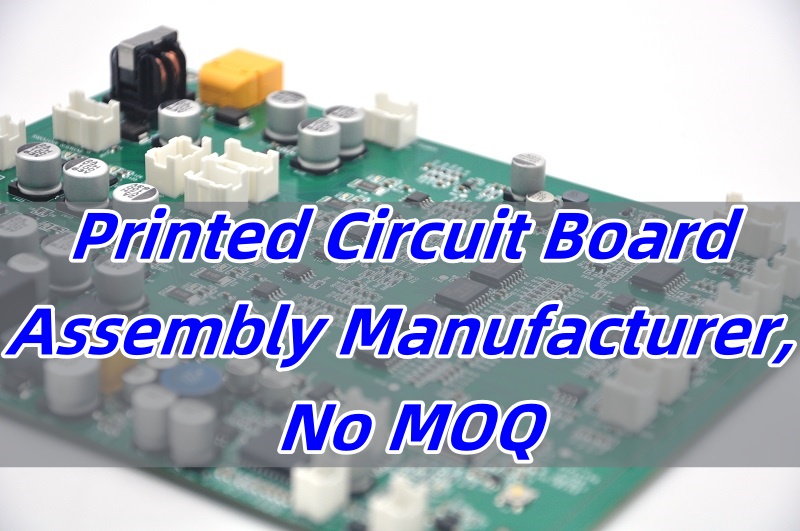

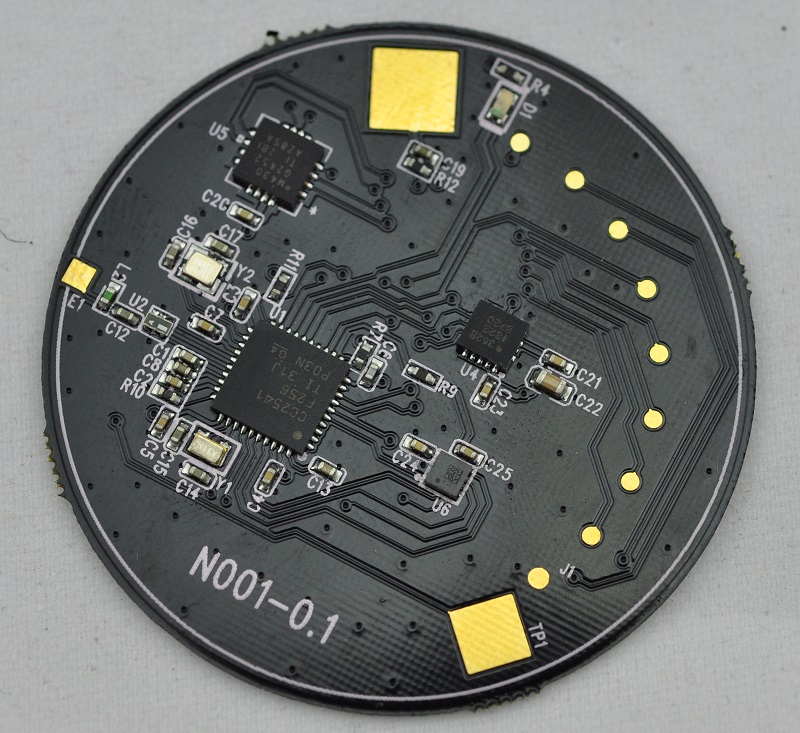

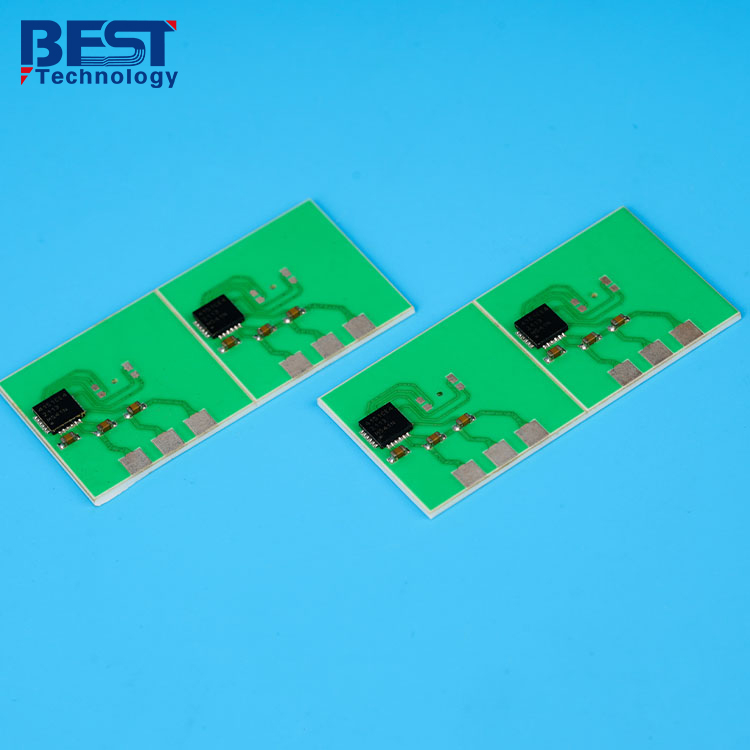

PCBA Printed Circuit Board Assembly is the key process that brings life to any electronic device. It’s more than just placing components on a board â it’s precision, quality, and smart engineering.

