BYD automotive LED aluminum substrate is a specially designed metal-core printed circuit board used in automotive LED lighting, providing excellent heat dissipation, mechanical stability, and reliable electrical performance. In this blog, you will find some significant information about the definition, features, types, materials, functions, working principle, manufacturing process, main applications, and cases about BYD automotive LED aluminum substrate.

Have you ever complained about these headaches before?

- Troublesome thermal dissipation problem?

- Worrying about deficits of manufacturing and design?

- Bothersome material and process problem?

- Difficult reliability and lifespan problem?

Here are the efficient solutions EBest Circuit (Best Technology) provides to solve the above issues for your reference.

- Adjust heat dissipation design: EBest Circuit (Best Technology) makes use of the high conductivity rate of the aluminum substrate and applies heat dissipation structure, such as heat sinks, to boost efficiency.

- Employ strict manufacturing and quality control: We adopt cutting-edge manufacturing processes to ensure the stable performance of the products. Besides, we strictly control material selection and process parameters to ensure every PCB is fully compatible with the standards.

- Enhance inspection and verification: We exploit innovative inspection equipment and methods to ensure the stable PCB performance.

- Boost the customer support and cooperation: We present quick prototype design, small batch manufacturing, turnkey assembly, quick delivery and other services to meet customers’ requirements.

EBest Circuit (Best Technology) has precious experience to provide sensible, tailored solutions of BYD automotive LED aluminum substrate. Our metal core PCBs and services include prototype to PCBA. If you need high quality and reliable aluminum LED board substrate, a warm welcome to contact us at sales@bestpcbs.com.

What is BYD Automotive LED Aluminum Substrate?

In short, it is a metal-based printed circuit board used in BYD vehicle lighting. It adopts an aluminum substrate to boost heat dissipation and mechanical strength. And the copper layer is isolated via the insulated layer, to ensure the LED current is well distributed. The structure supports high lumen density, meanwhile, keeps junction temperature low, ensuring the long-term stability of the brightness and colors.

In comparison with traditional FR4, the aluminum substrate conducts heat faster, which allows LEDs to be placed in high density for a compact space. Besides, the metal base improves rigidity and vibration tolerance. It adapts to the heat shock of the vehicle and the vibration of roads during driving.

What are the features of BYD Automotive LED Aluminum Substrate?

- Excellent thermal dissipation: Low heat resistance keeps low LED junction temperature, stable lumen and color, and long lifespan.

- Safe electricity: A highly insulated layer ensures electrical pressure loading capability, and the single-sided layouts meet the distance and the creepage requirements.

- Mechanical strength: aluminum substrate features of warp resistance and shock resistance, which are beneficial for mounting of lenses and brackets.

- Stable manufacturing: Clean copper layer, good solder paste, and finally, the low rework rate.

- Cost efficiency: It reduces layers and processes for single-layer layouts, and the tools are simple; finally, the yield rate is high.

