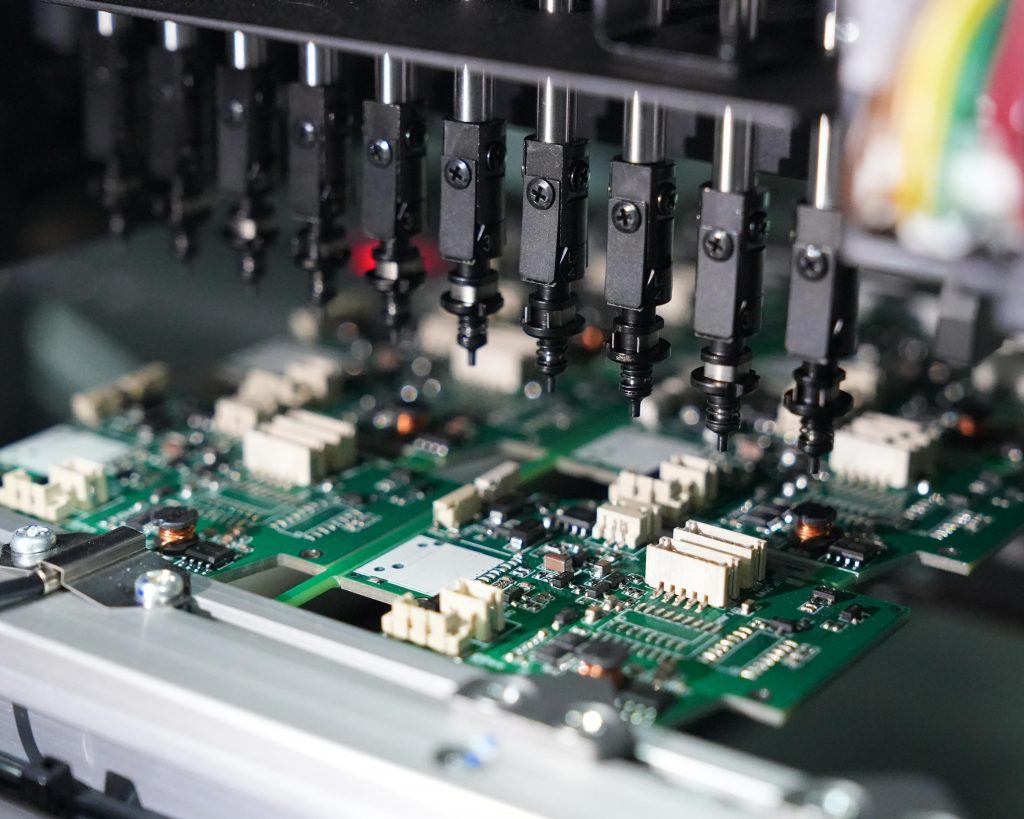

At EBest Circuit (Best Technology), we offer both SMT and through-hole assembly for various PCB types. With ISO certifications, our team guarantees precise quality and traceability. Whether you’re working on PCB prototypes or large-volume orders, we can handle the complete processâfrom PCB fabrication to full assemblyâwith competitive pricing and professional engineering support.

What Is Through-Hole Technology?