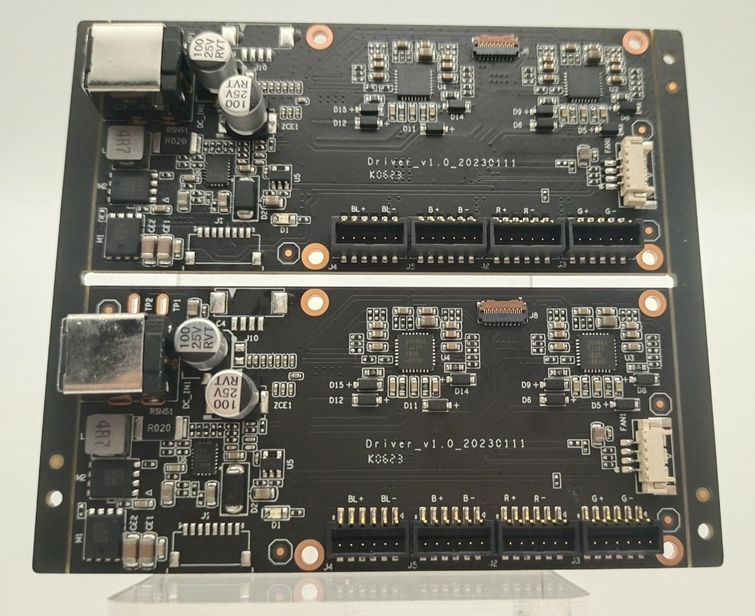

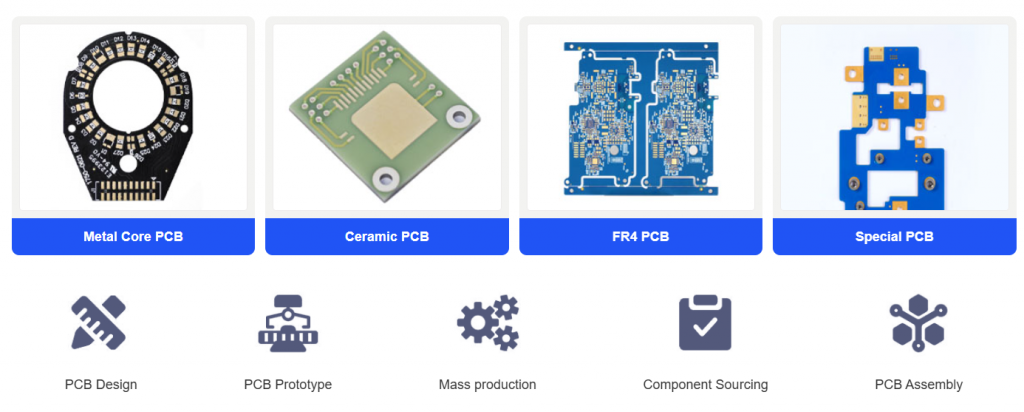

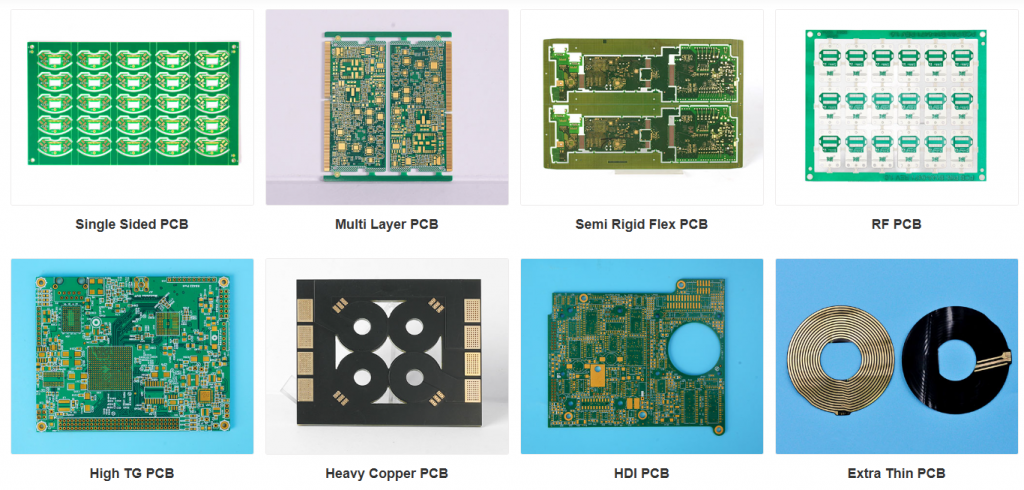

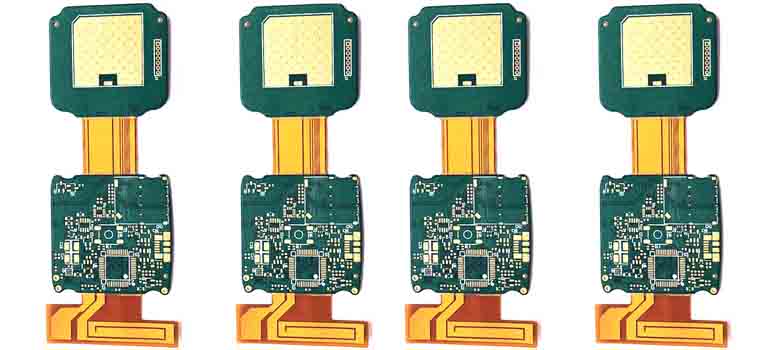

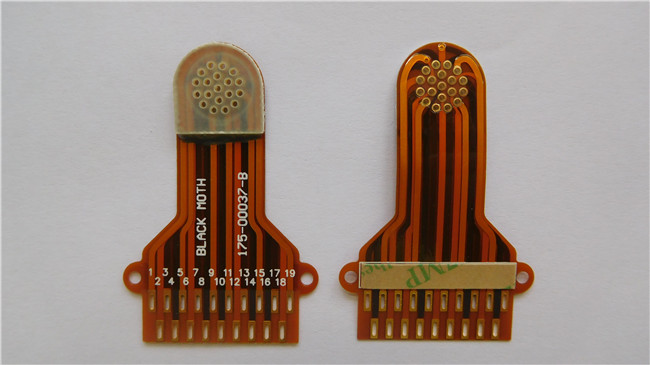

As a well-established OEM factory, EBest Circuit (Best Technology) is dedicated to providing top-quality PCBA (Printed Circuit Board Assembly) services to customers around the globe. Our SMT PCBA processes strictly adhere to industry standards. Our competitive advantages include high quality, on-time delivery, and 24/7 tech support.

