Looking for PCB manufacturer in Sri Lanka? This blog breaks down top local manufacturers, practical selection tips, industry challenges, and how EBest Circuit (Best Technology) addresses them helping you make informed sourcing decisions.

When sourcing PCBs, finding a reliable PCB Manufacturer in Sri Lanka that balances quality, speed, and cost is crucial for electronics businesses. As a leading global PCB Manufacturer in Sir Lanka, EBest Circuit (Best Technology) Co.,Ltd stands out among local players by integrating global standards with localized service solving the core pain points of both Sri Lankan startups and international brands.

Top PCB Manufacturer in Sri Lanka List

| Company Name | Core Business | Manufacturing Capability | Lead Time |

| EBest Circuit (Best Technology) Co.,Ltd | Rigid/Flex PCB, PCB Assembly, Custom PCB for Medical/Auto | 1-30 layers, Blind/Buried Vias, Controlled Impedance (¬Ī10%), AOI+X-ray Inspection | 72h for Prototypes, 1-2 Weeks for Mass Production |

| Micro Electronics Lanka (Pvt) Ltd | Consumer Electronics PCB, Single/Double-Layer PCB | 1-4 layers, Through-Hole Technology, Basic AOI Inspection | 5-7 Days for Prototypes, 2-3 Weeks for Mass Production |

| Sri Lanka PCB Industries (Pvt) Ltd | Telecom PCB, Industrial Control PCB | 1-8 layers, SMT Assembly, Visual Inspection | 7 Days for Prototypes, 3-4 Weeks for Mass Production |

| Techno Print Lanka (Pvt) Ltd | Low-Volume PCB, Prototype PCB for Local Startups | 1-6 layers, Manual Soldering, Basic Functional Testing | 3-5 Days for Prototypes, 2-3 Weeks for Small Batch |

How to Choose A Reliable PCB Manufacturer in Sri Lanka?

A Detailed Selection Guide to PCB Manufacturer in Sri Lanka:

1. Verify Certifications & Compliance Standards

- Seek manufacturers with globally recognized certifications such as ISO 9001, UL certification, or RoHS compliance. For example, Aptinex (a leading Sri Lankan PCB manufacturer) adheres to international quality standards and offers services from PCB prototyping to mass production. Certifications validate technical expertise and regulatory compliance, ensuring reliability for global markets.