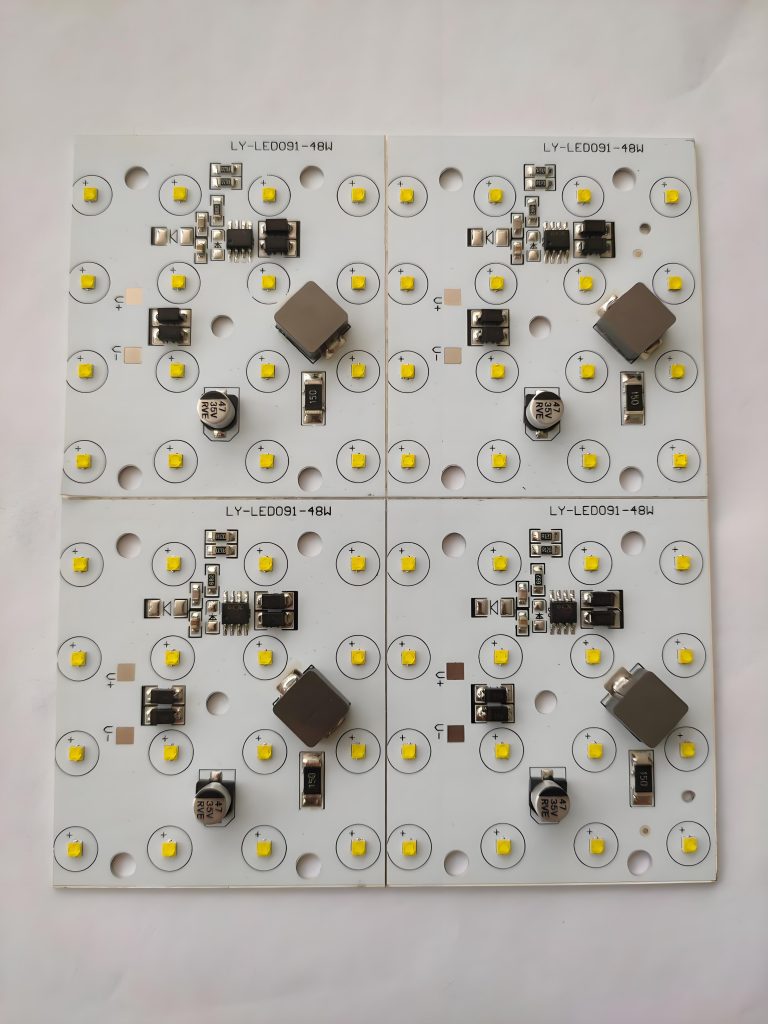

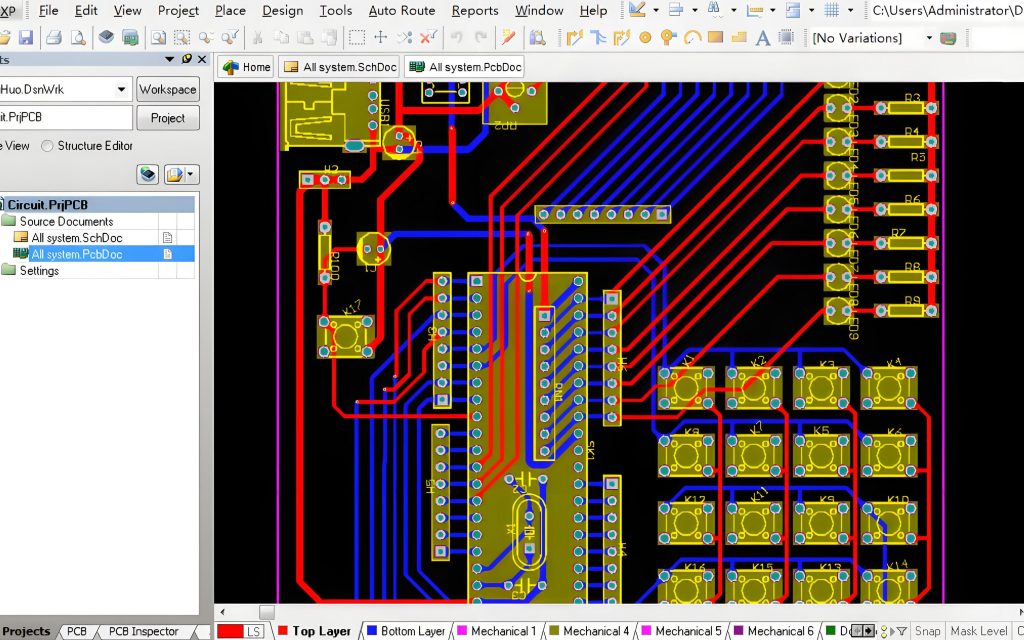

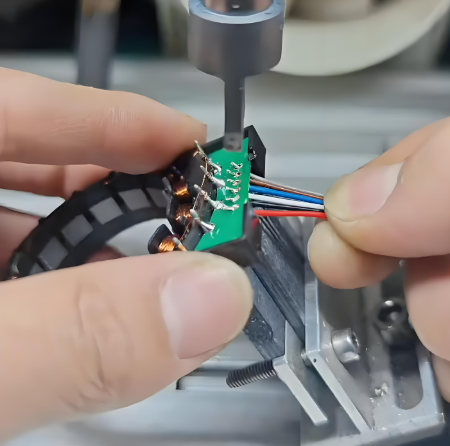

Through hole technology is a method used to mount electronic components on a printed circuit board (PCB). It involves drilling holes in the PCB where component leads are inserted and soldered to pads on the opposite side. This process creates a strong mechanical bond, which is especially useful for components that handle higher currents or need more stability.

