Estonia’s electronics sector relies heavily on reliable PCB manufacturer in Estonia to support diverse applications from industrial control to automotive electronics. As a key part of the European supply chain, PCB manufacturer in Estonia combines local technical advantages with global quality standards. Whether it‚Äôs small-batch prototypes or mass production, Estonia PCB manufacturers strive to meet market demands, though challenges in process precision and delivery efficiency persist. This guide explores top Estonia PCB companies, core pain points, and our tailored solutions to help you navigate the Estonia PCB manufacturing landscape.

Top 10 PCB Manufacturer in Estonia

| Company Name | Main Business | Core Advantages | Process Capability | Lead Time |

| Tallinn PCB Solutions O√ú | Rigid PCB, metal core PCB for industrial control equipment | Local quick response, strict environmental protection control | 2-12 layer PCB, thick copper (2-4OZ), thermal management process | Standard 8-12 days, prototype 4-6 days |

| Tartu Electronic Circuits Ltd. | PCB prototype, small-batch production for telecom and IoT | High-precision drilling, personalized technical support | 2-8 layer PCB, blind/buried hole, SMT | Prototype 3-4 days, mass production 9-14 days |

| Pärnu PCB Factory OÜ | Single/double-layer PCB, PCBA for consumer electronics | Cost-effective, large-volume production | 1-6 layer PCB, conventional soldering, conformal coating | Mass production 5-8 days, urgent 2-3 days |

| Narva Precision Circuits O√ú | High-frequency PCB, rigid-flex PCB for aerospace | Military-grade quality, advanced material application | 4-20 layer PCB, high-frequency processing, impedance matching | Standard 12-18 days, prototype 6-8 days |

| Eesti PCB Tech O√ú | Medical-grade PCB, diagnostic equipment customization | ISO13485 certification, traceability system | 2-10 layer PCB, biocompatible material, precision assembly | Standard 10-14 days, prototype 5-7 days |

| Rakvere Circuit Boards Ltd. | Automotive PCB, high-temperature engine parts | IATF16949 certification, vibration resistance testing | 4-14 layer PCB, high-temperature solder mask, thermal shock resistance | Standard 8-12 days, urgent 4-5 days |

| Viljandi Electronics Co., O√ú | PCB prototype, low-volume research production | Quick design adjustment, technical consultation | 2-6 layer PCB, fine-pitch assembly, functional testing | Prototype 2-3 days, small-batch 6-9 days |

| Sillamäe PCB Plant OÜ | Power supply PCB, thick copper industrial inverters | High-current capacity, long-term reliability | 2-10 layer PCB, 4-8OZ thick copper, heat dissipation optimization | Standard 7-11 days, mass production 10-15 days |

| Haapsalu Custom Circuits O√ú | Special-shaped PCB, custom-sized niche electronics | Flexible production, non-standard size customization | 1-8 layer PCB, special-shaped cutting, edge processing | Custom 9-13 days, prototype 4-6 days |

Pain Points of PCB Manufacturer in Estonia

- Design-process mismatch leading to rework, as some designs fail to adapt to local Estonia PCB Manufacturing processes, increasing production cycles and costs.‚Äč

- Slow prototype delivery, with most local Estonia PCB Factory taking 3-7 days for prototypes, unable to meet urgent project schedules.‚Äč

- Quality inconsistency in mass production, lacking full inspection capacity, resulting in unstable yield rates for high-precision PCB Estonia orders.‚Äč

- High cost of custom materials, as specialized materials for high-frequency or medical PCB require import, raising the overall cost of Estonia PCB Company projects.‚Äč

- Limited HDI process capability, with most local manufacturers unable to meet high-density interconnect requirements for advanced electronics.‚Äč

- Poor assembly-process coordination, leading to soldering defects such as cold joints or bridging in PCBA services.‚Äč

- Lack of real-time production tracking, making it difficult for clients to grasp the progress of orders from PCB Manufacturer in Estonia.

