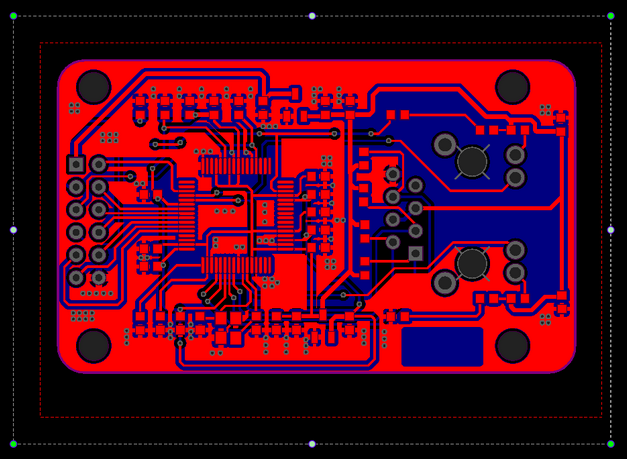

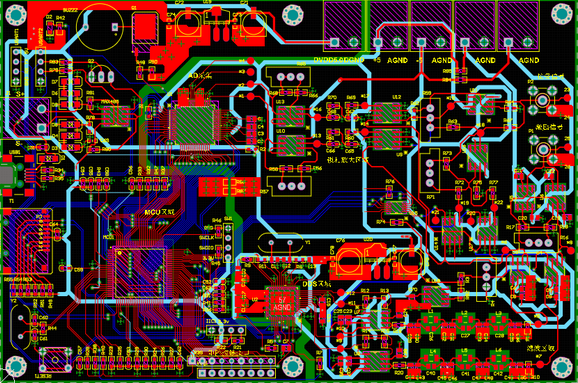

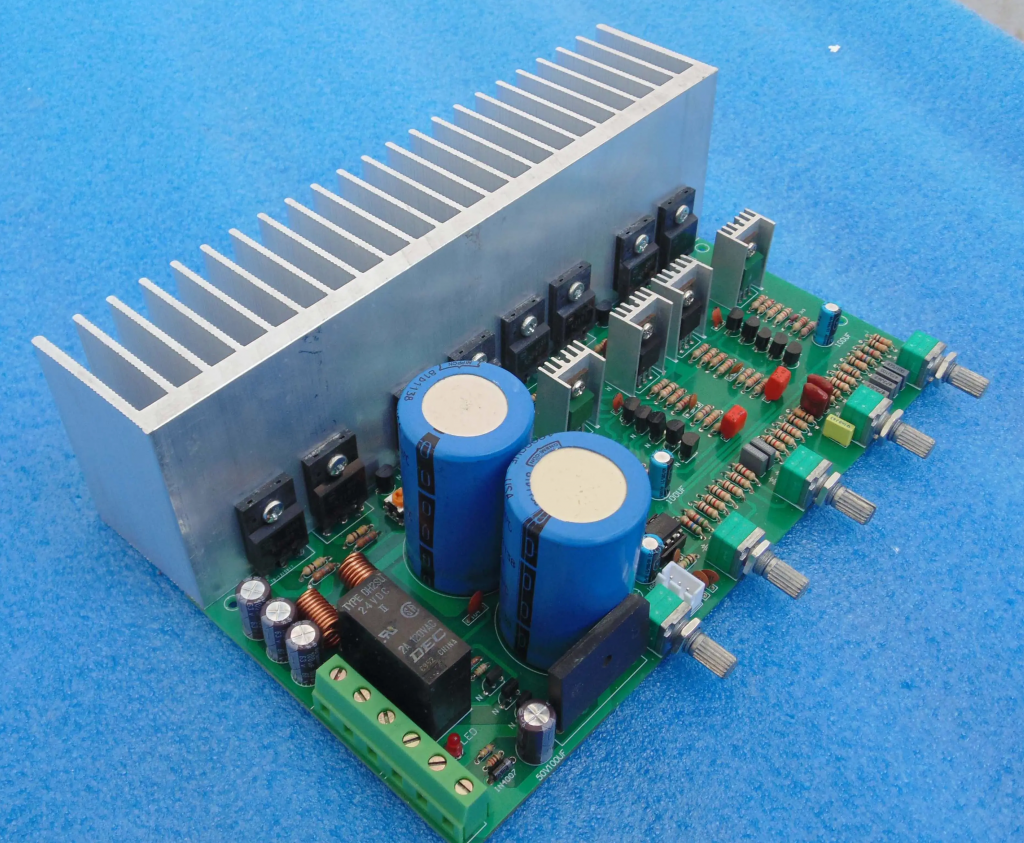

A power amplifier board is a circuit board specially designed to enhance audio signals. It is the core component of the audio system, which can enhance weak signals to a level that can effectively power speakers or other output devices. In modern audio equipment, the existence of power amplifier boards is indispensable.