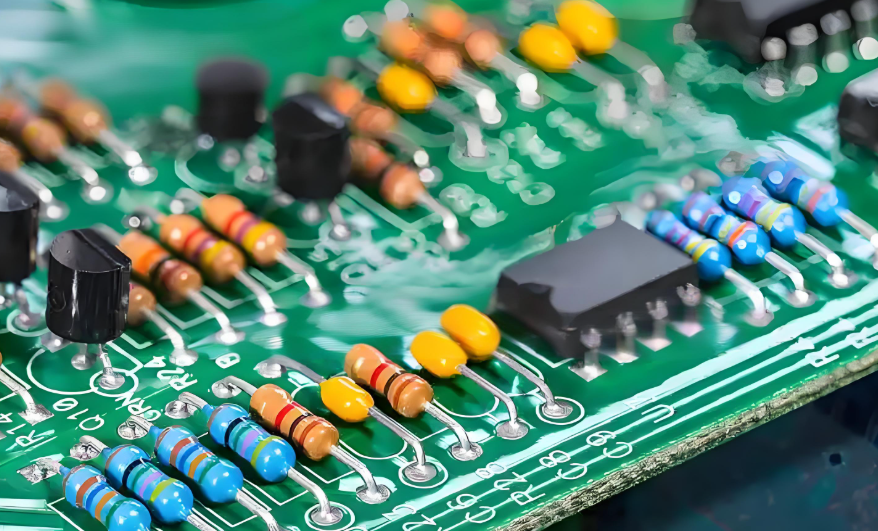

The term PCB through hole refers to those drilled spaces where leads pass through and connect circuits on different layers. Although newer surface-mount technology (SMT) is now more common, through-hole is still widely used in specific applications such as aerospace, military, and testing environments.

What Are the Characteristics of Through-Hole Technology?

Through-hole technology has a few defining features that separate it from SMT. First, it requires precise drilling into the PCB, which can add time and cost to production. Second, it uses leaded components, meaning parts have metal wires that must be placed through the holes. Third, the soldering can be done manually or by wave soldering, depending on the complexity and quantity of the assembly.

Another key trait is the mechanical strength of the joint. Unlike SMT components, through-hole parts have deeper anchoring, making them more reliable under stress, vibration, or high temperature.

Different Types of Through Holes

There are several types of PCB through holes, each serving different purposes in the assembly process:

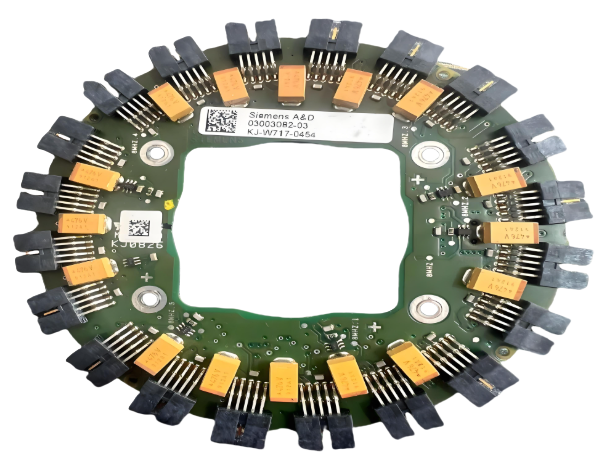

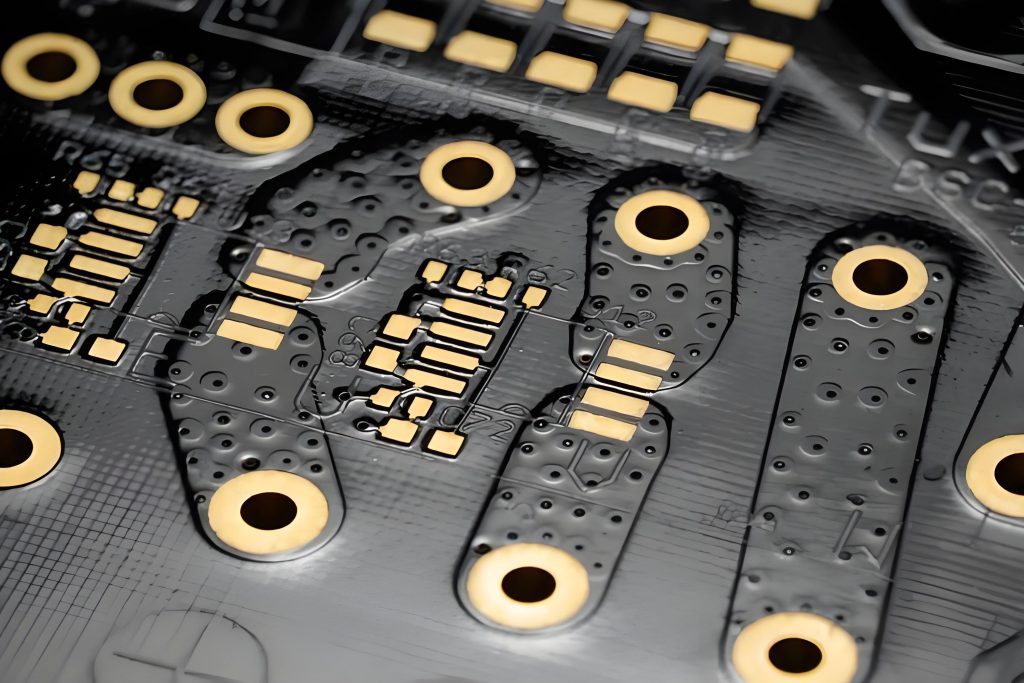

1. Plated Through Holes (PTH)

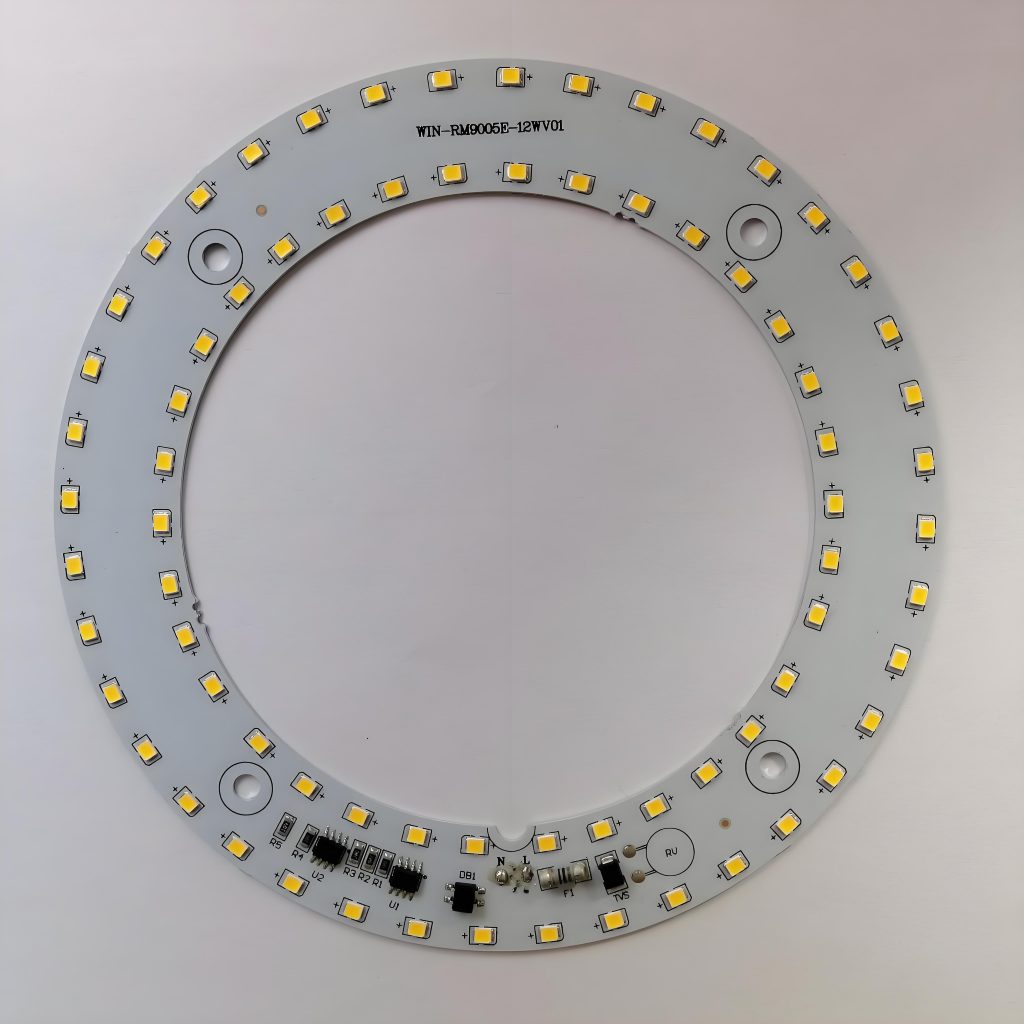

These are the most common. They have conductive copper plating inside the hole walls, creating electrical connections between layers of the PCB. PTHs are used for both signal routing and mounting components.

2. Non-Plated Through Holes (NPTH)

These holes have no copper inside and are used purely for mechanical reasonsâsuch as mounting screws or hardware. They donât connect circuits or carry current.

3. Via Holes

Though often grouped separately, vias are also a type of through hole. They connect one PCB layer to another electrically but are not used for inserting components. Vias can be through vias, blind vias, or buried vias depending on the layers they connect.

4. Component Holes

These are drilled specifically for component leads like resistors, capacitors, and connectors. Theyâre usually PTHs because they need both electrical connectivity and physical anchoring.