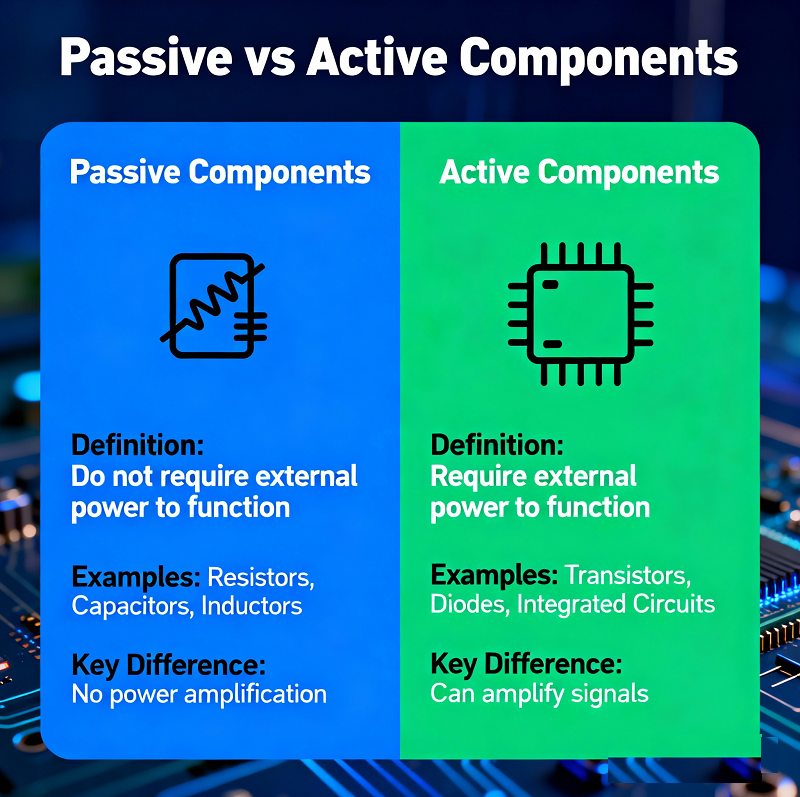

2. Assess Technical Expertise & Production Capabilities

- Evaluate the manufacturer’s ability to handle complex designs (e.g., multilayer PCBs, HDI, or flexible circuits). Aptinex demonstrates advanced capabilities through SMT/THT component assembly and firmware development, indicating robust technical infrastructure. Prioritize manufacturers with in-house prototyping, drilling, and assembly lines to ensure vertical integration and quality control.

3. Review Quality Control Processes

- Investigate automated defect detection systems and real-time monitoring. While specific PCB examples are limited, Sri Lanka’s apparel industry uses systems like SeamSense (leveraging machine learning for defect detection). Look for similar quality assurance protocols, such as motion-adaptive frame extraction or model-based augmentation, to minimize defects and ensure consistency.

4. Evaluate Industry Reputation & Customer Testimonials

- Prioritize manufacturers with verifiable client portfolios or case studies. DHL’s emphasis on customer loyalty in Sri Lanka highlights the importance of trust in B2B relationships. Seek references from global clients or partners to validate reliability. Avoid manufacturers lacking transparent client feedback or case studies.

5. Analyze Lead Times & Scalability

- Inquire about production lead times and scalability to meet demand fluctuations. Factors like logistics efficiency and supply chain resilience impact delivery times. For example, Alibaba’s insights on Sri Lankan manufacturing stress the need for scalable production and reliable logistics to avoid delays, especially for export-oriented businesses.

6. Ensure Cost Transparency & Fair Pricing

- Compare pricing structures to avoid hidden fees. Transparent pricing builds trust and long-term partnerships. Request detailed quotes outlining material costs, labor, and any additional charges. Manufacturers like Aptinex often provide clear cost breakdowns for prototyping and mass production.

7. Assess Communication & Technical Support

- Effective communication is critical. Prioritize manufacturers with responsive support teams and clear channels (e.g., email, phone, or chat). Look for technical expertise in PCB design, material selection, and troubleshooting to address challenges promptly.

8. Conduct Site Visits or Audits (If Feasible)

- If possible, visit the facility to assess equipment, cleanroom standards, and operational workflows. Direct observation confirms adherence to safety, quality, and environmental standards, enhancing trust in the manufacturer’s capabilities.

9. Review Contract Terms & IP Protection

- Ensure contracts include clear terms on intellectual property (IP) ownership, confidentiality, and dispute resolution. Protect your designs and innovations through legally binding agreements. Avoid vague clauses that could lead to disputes over ownership or liability.

10. Leverage Industry Networks & Referrals

- Seek recommendations from trusted industry peers, trade associations, or export agencies. Sri Lanka’s Colombo Development Dialogues (a knowledge-sharing initiative) highlights collaborative opportunities. Networking within regional manufacturing hubs can uncover reliable, vetted manufacturers.

Challenges of PCB Manufacturer in Sri Lanka

Below Are Main Pain Points of PCB Manufacturing Companies in Sri Lanka:

- Why do my PCB orders always arrive 2-3 weeks late, even with a confirmed timeline?‚Äč

- How to avoid getting PCBs with hidden defects that only show up during assembly?‚Äč

- Why can‚Äôt local manufacturers handle my 12-layer PCB design for industrial equipment?‚Äč

- Why do quotes jump by 30% after placing an order, with ‚Äúunexpected material costs‚ÄĚ as the excuse?‚Äč

- How to find a supplier that responds to technical issues outside working hours?

Our Solutions to These Challenges

- On-Time Delivery Rate ‚Č•98%: 3-month raw material stock + local supplier network cuts lead times by 50%. A telecom client‚Äôs 10,000-unit order was delivered 5 days early, helping them hit 5G rollout targets.