What is an amplifier board?

The amplifier board is an important part of the amplifier, which is mainly responsible for the power amplification function, that is, converting low-level signals into high-level signals to drive the speakers to produce loud and clear sounds.

The amplifier board is usually composed of a power amplifier device and a speaker protection device, and its effect directly affects the performance of the entire amplifier.

The difference between the amplifier board and the amplifier is that the amplifier usually contains a preamplifier, a post-amplifier and an output stage, etc., and is a complete unit suitable for larger occasions such as KTV rooms and theaters.

The amplifier board mainly contains a post-amplifier and an output stage, lacks a preamplifier, is smaller in size, has lower power, and is more suitable for personal use, such as home theaters. In addition, the price of the amplifier is higher, while the price of the amplifier board is relatively cheap.

What does an amplifier board do?

The main function of the amplifier board is to amplify the sound signal and increase the power of the audio signal, so that the sound is clearer and louder. â

The amplifier board plays a vital role in audio equipment. It is mainly responsible for converting the power of audio signals so that higher sound output can be produced in a relatively small space.

In the audio circuit, the role of the amplifier board is particularly obvious. It works together with components such as preamplifiers, control amplifiers, power amplifiers and speakers to amplify the input audio signals through the amplifier board and convert them into clear and high-fidelity sounds, achieving high-quality performance of the audio.

In addition, the use of amplifier boards can make audio equipment more powerful, not only providing more beautiful sound effects, but also better protecting the stability of the audio equipment itself. Therefore, amplifier boards are widely used as important components in the production of audio equipment.

In summary, the amplifier board amplifies the power of the audio signal, allowing the audio equipment to output higher quality and louder sound, thereby enhancing the listening experience. Whether it is a professional audio or a home theater system, the amplifier board is an indispensable componentâ.

How does an amplifier board work?

