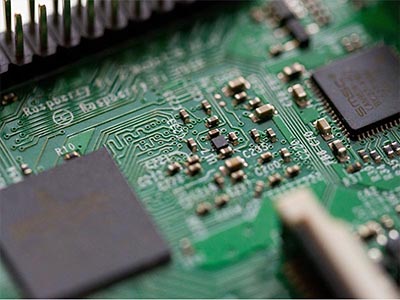

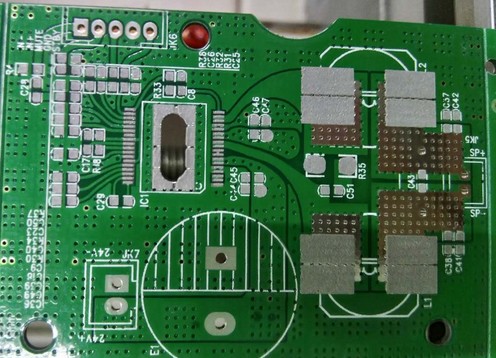

The reflow oven is one of the indispensable equipments in SMT. Putting the PCB with components goes through the reflow oven then the solder paste adhering on the printed circuit board will melt. After the solder paste getting cold, the components will adhere to the PCB stably.

After you have learned something about reflow oven, have you ever know how to make the reflow oven work better? Here are 3 benefits of putting nitrogen into reflow oven listed as following:

√ĘňÜŇ°√ā¬†It is able to make the surface tension of solder paste get smaller which is good for the components adhering to the PCB more easily.

√ĘňÜŇ°√ā¬†It can decrease the oxidization in a certain. Because the nitrogen is a kind of inert gas which is hard to produce chemical compound.

√ĘňÜŇ°√ā¬†Reducing the rate of void. Because the rate of void decreases with oxidation.

√ĘňÜŇ°√ā¬†Nowadays, some manufacturers also develop to put nitrogen in wave soldering oven. It is able to decrease the speed of oxidation of liquid tin in the bath. As the slag of tin will be formed when the liquid tin contacts with air. After that, the slag of tin will adhere on the printed circuit board. If it happens to the connect between two spots of tin, it will cause short circuit.

√ĘňÜŇ°√ā¬†It can increase the rate of tin feeding of pin components and then they will combine with the printed circuit board firmly.

EBest Circuit (Best Technology),√ā¬†a professional√ā¬†PCB√ā¬†solution provider, is always dedicated to catch up with times. Our unique technology and high quality products will give you a competitive supply of printed circuit board√ā¬†and PCB assembly and make your wearable devices more excellent. To learn more, contact us at 0755-29091601 or check our website: https://www.bestpcbs.com