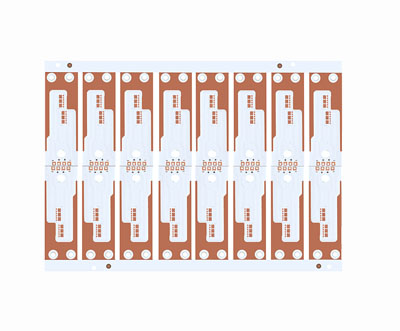

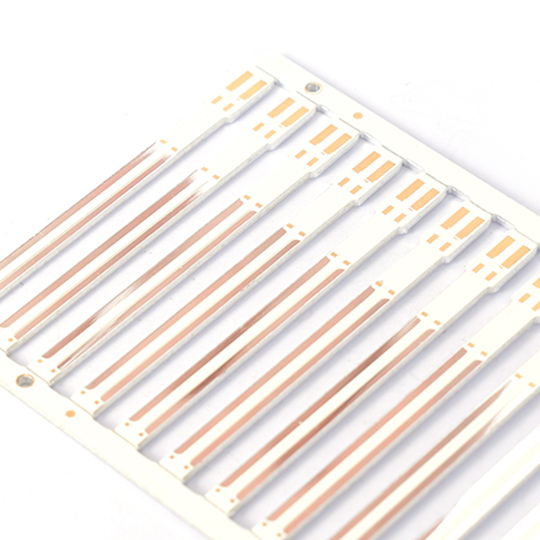

Metal Core PCB means the core (base) material for PCB is the metal, not the normal FR4/CEM1-3, etc. and currently the most common metal used for MCPCB manufacturer are Aluminum, Copper and steel alloy. Aluminum has good heat transferring and dissipation ability, but yet relatively cheaper; copper has even better performance but relatively more expensive, and steel can be divided into normal steel and stainless steel. It more rigid than both aluminum and copper, but thermal conductivity is lower than them too. People will choose their own base/core material according to their different application.

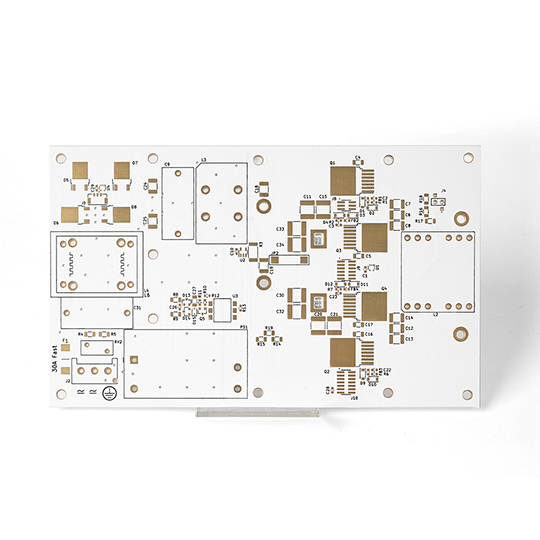

Generally speaking, aluminum is the most economic option considering thermal conductivity, rigidness, and cost. Therefore, the base/core material of normal Metal Core PCB are made of aluminum. In our company, if not special request, or notes, the metal core refer will be aluminum, then MCPCB will means Aluminum Core PCB. If you need Copper Core PCB, Steel Core PCB, or Stainless steel core PCB, you should add special notes in drawing.

Sometimes people will use abbreviation “MCPCB”, instead of the full name as Metal Core PCB, or Metal Core Printed Circuit Board. And also used different word refers the core/base, so you will also see different name of Metal Core PCB, such as Metal PCB, Metal Base PCB, Metal Backed PCB, Metal Clad PCB and Metal Core Board and so on.

MCPCBs are used instead of traditional FR4 or CEM3 PCBs because of the ability to efficiently dissipate heat away from the components. This is achieved by using a Thermally Conductive Dielectric Layer.

The main difference between a FR4 board and MCPCB is the thermal conductivity dielectric material in the MCPCB. This acts as a thermal bridge between the IC components and metal backing plate. Heat is conducted from the package through the metal core to an additional heat sink. On the FR4 board the heat remains stagnant if not transferred by a topical heatsink. According to lab testing a MCPCB with a 1W LED remained near an ambient of 25C, while the same 1W LED on a FR4 board reached 12C over ambient. LED PCB always be produced with Aluminum core, but sometimes steel core PCB also be used.