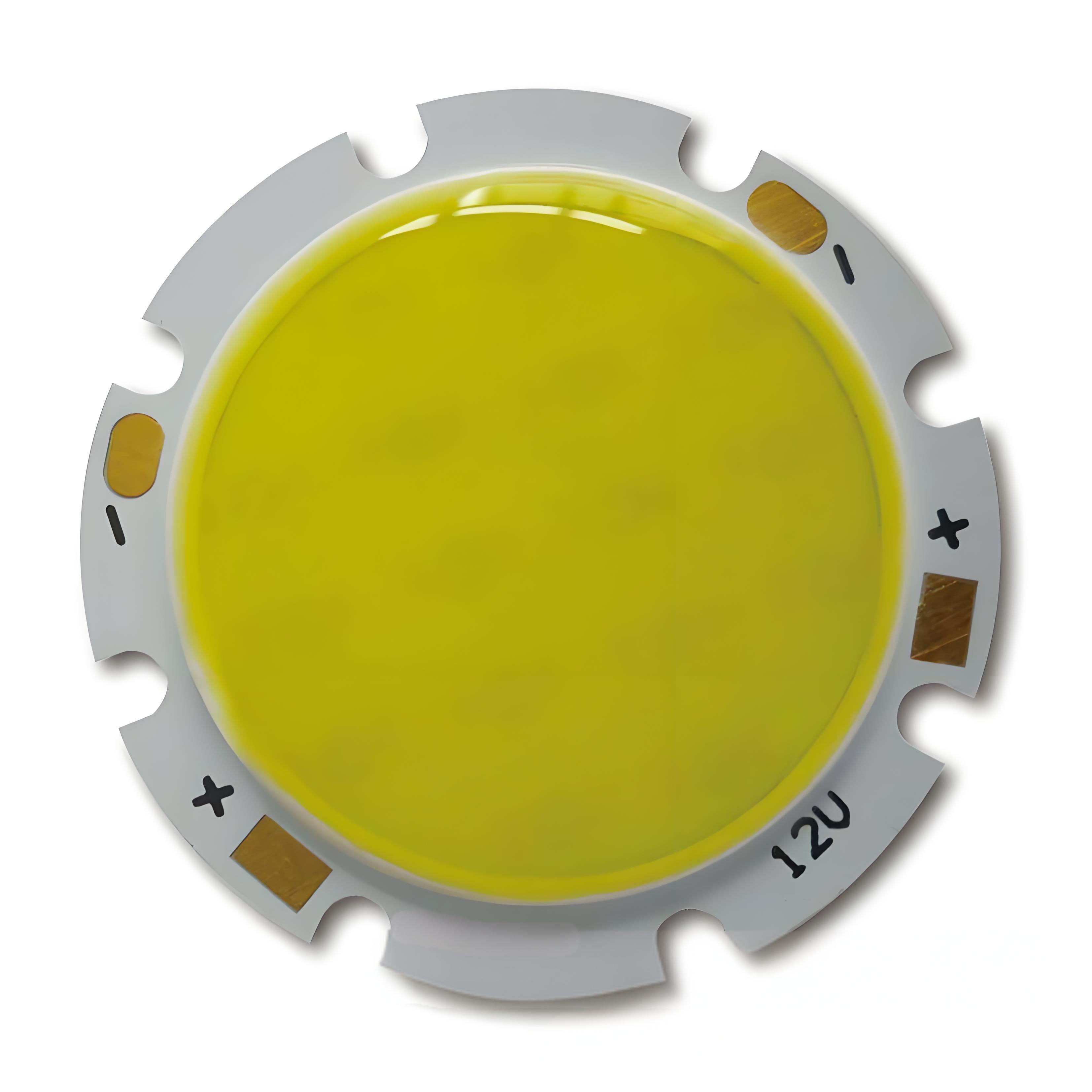

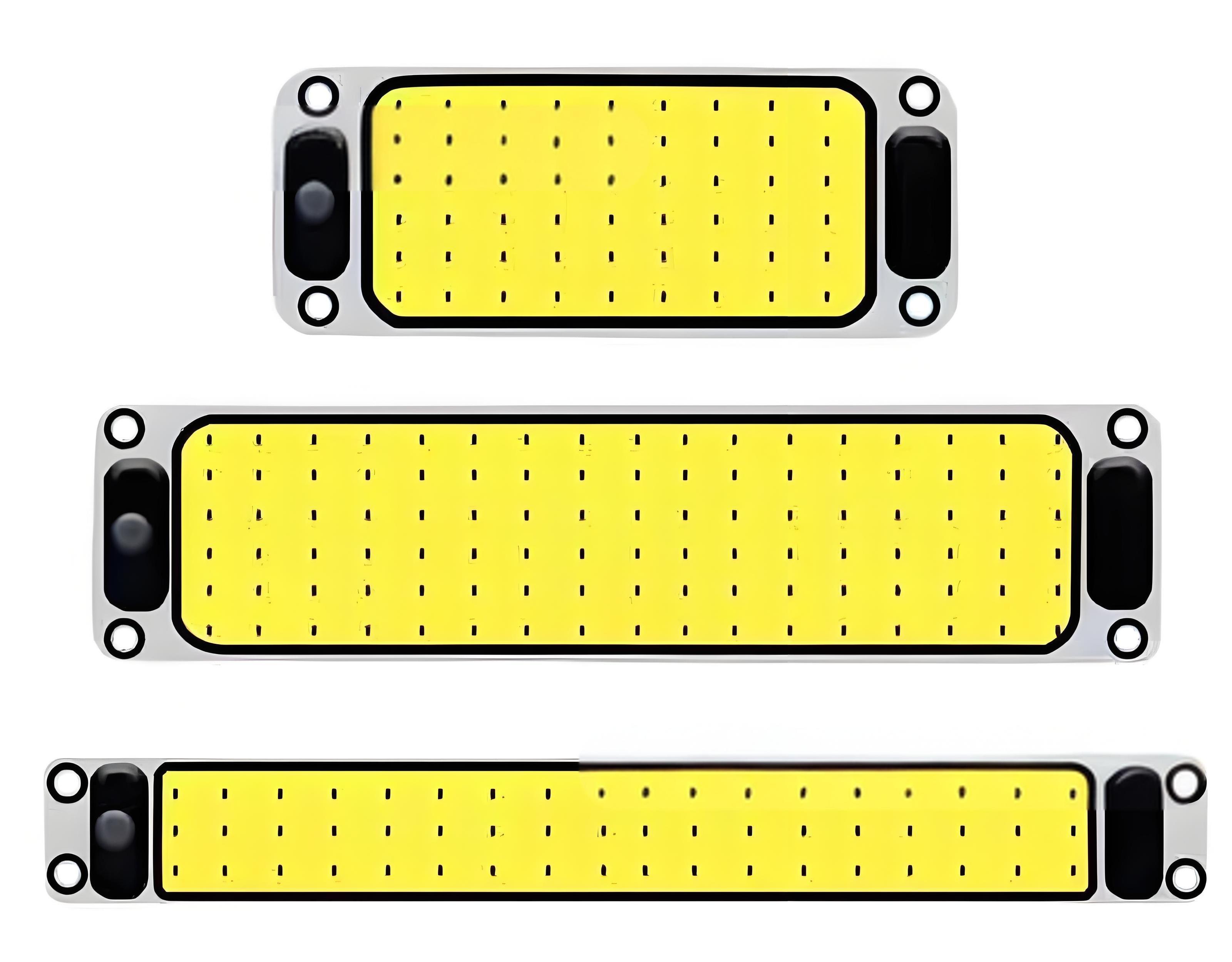

What are the Types of BYD Automotive LED Aluminum Substrate?

Here are the types of BYD automotive LED aluminum substrates.

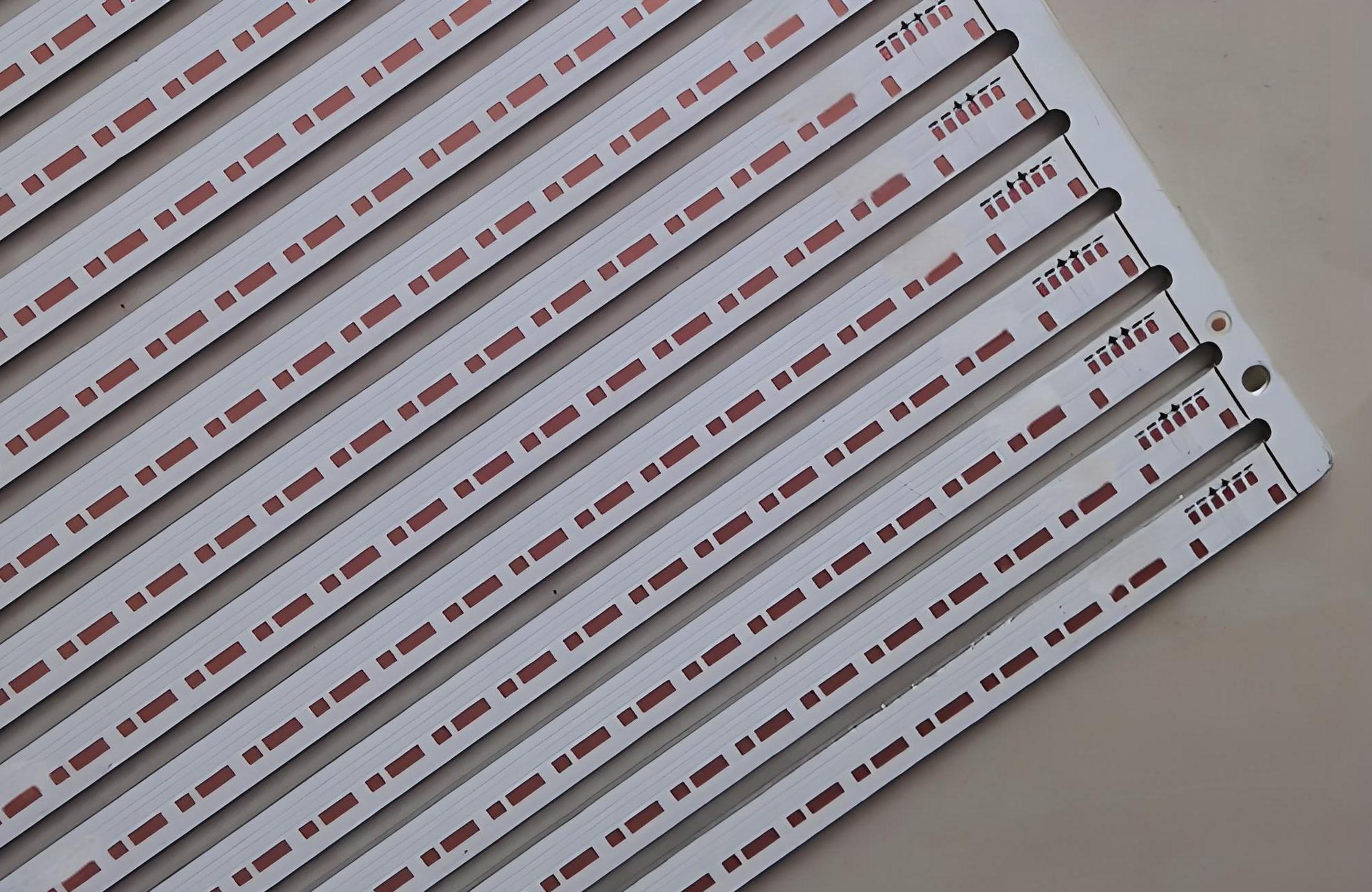

- Single-sided aluminum substrate: The most common choice for lamps and DRL strips.