- Defect Rate ‚ȧ0.2%: Triple inspection (AOI+X-ray+IPC-certified manual check) and 30-day quality guarantee. A medical device maker reduced rework costs by $12,000/year after switching to us.

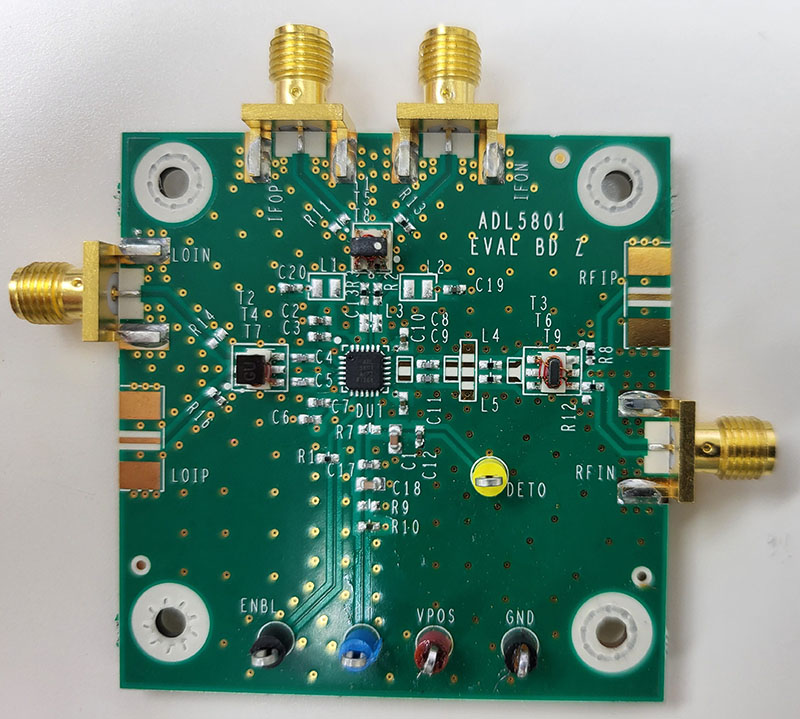

- 30-Layer PCB Capability: 15 IPC/IEEE-certified engineers handle complex designs (blind vias, ¬Ī10% impedance control). We‚Äôve completed 120+ industrial 12-20 layer PCB projects in 2024.

- 100% Transparent Pricing: Detailed quotes with material breakdowns; no hidden fees. A startup avoided a $2,000 cost hike when we clarified copper price terms upfront.

- 24/7 Technical Support: Dedicated account managers respond within 1 hour. A night-shift assembly team solved a soldering issue via our live chat, minimizing downtime.

Why Sri Lanka Clients Choose EBest Circuit (Best Technology) for PCB Manufacturer?

Reasons Why Sri Lanka Clients Choose EBest Circuit (Best Technology) for Global PCB Manufacturer:

- Competitive Pricing & Localized Supply Chain: Leverage 8+ local material partners to reduce import costs by 10‚Äď15% compared to average Sri Lankan PCB manufacturers. Example: A telecom client saved $35,000 annually on PCB expenses after switching.

- Cost-Optimized Design Solutions: Analyze schematics to replace high-cost components (e.g., 10-layer ‚Üí 8-layer optimization) without compromising performance. A consumer electronics brand reduced per-unit costs by $2.30 for a 50,000-unit order.