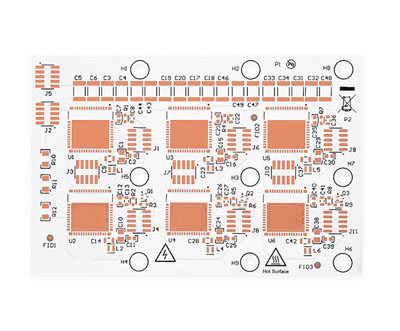

aluminum pcb manufacturer

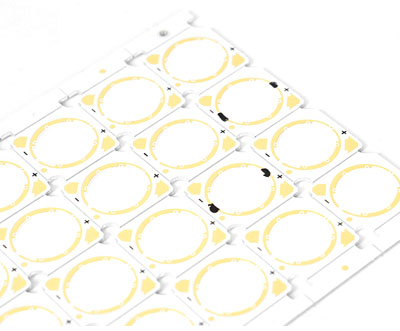

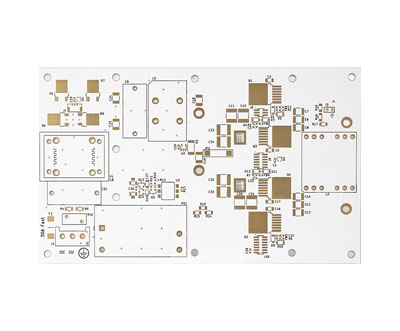

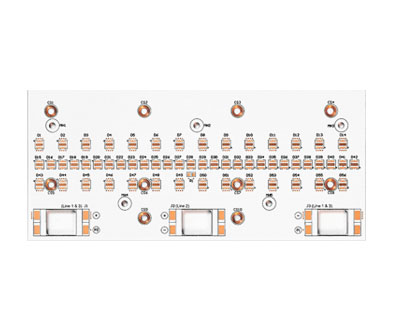

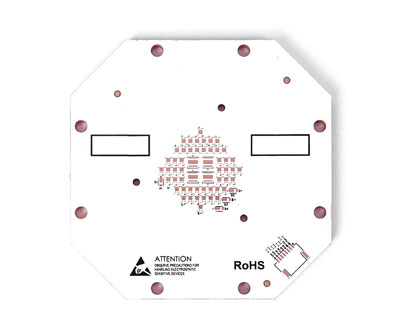

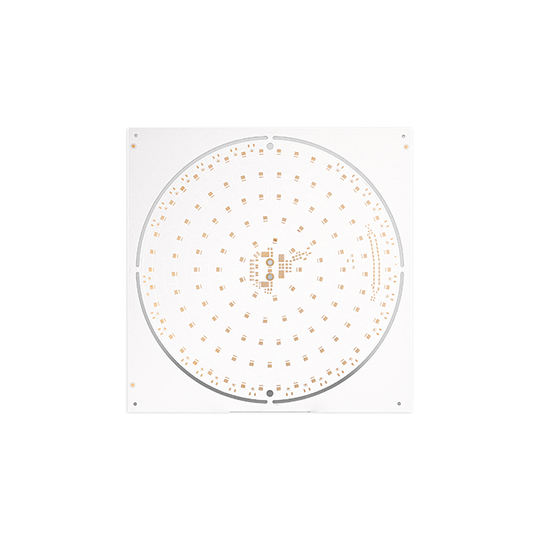

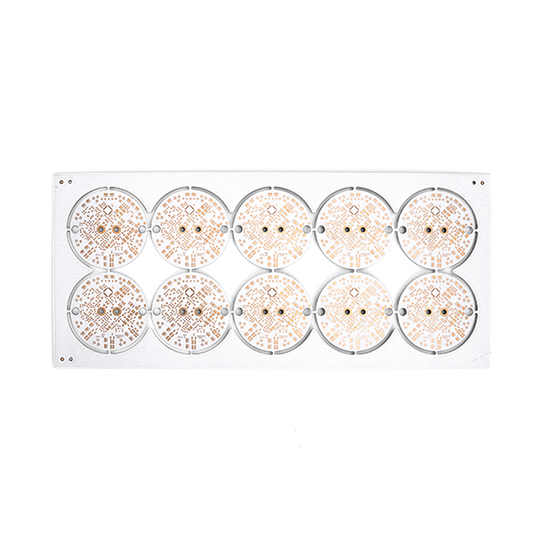

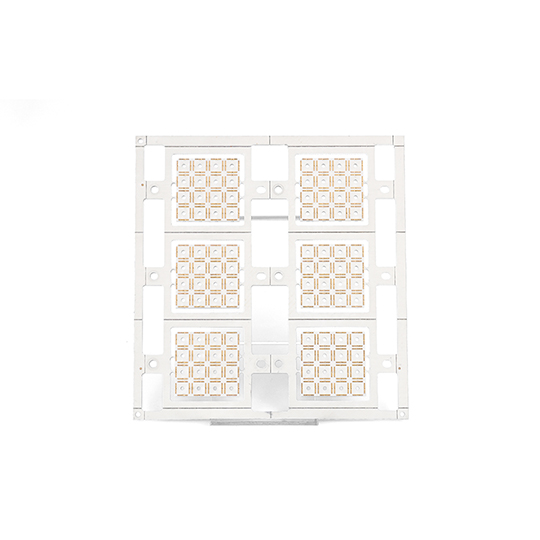

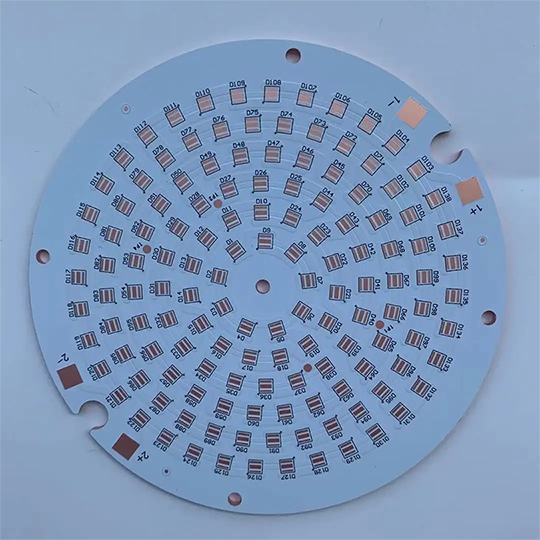

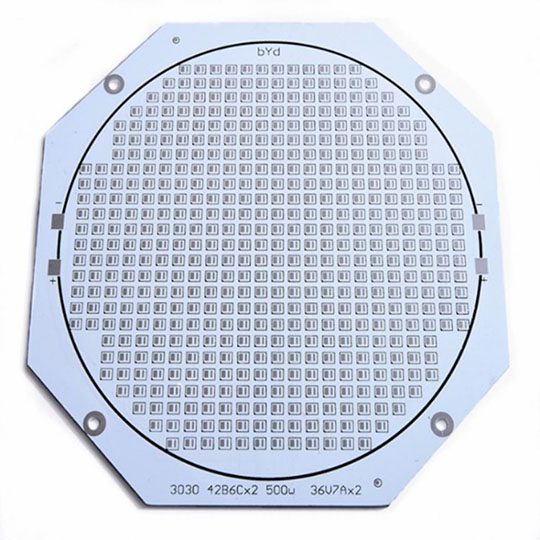

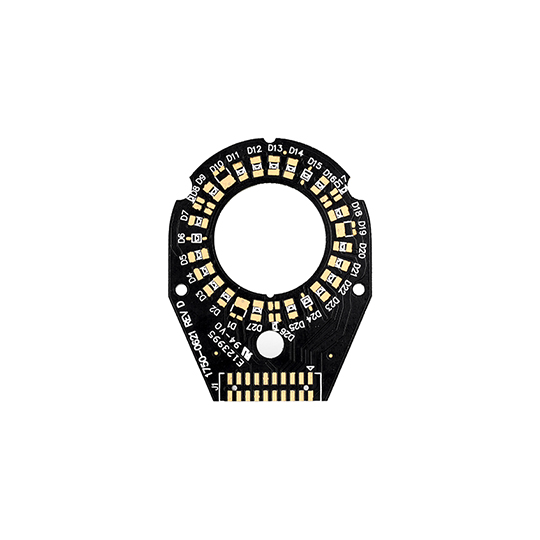

Aluminum substrate PCB also known as aluminum pcb board, it is a kind of metal core circuit board. Compared with normal PCB, aluminum PCB board features in good thermal conductivity around 237W/m.k and light weight, so it is always used in consumer electronics such as LED lighting. If you are working on a high power devices, then Sinkpad MCPCB is better, since it has excellent heat dissipation and thermal conductivity can reach up to 398W/m.k. As a professional aluminum PCB board manufacturer, our product ranges from single layer aluminum PCB, double sided aluminum PCB, 2 layers aluminum PCB, multilayer aluminum pcb. Contact us right now to get your instant quote.