- Boosted insulated IMS: The Insulated layer thickness or the breakdown pressure will be higher.

- High-thermal IMS: Dielectric engineered for lower thermal resistance, which is good for compact spaces and high flux.

- Hybrid boards: The LED area uses aluminum, and the control circuit area uses FR4.

- Rigid-flex circuit boards: Adopt an aluminum substrate for segments, connected with Flex cables, suitable for bended lighting strips.

What materials are used in an LED single-sided aluminum substrate?

- First, the aluminum base in 1.0ā2.0 mm thickness with 5052 or 1060 grades is often used.

- Second, the thermal conductivity insulated layer is 75ā150Āµm.

- Third, copper foil in 35ā105 Āµm.

- The solder paste protective layer and white surface coating will improve the optical gain.

- Finally, it is worth mentioning that the surface treatments are OSP or ENIG.

It is helpful to note that it needs to consider the thermal conductivity, insulation, and cost when doing the material selection.

What are the functions of aluminum substrate backed single layers boards for the LED lighting industry?

The main functions include thermal dissipation, electrical conductivity, and the mechanical structure support (which includes lenses and the bracket).

- Thermal dissipation: It is through the aluminum base and aluminum layer to realize fast thermal transmission.

- Electricity conductivity: The copper foil circuit is used in current transmission.

- Mechanical support: It provides a rigid structure to LED modules, lenses, and the heat sinks, particularly for automobile applications.

In an automobile, these functions take center stage. Single-layer boards are a practical foundation in applications.

How does an aluminum LED board substrate work in BYD automotive lighting?

It is important to understand the core mechanism that enhances thermal dissipation efficiency and operational stability.

First, there is the separated structure design, which is an aluminum core, an insulated layer, and a copper foil circuit layer.

- Aluminum core, such as 6061 aluminum alloy, offers mechanical support, which high thermal conductivity is up to 200ā235W/mĀ·K. It is beneficial to conduct heat away where LED chips are generated.

- Besides, it is through an insulation layer to ensure the electrical isolation, meanwhile to keep the heat conductivity, with a heat conductivity coefficient of 1ā3W/mĀ·K.

- Finally, the copper foil circuit layer is through etching to form the circuit, which connects the LED chips and the drive circuit.

Optimizing the thermal dissipation route is essential.

- Heat passes layer by layer: LED chips ā insulation layer ā aluminum substrate ā heat sinks.

- Compared to traditional FR4, heat resistance is reduced by over 50%.

Automobile-grade strengthened designs are also notable.

- The structure resists corrosion in moisture and salt spray environments and withstands vibration, with the aluminum core providing a 1.0 mm rigid layer.

Finally, it is worthy to note of the integration benefits.

- The single-layer deisgn simplifies the assembly, and reduce the material of the heat sinks and interface, reducing weight and costs.

This design helps to maintain the lifespan over 50,000 hours even if in high temperature, high moisture situations.

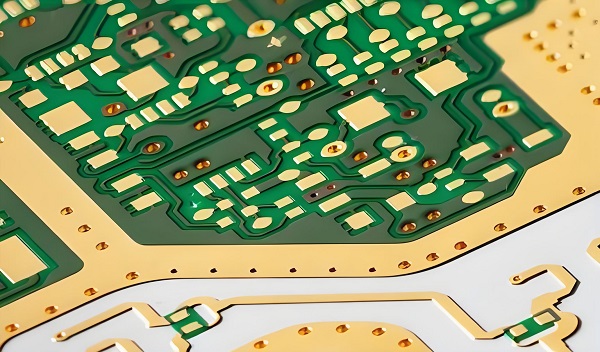

What is the manufacturing process of BYD Automotive LED Aluminum Substrate?

1. Data review: It is significant to check the stackup and IPC standards.

2. Material prep: Aluminum base cutting and deburring. Copper-laminate and dielectric selection based on thermal and voltage targets.

3. The dry film explosion: Transferring copper circuit pattern.

4. Etching: Controlling the line width precision.

5. Drilling: Including mounting holes and optical alignment holes.

6. Surface treatment: OSP or ENIG.

7. Coating: Proceed Solder paste and white coating

8. V-cut/route: Panels prepared for smooth depaneling at the SMT line.

9. Reliability inspection: pressure resistance, heat shock, solderability, and the smooth level.

10. QA: Finalize the QA and packing

What are the main applications of aluminum LED board substrate in BYD LED lighting?

The core applications are as follows:

- Headlamps and DRLs: High flux LED arrays with precise optics. It avoids the lumen depreciation since the high heat conductivity of the aluminum substrate conducts the LED chipsā heat quickly.

- Fog lamps: Compact housings with strong heat paths. Good for wet and cold cycles.

- Power and control modules: For example, the electrical adjust device or controlling device is for power transferring, such as a DC / AC inverter. Aluminum has a high current loading capability up to 4500V pressure resistance, and has low heat resistance, which largely improves the reliability.