In the fast-paced SMT PCBA industry, survival can be challenging. To enhance efficiency, EBest Circuit (Best Technology) manages both PCB manufacturing and PCBA printed circuit board assembly under one roof. With 19 years of experience in the PCB industry, we not only deliver high-quality PCBA products but also offer comprehensive assembly solutions tailored to your needs. If you have any SMT PCBA projects that require our expertise, please don’t hesitate to contact us at sales@bestpcbs.com.

What is a PCBA Printed Circuit Board Assembly?

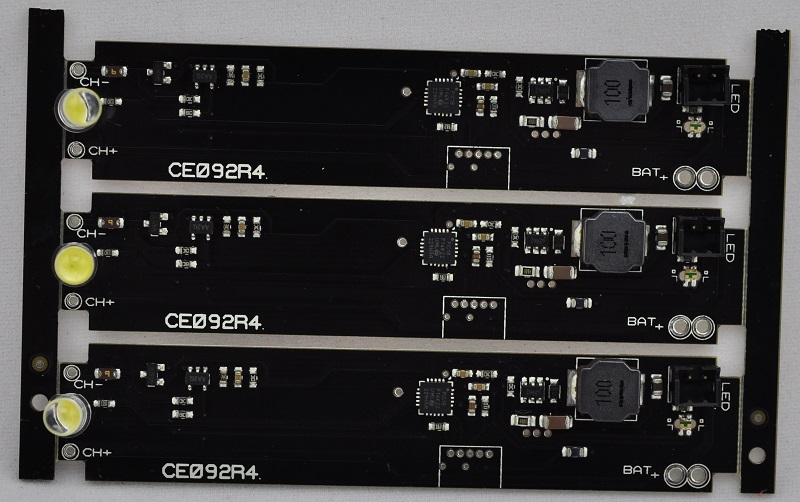

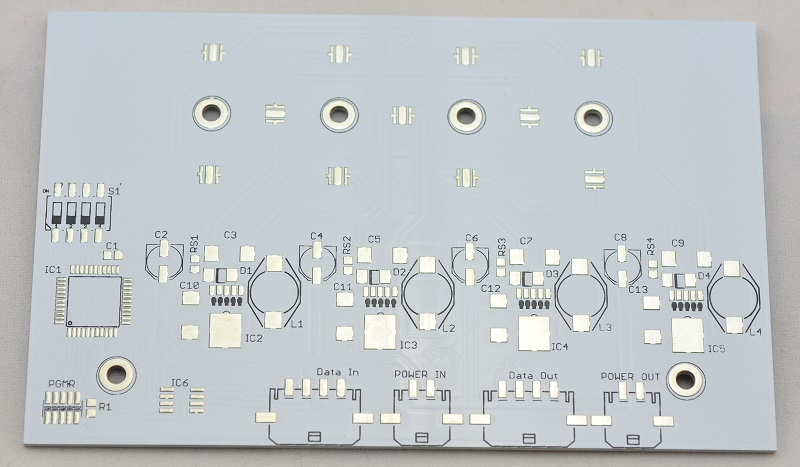

PCBA, short for Printed Circuit Board Assembly, refers to the complete board after all components have been soldered onto the bare PCB. It involves placing parts such as resistors, capacitors, and chips using technologies like SMT (Surface Mount Technology) and through-hole methods. The final board is tested and ready to perform its functions in the product.

