We all know that both Prepreg (PP) and CORE are important parts for the printed circuits board. And they are also very common on the PCB structure.

But what exactly they are? Whatââ¬â¢s the difference of a PP and Core for a FR4 PCB?

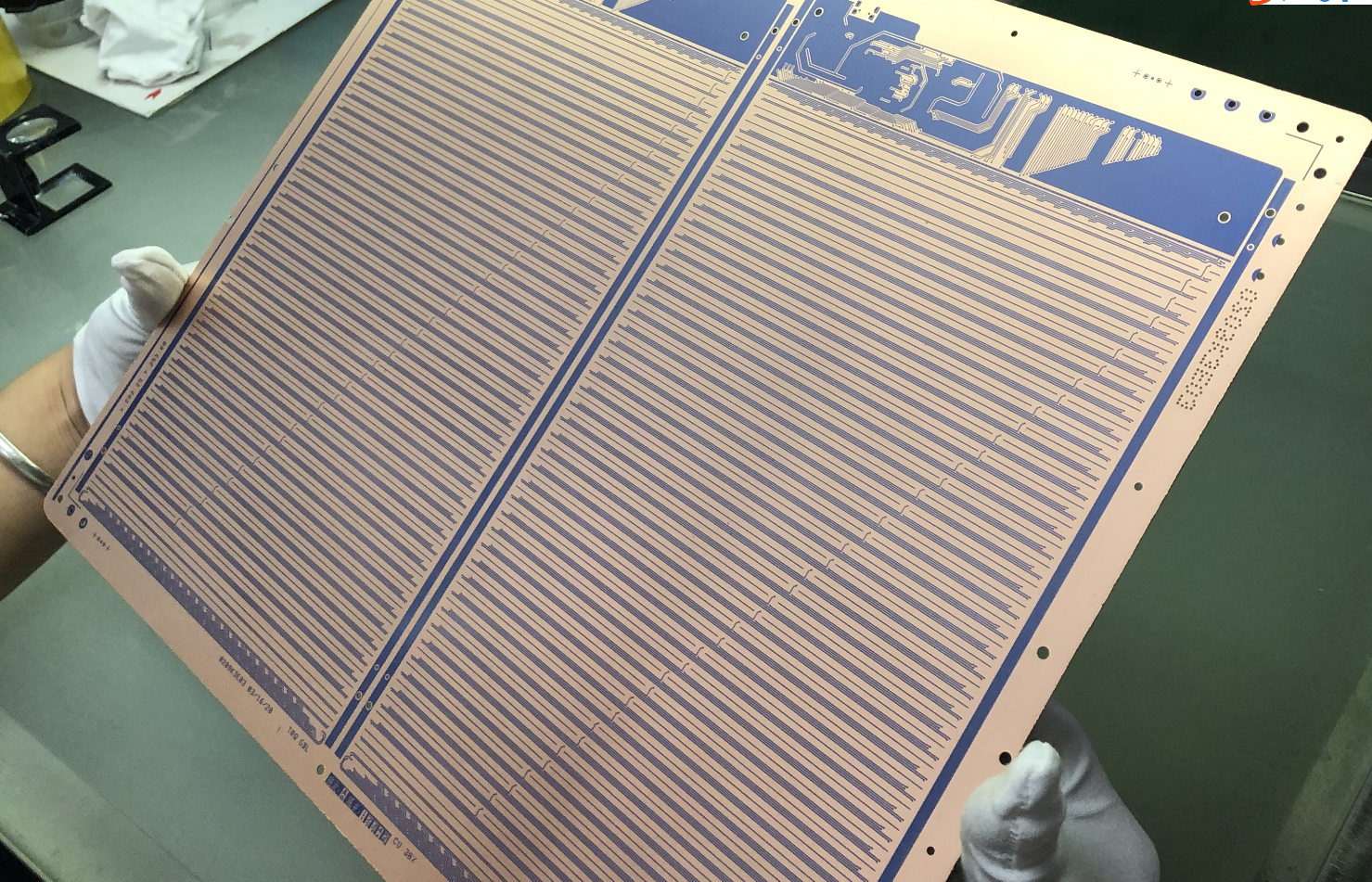

Prepreg, referred to as PP, it is a sheet material impregnated with resin and cured to an intermediate level (B-stage), known an insulating material for the PCB board.

