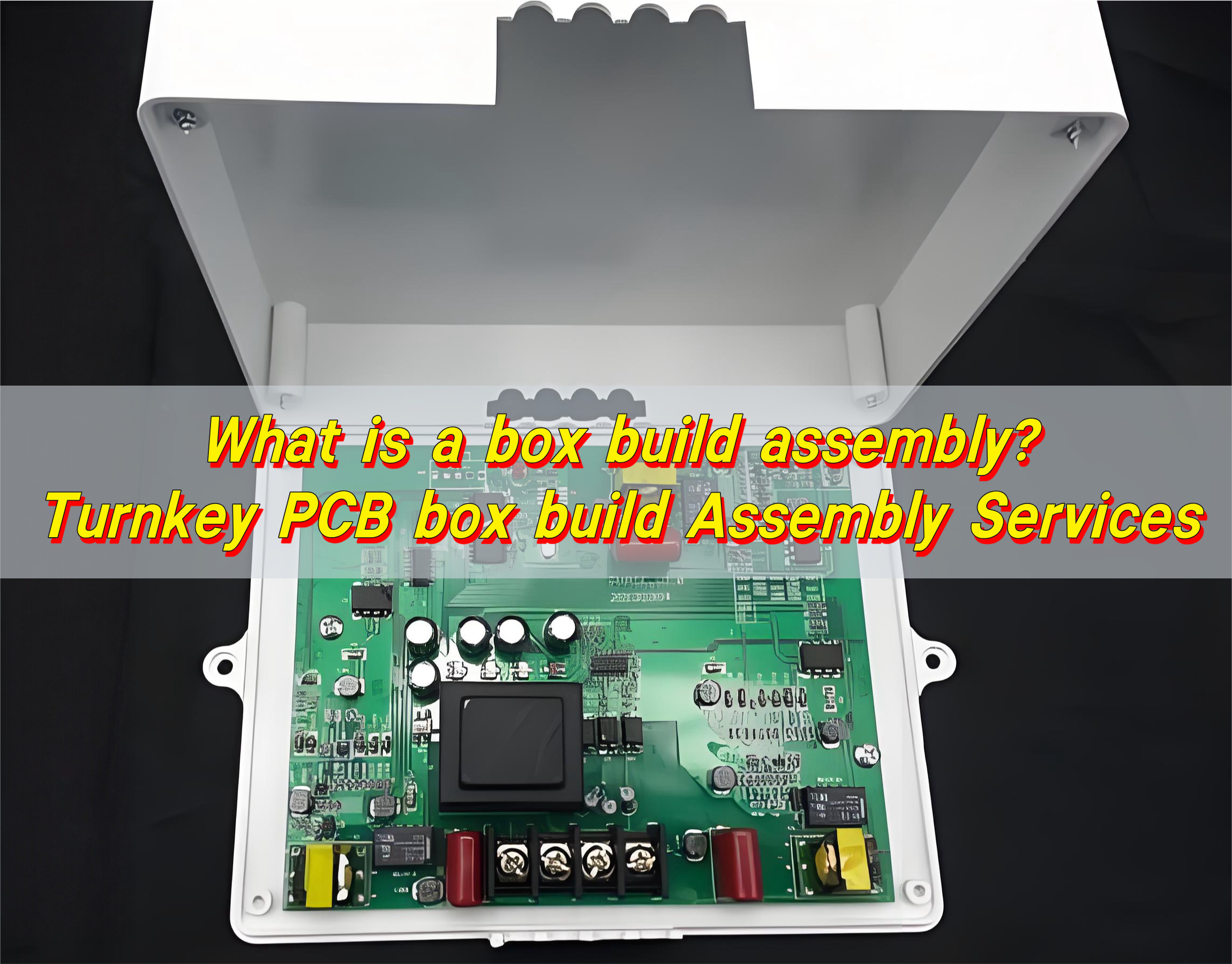

Box build assembly is the final stage of creating an electronic product. It takes a finished PCB and adds everything around it‚ÄĒcables, hardware, enclosure, firmware, and testing‚ÄĒuntil the unit becomes a complete device. It is the step where separate parts turn into one working system.

In simple terms, PCBA builds the board, while a box build creates the full product.

What is a box build assembly in electronics?

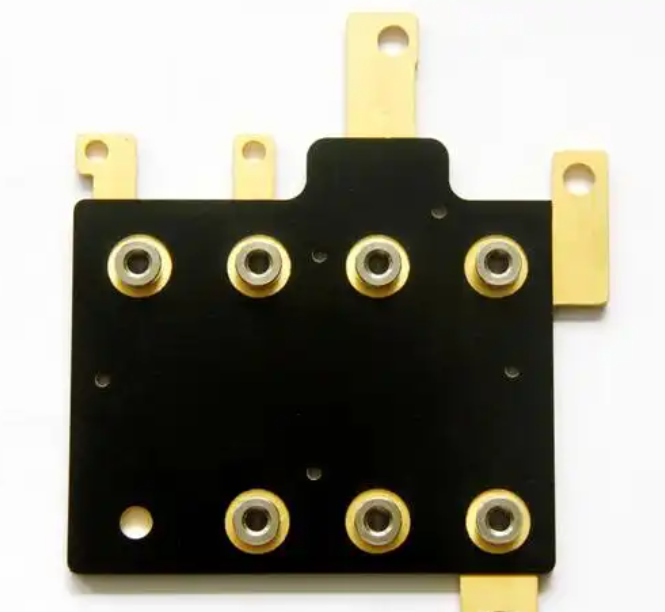

Box build assembly is the complete end stage of an electronic product. It brings the PCB, wiring, structure, enclosures, displays, and firmware together into one finished unit. It is often called a ‚Äúsystems integration service‚ÄĚ because everything inside the device is prepared, checked, connected, and tested.

When you work with a provider that handles both PCB assembly and box build assembly, the entire flow feels smoother. The engineering work stays consistent. The production team understands the design early. The build moves faster.

Instead of coordinating ten vendors for PCBs, cables, housings, firmware, and functional testing, you work with one partner who manages all parts and pieces.

For buyers, this type of service is reliable because it removes guesswork. It also lowers hidden costs like rework, shipping between suppliers, and poor communication. As a result, more teams now see box build assembly as an essential part of their product roadmap rather than an optional feature.

What does the box build assembly service include?

A complete box build assembly service covers many detailed steps. While different manufacturers offer different scopes, the core parts usually include:

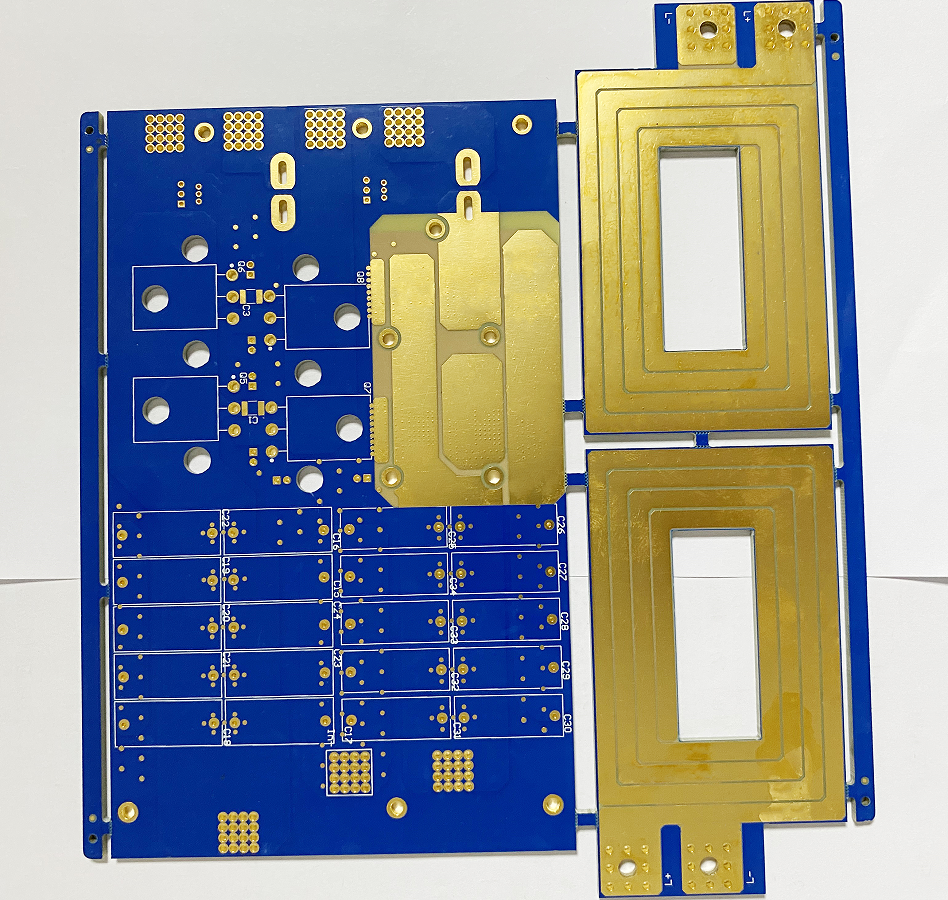

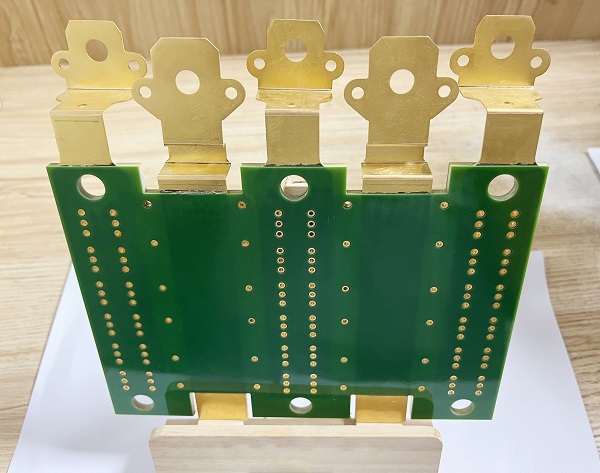

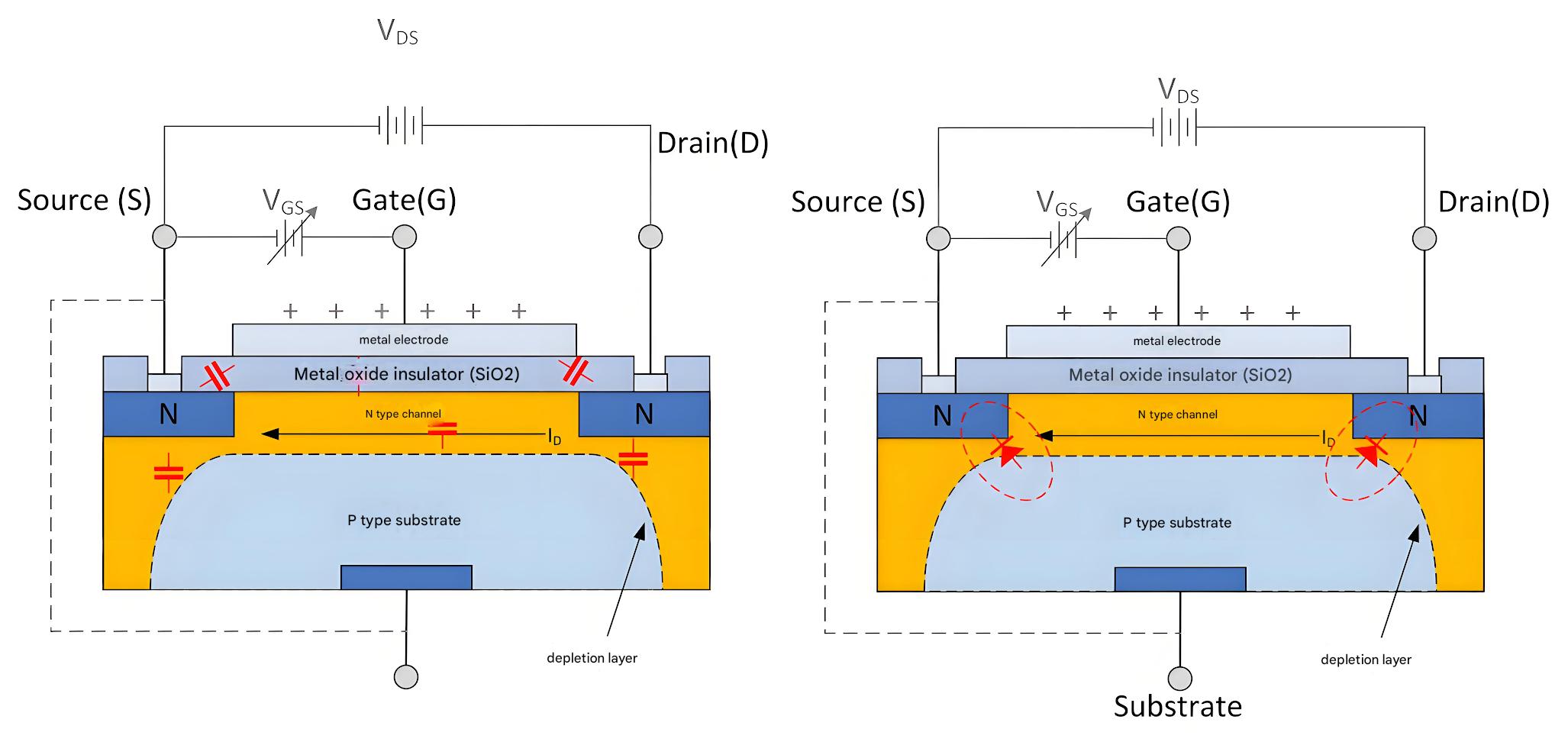

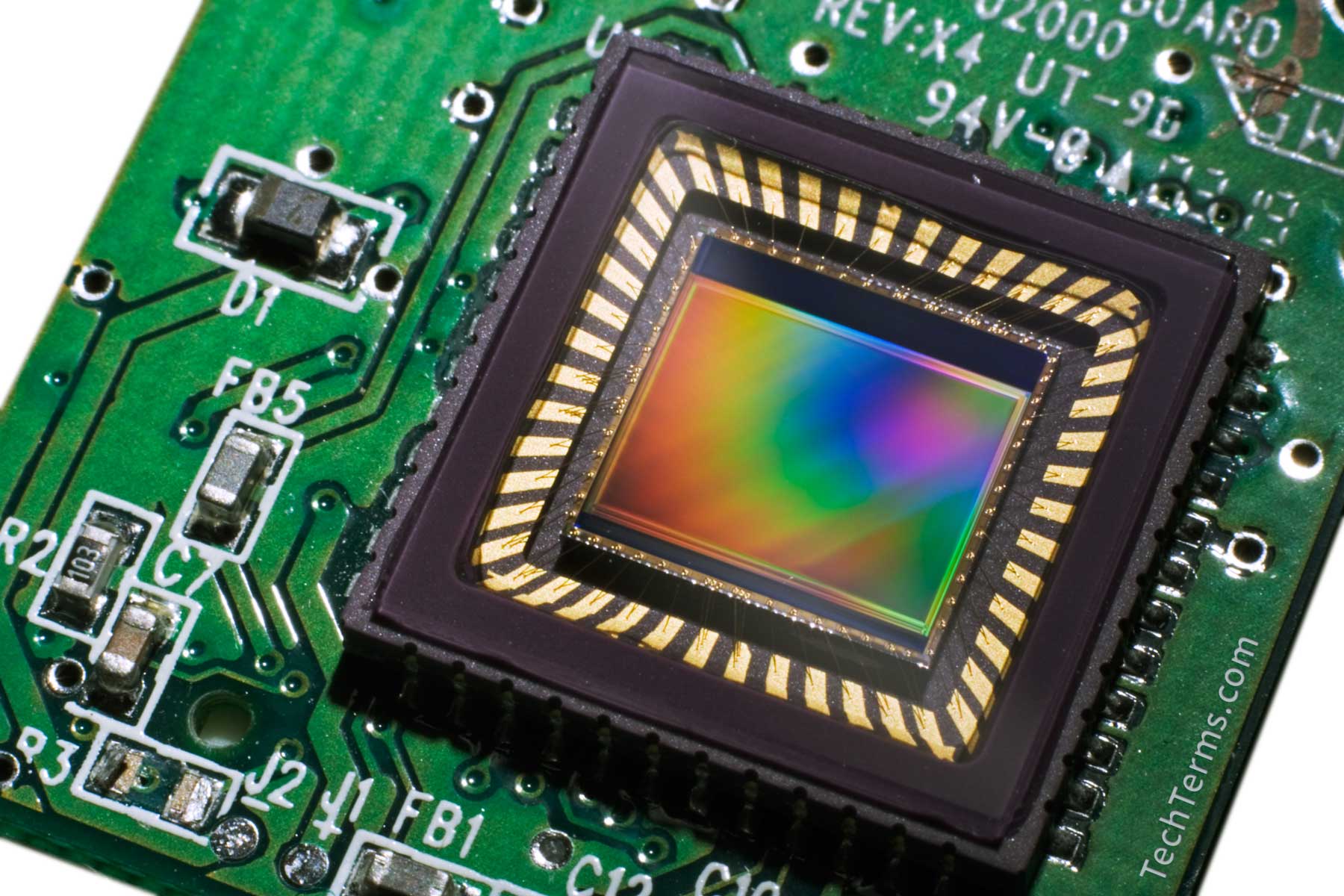

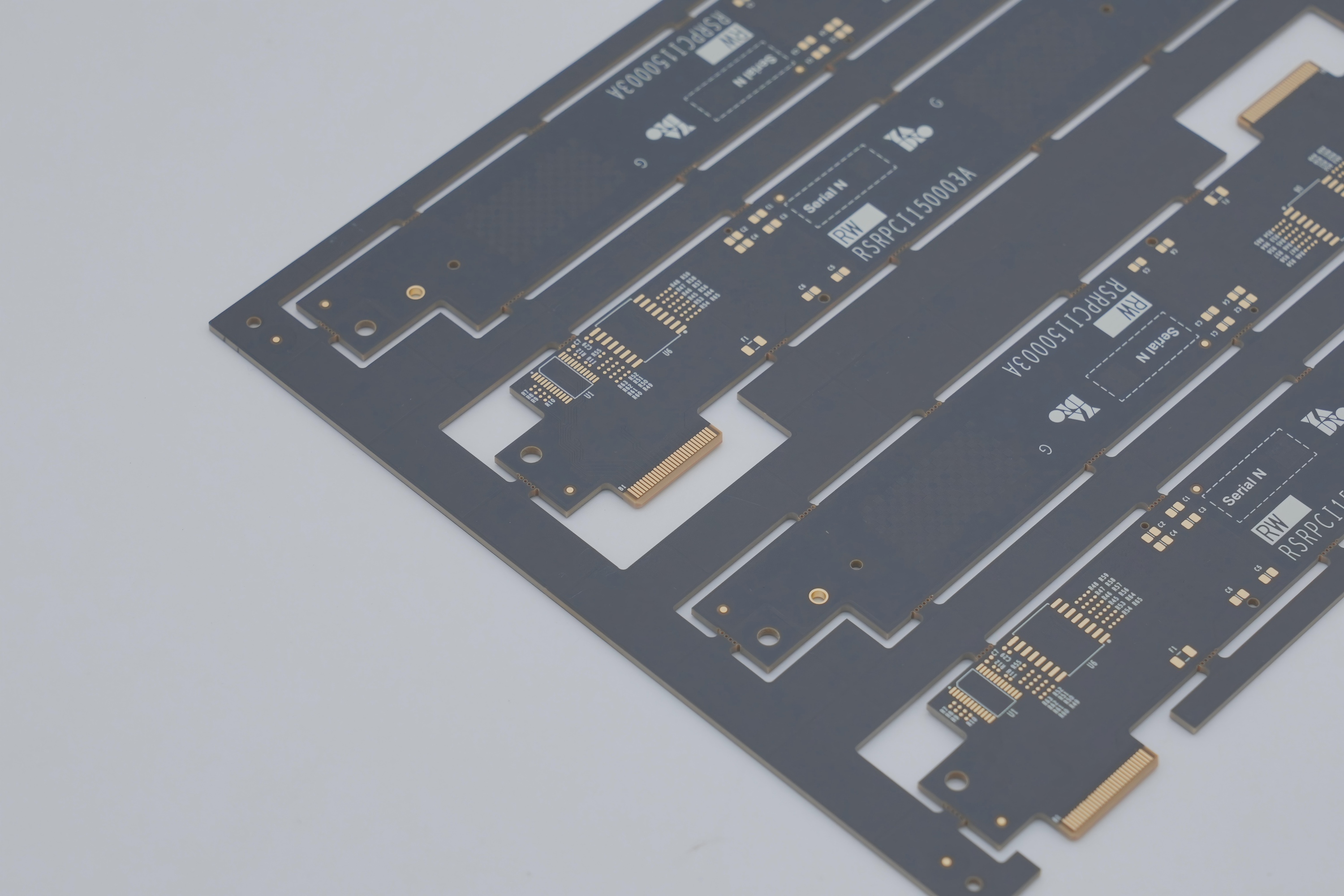

- 1. PCB assembly: This is the foundation. The PCB is built, soldered, inspected, and tested before going into the final unit.

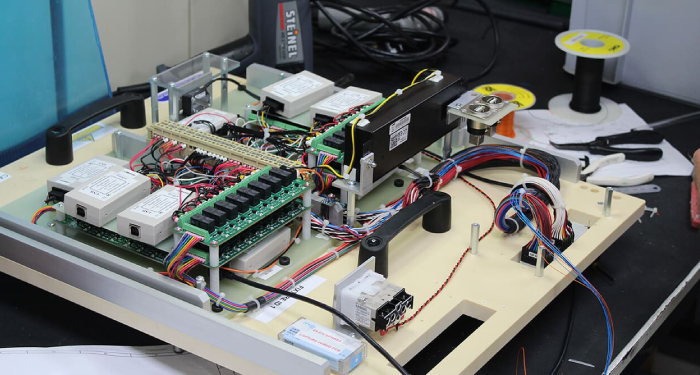