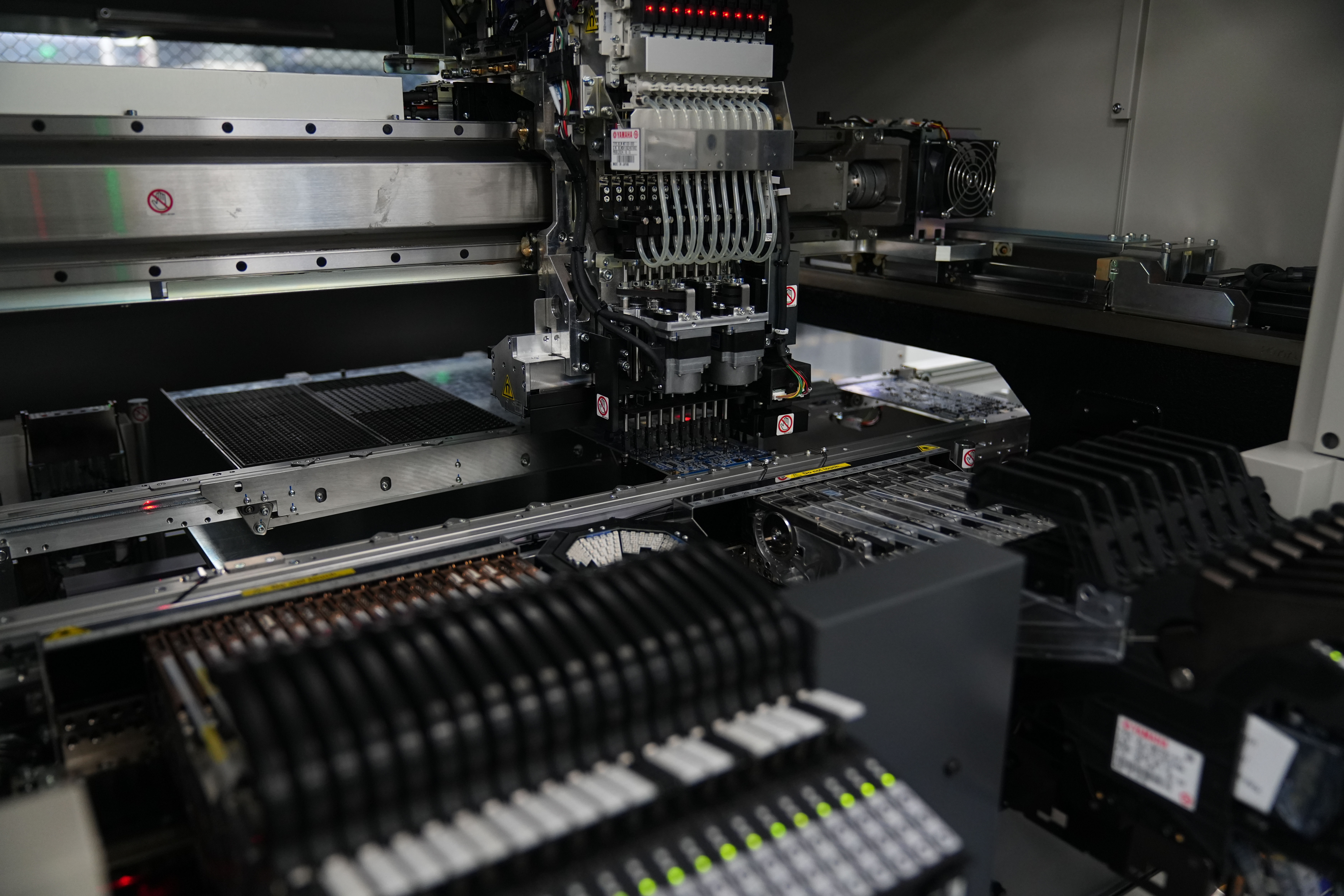

- 24-Hour Rapid Prototyping: Utilize automated SMT lines for 1‚Äď10 layer prototypes delivered within 24 hours‚ÄĒ3x faster than 95% of local competitors. A startup met investor deadlines 2 days early.

- 99.2% On-Time Delivery Rate: Maintain 3-month raw material inventory and real-time logistics tracking to ensure 99.2% on-time delivery. A medical client avoided $8,000 in late penalties last year.

- 100% Full Inspection for Bulk Orders: Apply AOI, X-ray, and functional testing to every bulk order (0.2% defect rate, verified by client cases). An industrial control client reduced rework from 7% to 0.2%.

