Prototype PCB USA‚Äč refers to the process of designing, fabricating, and assembling printed circuit board prototypes within the United States. This article serves as a comprehensive guide for engineers and procurement managers seeking reliable, high-quality, and fast ‚ÄčPCB prototype USA‚Äč services.

Are you struggling with your ‚Äčprototype PCB USA‚Äč projects? Many engineers and product developers face significant hurdles when sourcing ‚ÄčPCB prototyping USA services. Common challenges include:

- ‚ÄčSlow turnaround times‚Äč delaying critical R&D and product launch schedules.

- ‚ÄčInconsistent quality‚Äč leading to failed tests and costly reworks.

- ‚ÄčLack of clear communication‚Äč with overseas manufacturers causing misunderstandings.

- ‚ÄčHidden costs‚Äč that inflate the project budget unexpectedly.

- ‚ÄčDifficulty in finding a partner‚Äč capable of handling both fabrication and assembly under one roof.

Fortunately, these challenges have clear solutions when you partner with an experienced domestic manufacturer. By choosing a specialized PCB prototype service USA, you can overcome these obstacles effectively:

- ‚ÄčAccelerated Production:‚Äč‚Äč Leverage streamlined processes and local logistics for truly quick-turn ‚ÄčPCB prototype USA‚Äč projects.

- ‚ÄčStringent Quality Control:‚Äč‚Äč Ensure reliability with rigorous testing protocols at every production stage.

- ‚ÄčDedicated Support:‚Äč‚Äč Benefit from direct communication with engineering and customer service teams in the same time zone.

- ‚ÄčTransparent Pricing:‚Äč‚Äč Receive detailed, upfront quotes with no surprise fees.

- ‚ÄčTurnkey Services:‚Äč‚Äč Simplify sourcing with a single provider for ‚Äčprototype PCB assembly USA, from board fabrication to component sourcing.

At EBest Circuit (Best Technology), we bring nearly two decades of specialized expertise to every project. While our manufacturing facilities are strategically located in Asia, we have extensive experience serving the U.S. market, offering a crucial blend of technical excellence and cost efficiency for ‚Äčprototype PCB USA projects. Our core strength lies in mastering complex PCB technologies‚ÄĒincluding advanced ‚ÄčPCB prototyping USA with heavy copper, HDI, and ceramic substrates‚ÄĒwhile maintaining rapid turnaround times. For a partner that combines sophisticated capabilities with responsive, value-driven service, pls feel free to contact us at ‚Äčsales@bestpcbs.com.

‚ÄčWhat is Prototype PCB USA?‚Äč‚Äč

In essence, ‚ÄčPrototype PCB USA‚Äč encompasses the entire ecosystem of designing, fabricating, and testing initial small batches of printed circuit boards within the United States. This approach is crucial for validating designs before moving to mass production. The key differentiator is the geographical location‚ÄĒall manufacturing and support activities are based stateside.

This offers distinct advantages, particularly for projects requiring rapid iteration, stringent intellectual property (IP) protection, and close collaboration between the design team and the manufacturer. Whether you need a simple ‚ÄčPCB prototype in USA‚Äč or a complex ‚Äčprototype PCB assembly USA, domestic production streamlines the process significantly.

‚ÄčWhat Are the Advantages of PCB Prototype Service USA?‚Äč‚Äč

Choosing a domestic ‚ÄčPCB prototype service USA provides numerous benefits that directly impact project efficiency, cost, and success.

- ‚ÄčSpeed and Agility:‚Äč‚Äč Local production eliminates long international shipping times. Coupled with ‚Äčquick turn PCB USA‚Äč ‚Äč capabilities, this allows for faster design validation and a shorter overall product development cycle.

- ‚ÄčEnhanced Communication:‚Äč‚Äč Working within the same or similar time zones facilitates real-time communication. This minimizes delays in resolving design queries and production issues, a common hurdle with overseas partners.

- ‚ÄčIP Protection and Security:‚Äč‚Äč The USA has robust intellectual property laws. Manufacturing your ‚Äčprototype PCB manufacturing USA domestically offers greater legal recourse regarding the security of your proprietary designs.

- ‚ÄčSupply Chain Reliability:‚Äč‚Äč Domestic manufacturers often have more resilient and transparent supply chains, reducing the risk of disruptions that can affect component availability for ‚Äčprototype PCB assembly USA.

- ‚ÄčSuperior Quality Standards:‚Äč‚Äč Many ‚Äčtop PCB manufacturers in USA‚Äč adhere to stringent quality certifications (e.g., ISO, UL, ITAR), ensuring that your prototypes meet high-reliability standards required for demanding industries like aerospace, medical, and defense.

‚ÄčHow to Select Prototype PCB Manufacturer USA?‚Äč‚Äč

Selecting the right ‚Äčprototype PCB manufacturer USA‚Äč is a critical decision. Here‚Äôs a structured approach:

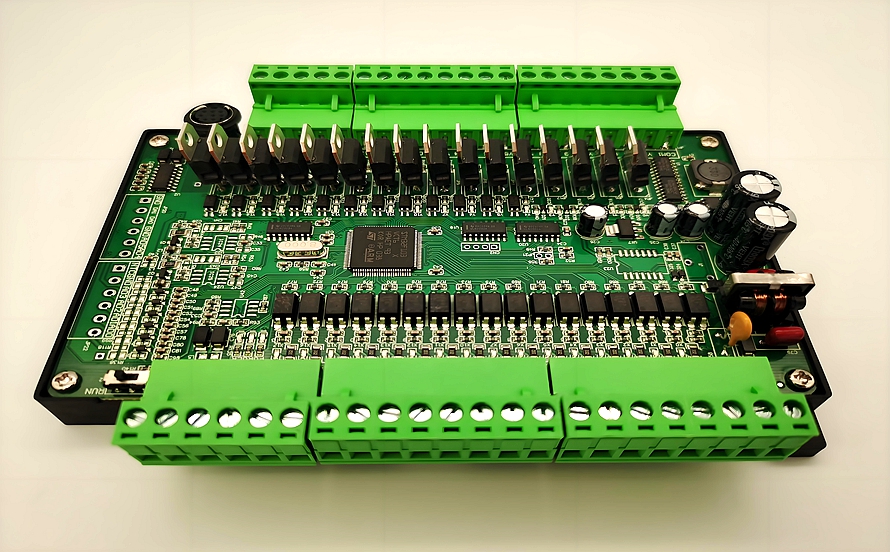

- ‚ÄčAssess Technical Capabilities:‚Äč‚Äč Ensure the manufacturer can handle your specific requirements‚ÄĒboard type, layer count, materials, and technologies like HDI or impedance control.

- ‚ÄčEvaluate Turnaround Times:‚Äč‚Äč Inquire about standard and expedited lead times for both ‚Äčprototype PCB fabrication‚Äč and assembly. A true partner for ‚Äčquick turn PCB USA‚Äč ‚Äč projects will offer flexible options.

- ‚ÄčCheck Certifications and Quality Systems:‚Äč‚Äč Look for relevant certifications (discussed next) that validate their commitment to quality and industry standards.

- ‚ÄčReview Customer Support:‚Äč‚Äč The quality of pre-sales and technical support is indicative of the partnership experience. Responsive, knowledgeable support is invaluable.

- ‚ÄčAnalyze Cost Structure:‚Äč‚Äč While seeking ‚Äčcheap PCB prototype USA services is understandable, prioritize value over the lowest price. Consider the total cost of ownership, including quality, reliability, and potential delays.

‚ÄčTop 10 PCB Prototype Manufacturer USA‚Äč

The demand for rapid, high-quality PCB prototypes is critical for innovation in the American electronics industry. While many companies source prototypes globally, partnering with a US-based manufacturer offers distinct advantages, including faster shipping, seamless communication, and stronger intellectual property (IP) protection. This outline details ten of the leading PCB prototype manufacturers operating within the United States, highlighting their unique strengths and specializations to help you make an informed sourcing decision.

‚Äč1. Advanced Circuits (PCBONLINE)‚Äč‚Äč

A well-established leader known for its user-friendly online quoting and ordering system. They are a go-to for hobbyists, engineers, and large companies needing reliable, quick-turn prototypes with no minimum order quantity.

‚Äč2. Sunstone Circuits‚Äč

Another major player with a strong focus on prototype and small-volume production. They are praised for their robust online design rule checks (DRC) and customer service, making them ideal for quick iterations and design validation.

‚Äč3. San Francisco Circuits (SFC)‚Äč‚Äč

Specializes in advanced, high-tech PCBs, including HDI, rigid-flex, and high-layer count boards. They cater to demanding industries like aerospace, medical, and military, offering high-mix, low-volume engineering support.

‚Äč4. Imagineering, Inc.‚Äč‚Äč

A competitive prototype specialist known for fast turnaround times and excellent customer support. They are a popular choice for standard to moderately complex multi-layer prototypes that need to be delivered quickly.

‚Äč5. Royal Circuits‚Äč

A manufacturer that bridges the gap between prototyping and mid-volume production. They excel in complex designs, including heavy copper and advanced materials, and are known for their technical expertise and quality.

‚Äč6. Accu-Tech Corporation‚Äč

Focuses on quick-turn prototypes and on-demand production. They offer a full range of services, including assembly, and are known for their responsiveness and ability to handle urgent orders effectively.

‚Äč7. PCB Universe‚Äč

A reliable source for fast and affordable prototype PCBs, particularly for standard FR4 boards. They offer a straightforward online ordering process suitable for less complex projects and educational purposes.

‚Äč8. Axiom Electronics‚Äč

Specializes in complex assembly and box-build services alongside PCB fabrication. They are a strong choice for prototypes that require full turnkey assembly and functional testing.

‚Äč9. Heartland Technology Systems‚Äč

A smaller, service-oriented manufacturer known for personalized support. They are a good option for projects requiring direct engineer-to-engineer communication and custom solutions.

‚Äč10. PCB-POOL‚Äč

A service of Advanced Circuits, PCB-POOL is tailored for the European and North American markets, offering a streamlined process for prototype orders with a focus on accessibility for individual engineers and small businesses.

In essence, selecting the right PCB prototype partner in the USA depends heavily on your project’s specific requirements for complexity, speed, volume, and budget. The manufacturers listed here represent a spectrum of capabilities, from highly automated online services ideal for standard boards to specialized engineering firms tackling the most advanced technologies. By evaluating their core strengths against your design’s needs, you can form a productive partnership that accelerates your product from concept to reality. For projects where cost is the primary driver and lead time is flexible, overseas manufacturers like EBest Circuit (Best Technology) (as discussed previously) remain a compelling alternative.

‚ÄčWhat Certifications Are Required to Support the Prototype PCB Manufacturing USA Projects?‚Äč‚Äč

Certifications are a benchmark of a manufacturer’s commitment to quality and reliability. For ‚Äčprototype PCB manufacturing USA projects, key certifications include:

- ‚ÄčISO 9001:‚Äč‚Äč The international standard for Quality Management Systems, ensuring consistent quality.