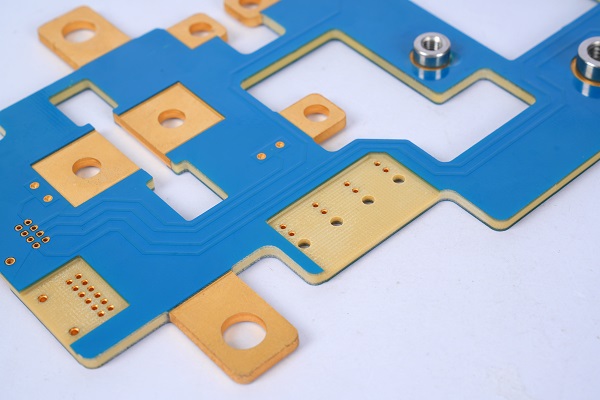

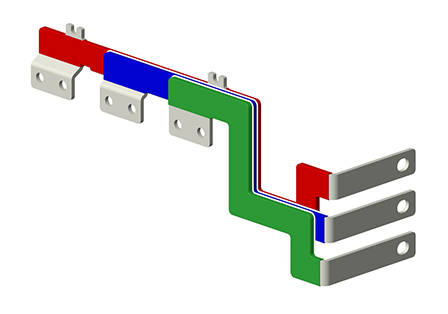

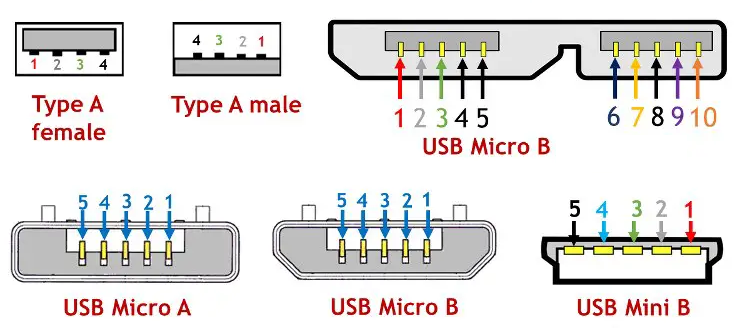

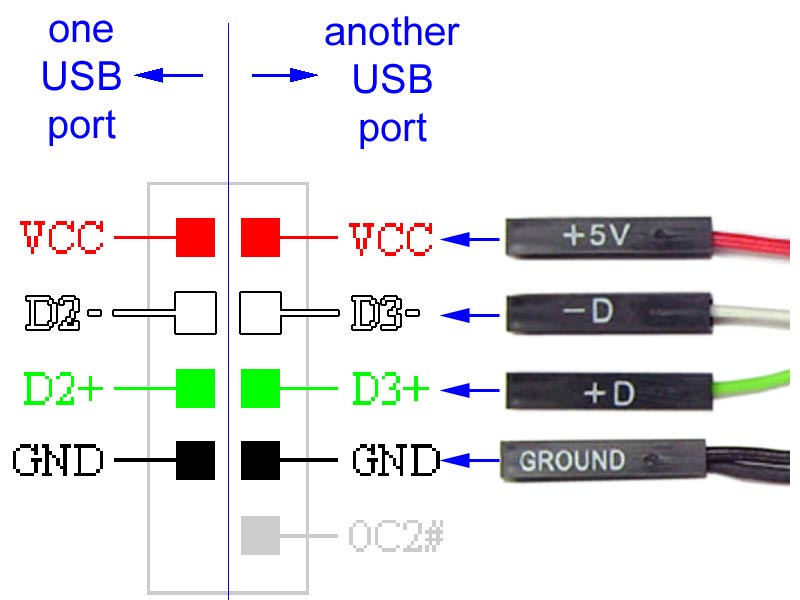

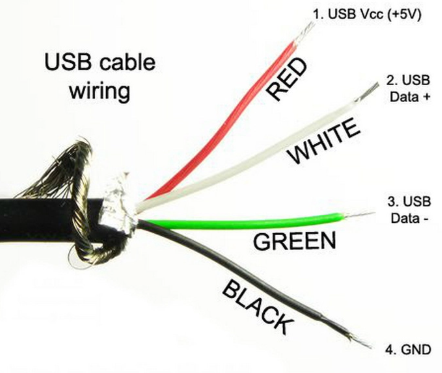

- 2. Cable and wire harness assembly: Most products need wires to connect modules. A box build service includes cable cutting, crimping, labeling, bundling, and routing.