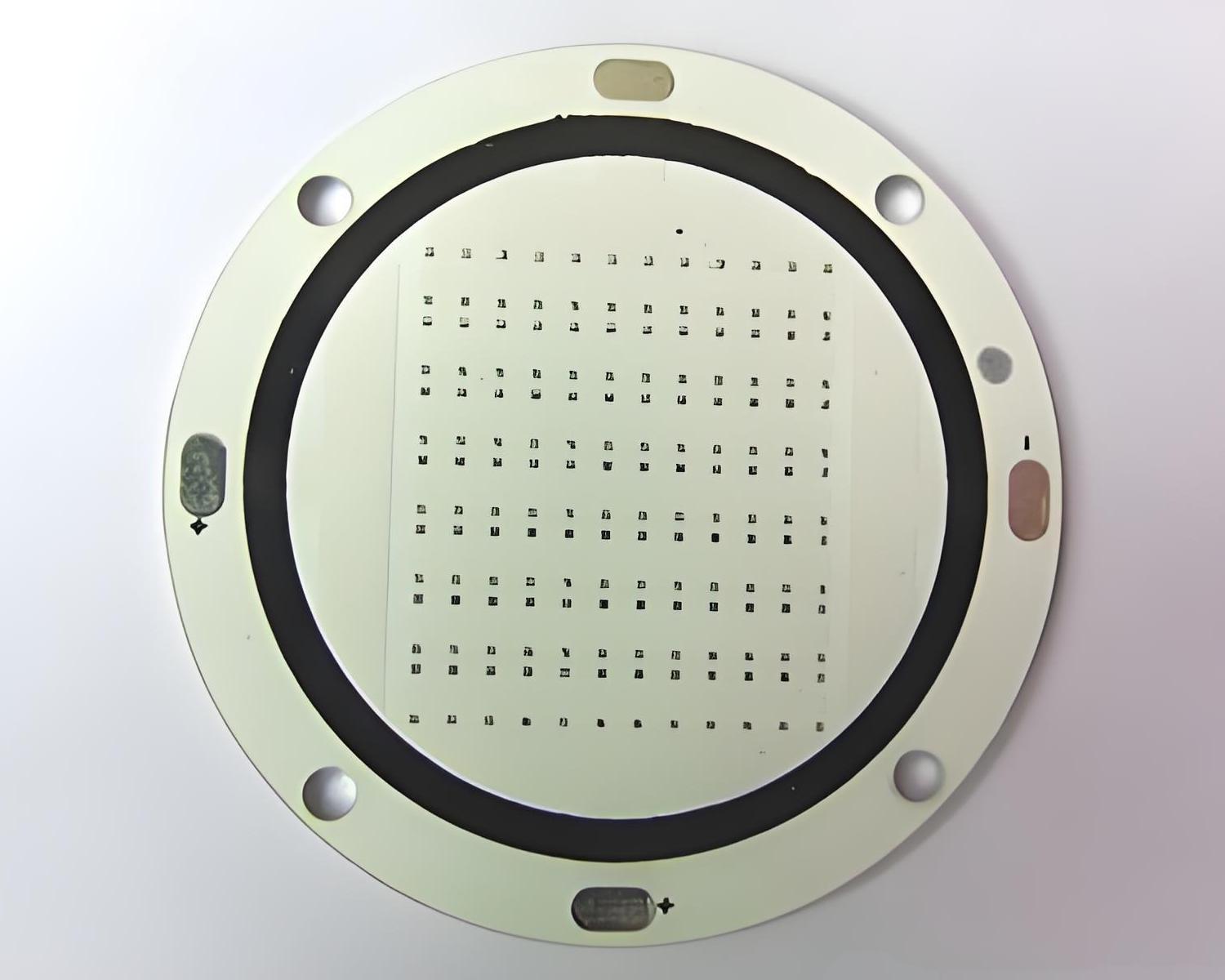

- The Taillights/Interior lighting: It meets the thinner and lighter-weight needs via the high density assembly of the SMT process.

It is important to note that the heat conductivity rate of the aluminum substrate boards is of over 6.7 times that of the FR4. Hence, it will be a good fit for high-power LED lighting.

Case about BYD Automotive LED Aluminum Substrate

Here is a condensed case from a recent platform lamp refresh for our customer.

We proposed a single-sided aluminum substrate with a high-thermal dielectric. A thin thermal pad bridged the back to the cast housing. Junction temperature dropped by 16ā22 Ā°C in the worst case.