Full-Process Guarantee from Requirement to Delivery

- Pre-design Optimization: Provide free DFM analysis to align designs with Estonia PCB Manufacturing processes, eliminating rework risks and reducing costs.‚Äč

- Rapid Prototyping Support: 24-hour fast prototyping service to meet urgent project needs, far exceeding the average lead time of local Estonia PCB Plant.‚Äč

- Intelligent Production Control: Adopt digital management system to realize real-time order tracking, ensuring transparent progress for every PCB Manufacturer in Estonia order.‚Äč

- Strict Quality Inspection: Implement full inspection for mass production with automated testing equipment, ensuring 100% qualified rate for Estonia PCB orders.‚Äč

- Material Supply Chain Integration: Cooperate with global material suppliers to provide cost-effective specialized materials, reducing the cost burden of custom Estonia PCB Company projects.‚Äč

- HDI Process Advancement: Master advanced HDI technology to meet high-density requirements for advanced electronics, filling the gap of local Estonia PCB Manufacturer.‚Äč

- Integrated Assembly Service: Optimize assembly-process coordination with professional soldering technology, eliminating common defects and ensuring PCBA quality.‚Äč

- After-sales Support: Provide technical consultation and problem-solving services within 24 hours, ensuring smooth use of products from our PCB Manufacturer in Estonia.

Why Estonian Clients Choose EBest Circuit(Best Technology) for PCB Manufacturer?

Reasons Why Estonian Clients Choose EBest Circuit( Best Technology) for PCB Manufacturer:

- Comprehensive Certifications: Hold ISO9001:2015, ISO13485:2016, REACH, RoHS, IATF16949 certifications, meeting diverse industry requirements for Estonia PCB.‚Äč

- 24-hour Rapid Prototyping: Unique urgent prototyping line realizes 24-hour delivery for emergency orders, saving valuable project time.‚Äč

- High On-time Delivery Rate: Maintain 99.2% on-time delivery rate for years, ensuring stable project progress for clients cooperating with our PCB manufacturer in Estonia.‚Äč

- Strict Quality Control: Batch production full inspection combined with 8-stage quality control process, achieving 100% qualified rate for finished products.‚Äč

- Competitive Pricing: Adopt scale procurement and efficient production management to provide cost-sensitive solutions, reducing project costs by 15%-20% compared to other Estonia PCB manufacturer.‚Äč

- 19 Years of Production Experience: Rich industry experience in Estonia PCB manufacturing to optimize processes and reduce unnecessary costs for clients.‚Äč

- Free DFM Analysis: Professional pre-design analysis to avoid process conflicts, improving production efficiency and reducing rework costs.‚Äč

- Advanced HDI Capability: Support 20-layer HDI PCB production with blind/buried hole technology, satisfying high-precision product needs.‚Äč

- Localized Service: Set up a service center in Estonia to provide quick response, with technical support available within 24 hours for PCB Estonia orders.‚Äč

- Sustainable Production: Adopt environmental protection processes to meet EU environmental standards, realizing green Estonia PCB manufacturing.

