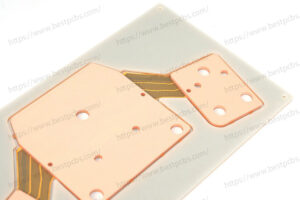

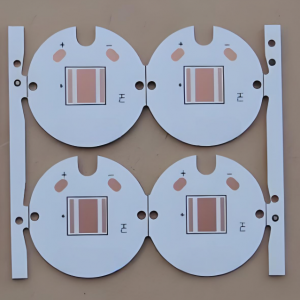

Being the market leader, we offer high quality range of LED Street Light MCPCB or Street Light PCB. These PCB are manufactured using high grade raw material under the supervision of expert and professional team with international quality standards.

Street Light PCB

5w12V led street light mcpcb,size:14x14mm ① 10mm 5W 12V 2C2B 300mA 120- 130lm+/W

10w24V led street light mcpcb,size:18x18mm ① 13mm 10W 24V 4C2B 300mA 120-130lm+/W

15w30V led street light mcpcb,size:19x19mm ① 16mm 15W 36V 6C2B 300mA 120-130lm+/W

20w30V led street light mcpcb,size:24x24mm 019mm 20W 30V 5C4B 600mA 120-130lm+/W

20w30V led street light mcpcb,size:56x40mm 24x24mm 20W 30V 5C4B 600mA 120- 130lm+/W

30w30V led street light mcpcb,size:56x40mm 24x24mm 30W 30V 5C6B 900mA 120-130lm+/W

50w32V led street light mcpcb,size: 56x40mm 24x24mm 50W/4 32V 5C9B 1.5A 120-130lm+/W

50w42V led street light mcpcb,size: 56x40mm 24x24mm 50W/4 42V 7C7B 1A 120-130lm+/W

50w32V led street light mcpcb,size:56x40mm 24x24mm 50W 32V 5C10B 1.5A 120-130lm+/W

200w36V led street light mcpcb,size:194mm ① 185mm 200W 36V 10C5BM 1.5Ax4 130- 140lm+/W

These Street Light PCB are available for our valuable customers at affordable cost in market. Due to their precise design and high functionality our offered materials are ideal for making wide variety of led street light of various watt and models.

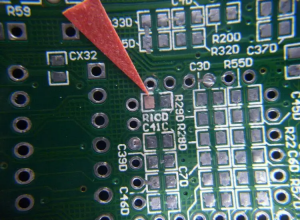

Street Light MCPCB

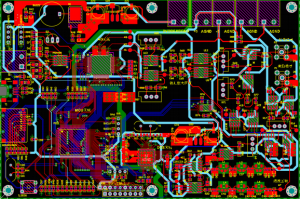

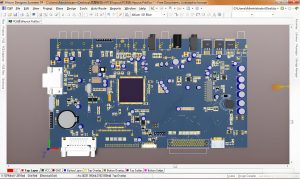

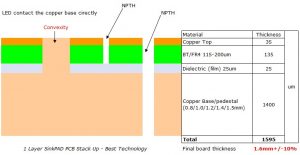

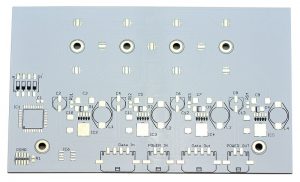

MCPCB production process

Substrate preparation: Select appropriate metal substrates, such as aluminum, iron, copper, indium copper, tungsten-molybdenum alloy, etc., as the base of MCPCB. These metal substrates have good thermal conductivity and are the core components of MCPCB.

Insulating dielectric layer coverage: Cover the metal substrate with an insulating dielectric layer. Common insulating dielectrics include modified epoxy resin, polyphenylene ether, polyimide, etc. This layer not only provides the insulation performance required by the circuit, but also enhances the mechanical strength and durability of the MCPCB.

Copper layer laying: Lay the copper layer on the insulating dielectric layer to form the conductive part of the circuit. The copper layer is made through the production process of printed circuit boards, and the corresponding circuits are laid according to the needs of electronic circuits.

Thermocompression bonding process: The metal substrate, insulating dielectric layer and copper layer are combined together through the thermocompression bonding process to form the basic structure of the MCPCB. This step ensures the close bonding between the layers and improves the stability and reliability of the MCPCB.

Circuit production: According to the design requirements, circuit lines are made on the copper layer. This includes drilling, dry film covering, exposure, development and other steps to ensure the accuracy and conductivity of the circuit line.

Inspection and testing: Inspect and test the completed MCPCB to ensure that its performance meets the design requirements. This includes inspection of the circuit surface and aluminum base surface, as well as testing of conductivity and insulation performance.