- ‚ÄčUL Certification:‚Äč‚Äč Underwriters Laboratories certification, often required for safety-critical products.

- ‚ÄčAS9100:‚Äč‚Äč The quality management standard for the aerospace industry, denoting extreme rigor.

- ‚ÄčITAR Registration:‚Äč‚Äč Essential if your project involves defense or military-related data; it ensures compliance with U.S. export control laws.

- ‚ÄčIPC Standards:‚Äč‚Äč Adherence to IPC standards (e.g., IPC-A-600 for acceptability of printed boards) is a baseline for quality workmanship.

A manufacturer holding these certifications demonstrates the capability to handle the ‚Äčmost reliable PCB prototyping components in USA‚Äč and deliver products that meet the highest industry benchmarks.

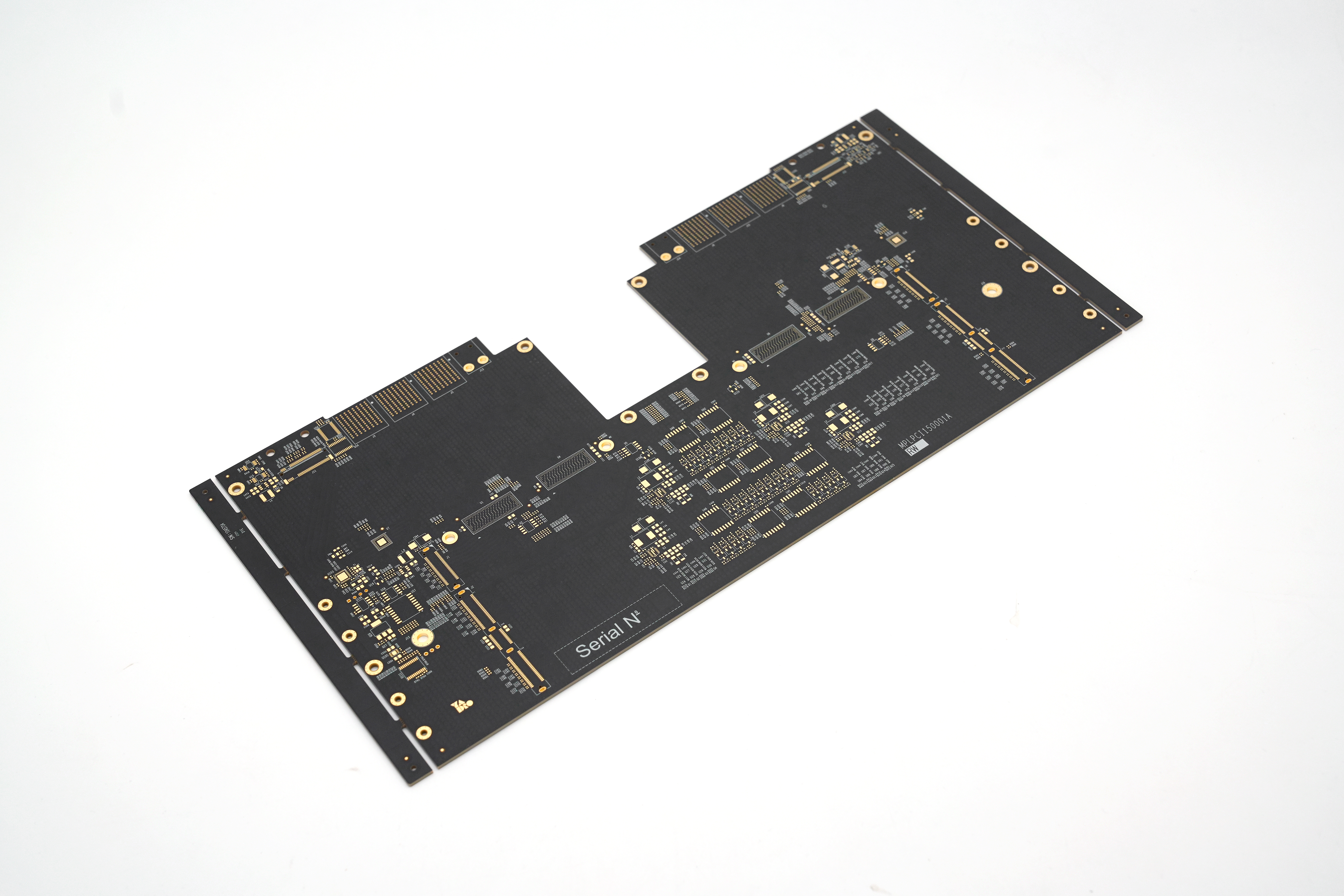

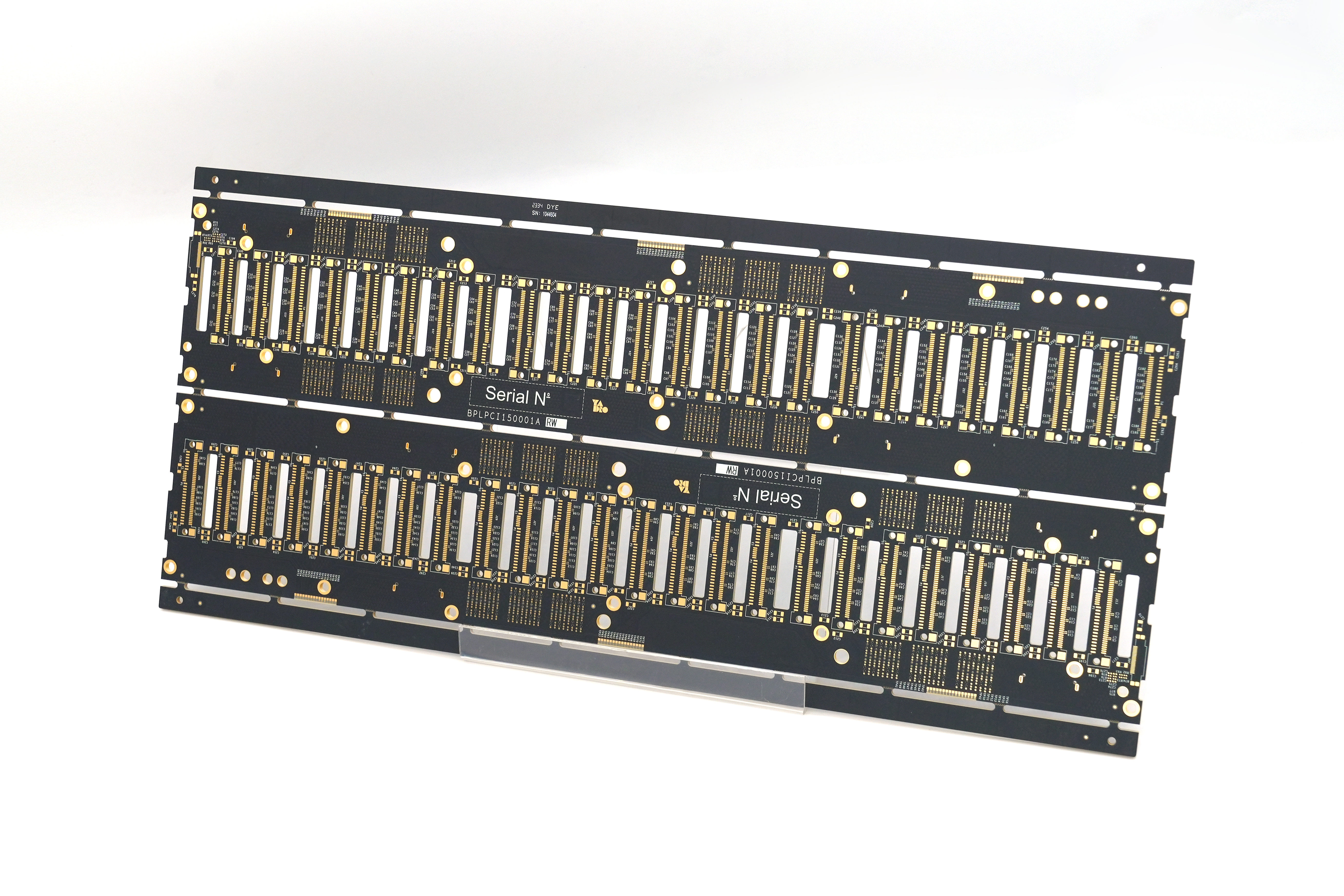

‚ÄčCase Study: Real PCB Prototyping USA Solutions by EBest Circuit (Best Technology)‚Äč