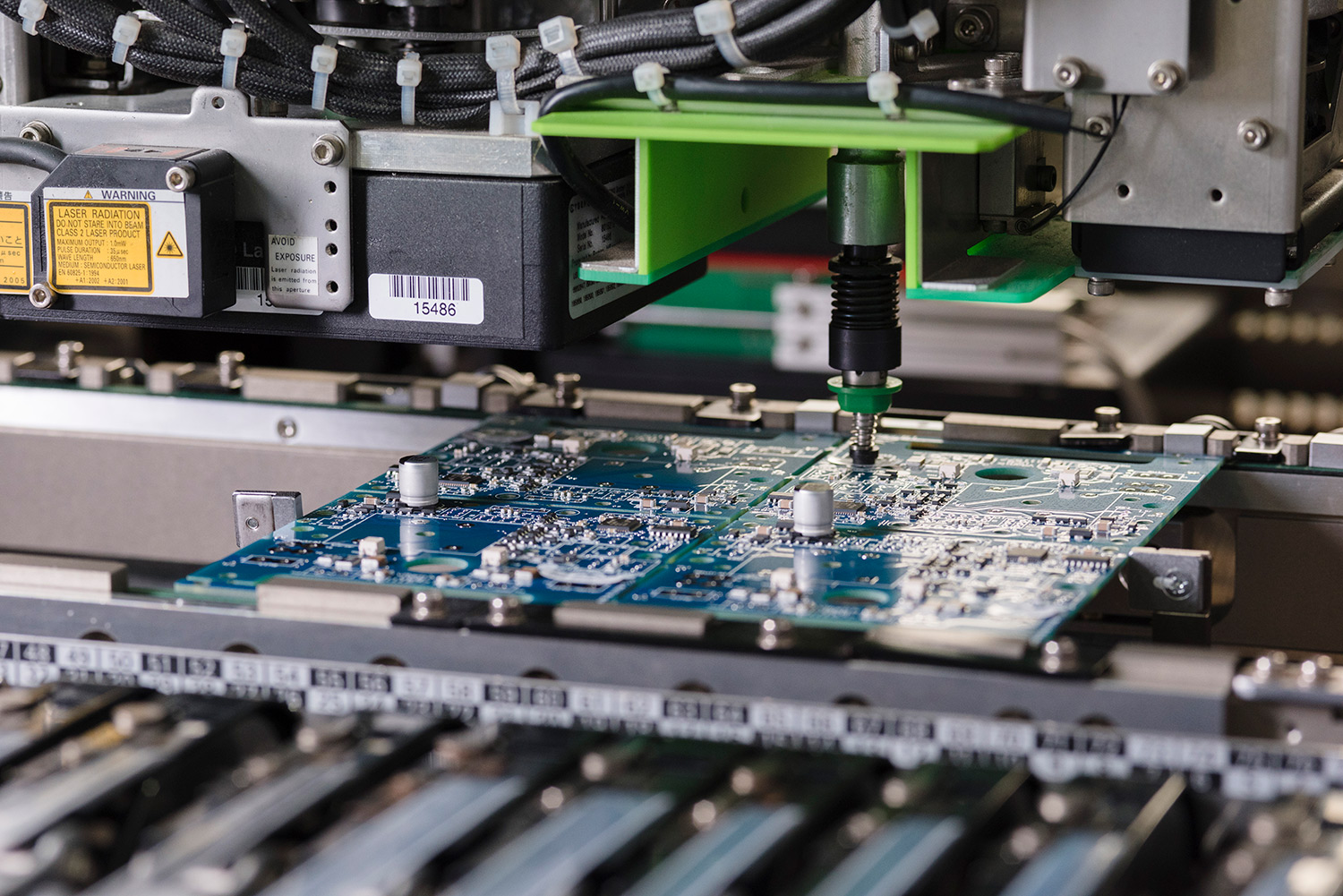

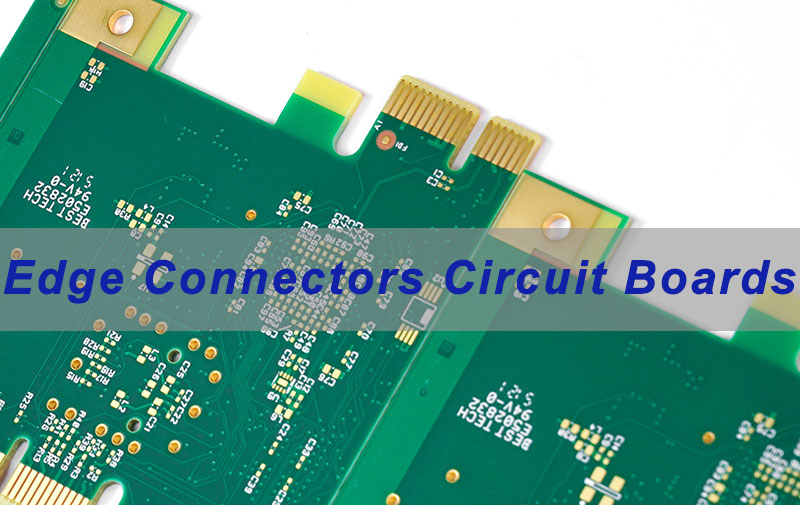

PCB Design & Prototyping Service We Can Offer You

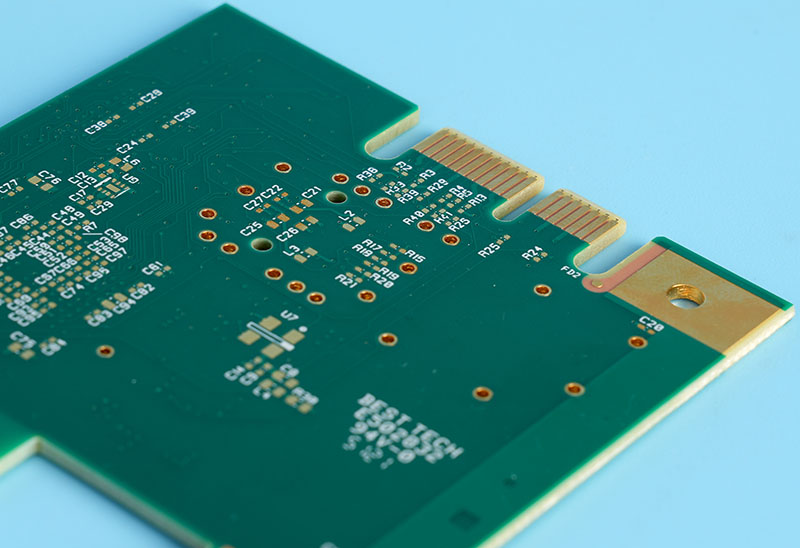

We provide high-precision Estonia PCB prototyping services tailored to local market demands, covering automotive, medical, and industrial fields. Our prototyping service supports 1-20 layer PCBs, including HDI, rigid-flex, and metal core types, with core precision parameters controlled at a minimum line width/space of 3mil/3mil and minimum hole diameter of 0.1mm, fully meeting the high-density requirements of advanced electronics in Estonia.‚Äč

Equipped with advanced flying probe testing equipment, we achieve a test coverage rate of over 90% for prototypes, ensuring performance consistency with mass production standards. Our one-stop prototyping solution integrates free DFM analysis, customized material selection, and full-functional testing, boosting design verification efficiency by 30% and maintaining a prototype yield rate of 99.5%+, helping clients accelerate project progress efficiently as a reliable PCB manufacturer in Estonia.