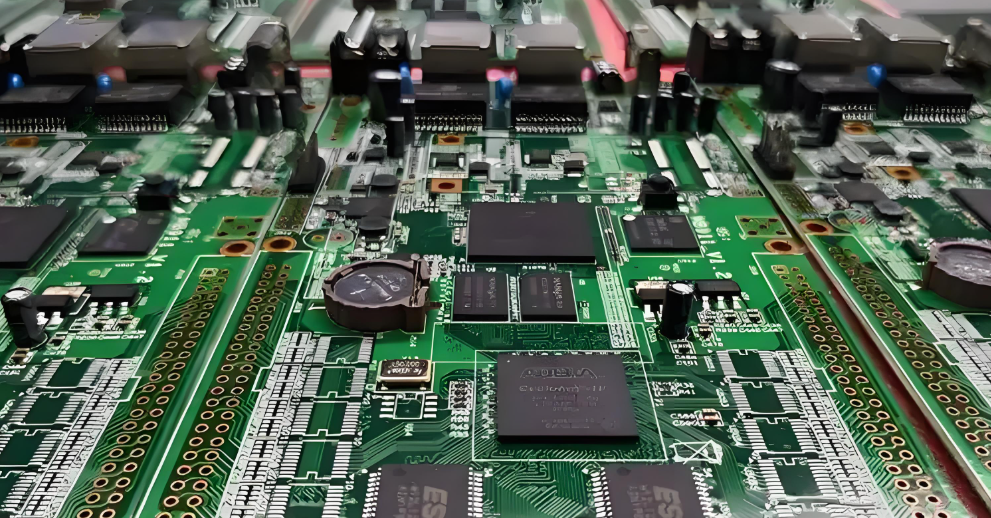

What Is the Difference Between SMT and Through-Hole Technology?

The key difference lies in how components are mounted onto the PCB:

| Feature | Through-Hole Technology | Surface Mount Technology (SMT) |

| Component Placement | Leads inserted through drilled holes | Mounted directly on PCB surface |

| Board Sides Used | Both sides (top for components, bottom for solder) | Mostly one side |

| Assembly Type | Manual or wave soldering | Automated solder reflow |

| Mechanical Strength | High | Moderate |

| Suitable For | High-stress environments | High-density, lightweight electronics |

| Cost | Higher due to drilling and manual labor | Lower with automated production |

In short, through-hole technology vs SMT often comes down to reliability vs efficiency. SMT is ideal for modern, compact devices, while through-hole is preferred for heavy-duty or high-reliability circuits.

What Are the Advantages of Through-Hole?

- âStrong mechanical connection: Through-holes provide a strong mechanical connection by welding the pins of components onto the PCB, suitable for withstanding large mechanical stress.

- âMature manufacturing process: The manufacturing process of through-holes is relatively mature, with low cost, and suitable for large-scale production.

- âHigh compatibility: Through-hole PCBs have good compatibility with the packaging forms of components, suitable for traditional through-hole packaging and larger-sized, special-shaped components.

- For manual soldering and maintenance: Through-hole PCBs are convenient for manual soldering and maintenance, and can be completed with ordinary soldering irons and other tools.

- Higher Current Capacity: Larger leads and deeper solder joints handle more power.

- Reliable for Prototyping: Easier to work with manually, which helps in R&D.

Disadvantages of Through-Hole Technology

While useful in many cases, through-hole also comes with limitations:

- More Expensive: Drilling adds manufacturing time and cost.

- Lower Component Density: Takes more space on the PCB compared to SMT.

- Slower Assembly: Manual or wave soldering is not as fast as automated SMT.

- Double-Sided Processing: Components on one side, solder on the other, complicating rework or inspection.

- Affects Signal Integrity: In high-speed signal transmission, through-holes will generate parasitic capacitance and inductance, which may cause signal delay and crosstalk, affecting signal integrity.

These drawbacks make through-hole less suitable for modern high-volume or miniaturized electronics.

What Materials Are Used in Through Hole Technology?

The materials involved in through-hole assembly include:

- PCB Substrate: Usually FR-4, a flame-retardant fiberglass material.

- Copper Foil: Used for plating the walls of the hole to make electrical connections.