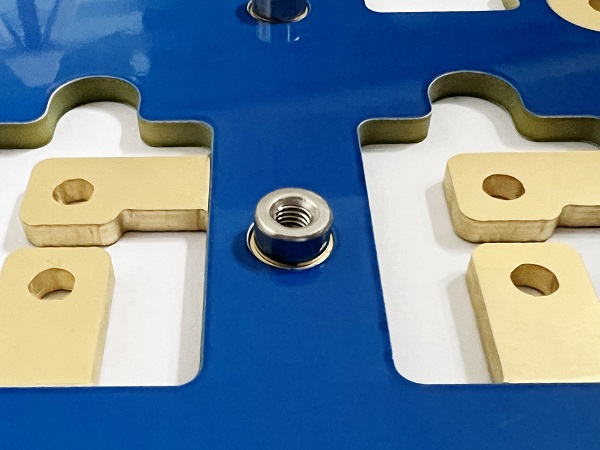

- 3. Mechanical structure assembly: This includes mounting brackets, frames, plates, screws, spacers, supports, buttons, and switches.

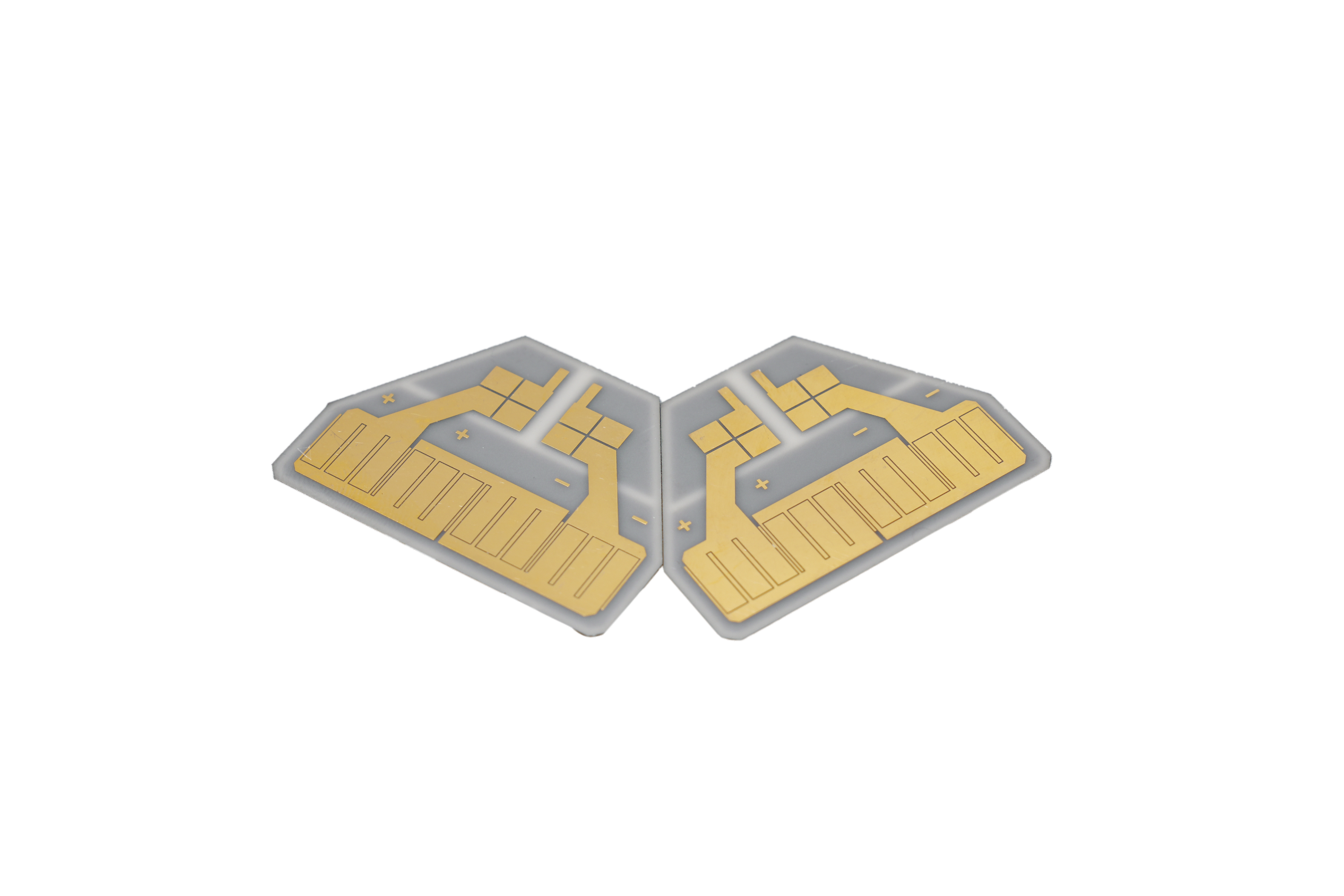

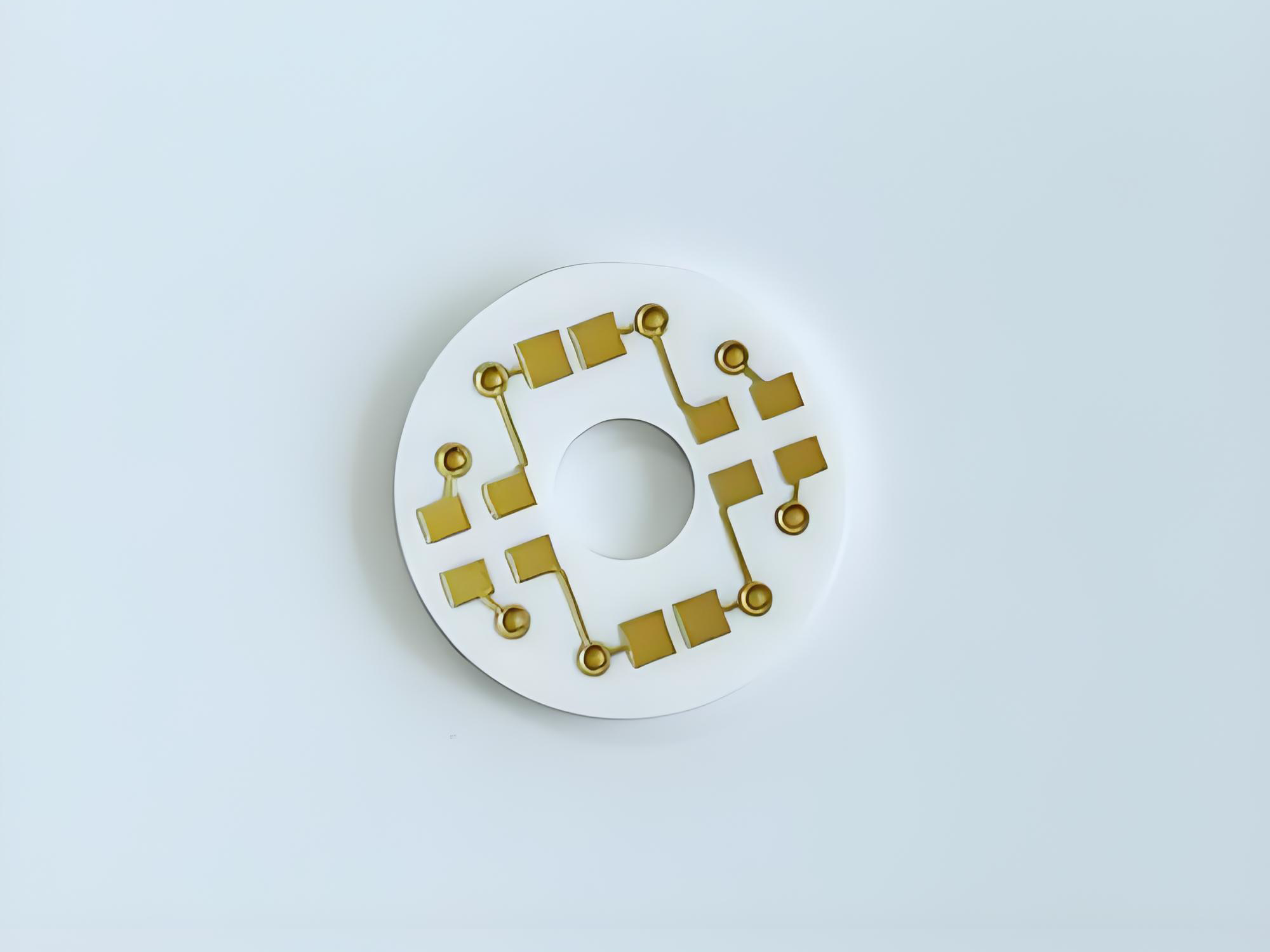

- 4. Enclosure integration: The full housing is installed. It may be metal, plastic, or a hybrid. Every part must match the PCB layout and thermal needs.

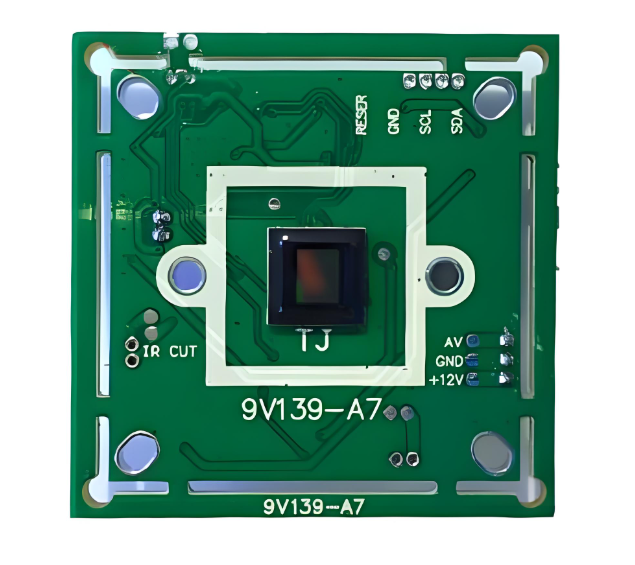

- 5. Display, sensor, or module installation: Many products involve screens, cameras, antennas, batteries, motors, or sensors.

- 6. Software programming and firmware flashing: Your unit receives its firmware, bootloader, or custom programming scripts.

- 7. Functional testing: This step checks if the product works as intended. It may include signal tests, power-on checks, button tests, noise checks, or communication protocol tests.

- 8. Reliability testing: Drop test. Vibration test. Temperature test. Burn-in test. These tests confirm long-term stability.

- 9. Packaging and labeling: The final step adds barcodes, serial labels, or QR codes. The product is packed and ready for shipment or retail shelves.

When all of these steps are handled by a single factory, your project gains better control. You get fewer delays. You avoid repeated communication loops. And your team has more time to focus on design, marketing, and new products.

How do box build electronics improve device integration?

Many companies struggle when they use separate suppliers for PCB assembly, wiring, structure, and testing. Each vendor sees only one part of the product. When something does not match, the project slows down. The schedule becomes tight. Energy drains from your team.

This is where box build electronics shine. Because one team oversees all stages, the integration becomes tighter. The design has fewer risks. Every step flows into the next without friction. Here is how box build services enhance product integration:

- Better Alignment of Electronics and Mechanics: PCB engineers and mechanical engineers stay in sync.

- Cleaner Wire Management: Cable routing stays neat. This reduces electrical noise and movement inside the product.

- Lower Failure Rates: With fewer vendors touching the product, the risk of assembly mistakes drops.

- Consistent Material Flow: Components arrive at the same factory. This reduces lead time and shipping costs.

- Better Communication: A single team handles questions.

- Stronger Quality Control: One factory follows one standard, so quality stays stable.

It also builds trust between your team and the manufacturer because every step is transparent.

What is the box build assembly process?

The box build assembly process moves step by step from a bare PCB to a complete product. Below is a detailed walk-through of how the process works in a professional manufacturing environment.

- Incoming Material Review: Every part enters the factory with labels and origin data. Teams verify quantity, certification, and condition.