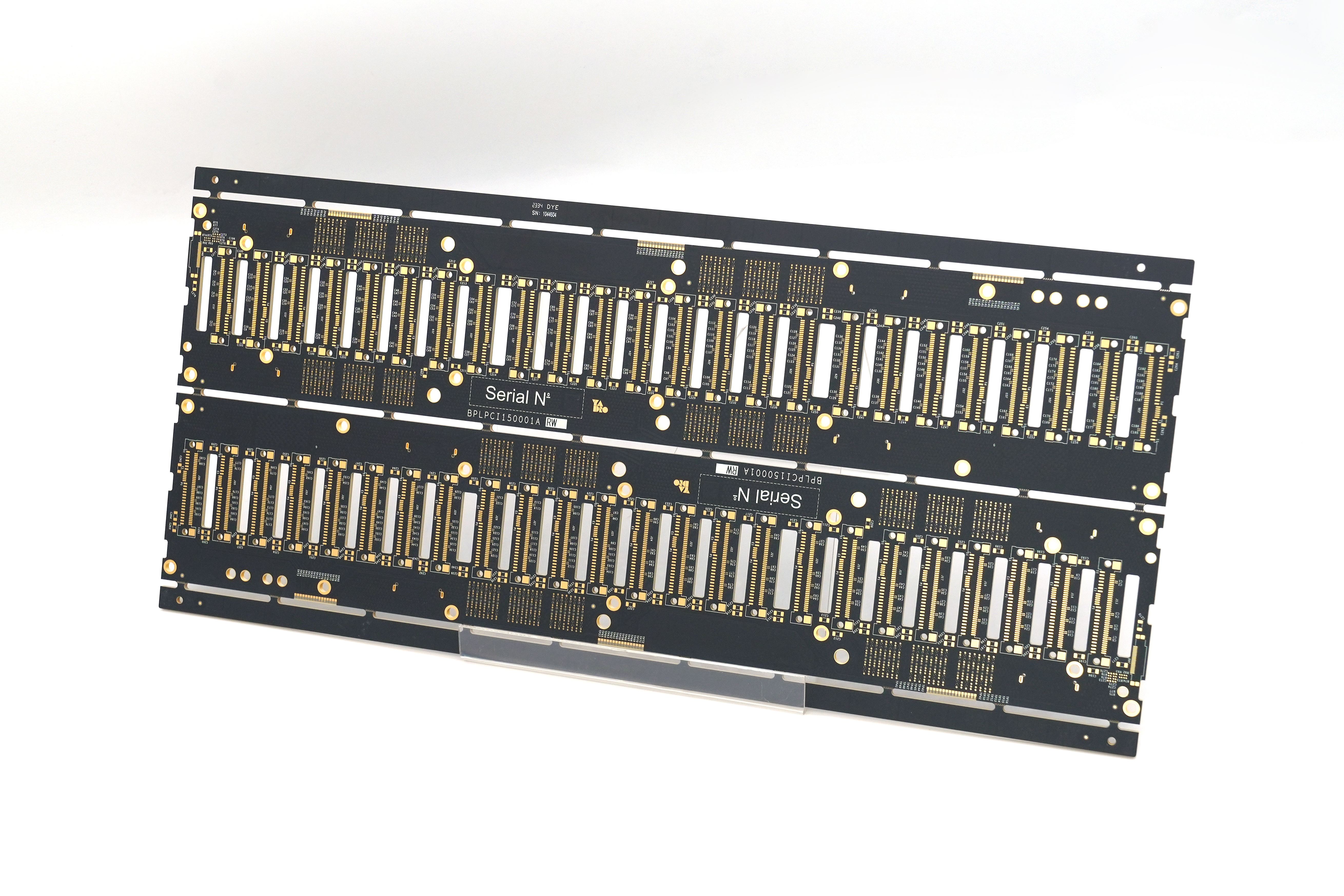

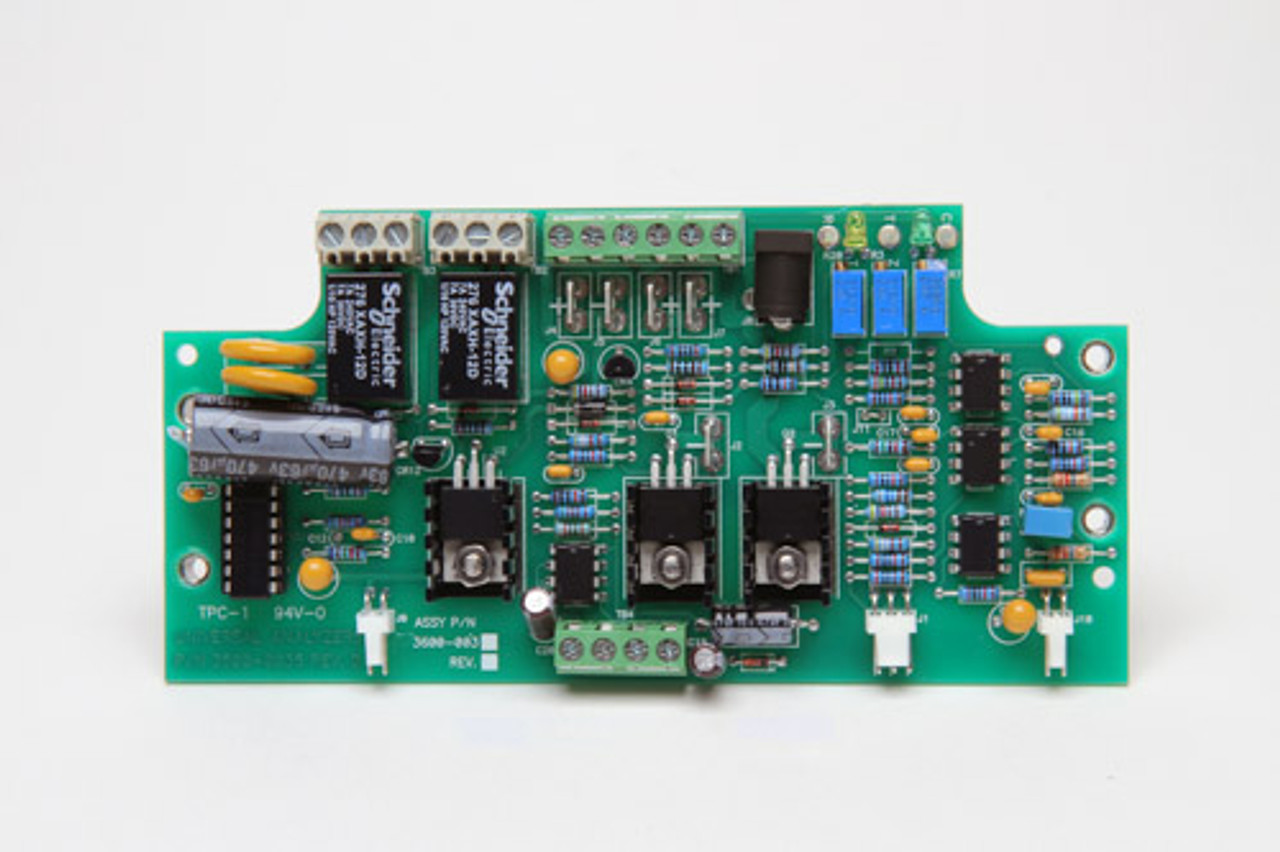

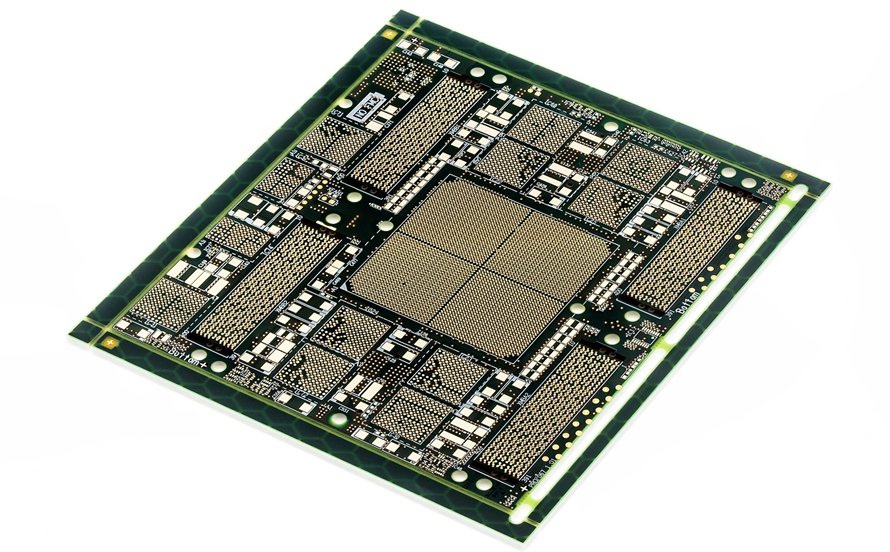

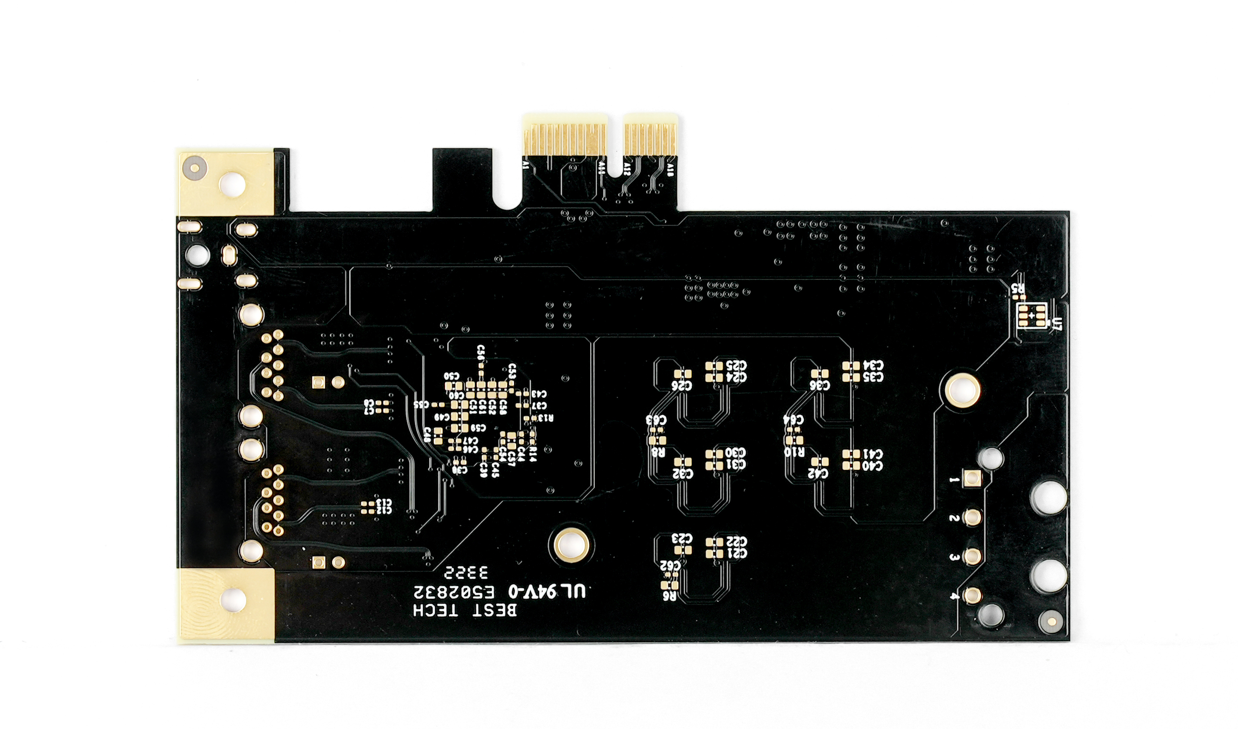

This high-reliability, heavy-copper PCB prototype is engineered for applications where performance, durability, and safety under demanding conditions are non-negotiable. Its robust specifications make it an ideal solution across a diverse range of advanced industries:

- ‚ÄčIndustrial Automation & Motor Drives:‚Äč‚Äč The board’s 3OZ copper thickness and high thermal endurance (TG170) are critical for controlling high-power motors and drives. It can efficiently manage significant current loads and dissipate heat generated in harsh factory environments, ensuring stable operation of programmable logic controllers (PLCs) and industrial servo drives.

- ‚ÄčAutomotive Electronics (BMS & OBC):‚Äč‚Äč In the automotive sector, this PCB is perfectly suited for Battery Management Systems (BMS) and On-Board Chargers (OBC). Its compliance with stringent automotive-grade standards (UL, IPC Class 2) guarantees the longevity and reliability required for safety-critical vehicle components that experience wide temperature variations and vibrations.

- ‚ÄčRenewable Energy Systems (Solar & Wind Inverters):‚Äč‚Äč For power conversion and management in solar inverters or wind turbine controllers, the heavy copper construction allows for efficient power handling with minimal losses. The robust construction and comprehensive testing reports ensure long-term reliability in outdoor and fluctuating power conditions.

- ‚ÄčMedical Equipment (Imaging & Diagnostic Systems):‚Äč‚Äč High-end medical devices, such as portable imaging systems or diagnostic monitors, require PCBs that are extremely reliable and produce clean signals. The 6-layer design provides excellent EMI suppression, while the ENIG finish ensures a flat, reliable surface for fine-pitch components, critical for patient safety and equipment accuracy.