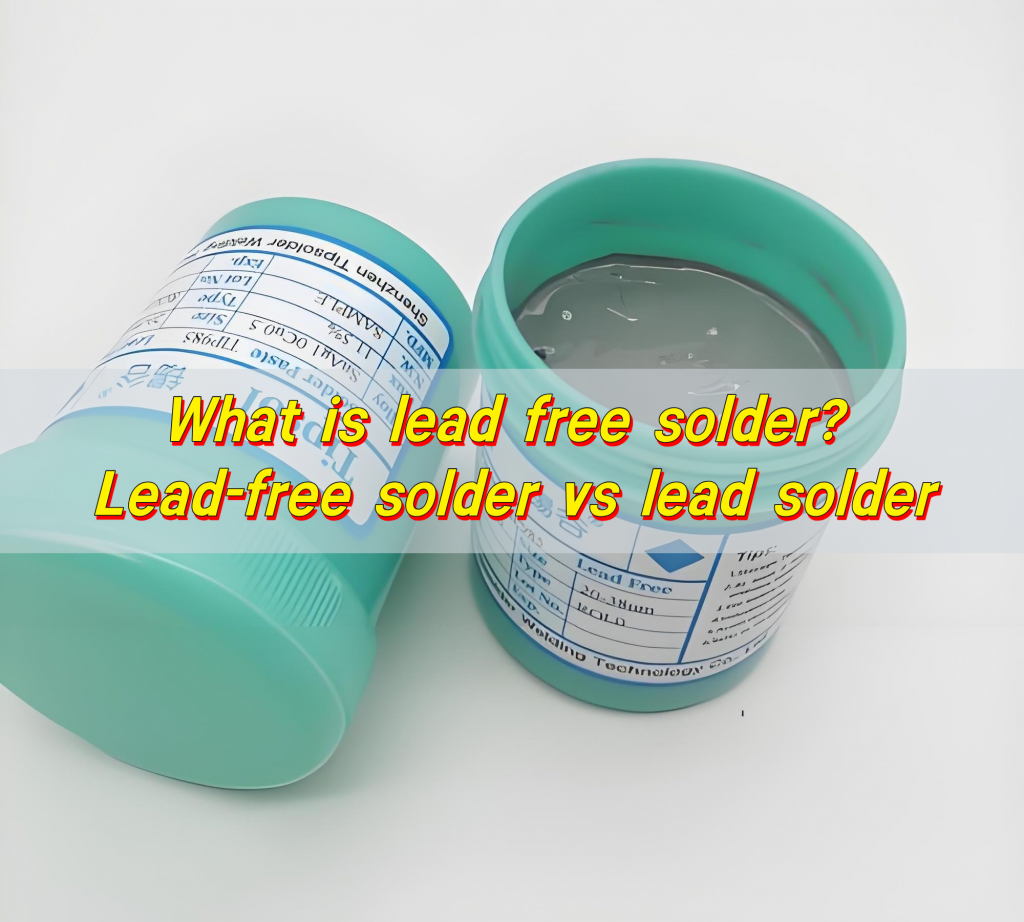

- Solder: Commonly a tin-lead alloy or lead-free alternatives for RoHS compliance.

- Flux: Helps the solder flow and bond to the metal surfaces.

- Leaded Components: With metal leads or wires that go through the board.

- Masking Ink: Protects areas not intended for soldering.

These materials work together to create strong, conductive joints that last over time.

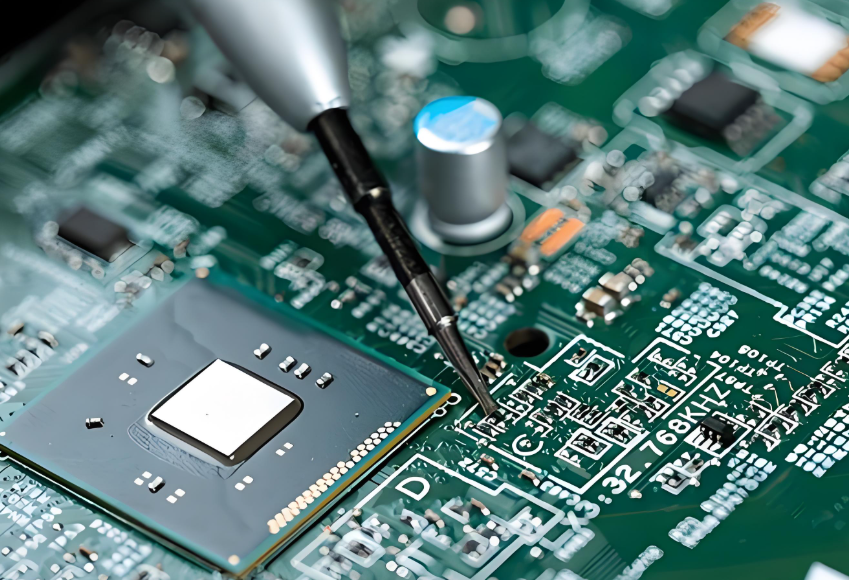

Considerations During Solder Through Hole Components

When soldering through-hole components, keeping the following factors in mind helps ensure a reliable and high-quality connection:

1. Hole and Lead Size Matching

The drilled hole must closely match the component lead diameter. Too loose causes weak joints; too tight restricts solder flow.

