)√ā¬†at 0755-29091601 or check the website: https://www.bestpcbs.com/