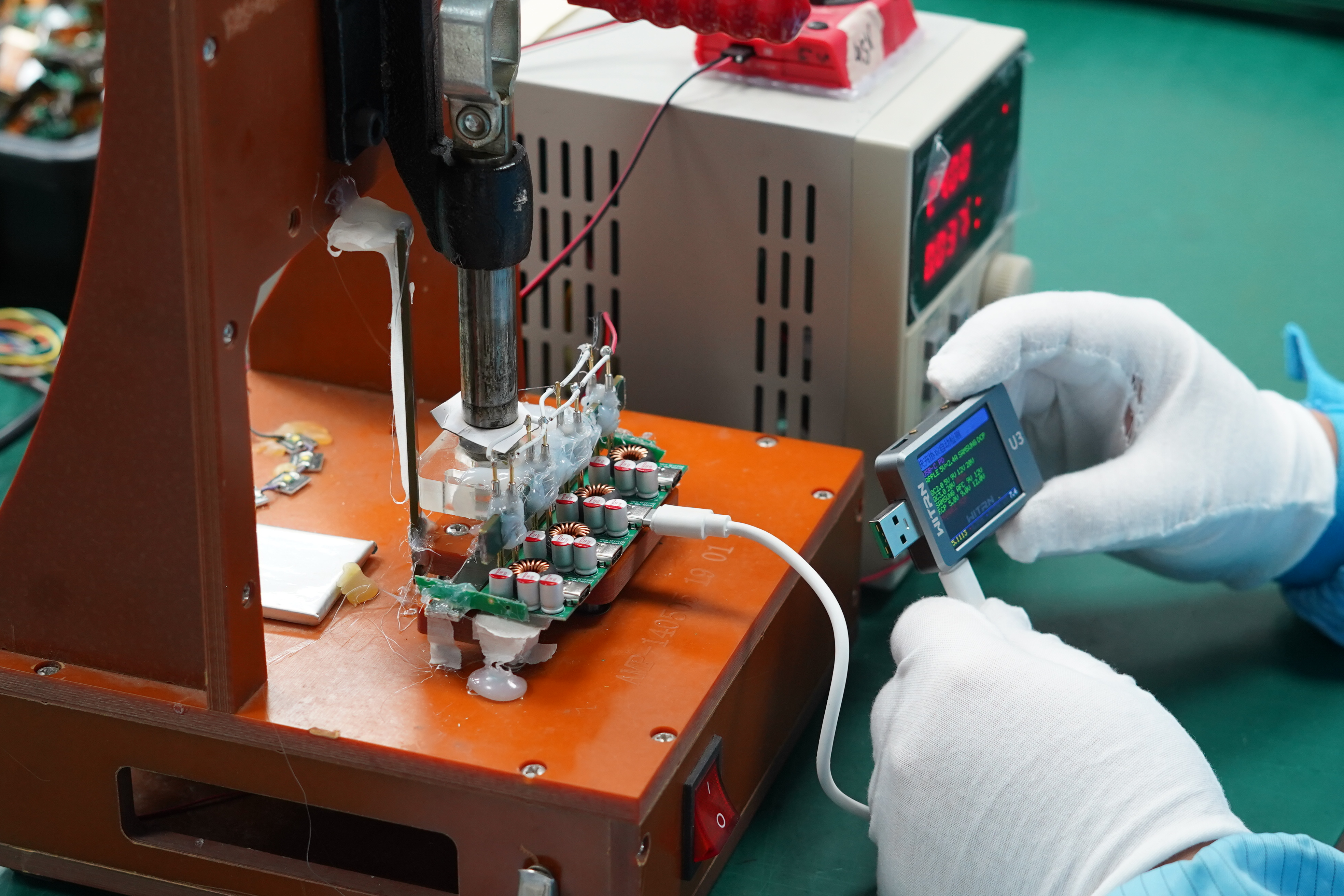

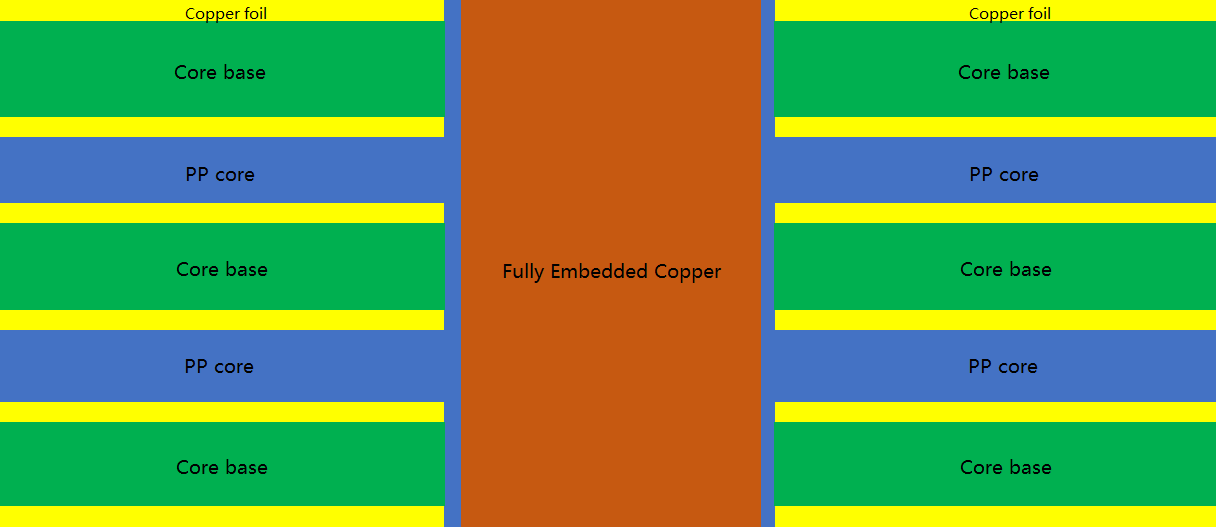

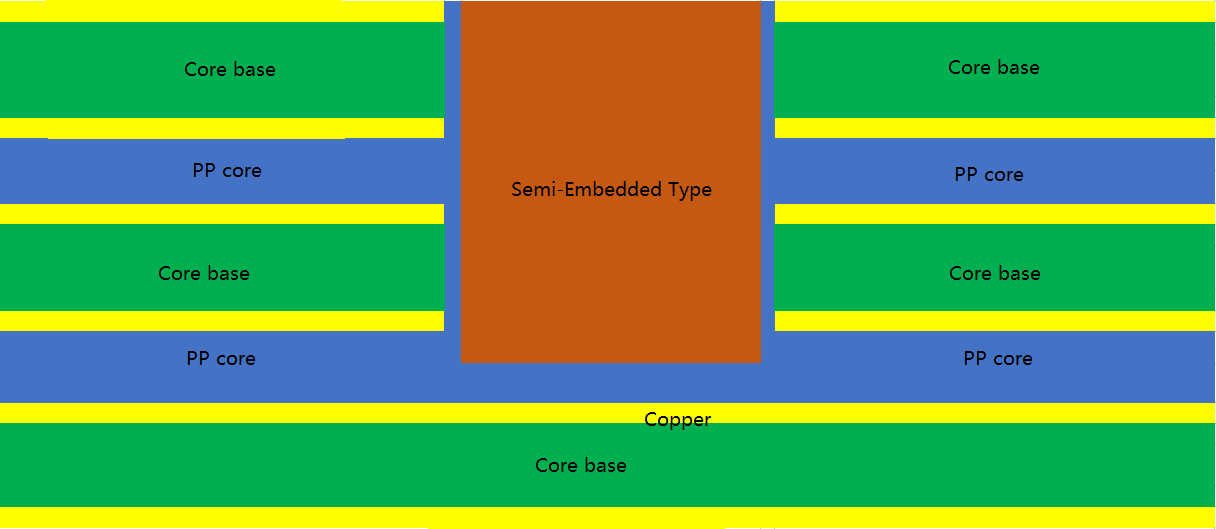

- PCB Assembly and Testing: The PCB is produced, components are placed, soldered, cleaned, and inspected. AOI and X-ray are used if needed.

- Wiring and Harnessing: Wires are cut, stripped, crimped, and checked. Harnesses are grouped using heat-shrink, sleeving, or cable ties.

- Mechanical Prep: Housings, plates, standoffs, nuts, and brackets are inspected.

- Sub-Assembly Build: Modules such as screens, antennas, microphones, and sensors are prepared as smaller units.

- Full Assembly: The PCB, wiring, and mechanical parts come together. The technicians work with torque limits, grounding rules, and ESD protection.

- Programming and Firmware: Firmware is flashed. Functional software is loaded. Internal memory is tested.