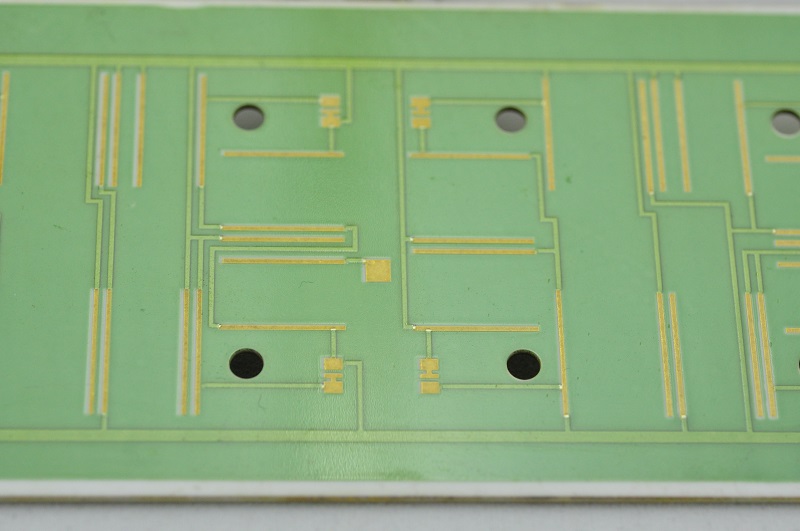

What is the difference between PCB and PCBA Printed Circuit Board Assembly?

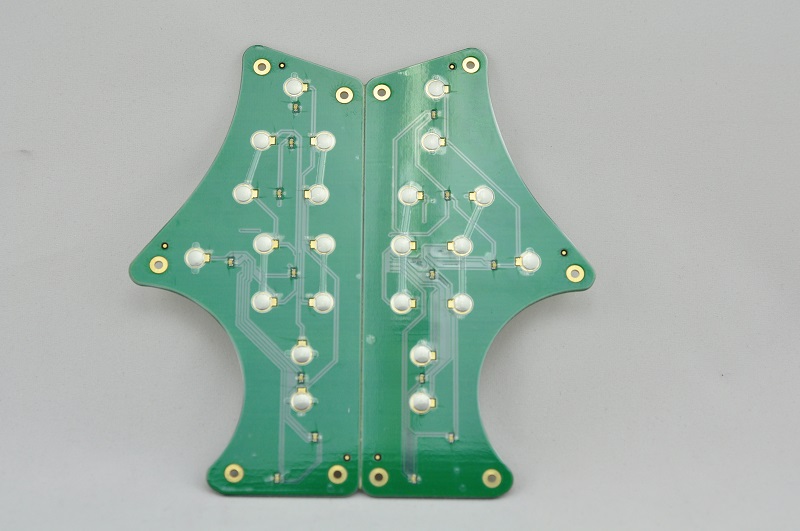

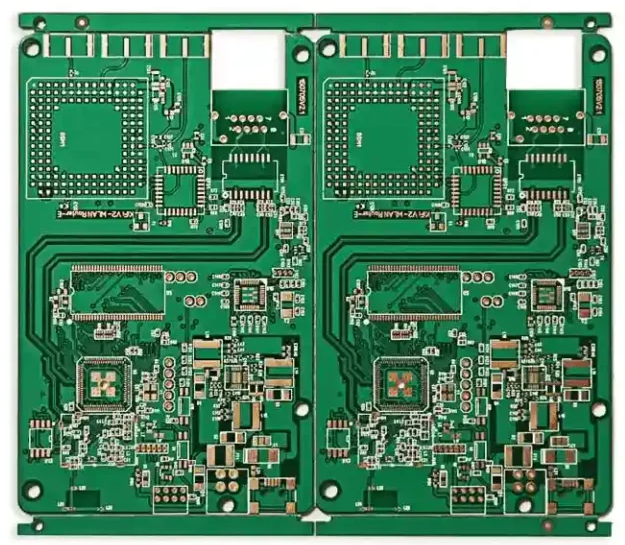

The PCB is the bare board, made of materials like FR4, with copper traces but no components. On the other hand, PCBA Printed Circuit Board Assembly is the complete unit with all components installed. Think of PCB as the foundation and PCBA as the finished building. While a PCB is passive, PCBA is active and functional.