Lead Time for Our PCB Prototyping

| Layers | Normal Service | Fastest Service |

| 1 | 7 Days | 24 H |

| 2 | 8 Days | 24 H |

| 4 | 10 Days | 48 H |

| 6 | 10 Days | 72 H |

| 8 | 12 Days | 72 H |

| ‚Č•10 | TBD | TBD |

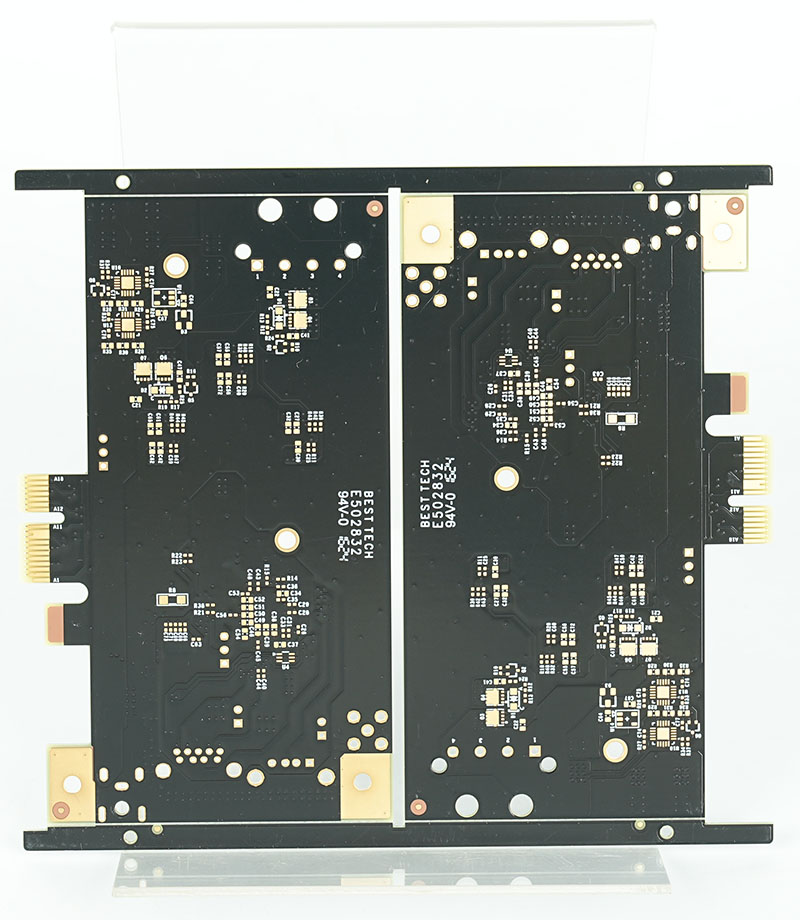

Our PCB Manufacturer Capabilities

| Item | Capabilities |

| Layer Count | 1 – 32 Layers |

| Max Board Dimension | 2424″ (610610mm) |

| Min Board Thickness | 0.15mm |

| Max Board Thickness | 6.0mm – 8.0mm |

| Copper Thickness | Outer Layer: 1oz~30oz, Inner Layer: 0.5oz~30oz |

| Min Line Width/Line Space | Normal: 4/4mil (0.10mm); HDI: 3/3mil (0.076mm) |

| Min Hole Diameter | Normal: 8mil (0.20mm); HDI: 4mil (0.10mm) |

| Min Punch Hole Dia | 0.1″ (2.5mm) |

| Min Hole Spacing | 12mil (0.3mm) |

| Min PAD Ring(Single) | 3mil (0.075mm) |

| PTH Wall Thickness | Normal: 0.59mil (15um); HDI: 0.48mil (12um) |

| Min Solder PAD Dia | Normal: 14mil (0.35mm); HDI: 10mil (0.25mm) |

| Min Soldermask Bridge | Normal: 8mil (0.2mm); HDI: 6mil (0.15mm) |

| Min BAG PAD Margin | 5mil (0.125mm) |

| PTH/NPTH Dia Tolerance | PTH: ¬Ī3mil (0.075mm); NPTH: ¬Ī2mil (0.05mm) |

| Hole Position Deviation | ¬Ī2mil (0.05mm) |

| Outline Tolerance | CNC: ¬Ī6mil (0.15mm); Die Punch: ¬Ī4mil (0.1mm); Precision Die: ¬Ī2mil (0.05mm) |

| Impedance Controlled | Value>50ohm: ¬Ī10%; Value‚ȧ50ohm: ¬Ī5ohm |

| Max Aspect Ratio | 0.334027778 |

| Surface Treatment | ENIG, Flash Gold, Hard Gold Finger, Gold Plating(50mil), Gold finger, Selected Gold plating, ENEPIG, ENIPIG; HAL, HASL(LF), OSP, Silver Immersion, Tin Immersion |