- Functional Testing: Now the product ‚Äúcomes alive.‚ÄĚ Buttons are checked. Signals are tracked. Power flow is monitored. Communication ports are tested.

- Reliability Run: A batch may go through aging tests, vibration tests, drop tests, or thermal cycles.

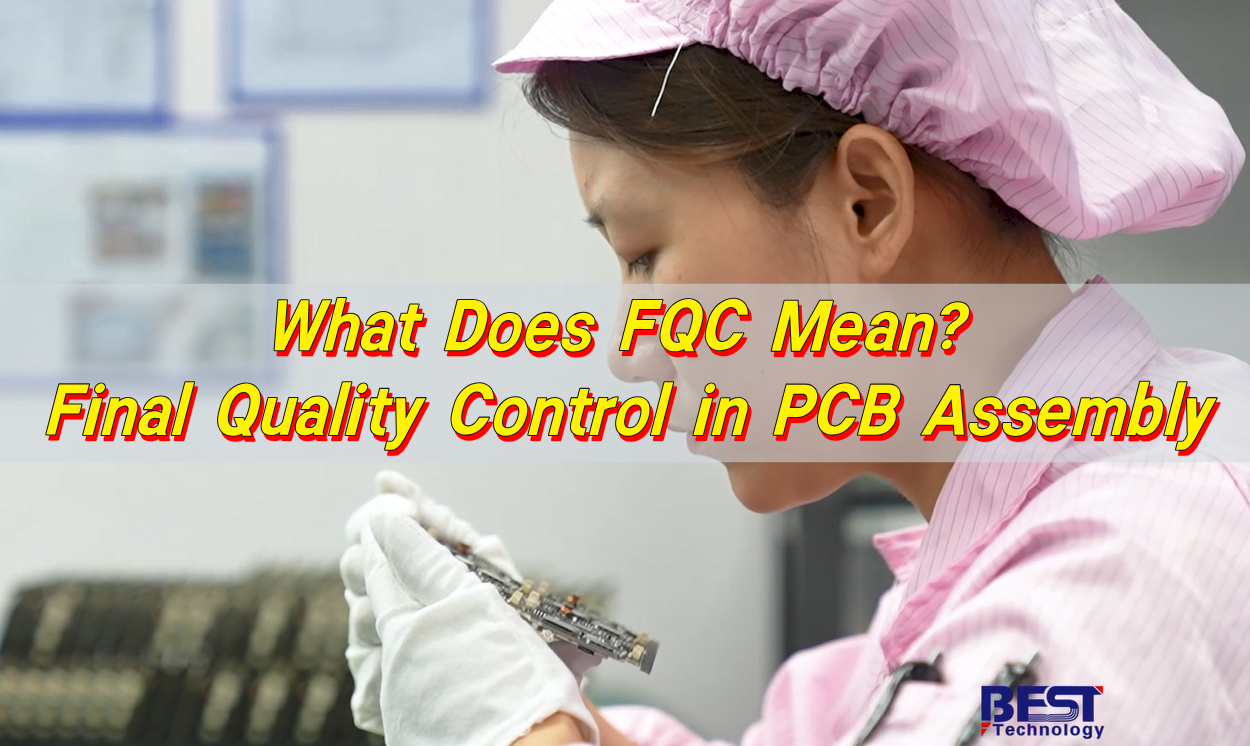

- Final QC and Packaging: Labels are added. Serial tracking is created in MES.

This full process forms the backbone of any modern electronic device. When the flow is strong, your final product feels strong as well.

What are the benefits of box build assemblies?

Companies choose box build assemblies because they offer advantages across the full production chain. These benefits help teams launch products faster with fewer problems.

- 1. One Supplier for Many Tasks

The more vendors you manage, the more time you lose. Box build assembly compresses your supply chain into one partner. It cuts delays. It boosts clarity.