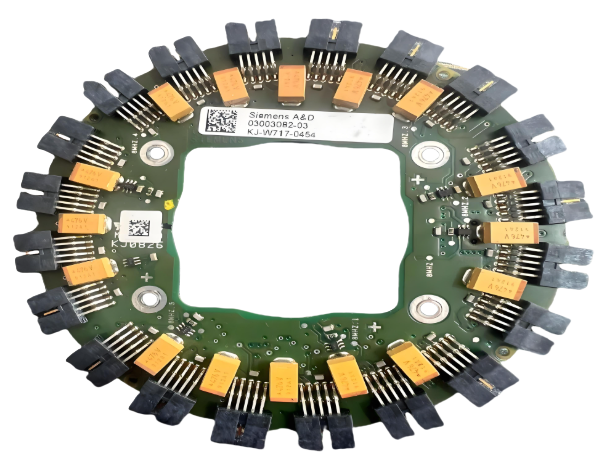

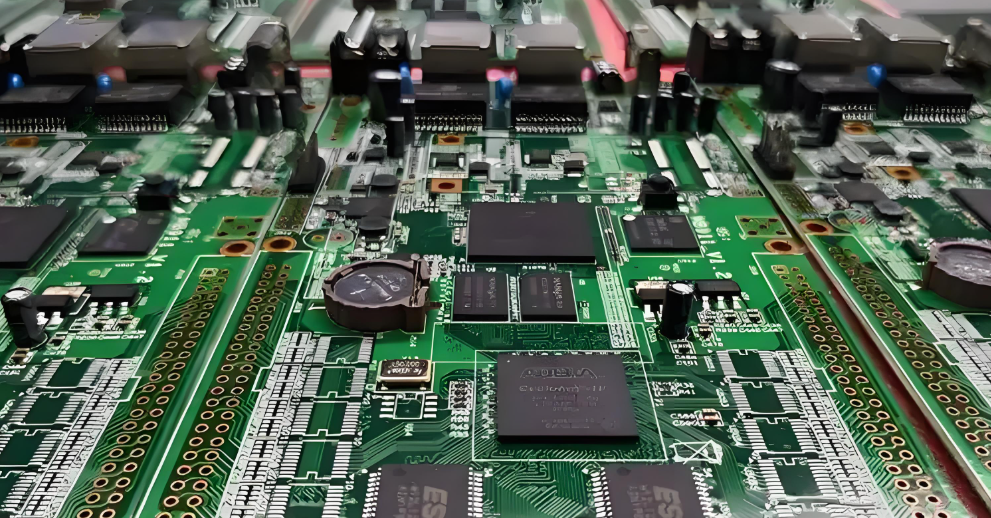

What is the difference between a motherboard and a PCBA Printed Circuit Board Assembly?

A motherboard is a specific type of PCBA Printed Circuit Board Assembly used in computers. It supports other boards and components like RAM, CPUs, and GPUs. A PCBA can be any assembled board used in different industries like automotive, medical, and telecom. So, every motherboard is a PCBA, but not all PCBAs are motherboards.