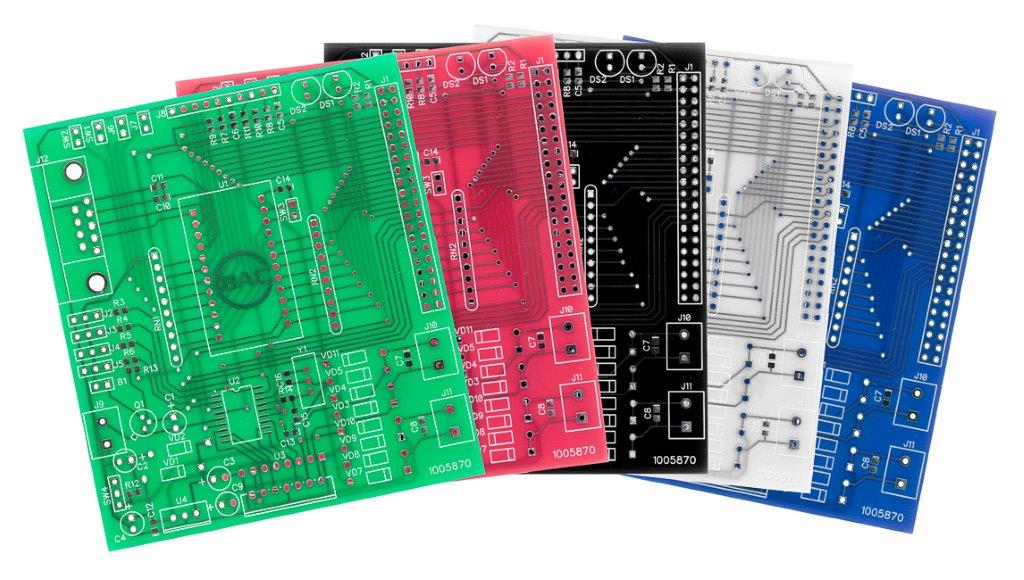

| Soldermask Color | Green/White/Black/Yellow/Blue/Red |

How to Get A Quote For Estonia PCB Manufacturing?

1. Define Technical Specifications

- Clearly outline PCB layer count, material type (e.g., FR4, polyimide), copper thickness, surface finish (ENIG, HASL), and impedance requirements.

- Include dimensional details, drilling specifications, and tolerance thresholds.

- Example: “4-layer PCB with 2oz copper, ENIG finish, and 0.15mm minimum trace/space” ensures precise cost estimation.

2. Prepare Design Files

- Submit Gerber files, BOM (Bill of Materials), and CAD files (Altium, Eagle, or KiCad).

- Attach DFM (Design for Manufacturability) reports to identify potential production issues early.

- Use standardized formats to minimize errors and accelerate quote processing.

3. Select Certified Manufacturers

- Prioritize Estonia-based PCB manufacturers with certifications like ISO9001, IATF16949 (automotive), or ISO13485 (medical).

- Verify their production capabilities (e.g., HDI, rigid-flex, metal-core PCBs) through official websites or industry directories.

- Example: Tallinn PCB Solutions O√ú offers local quick response and strict environmental controls for industrial control PCBs.

4. Request Multi-Option Quotes

- Contact 3‚Äď5 manufacturers for comparative quotes, specifying batch size (prototype/mass production) and urgency (24-hour express vs. standard lead time).

- Include shipping preferences (air/sea/land) and payment terms (Net 30, prepayment).

- Use platforms like PCB Directory or local EMS providers to streamline RFQ (Request for Quote) processes.

5. Leverage Value-Added Services

- Optimize for manufacturers offering free DFM analysis, design consultation, or rapid prototyping (e.g., 24-hour turnaround).

- Confirm their capacity for small-batch customization and scalability to large volumes.

- Example: Eesti PCB Tech O√ú provides ISO13485-certified medical PCBs with traceability systems for critical applications.

6. Evaluate Total Cost and Support

- Compare quotes based on PCB cost, assembly fees, component sourcing, and logistics.

- Assess technical support availability (24/7 engineering assistance) and post-sale services (warranty, rework policies).

- Prioritize manufacturers with transparent pricing (no hidden fees) and proven track records in on-time delivery.

Welcome to contact us if you have any request for Estonia PCB manufacturing: sales@bestpcbs.com.