|

Two (Double) layers MCPCB is consisting of two layers of copper conductor, put them on same side of metal core (usually aluminum, copper or iron alloy). The metal base is on the bottom of whole MCPCB, which is different from double sided MCPCB (the two copper layers were put on the each side of metal core respectively), and you can only populate SMD on top side. Different with Single layer MCPCB, 2 layers MCPCB requires an additional pressing step to laminate the imaged thermal conductive laminate and metal core (also known as metal base) together. Compared with normal FR4, this sturcture need more technology and experience on laminating of two layers together with metal core. The processing steps of the MCPCB with the metal base embedded in the PCB are comparatively complex as hole plugging is required after primary drilling on the metal base in order to isolate it from the circuitry. |

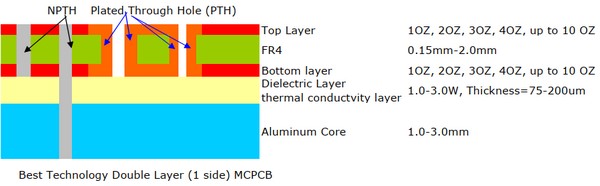

Structure of 2L MCPCB |

|

| Capability of 2L MCPCB |

|

| Please click here for immediate quotation online Please contact us for more information about the double layers MCPCB. |

ISimply drop your email or phone number in the contact form, and we'll promptly provide you with a quotation.