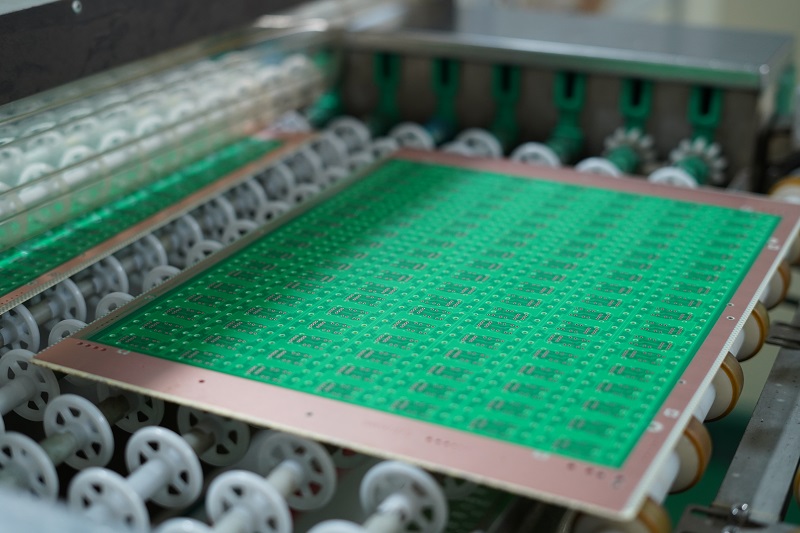

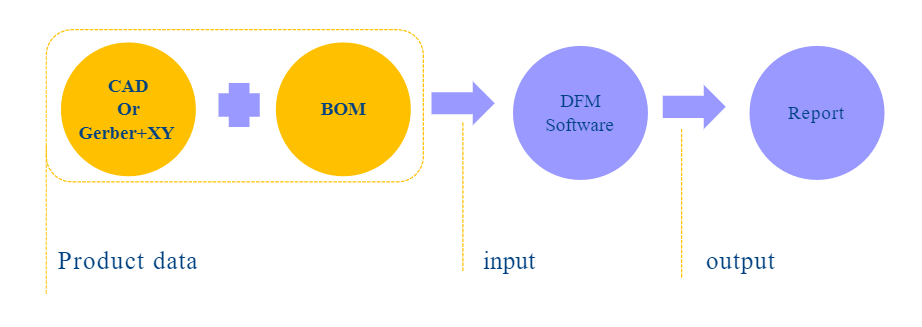

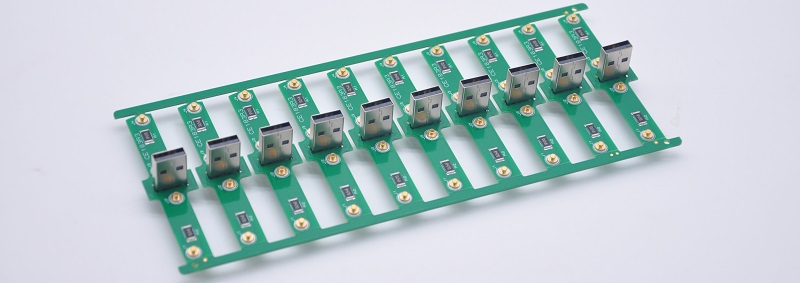

What is the process flow of SMT PCBA?

Here’s a quick overview of the SMT PCBA process:

- Solder Paste Printing: A stencil printer applies solder paste to the board.

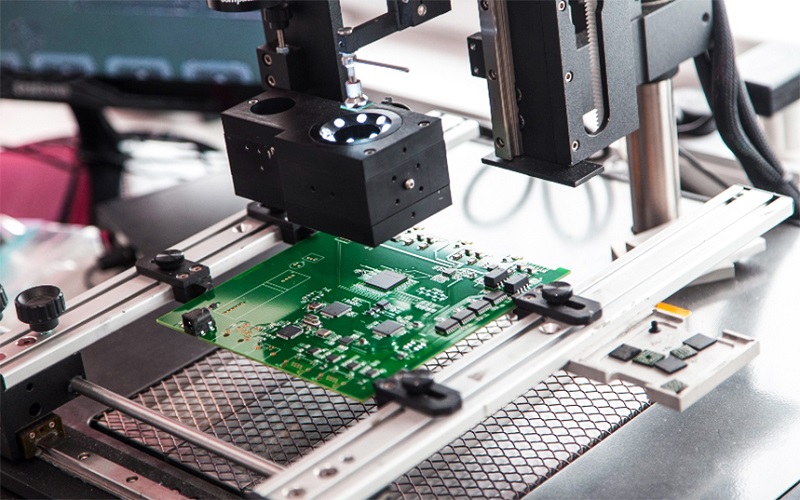

- Component Placement: High-speed pick-and-place machines accurately position components.

- Reflow Soldering: Boards go through a reflow oven to solidify the solder joints.

- AOI Inspection: Automatic Optical Inspection checks for misaligned or missing parts.

- X-ray Inspection: For BGA or hidden solder joints, X-ray checks are performed.

- Functional Testing: Final tests ensure the board works as expected.

This process is designed to meet the strict quality expectations of todayâs high-tech products.

How long can solder paste sit before reflow?

Solder paste shouldnât sit too long. Generally, once itâs printed, it should be reflowed within 4 to 8 hours. Delays may cause oxidation or poor soldering. EBest Circuit (Best Technology) selects various solder pastes based on the specific components and SMT technologies involved, ensuring optimal solder joint performance. Each bottle of solder paste goes through our MES system, allowing us to monitor and make sure that we are using the correct solder paste for each application.