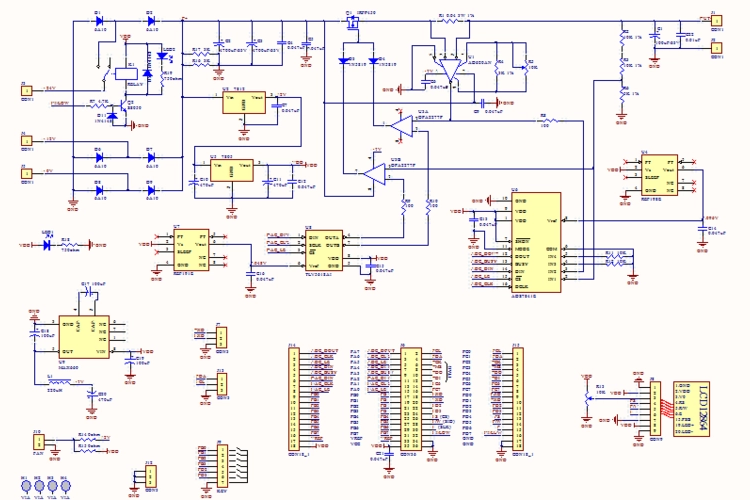

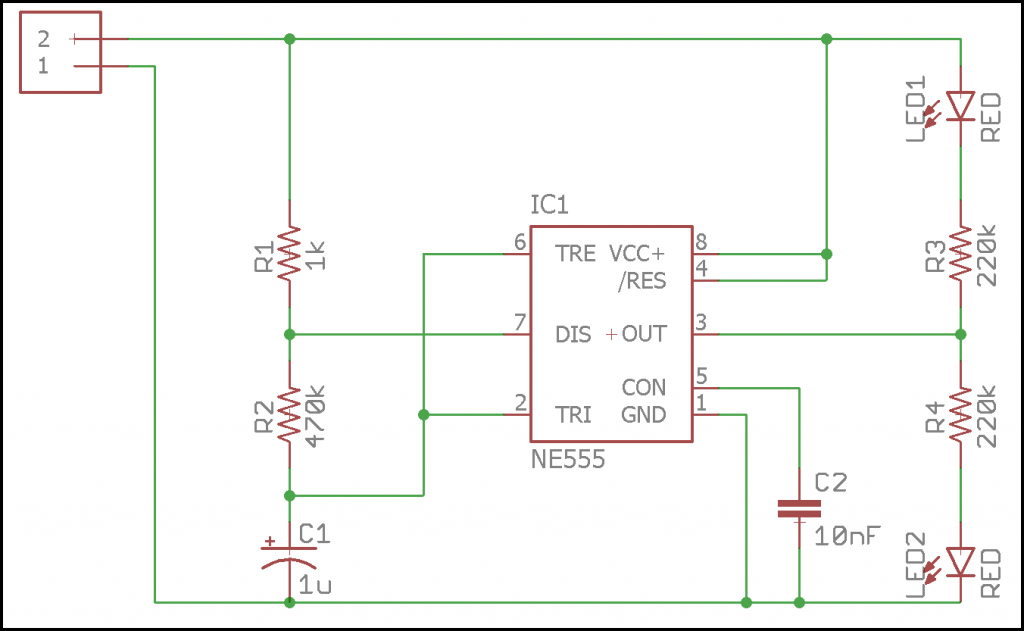

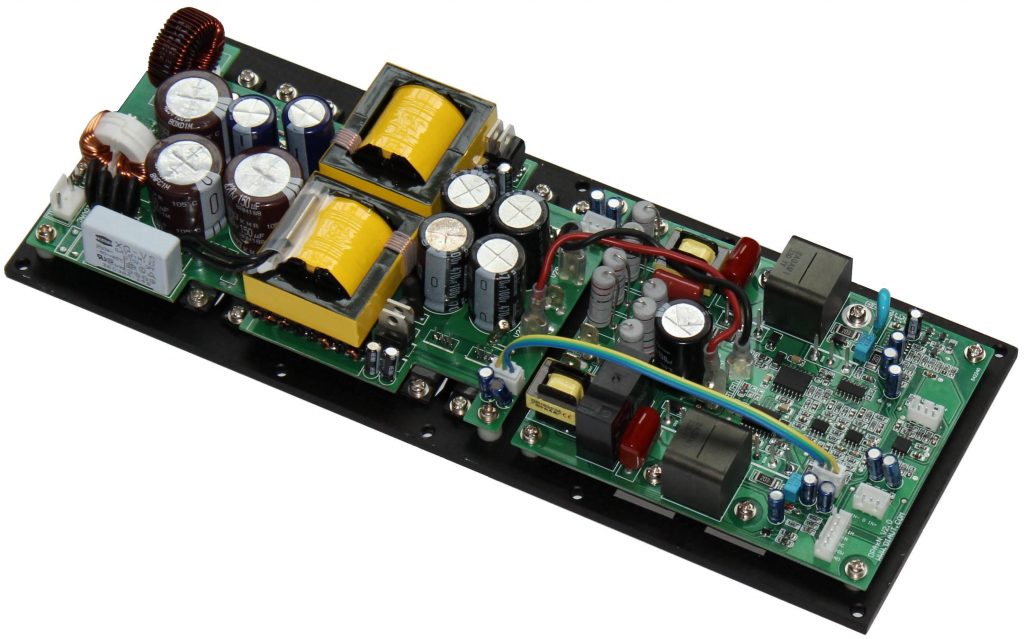

The working principle of the amplifier board is mainly based on the principles of electronic engineering and physics. Through the combination of amplifiers and power supplies, the input signal is amplified and output to the speaker. â

The core component of the power amplifier board is the amplifier, which has many types, such as voltage amplifier, current amplifier, damping amplifier, etc. Each type of amplifier has different amplification effects and signal transmission methods.

When the input signal is transmitted to the power amplifier board through the amplifier, the energy supplied by the power supply makes the level of the output signal greater than the input signal level, thereby playing the role of amplifying the signal. In this process, the power supply provides energy to the amplifier in the form of direct current to control the waveform and frequency of the output signal.