What are the advantages of mcpcb

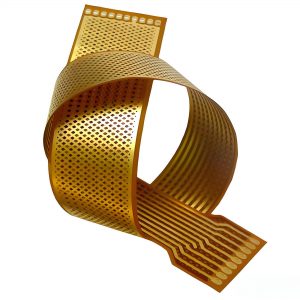

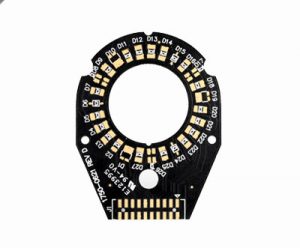

Excellent heat dissipation performance: MCPCB usually adopts aluminum substrate or copper substrate, which has good thermal conductivity, can effectively dissipate the heat generated by electronic components, and improve the stability and reliability of the circuit board. This excellent heat dissipation performance makes MCPCB particularly suitable for high switching power applications, such as LED lighting, power modules, automotive electronics and power electronics, among which LED lighting is one of the most widely used fields of MCPCB.

High mechanical strength: The base material of metal core PCB is thicker, with high mechanical strength and bending and torsion resistance, which is conducive to the assembly and transportation of electronic products. This feature makes MCPCB perform well in environments that need to withstand greater physical pressure or frequent movement.

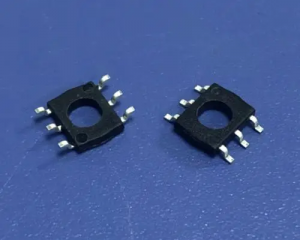

Reliable welding performance: After the surface of metal core PCB is coated with solder paste, it has good welding performance and is suitable for surface mount technology (SMT) and plug-in welding technology. This feature improves the applicability of MCPCB in PCBA processing, making it a preferred material in the manufacture of modern electronic products.

Corrosion and wear resistance: Metal core PCB has strong corrosion resistance and wear resistance, which is suitable for electronic products in harsh environments. This feature enables MCPCB to work stably for a long time under high temperature, humidity or other extreme conditions, improving the durability and reliability of the product.

Space saving: Compared with traditional FR-4 substrates, MCPCB has higher heat dissipation performance, which can design smaller electronic products and save space. This advantage is particularly important in devices with limited space, such as portable electronic devices such as smartphones and tablets.

Improve reliability: Good welding performance and corrosion resistance can improve the reliability and stability of the circuit board and reduce the failure rate. This is especially important in critical systems and equipment, such as medical equipment, industrial control systems, etc., where reliability and stability are crucial factors.

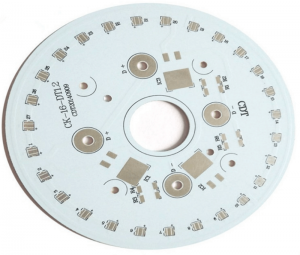

What accessories does a street lamp have?

- Lamp holder. The lamp holder of a street lamp is usually an LED lamp, which is the core part of the street lamp. It is responsible for converting electrical energy into light energy to provide lighting services for people. The quality of the lamp holder directly affects the lighting effect and life of the street lamp.

- Lamp pole. The lamp pole is the part that supports the lamp holder. It is usually made of metal and has various shapes such as conical poles and prismatic poles. Street lamps in different scenes may require lamp poles of different heights and shapes to meet lighting needs. In addition, safety issues should also be considered, such as anti-theft design and prevention of excessive wind force. In addition, installation accessories such as clamps are also used to fix the lamp pole.

- Light source. The light source is an important part of the street lamp, including LED lamp beads, bulbs, etc. The choice of light source is related to key indicators such as brightness, energy consumption and life of the street lamp. At present, LED light sources are widely used in street lamps due to their high efficiency, energy saving and long life.

- Electrical control device. The electrical control device includes components such as ballast, trigger, light control switch, etc., which are used to control the working state of the street lamp and protect the circuit safety. For example, light-operated switches can automatically turn streetlights on and off according to ambient light, saving energy. In addition, some advanced streetlights may also be equipped with intelligent control systems to achieve remote monitoring and management.

- Installation accessories. These include small parts such as clamps and screws. Although these parts are not conspicuous, they are very important for the installation and maintenance of streetlights. For example, clamps are used to fix the connection between the top of the lamp pole and the lamp head, and screws are used to fix various parts to ensure the stability and safety of the streetlight.

What are the street lights?

Ordinary street lights

Ordinary street lights are the most common lighting facilities on the streets. They usually use light bulbs or LED lamp heads and are installed on light poles to provide basic lighting for pedestrians at night.

Solar street lights

Solar street lights are an environmentally friendly street light that uses solar panels to absorb solar energy, converts energy into electrical energy, stores it in batteries, and lights up the street lights at night through control devices. Solar street lights do not need to be connected to an external power supply, have low maintenance costs, and are widely used in parks, suburban roads and other places.

LED street lights

LED street lights use light-emitting diodes as light sources, which have the advantages of high efficiency, energy saving, long life, safety and reliability. LED street lights have good lighting effects and can be intelligently adjusted according to different environments. They are the first choice for modern urban street light renovation.

Landscape street lights

In addition to the basic lighting function, landscape street lights also emphasize artistic decorative effects. It is usually integrated with the surrounding environment, with unique design and diverse shapes, and is used to increase the beauty and cultural atmosphere of street landscapes.

Multifunctional street lights

Multifunctional street lights integrate multiple functions such as lighting, monitoring, and communication. In addition to providing lighting, this type of street lamp is also equipped with cameras, display screens and other devices for urban management and security monitoring.