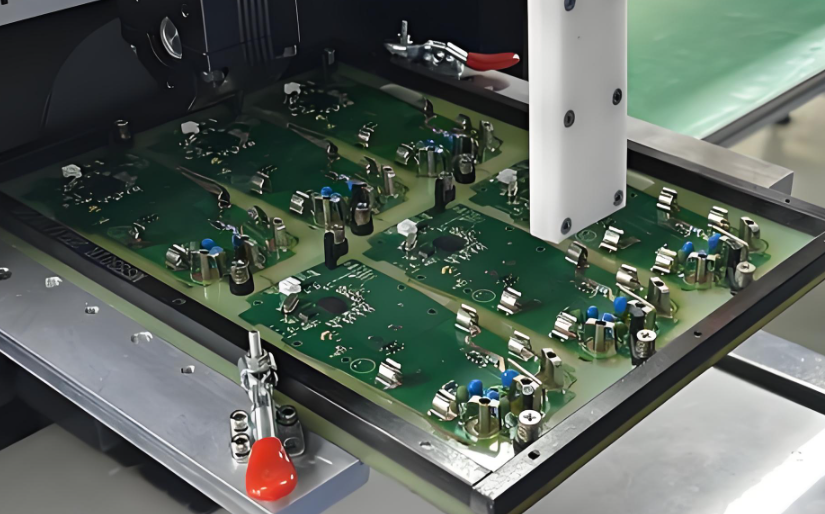

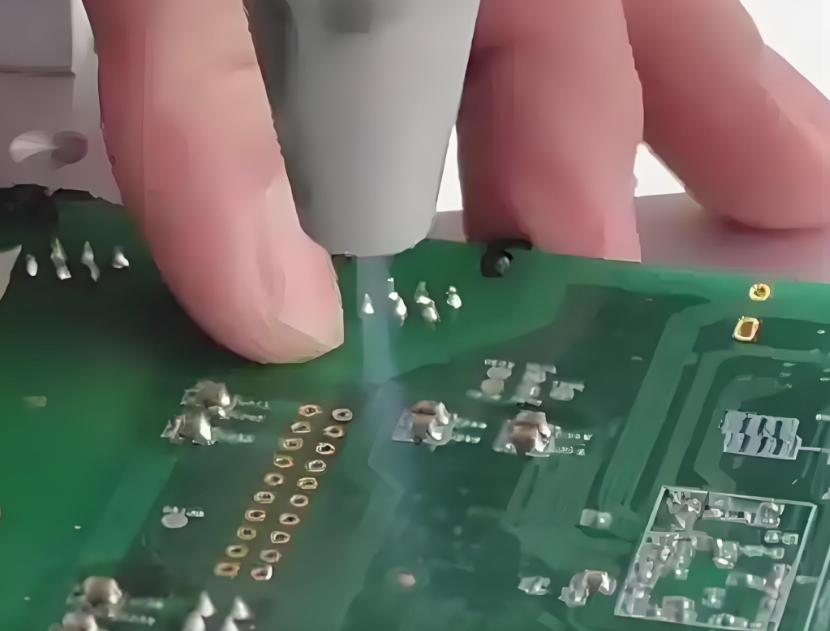

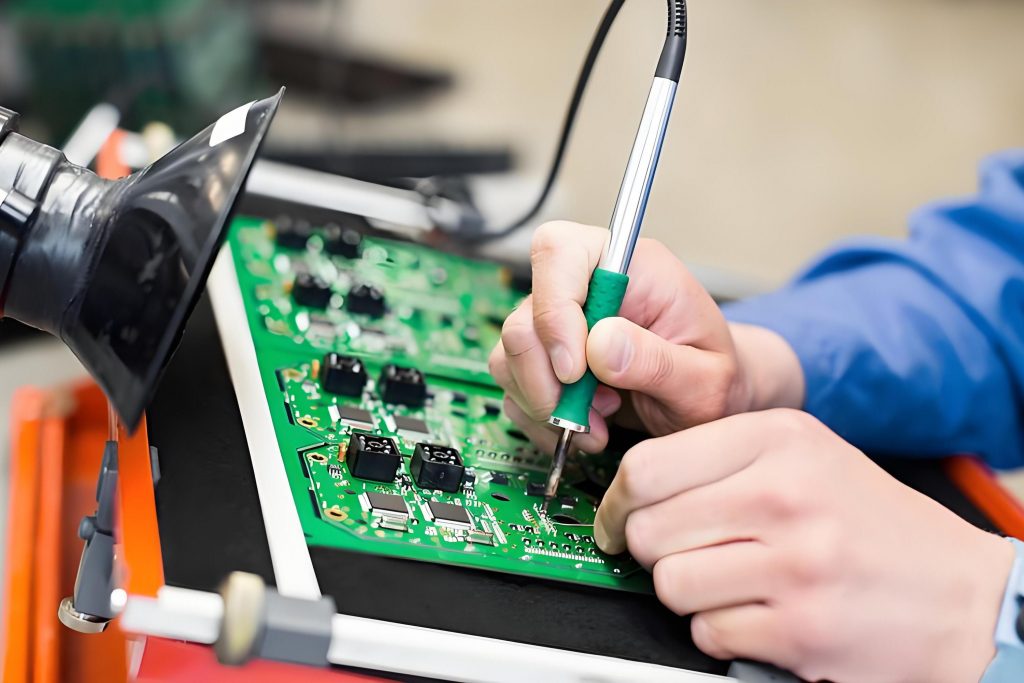

2. Proper Soldering Method

- Manual soldering is ideal for prototypes or low-volume assemblies.