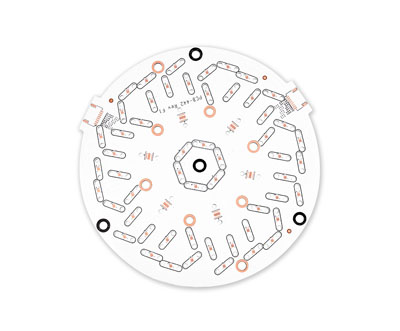

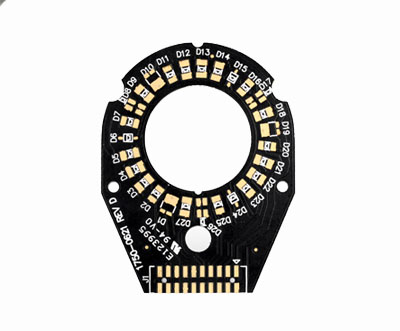

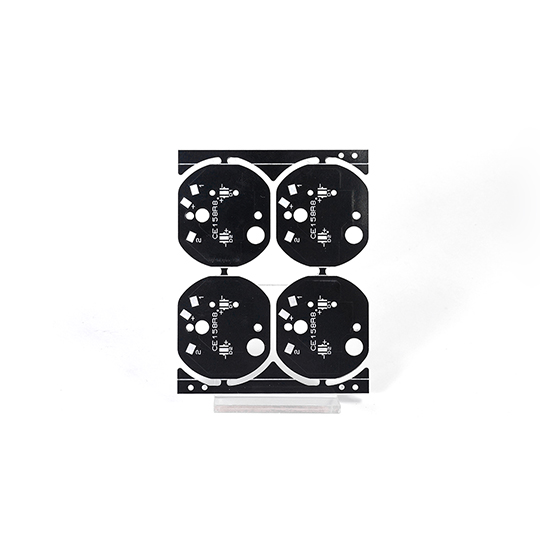

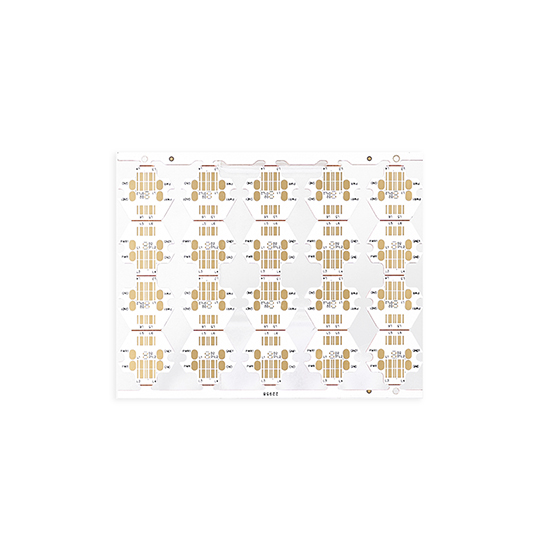

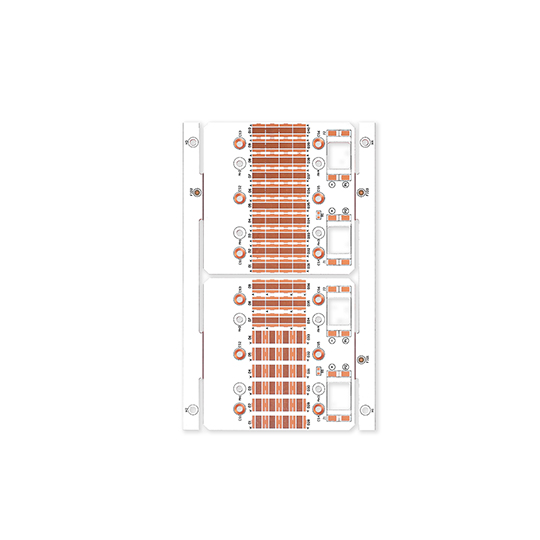

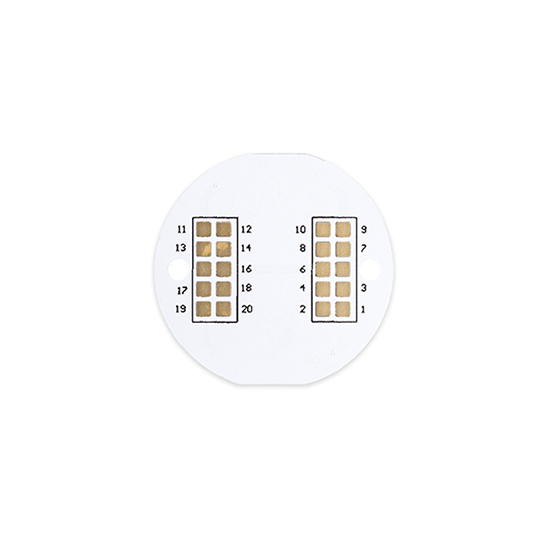

According to the different shapes and layers, MCPCB can be divided into various types. In general, square MCPCB and circle MCPCB are the normal shape, irragular shapes like "star mcpcb" can be customized too. Best Technology is one-stop aluminum PCB supplier, we are dedicated to provide customer with best service, quick turn, fast delivery and high quality.

| Advantage of MCPCB | |

1.heat dissipation Some LEDs dissipate between 2-5W of heat and failures occur when the heat from a LED is not properly removed; a LED’s light output is reduced as well as degradation when the heat remains stagnant in the LED package. The purpose of a MCPCB is to efficiently remove the heat from all topical IC’s (not just LEDs). The aluminum base and thermally conductive dielectric layer act as bridges between the IC’s and heat sink. One single heat sink is mounted directly to the aluminum base eliminating the need for multiple heat sinks on top of the surface mounted components. |

|

2. thermal expansion Thermal expansion and contraction is the common nature of the substance, different CTE is different in thermal expansion. As its own characterics, aluminum and copper have unique advance than normal FR4, thermal conductivity can be 0.8~3.0 W/c.K. |

|