- 2. Faster Time to Market

Because the assembly work stays in one place, your schedule moves smoothly. There is less waiting and fewer handoffs.

- 3. Lower Operational Costs

You save on shipping between suppliers. You save on troubleshooting. And you save on hidden mistakes.

- 4. Higher Quality Control

A single factory watches every step, so defects have fewer chances to hide.

- 5. Improved Product Reliability

The product feels stronger because the entire flow is planned. Wiring stays neat. PCB placement is optimized. Mechanical alignment stays accurate.

- 6. Better Engineering Support

When the same team handles PCB assembly and box build, your questions get solved quickly.

- 7. Easier Scaling

Once your product passes small runs, scaling to mass production becomes easier.

- 8. Greater Flexibility in Custom Designs

If you need a reverse-L enclosure, a compact sensor module, or a special bracket, box build partners can adjust quickly.

These benefits turn box build assembly into a strong tool for innovators who want fast, reliable production with fewer headaches.

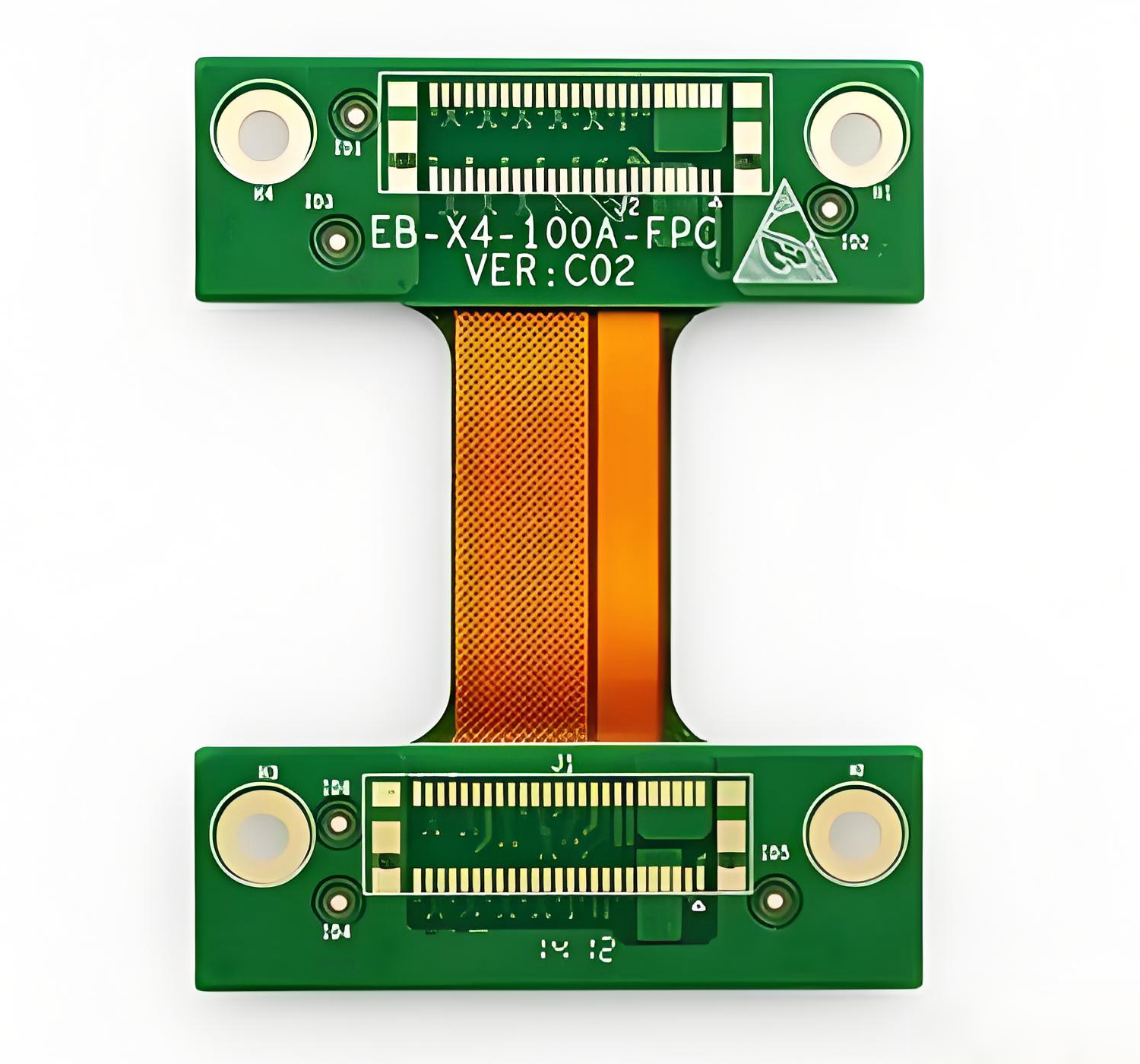

What is the difference between box build and PCBA?

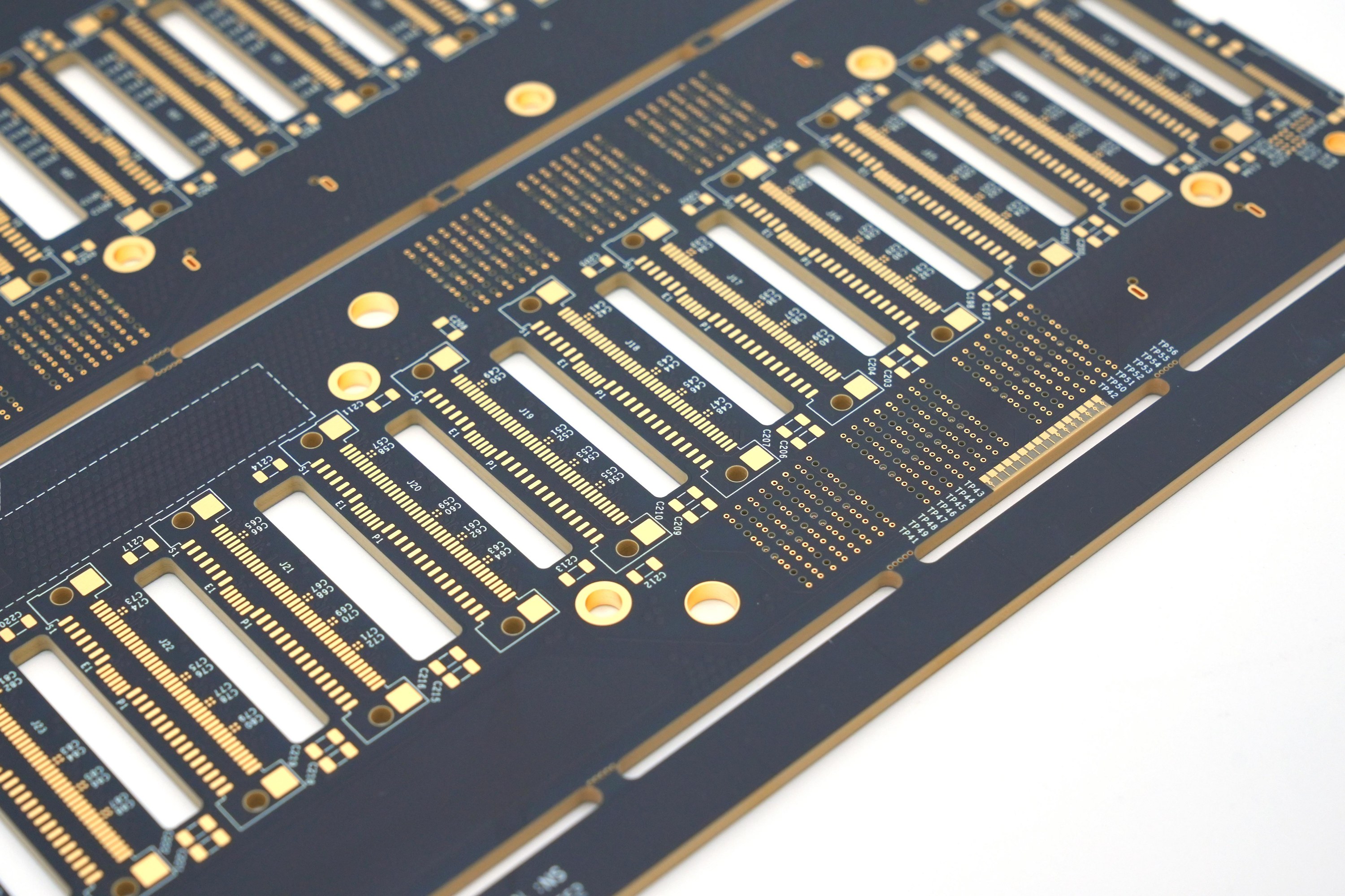

Although box build and PCBA often work together, they are two distinct stages. Below is a clear comparison that shows how the two processes work, how they support each other, and why both matter in electronics manufacturing. Here is the table version for better clarity:

| Item | PCBA (Printed Circuit Board Assembly) | Box Build Assembly |

| Main Purpose | Build the electronic circuit on the PCB | Build the complete final product |

| Core Scope | Soldering components, reflow, AOI, X-ray, ICT, FCT | PCBA + wiring + housing + firmware + labeling + packaging |

| What It Produces | A functional electronic board | A ready-to-ship device |

| Key Components | PCB, ICs, resistors, capacitors, connectors | PCBA, cables, screws, display, enclosure, sensors, batteries |

| Skill Focus | Electronics assembly | Full system integration |

| Testing Level | Electrical testing only | Electrical + functional + reliability testing |

| Required Files | Gerber, BOM, pick-and-place file | Assembly drawing, wiring list, enclosure drawing, test instructions |

| Who Uses It | R&D teams, electronics designers | Hardware companies, system integrators, product brands |

| Typical Output | A finished circuit board | A final box-build unit ready for distribution |

| Production Complexity | Medium | High |

| Where It Fits in the Flow | Middle of the manufacturing chain | Final stage before shipment |

What defines a reliable box build electronics manufacturer?

Choosing the right box build electronics manufacturer can change your entire production journey. A strong partner raises your product quality, reduces your stress, and protects your timeline.

Here are the qualities that signal a trustworthy supplier:

- 1. Strong Engineering Team

A good partner can read your drawings, identify risks early, and confirm each detail. They discuss material options, connector choices, and safety needs.

- 2. Full Manufacturing Flow

The best providers offer PCB assembly, wiring, molding, machining, testing, and packaging.

- 3. Traceability System

MES tracking records component batch numbers, operator actions, test data, and timestamps. This gives you visibility and peace of mind.

- 4. Certifications

A reliable manufacturer holds certifications such as ISO9001, ISO13485, IATF16949, and AS9100D.

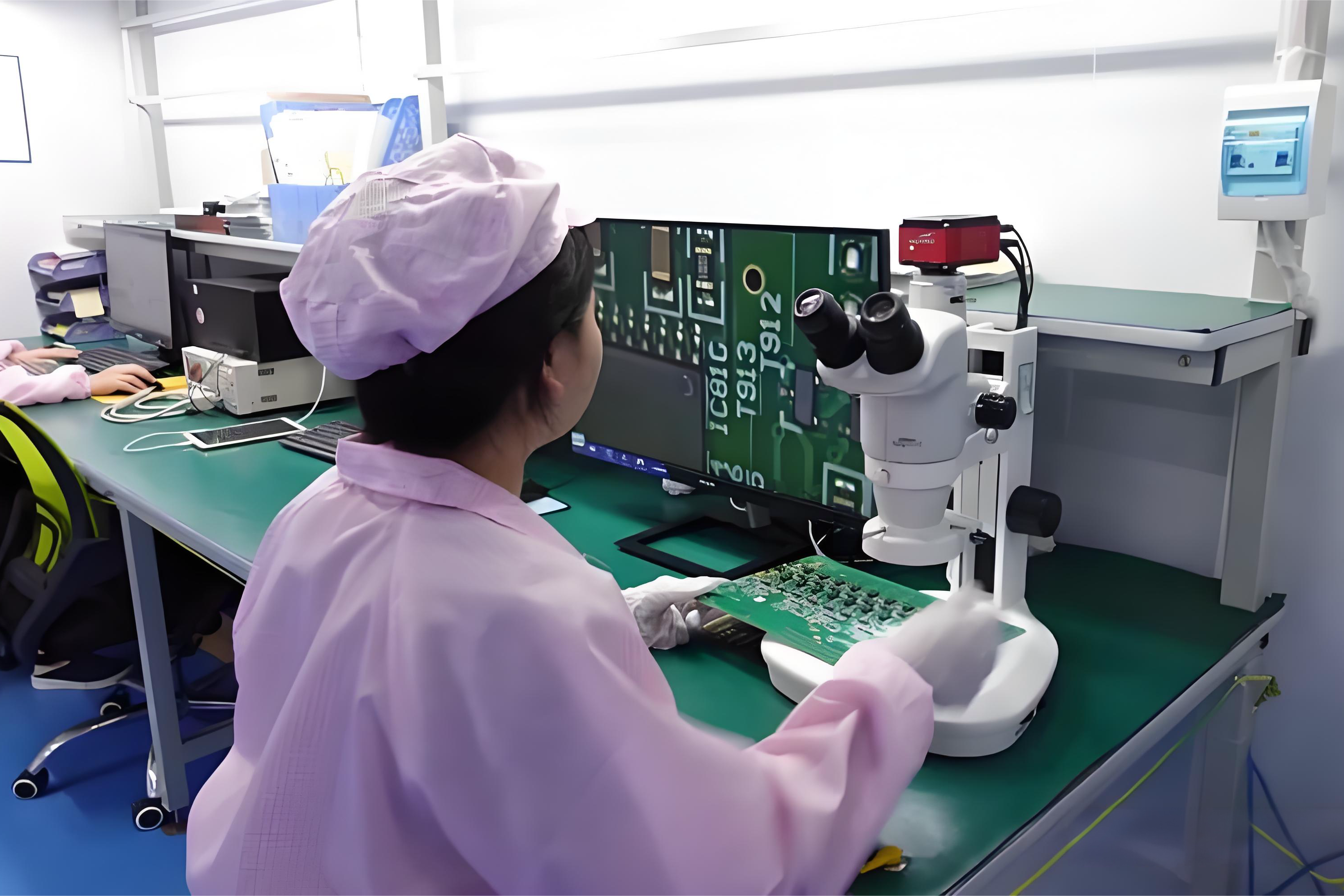

- 5. Clean Production Environment

ESD flooring, controlled humidity, and temperature-stable rooms support sensitive electronics.

- 6. Clear Communication

Fast, accurate engineering communication removes confusion. When changes happen, the team updates you quickly.

- 7. Transparent Quality Reports

This includes FAI, CPK, SOP, SPI, AOI, ICT, FCT, and final inspection.

- 8. Experience Across Industries

A skilled partner has handled automotive, medical, industrial, and consumer electronics.

These traits help you identify a manufacturer that can protect your product from design to delivery.

Why choose BEST Technology for your box build assembly needs?

Choosing the right partner for box build assembly services is a crucial decision. BEST Technology stands out because of strict quality control, strong engineering, and a clear commitment to customer success.

- 1. Complete One-Stop Production

BEST Technology covers PCB fabrication, SMT assembly, wiring, mechanical parts, testing, and final box build. The full flow stays in-house for better stability.

- 2. Strong Engineering Support

From DFM to DFA, our engineers help refine layouts, structures, and wiring plans.

- 3. Quality Certifications

BEST Technology holds ISO9001, ISO13485, IATF16949, and AS9100D. These certifications reflect our commitment to strict quality. Your products follow robust procedures from incoming materials to the final build.

- 4. MES Traceability System

The MES system records every step‚ÄĒcomponent batch, solder temperature, inspection data, test results, and operator ID.

- 5. Advanced Equipment

AOI systems, X-ray inspection, reflow ovens, SMT lines, machining tools, and test jigs create a strong foundation for stable builds.

- 6. Reliable Supply Chain

We work with trusted suppliers for connectors, housings, cables, and custom parts. Every item is tracked and verified.

- 7. Custom Box Build Solutions

Whether you need a compact IoT device, a sensor module, an industrial controller, or a medical box build, the team handles complex requirements with skill and patience.

- 8. Smooth Communication

Your project manager updates you on progress, issues, schedules, and tests.

- 9. Competitive Pricing

You get strong engineering, stable quality, and reliable service at cost-efficient rates.

All these advantages make BEST Technology a dependable partner for turnkey box build and PCB assembly services.

Conclusion:

Box build assembly gives companies a clean path from PCB to final product. It brings electronics, wiring, structure, testing, and packaging into one controlled flow. This approach reduces risks, improves speed, strengthens reliability, and sharpens the final user experience.

BEST Technology provides this level of support with a friendly, detail-oriented team that understands how much each project matters.

If you want dependable and powerful box build assembly services, reach out to us anytime. Contact: sales@bestpcbs.com