- Wave soldering suits larger batches with consistent quality and speed.

3. Controlled Flux Application

Apply just enough flux to clean surfaces and improve solder flow. Excess flux may leave residues or cause corrosion.

4. Accurate Component Placement

Leads should be inserted straight and fully into the hole to avoid stress during soldering or later use.

5. Correct Soldering Temperature and Time

Maintain proper heat levels and dwell time to prevent cold solder joints or overheating.

6. Avoiding Solder Bridges

Ensure solder doesnât accidentally connect two adjacent pads or leads, especially in tight areas.

7. Mechanical Stability

For connectors or large components, use support fixtures during soldering to keep parts from shifting.

8. Inspection After Soldering

Visually check for smooth, shiny solder joints. Use magnification or x-ray for dense or complex boards.

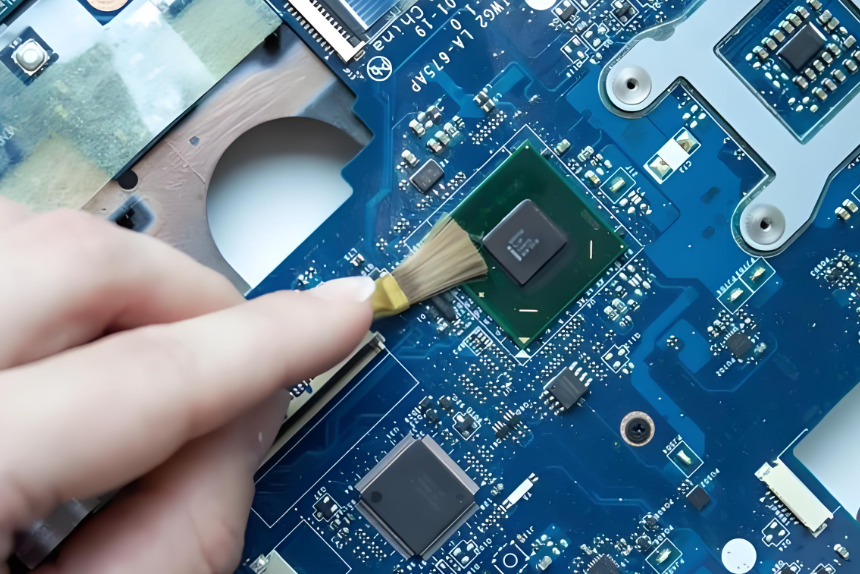

9. Post-Solder Cleaning

Remove any leftover flux residues with appropriate solvents or cleaning processes to prevent long-term damage.

10. ESD Safety Measures

Handle components with ESD precautions to protect sensitive devices from electrostatic discharge during assembly.

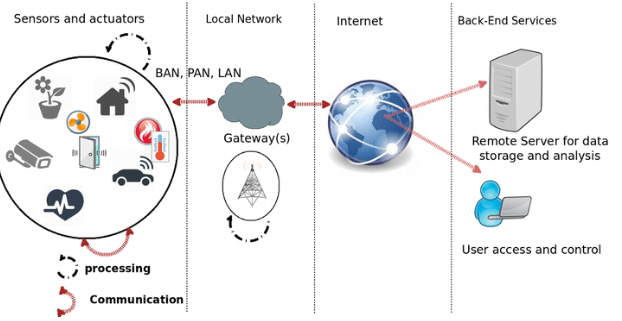

What Is a Through-Hole Used For?

Through-holes are used in many areas of PCB manufacturing and assembly. Their main function is to:

- Mount Large Components: Like capacitors, connectors, or inductors.

- Transfer Signals or Power: Across multiple layers of the PCB.

- Anchor Parts: Where strong mechanical support is necessary.

- Support Prototyping: Breadboards and experimental PCBs often use through-hole components because theyâre easier to insert and replace.

- Handle Harsh Conditions: Ideal for products exposed to motion, heat, or heavy-duty usage.

In short, PCB through hole designs are a practical solution when strength, reliability, and repairability are key.

FAQs

1. Is through-hole technology still used today?

Yes, especially in aerospace, automotive, and high-power applications where strength and reliability are crucial.

2. Can through-hole and SMT be used on the same PCB?

Yes. Mixed technology boards combine both methods to meet different design requirements.

3. Why is through-hole better for testing?

Leaded components are easier to probe and replace, which helps during R&D or repair.

4. Is through-hole more expensive than SMT?

Generally, yesâdue to manual labor, hole drilling, and larger component size.

5. Which is better: SMT or through-hole?

It depends. SMT is better for compact, automated designs. Through-hole is better for strength and harsh environments.