- ‚ÄčTelecommunications Infrastructure (Base Station Power Supplies):‚Äč‚Äč This PCB can be used in the power supply units of telecommunications base stations, where it must handle high currents and maintain signal integrity. The TG170 material and thick copper ensure stability under continuous operation, which is vital for maintaining network uptime.

‚ÄčPCB Parameters & Specifications‚Äč

- ‚ÄčProduct Type:‚Äč‚Äč 6-Layer FR4 PCB

- ‚ÄčBoard Thickness:‚Äč‚Äč 2.06mm +/-10%

- ‚ÄčGlass Transition Temperature (Tg):‚Äč‚Äč 170¬įC

- ‚ÄčCopper Thickness (Inner/Outer Layers):‚Äč‚Äč 3 OZ

- ‚ÄčSurface Finish:‚Äč‚Äč ENIG (Electroless Nickel Immersion Gold), Gold Thickness 1U”

- ‚ÄčSolder Mask & Silkscreen:‚Äč‚Äč Green Solder Mask, White Silkscreen

- ‚ÄčCompliance Standards:‚Äč‚Äč UL, RoHS, IPC-6012 Class 2

- ‚ÄčQuality Assurance Documentation:‚Äč‚Äč COC (Certificate of Conformity), Cross-Section Report, Electrical Test Report, Solderability Test Report, Copper Thickness Report

- ‚ÄčFinal Testing:‚Äč‚Äč 100% Continuity Testing (Electrical Test)

‚ÄčWhy EBest Circuit (Best Technology) Is the Premier Partner for USA PCB Prototype Projects?‚Äč‚Äč

EBest Circuit (Best Technology) stands out as a premier PCB prototype partner for USA-based projects by combining nearly two decades of manufacturing expertise with a robust, customer-centric approach. Their comprehensive turnkey solutions, stringent quality controls, and agile production capabilities are tailored to meet the demanding standards and fast-paced requirements of American clients, ensuring reliability and excellence from concept to delivery.