- Global Compliance Certifications: Hold ISO 9001, IATF 16949 (automotive), ISO 13485 (medical), and RoHS certifications. A client exported 50,000+ PCBs to the EU without compliance delays.

- 19-Year Expertise & Error Database: Leverage a 10,000+ entry error database from 19 years of production to prevent common design flaws, cutting trial-and-error costs by 50% on average.

- Free DFM Analysis by IPC-Certified Engineers: Identify and resolve issues like impedance mismatches early. A RF client avoided $12,000 in rework for a 20-layer PCB design.

- One-Stop Service for Streamlined Projects: Cover PCB design, production, assembly, and testing under one roof, saving clients 20+ hours per project. An IoT client reduced project management time by 23 hours per order.

- Localized Support for Real-Time Collaboration: Access Colombo-based teams via in-person meetings and a 24/7 local hotline. A university lab resolved a technical issue in 45 minutes (vs. 3 days with an overseas supplier).

Our PCB Manufacturing Capability

| Item | Capabilities |

| Layer Count | 1 – 32 Layers |

| Max Board Dimension | 2424″ (610610mm) |

| Min Board Thickness | 0.15mm |

| Max Board Thickness | 6.0mm – 8.0mm |

| Copper Thickness | Outer Layer: 1oz~30oz, Inner Layer: 0.5oz~30oz |

| Min Line Width/Line Space | Normal: 4/4mil (0.10mm); HDI: 3/3mil (0.076mm) |

| Min Hole Diameter | Normal: 8mil (0.20mm); HDI: 4mil (0.10mm) |

| Min Punch Hole Dia | 0.1″ (2.5mm) |

| Min Hole Spacing | 12mil (0.3mm) |

| Min PAD Ring(Single) | 3mil (0.075mm) |

| PTH Wall Thickness | Normal: 0.59mil (15um); HDI: 0.48mil (12um) |

| Min Solder PAD Dia | Normal: 14mil (0.35mm); HDI: 10mil (0.25mm) |

| Min Soldermask Bridge | Normal: 8mil (0.2mm); HDI: 6mil (0.15mm) |

| Min BAG PAD Margin | 5mil (0.125mm) |

| PTH/NPTH Dia Tolerance | PTH: ¬Ī3mil (0.075mm); NPTH: ¬Ī2mil (0.05mm) |

| Hole Position Deviation | ¬Ī2mil (0.05mm) |

| Outline Tolerance | CNC: ¬Ī6mil (0.15mm); Die Punch: ¬Ī4mil (0.1mm); Precision Die: ¬Ī2mil (0.05mm) |

| Impedance Controlled | Value>50ohm: ¬Ī10%; Value‚ȧ50ohm: ¬Ī5ohm |

| Max Aspect Ratio | 0.334027778 |

| Surface Treatment | ENIG, Flash Gold, Hard Gold Finger, Gold Plating(50mil), Gold finger, Selected Gold plating, ENEPIG, ENIPIG; HAL, HASL(LF), OSP, Silver Immersion, Tin Immersion |

| Soldermask Color | Green/White/Black/Yellow/Blue/Red |

Our Lead Time for PCB Prototyping

| Layers | Normal Service | Fastest Service |

| 1 | 7 Days | 24 H |

| 2 | 8 Days | 24 H |

| 4 | 10 Days | 48 H |

| 6 | 10 Days | 72 H |

| 8 | 12 Days | 72 H |

| ‚Č•10 | TBD | TBD |

Case Studies of Our Sir Lanka PCB Manufacturing

Case Studies of Our Sri Lanka PCB Manufacturing

Project Background: In 2025, a Sri Lankan electronics manufacturer sought to upgrade its local electronics manufacturing capabilities to meet international customer demands for high-precision, short-lead-time, and cost-effective double-sided/multilayer PCBs. As a technical partner, we provided end-to-end support from process optimization to mass production.

Project Requirements

- Technical Specifications: Support 0.2mm line width/spacing, 2-12 layer board design, impedance control accuracy ¬Ī8%, compliant with IPC-A-600G Class 2 standards.