3. dimensional stability It is clear that the size of the metal-based printed circuit board more stable than insulating materials. The size change of 2.5 ~ 3.0% when Aluminum PCB and aluminum sandwich panels was heated from 30 ℃ to 140 ~ 150 ℃. |

|

| Application of MCPCB | |

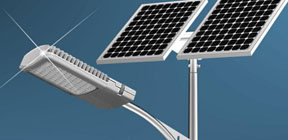

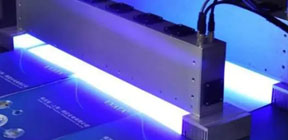

LED lights |

High-current LED, Spotlight, high-current PCB |

Industrial power equipment |

High-power transistors, transistor arrays, push-pull or totem pole output circuit (to tem pole), solid-state relay, pulse motor driver, the engine Computing amplifiers (Operational amplifier for serro-motor), pole-changing device (Inverter) |

Cars |

firing implement, power regulator, exchange converters, power controllers, variable optical system |

Power |

voltage regulator series, switching regulator, DC-DC converters |

Audio |

input - output amplifier, balanced amplifier, pre-shield amplifier, audio amplifier, power amplifier |

OA |

Printer driver, large electronic display substrate, thermal print head |

Audio |

input - output amplifier, balanced amplifier, pre-shield amplifier, audio amplifier, power amplifier |

| Others | Semiconductor thermal insulation board, IC arrays, resistor arrays, Ics carrier chip, heat sink, solar cell substrates, semiconductor refrigeration device |

Sorting of Metal Core PCBs |

|

According to different location of metal core and trace layers of PCB, right now, we divide into five basic types:

|

|