‚Äč1. Extensive Experience and Specialized Expertise‚Äč

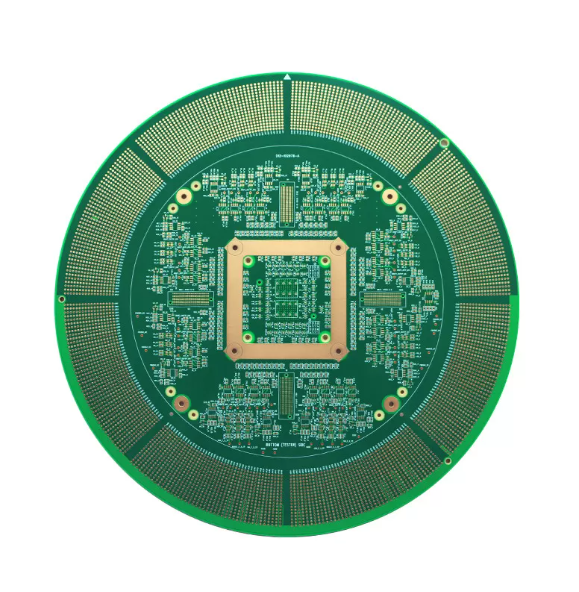

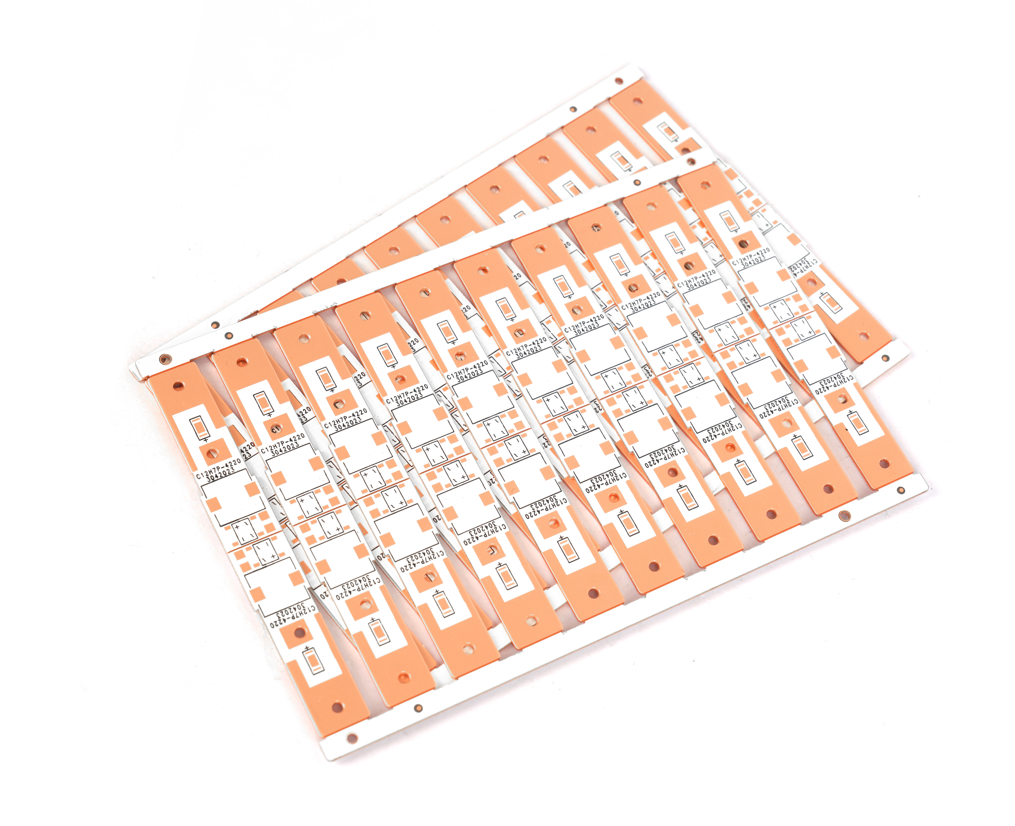

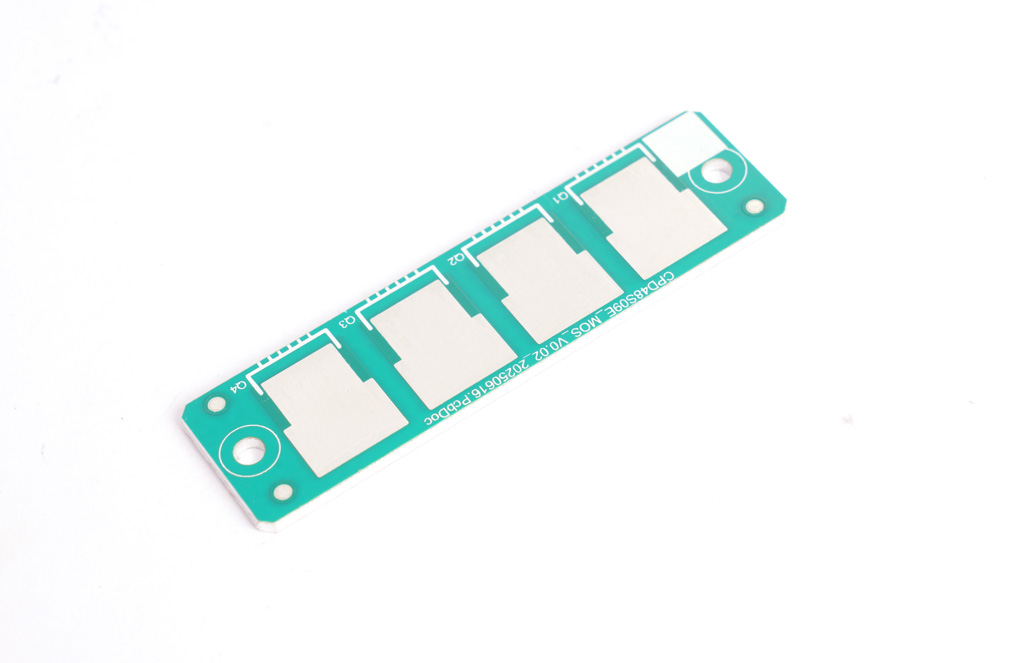

With over 19 years of focused PCB manufacturing experience, EBest Circuit (Best Technology) has deep expertise in advanced PCB types like Metal Core (MCPCB), Ceramic, FR4, and specialized boards (e.g., heavy copper up to 20 oz). This knowledge ensures that even complex prototype requirements are handled with precision, reducing risks for USA clients innovating in sectors like aerospace, automotive, or telecommunications.

‚Äč2. Rapid Prototyping and Flexible Lead Times‚Äč

The company offers exceptionally fast prototype turnaround‚ÄĒas quick as 24 hours for 1‚Äď2 layer FR4 PCBs and 48‚Äď72 hours for multilayered designs. Such speed is critical for USA projects with tight R&D cycles, allowing designers to test and iterate rapidly without compromising on quality.

‚Äč3. Rigorous Quality Assurance and Certifications‚Äč

EBest Circuit (Best Technology) adheres to international quality standards, including ISO 9001, ISO 13485, IATF 16949, AS9100D. Their quality control spans every production stage, from material sourcing to final testing, using advanced equipment like X-ray thickness testers and automated optical inspection. This commitment guarantees prototypes that meet stringent U.S. regulatory and performance expectations.

‚Äč4. One-Stop Turnkey Solution‚Äč

From PCB design, component sourcing, and assembly to full box-build integration, EBest Circuit (Best Technology) provides end-to-end services. This simplifies the supply chain for American customers, reducing coordination overhead and ensuring seamless project management under a single, accountable partner.