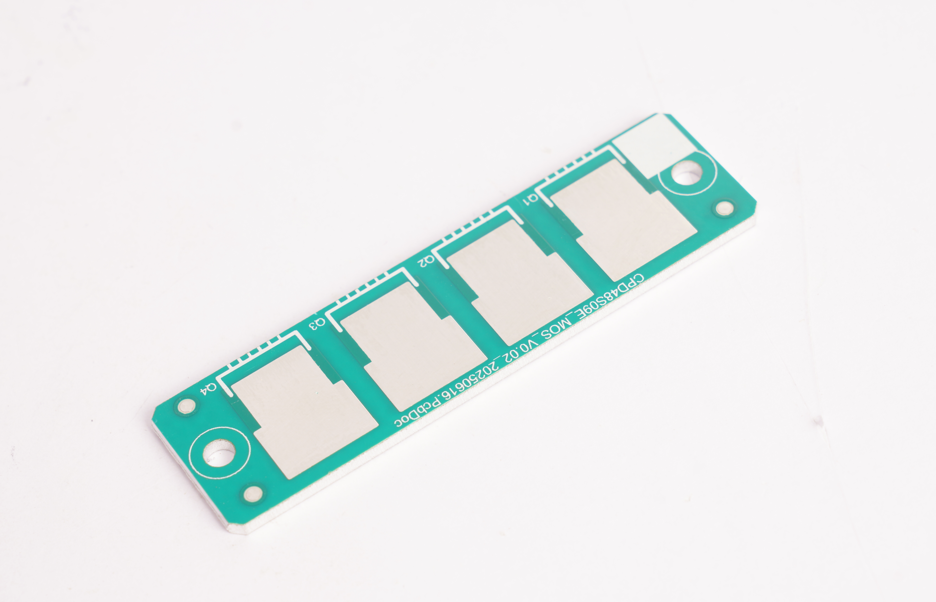

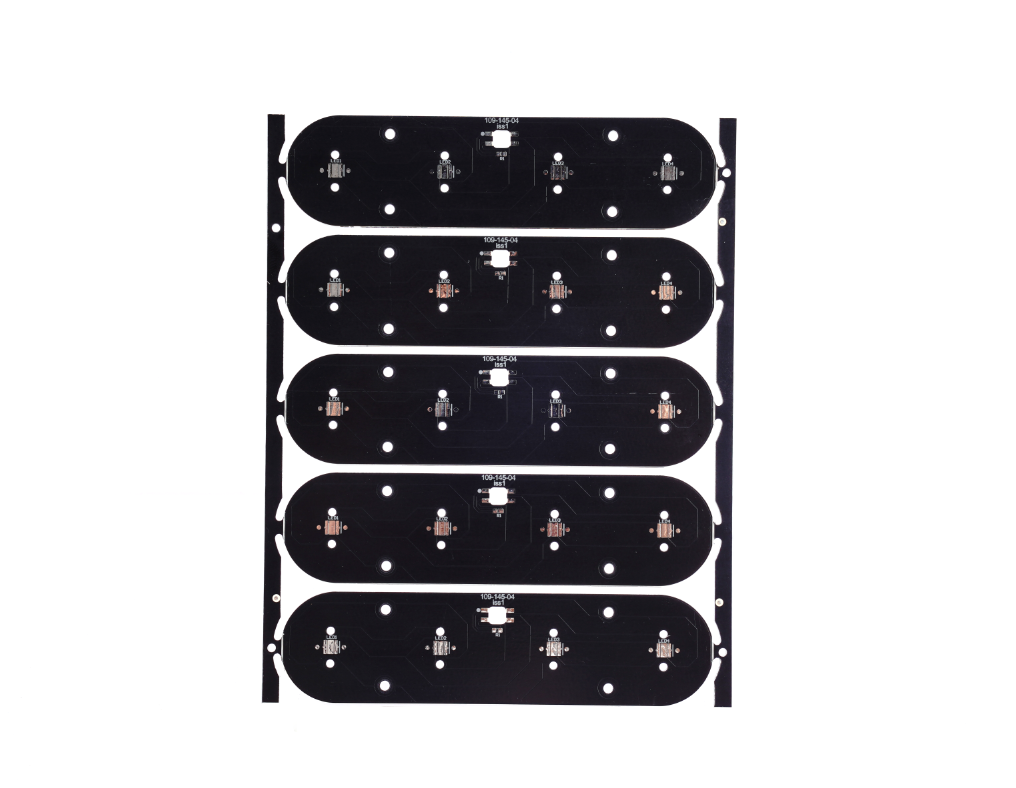

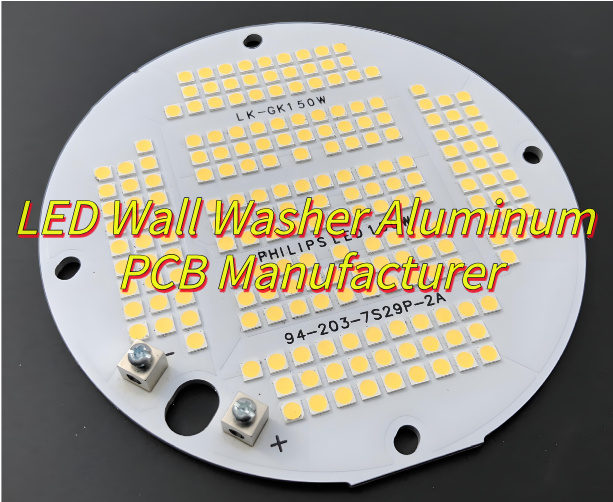

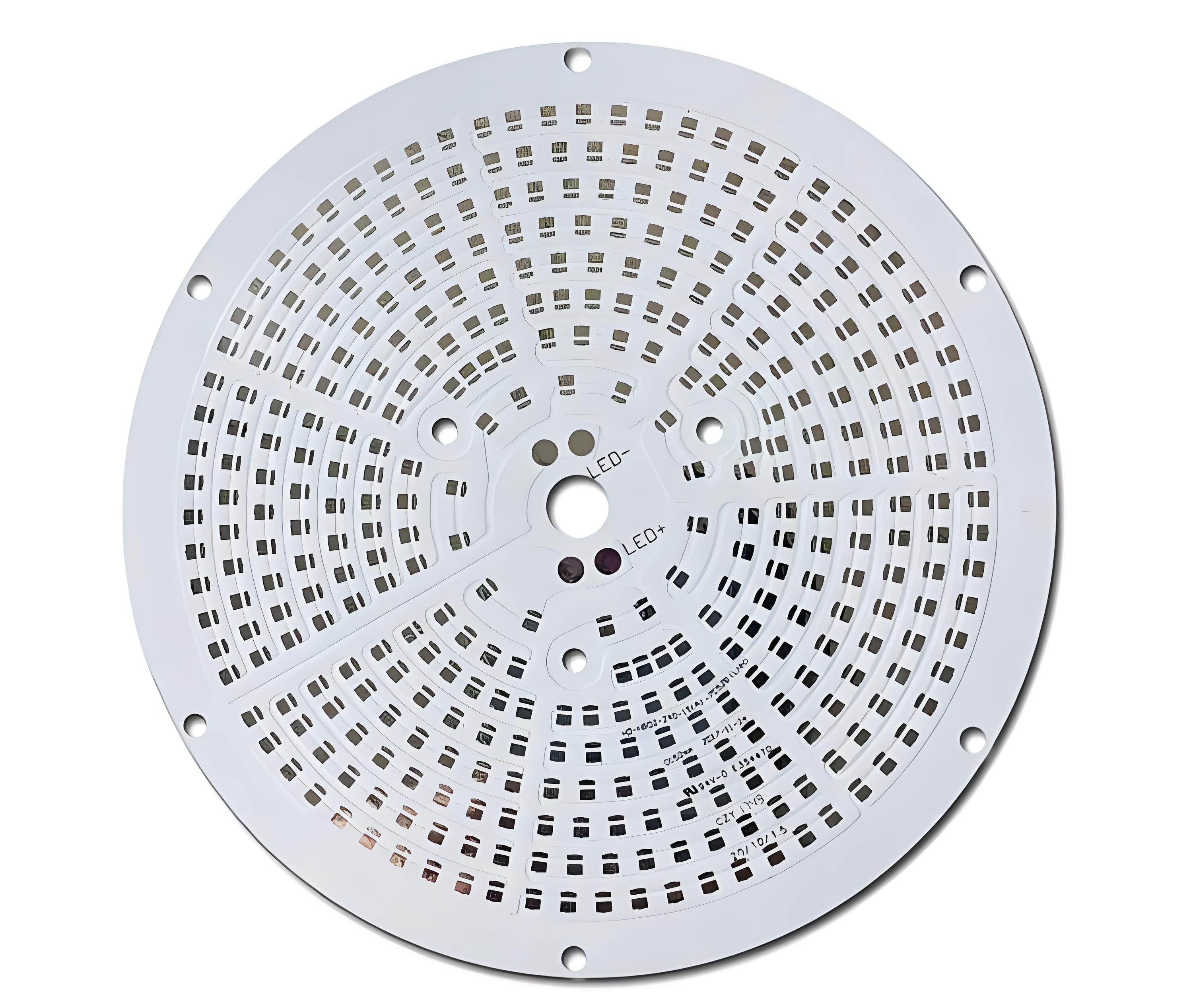

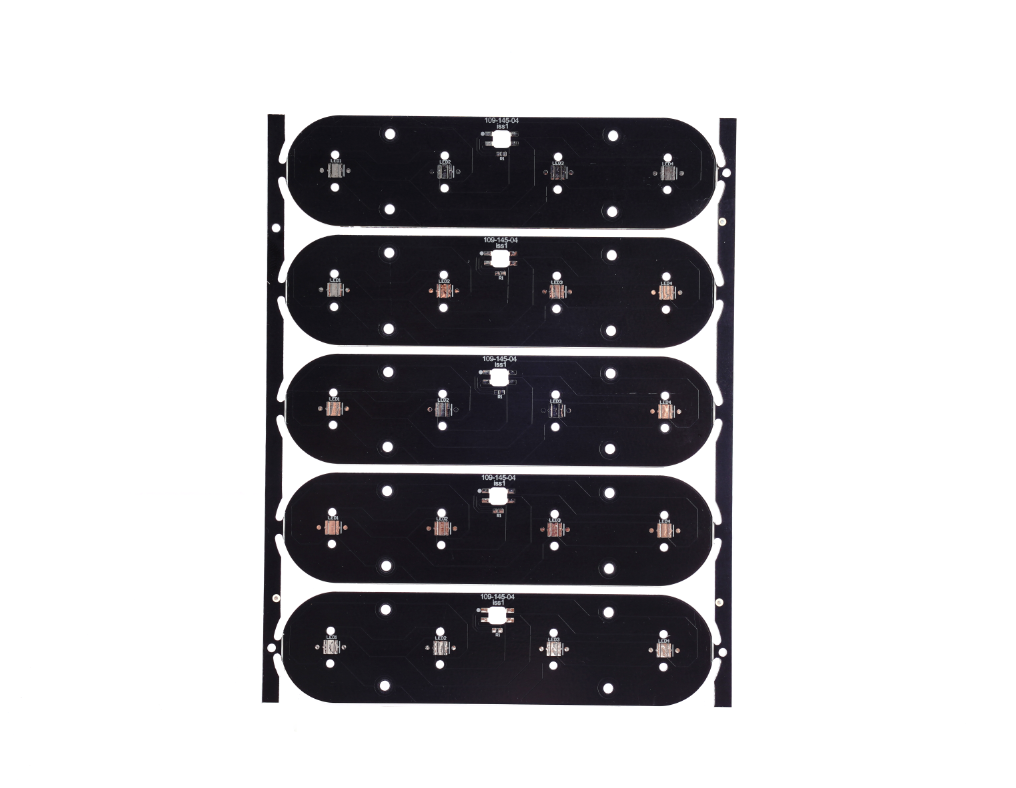

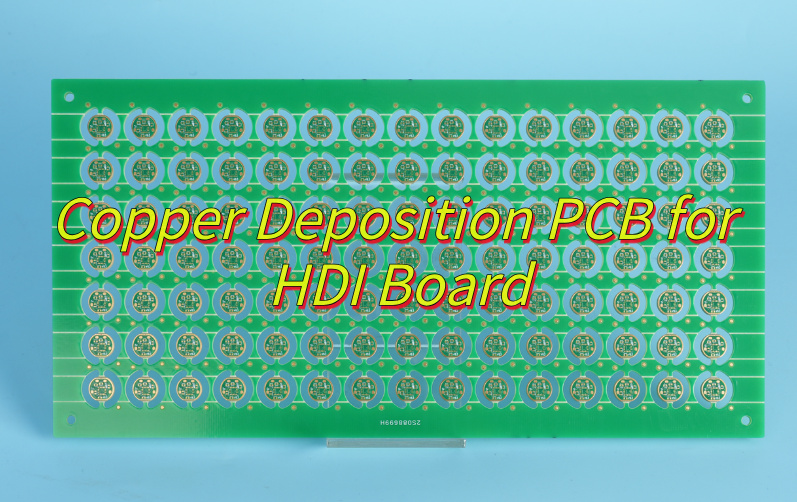

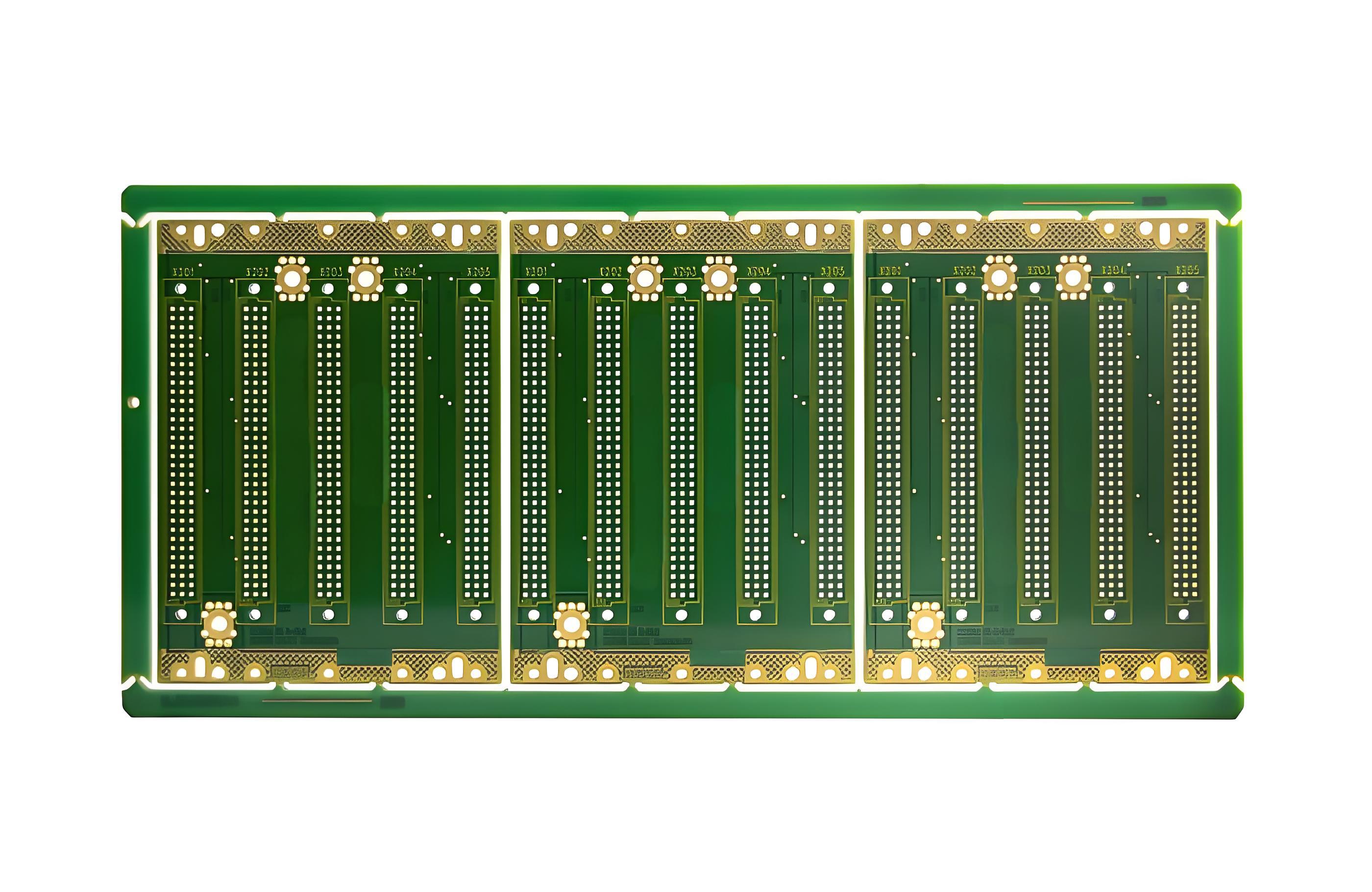

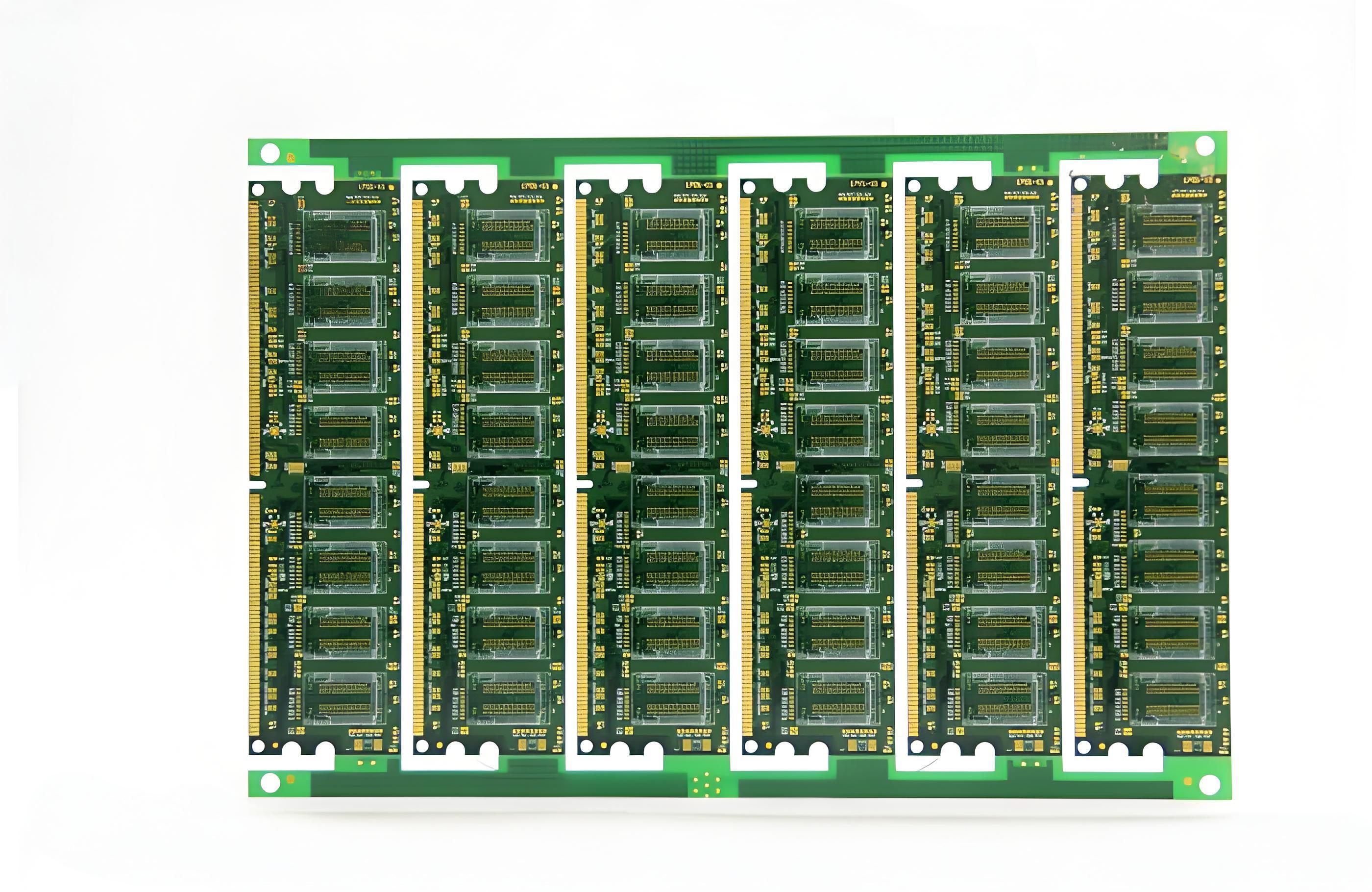

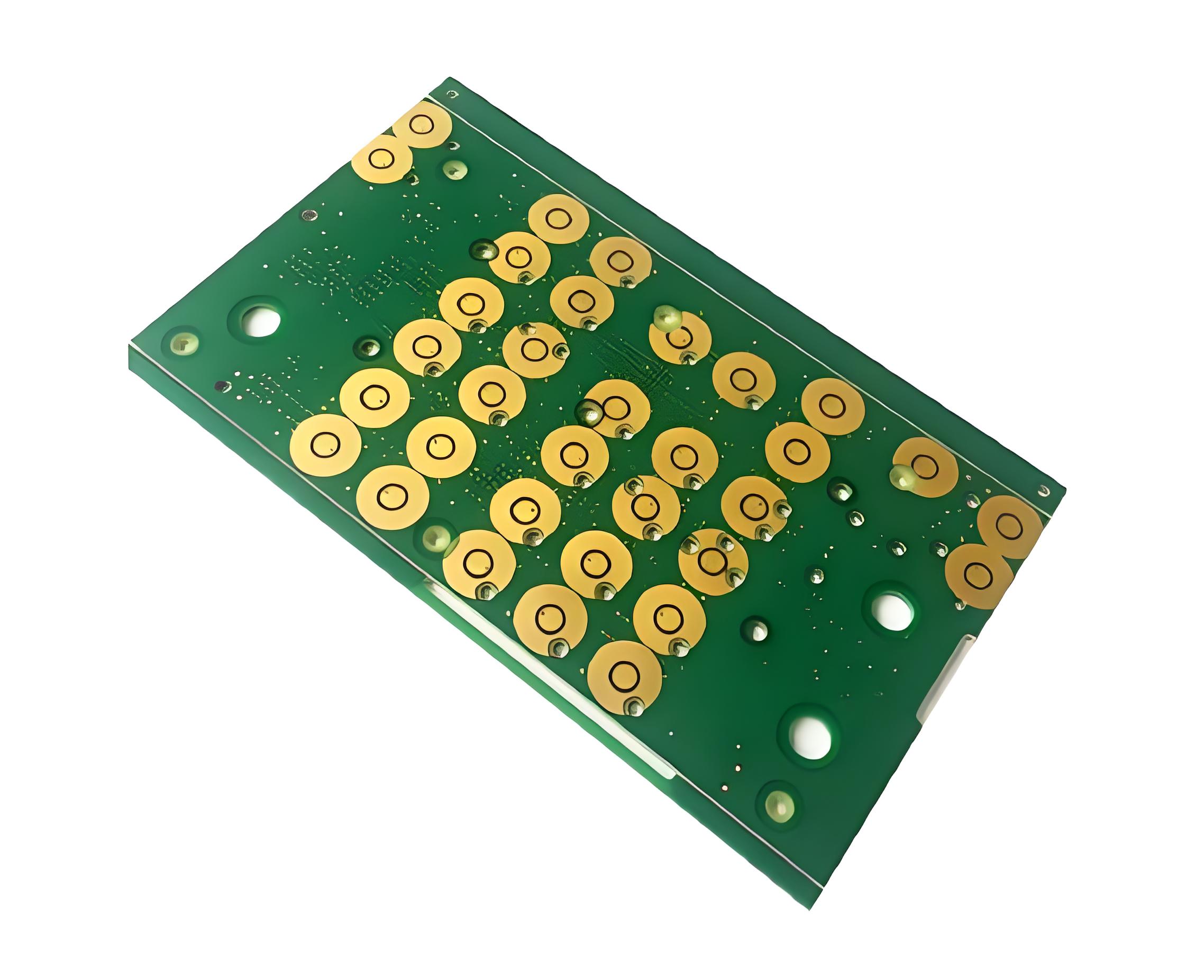

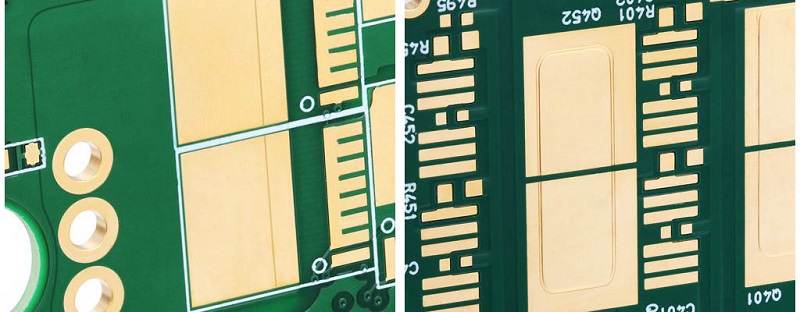

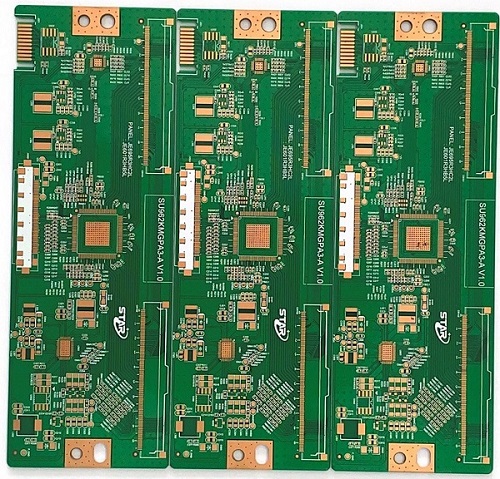

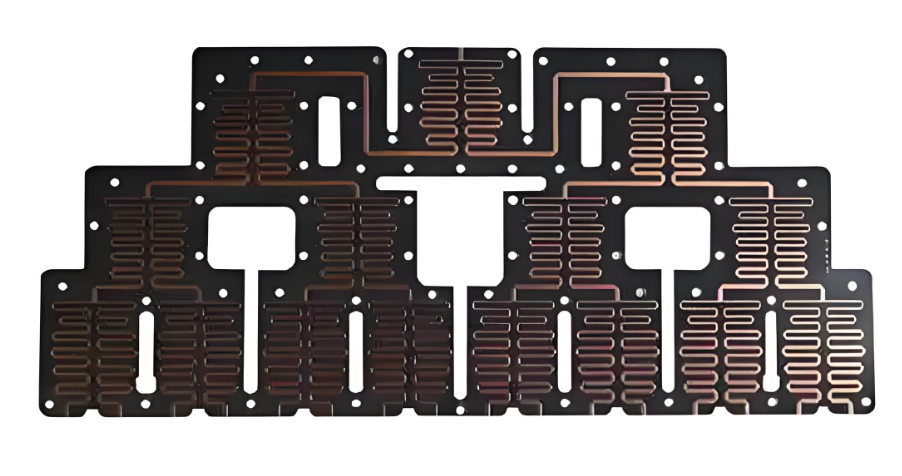

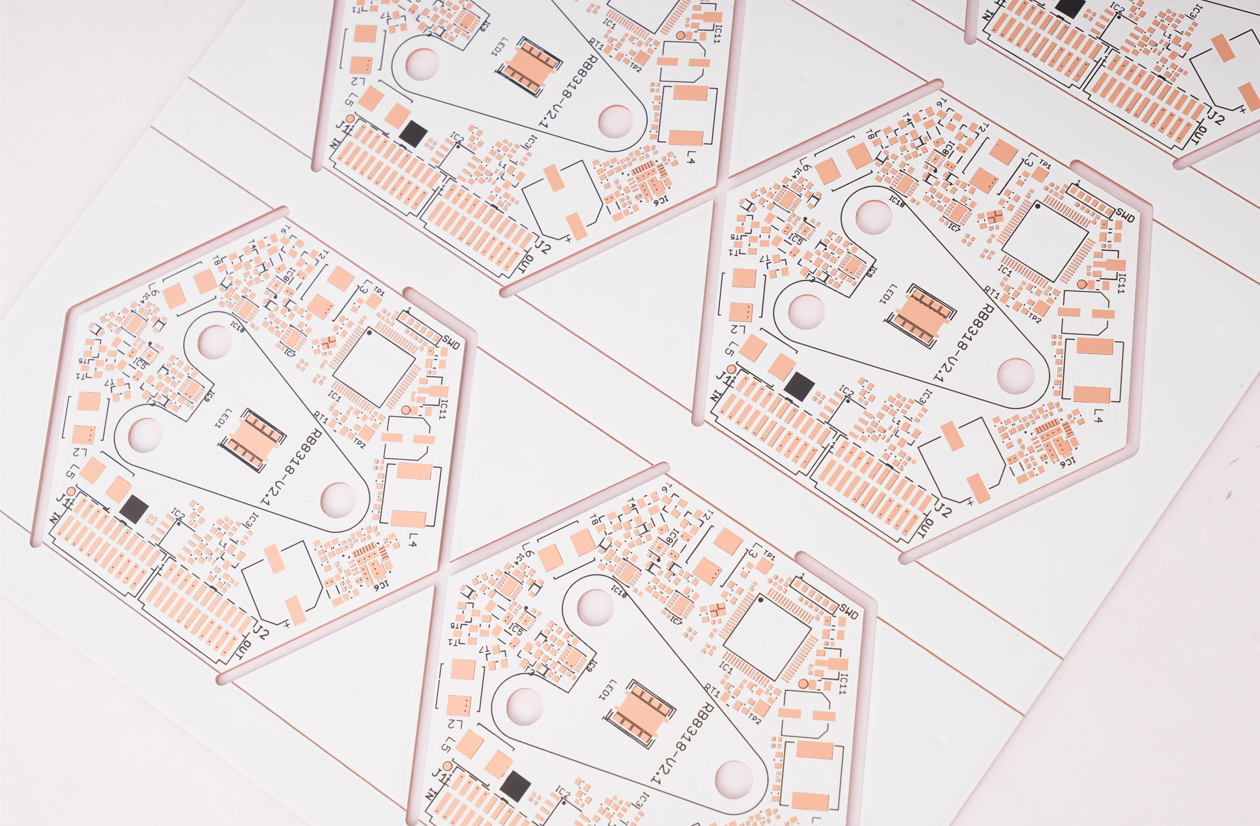

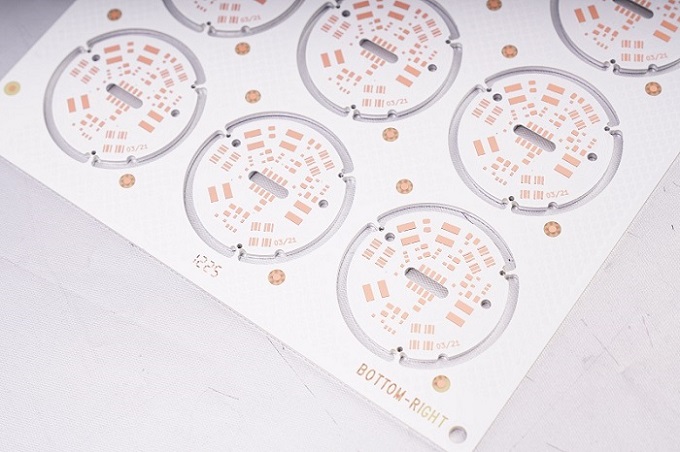