- Delivery Timeline: Sample delivery within 3-5 working days, bulk orders within 7-10 working days.

- Cost Control: Achieve 15% reduction in unit area cost compared to Sri Lanka‚Äôs market average while maintaining a yield rate of ‚Č•95%.

- Sustainability: Adopt lead-free soldering processes, comply with RoHS standards, and reduce production waste by 20%.

Solutions Implemented:

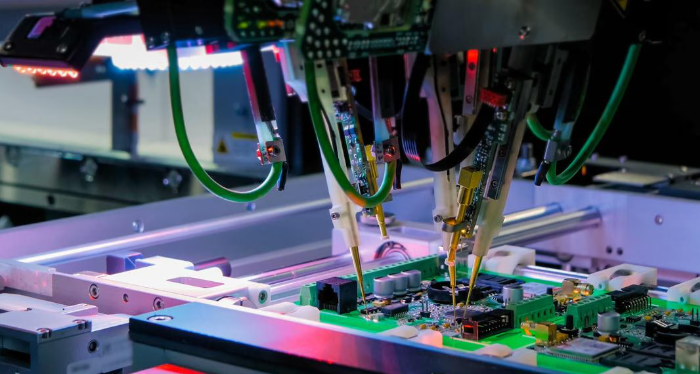

- Process Optimization: Introduced Laser Direct Imaging (LDI) technology to replace traditional exposure methods, enhancing line width consistency. Adopted Vertical Continuous Plating (VCP) to improve via reliability.

- Process Reengineering: Implemented a Manufacturing Execution System (MES) for full production traceability, paired with AI-powered visual inspection systems for automated defect detection.

- Supply Chain Integration: Established a localized warehouse in Colombo to stock common substrates (e.g., FR-4, high-frequency materials) and secured long-term agreements with local etching solution suppliers to reduce costs.

- Talent Development: Trained 15 certified engineers through on-the-job training (OJT) programs to master critical operational processes.

Project Outcomes

- Efficiency Gains: Sample lead time reduced by 40%, bulk order on-time delivery rate reached 98%.

- Cost Optimization: Unit cost decreased by 18%, exceeding project targets. Annual production capacity expanded from 50,000m² to 120,000m².

- Quality Improvements: Yield stabilized at 96.5%, customer complaint rate dropped by 60%, and NADCAP certification achieved.

- Market Expansion: Successfully entered the European electric vehicle supply chain, securing orders from Siemens (Germany) and ABB (Switzerland).

- Sustainable Benefits: Production waste reduced by 22%, unit energy consumption lowered by 10%, and awarded Sri Lanka’s Green Manufacturing Certification.

How to Get a Quote for Your PCB Project?

To receive an accurate and efficient PCB quote, submit the following materials in a structured, clear format. Each item ensures precise cost estimation and production feasibility:

1. Design Files

- Gerber files (layer layout, solder mask, silkscreen, drill files).

- Bill of Materials (BOM) with part numbers, footprints, quantities.

- Centroid/Pick-and-Place data for component placement.

2. Technical Specs

- Layer count & stackup (e.g., 4L, FR-4, copper thickness).

- Board dimensions, thickness, min trace/space (e.g., 0.2mm/0.2mm).

- Surface finish type (HASL, ENIG, OSP, etc.).

3. Performance Requirements

- Impedance control specs & tolerance.

- Required certifications (IPC, RoHS, UL, NADCAP).

- Testing preferences (AOI, X-ray, thermal stress).

4. Production Details

- Order quantities (prototypes, batches, mass production).

- Lead time expectations (samples, bulk).

- Packaging/shipping preferences (anti-static, destination).

5. Additional Requirements

- Special processes (blind vias, via-in-pad, edge plating).

- Sustainability targets (waste reduction, recycled materials).

- Documentation (NRE fees, tooling costs, ECO history).

Welcome to contact us if you have any request for PCB design, prototyping, mass production and PCBA service: sales@bestpcbs.com.