‚Äč5. No Minimum Order Quantities (MOQ)‚Äč‚Äč

The company offers cost-effective prototyping with no MOQ restrictions, enabling USA clients to order small batches economically. By optimizing production processes, they deliver high value without sacrificing quality‚ÄĒkey for startups and enterprises managing budget constraints.

‚Äč6. Dedicated Communication and Customer Support‚Äč

EBest Circuit (Best Technology) emphasizes personalized support with one-on-one sales engineering and 24-hour online assistance. Their responsiveness (e.g., replying within 12 hours) and English-friendly services bridge geographical and cultural gaps, ensuring smooth collaboration across time zones.

‚ÄčIn brief, EBest Circuit (Best Technology)‚Äôs blend of technical proficiency, speed, quality assurance, and comprehensive service makes them an ideal PCB prototype partner for USA projects. By aligning their capabilities with the needs of dynamic American markets, they empower innovation while ensuring reliability, efficiency, and competitive advantage.

‚ÄčAll in all, prototype PCB USA‚Äč is a strategic approach to product development that prioritizes speed, quality, and collaboration. This guide has outlined the key considerations for engaging in successful PCB prototyping USA projects. For engineers and businesses that cannot afford delays or compromises, partnering with a certified and capable domestic manufacturer is essential. For your next ‚Äčquick turn PCB USA‚Äč project, just feel free to contact EBest Circuit (Best Technology) at ‚Äčsales@bestpcbs.com.