It has the key wins that it has less heat at the LED. Cleaner color over life. Higher yield at SMT. And no tooling changes. That is one of the true solutions of a well-built aluminum LED board. Here are some of our parameters and corresponding PCB pictures for your reference.

- Layer: 2 Layer (Single Sided Aluminum PCB)

- Material: FR-4+ALĀ base pressed, 1.6 mm, 2 oz/2 oz, 100 Ī¼m insulated layer, 3 W/(mĀ·K)

- Solder Mask: White

- Silk Screen: None

- Surface Treatment: OSP (Organic Solderability Preservative)

- Workmanship: FR-4+AL base pressed, CNC routing, aluminum back groove

- Application: Automotive LED lighting, industrial control

Why choose EBest Circuit (Best Technology) for aluminum substrate LED manufacturing?

EBest Circuit (Best Technology) focuses on the high quality aluminum substrate LED manufacturing and the assembly service to a highly competitive market.

- Quick Quote: Our engineers reply the inquiry with 4 hours. We will confirm the stackup and process, and will give the rational solution with the specific quote.

- Quick delivery time: We will evaluate the delivery time in advance and will update the manufacturing schedule. We promise 2 ā 3 weeks delivery time no matter how complicated the boards are.

- Optimized design: Our engineers will improve insulation, aluminum material, and the thermal dissipation design.

- Comprehensive quality system: Our factory is full compatible with ISO 9001, ISO 13485, IATF 16949, AS9100D, UL, REACH, and RoHS standards. We will meet your requirements of automobile, medical, and aerospace grade requirement. You can enjoy our full technical support.

In conclusion, BYD automotive LED aluminum substrate features reliable heat dissipation and optical stability, which could meet the stable lighting and the lasting brightness requirement of BYD automobile. If you would like to find a reliable manufacturer to tackle the pain points of material procurement, engineering, lead time, or LED PCB performance, just feel free to get in touch with us at sales@bestpcbs.com, and we will ensure your project runs smoothly.