From a technical point of view, the power amplifier board is like a current modulator, which converts alternating current into direct current, and then is controlled by the sound signal played by the sound source to transmit currents of different sizes to the speakers at different frequencies, so that the speakers emit sounds of corresponding sizes and frequencies.

The working modes of the power amplifier include Class A power amplifier, Class B power amplifier and Class AB power amplifier, each type has its own characteristics and applicable scenarios.

In short, the working principle of the power amplifier board involves the interaction of multiple physical and electronic engineering principles. Through carefully designed circuits and components, the input audio signal is amplified and output to the speaker, thereby producing the sound we hearâ.

What are the different types of amplifier boards?

There are four main types of amplifier boards: Class A, Class B, Class AB, and Class D. â

1. Class A amplifier:

Class A amplifiers are amplifiers in which no power output element of the amplifier will experience current cutoff (i.e. stop output) during the entire cycle of the signal. This type of amplifier generates high heat when working and has very low efficiency, but the inherent advantage is that there is no crossover distortion.

Class A amplifiers have the best linearity and almost no distortion, so they can provide high-quality audio amplification with pure and realistic sound quality. However, due to low efficiency, Class A amplifiers have high body temperatures and require good heat dissipation design.

2. Class B amplifiers:

Class B amplifiers work completely differently from Class A amplifiers. In Class B amplifiers, the positive and negative channels of the transistors are usually in a closed state unless there is a signal input. This means that when there is no signal input, the output transistors do not conduct electricity and consume no power.

When there is a signal, each pair of output tubes amplifies half of the waveform, and takes turns to complete a full-wave amplification, thus generating crossover distortion. The advantage of Class B amplifiers is high efficiency, but the sound begins to distort when the signal is very low, and the sound becomes rough.

3. Class AB amplifiers:

Class AB amplifiers combine the characteristics of Class A and Class B. They use Class A when the signal is small, and gradually transition to Class B working mode as the signal increases. This method aims to balance the high fidelity of Class A with the high efficiency of Class B, reduce crossover distortion, and improve efficiency.

4. Class D amplifiers:

Class D amplifiers are high-efficiency amplifiers that achieve high-efficiency conversion through high-frequency pulse width modulation technology. The design of Class D amplifiers makes it consume almost no power when there is no signal input, and when there is a signal input, it amplifies the signal through high-frequency switching, thereby achieving high-efficiency energy conversion.

The advantage of Class D amplifiers is extremely high efficiency, but the design is relatively complex and requires precise control circuits to ensure sound quality.

In summary, different types of amplifiers have their own characteristics in terms of efficiency, sound quality, application scenarios, etc. Choosing the right type of amplifier depends on specific application requirements and personal preferences.

What are the disadvantages of amplifier board?

The disadvantages of amplifier boards mainly include high power consumption, high cost, high distortion, severe digital flavor, and cold sound. â

1. High power consumption and high cost:

Due to its working mode, Class A amplifiers have the problems of high power consumption and high cost. This type of amplifier performs well in bass performance and distortion control, but the corresponding energy consumption and cost investment are also high.

2. High distortion:

Digital amplifiers may generate noise and nonlinear distortion during digital conversion, which will affect the sound quality. In addition, digital amplifiers have high requirements for power supply noise processing, and the cost of the whole machine is relatively high, especially compared with traditional analog amplifiers.

3. Severe digital flavor and cold sound:

Digital amplifiers may be considered to have a serious digital flavor in sound quality, and the sound is cold and not warm enough, which may not meet the hearing preferences of all users.

In summary, different types of power amplifier boards have their own advantages and disadvantages, and the choice needs to be weighed according to personal needs and preferences.

What is the difference between a power amplifier and an amplifier board?

A power amplifier is an electronic device designed to amplify the power of an input signal to drive a load (such as a speaker, antenna, etc.). It is a key component in audio systems, radio communication equipment, etc.

A power amplifier board generally refers to a circuit board or module used to assemble or apply a power amplifier. It contains all the components and circuit designs required for a power amplifier. An amplifier board can be a stand-alone circuit board for integration into a larger system or for DIY projects.

Conclusion:

Amplifier boards are an indispensable component in modern audio systems, providing the necessary amplification to ensure clear and powerful sound. Whether you are looking for high efficiency, excellent sound quality, or both, there is an amplifier board that suits your needs.