Why is PCBA Printed Circuit Board Assembly important?

Every modern device you useâphones, TVs, or even carsâdepends on PCBA Printed Circuit Board Assembly. It connects the logic of your device and keeps it running reliably. A strong PCBA process ensures performance, durability, and safety. In industries like aerospace and healthcare, there’s no room for error, and that’s where professional PCBA services come in.

Why should you choose EBest Circuit (Best Technology) as your OEM SMT PCBA Factory Partner?

EBest Circuit (Best Technology) offers a tailored approach to PCBA manufacturing. Our competitive edges are as following:

- Production Flow & Scheduling: How well production processes are optimized directly impacts delivery timelines. At EBest Circuit (Best Technology), we use smart material tracking systems (like MES) and adaptable production planning to avoid missing parts and cut down delays and make the most of every resource.

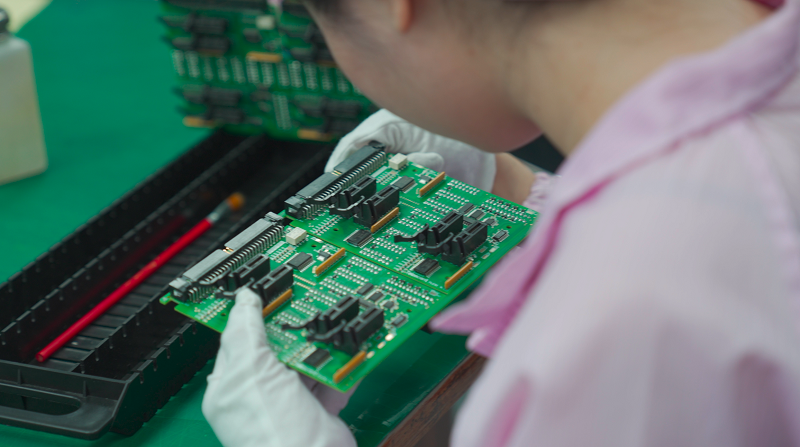

- Fast Turnaround: With 10+ SMT lines, we shorten the production cycle and deliver faster.

- High-Mix, Low-Volume Ready: Our team handles customized, small-batch PCBA projects with care and agility.

- Strong Quality Control: From solder paste printing to reflow and inspection, we use AOI, 3D SPI, X-ray, and functional tests.

- Advanced Equipment: Machines like, GKG automated solder paste printer, Yamaha SMT placers, JUKI SMT placers, Panasonic NPM, and Suneast 10 zones Nitrogens Reflow Oven ensure stable quality and speed.

- Global Certifications: Our factory holds ISO 9001, ISO 13485 (medical), IATF 16949 (automotive), and AS9100D (aerospace).

- Dedicated Support: From prototyping to mass production, our engineers offer design suggestions and instant feedback.

Customers often face delayed orders due to supply issues. We address this by having stable supplier networks and safety stocks. You also donât need to worry about frequent design changes. Our flexible production and strong engineering team ensure smooth updates at every step. Moreover, we believe in transparent and fast communication. Our support team replies in under 8 hours, and we offer expedited services when needed.

In brief, EBest Circuit (Best Technology) provides reliable, efficient, and custom-fit PCBA Printed Circuit Board Assembly services. Whether itâs a prototype or volume order, we manage everything from sourcing to shipment with precision and care. So if youâre looking for a partner who truly understands your project needs and delivers on timeâEBest Circuit (Best Technology) is here to help. A warm welcome to contact us at sales@bestpcbs.com for support at any time.

To conclude, PCBA Printed Circuit Board Assembly is essential in bringing electronics to life. Understanding its process and value can guide you in choosing the right supplier. At EBest Circuit (Best Technology), we process your orders with smart systems, expert teams, and full certifications. From prototype to production, we promise high quality, fast turnaround, and full customization. Thatâs what makes us a preferred partner for many companies around the globe. In SMT PCBA, EBest Circuit (Best Technology) is your trusted OEM factory partner. Please contact us at sales@bestpcbs.com for any PCBA printed circuit board assembly inquiries.