As a prepreg material while the PCB production process, before lamination, it is mainly used as an adhesive material and insulating material for the inner conductive pattern of a multilayer PCB.

After the Prepreg is laminated, the semi-cured epoxy resin is squeezed away, starts to flow and solidify, bonding the multilayer circuit boards together, and forming a reliable insulator.

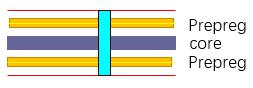

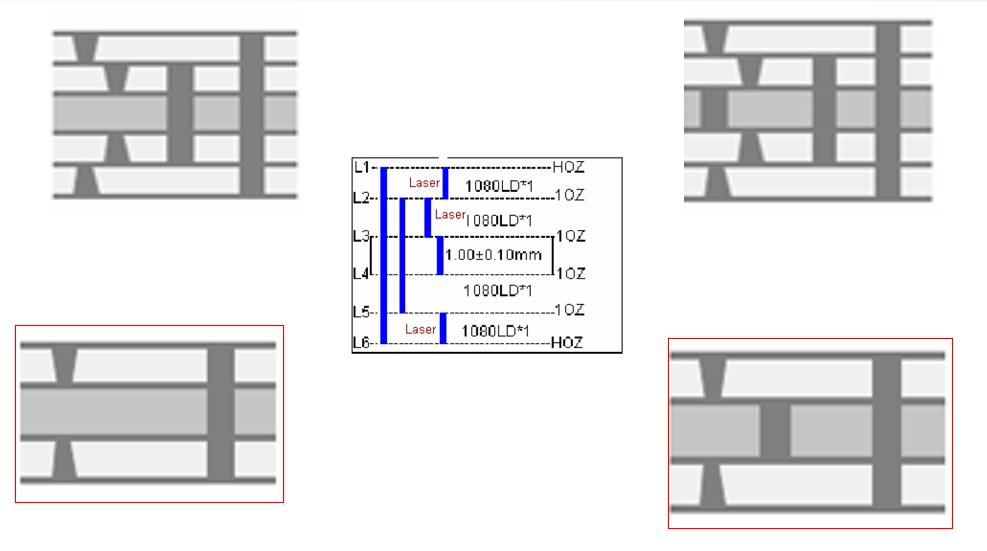

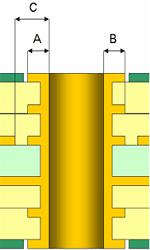

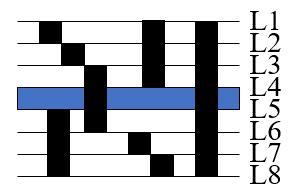

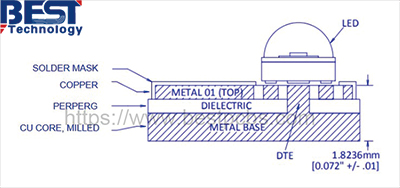

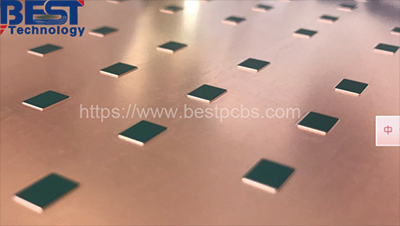

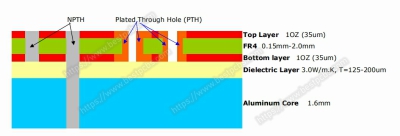

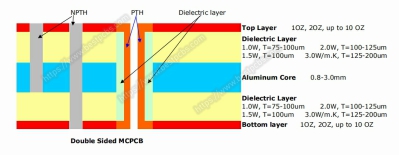

PP, it is placed between the two copper layers to isolate and make the two copper layers adhere. Below picture for you to see where the PP is on a PCB stack up.

And CORE, it is totally different as the Prepreg.

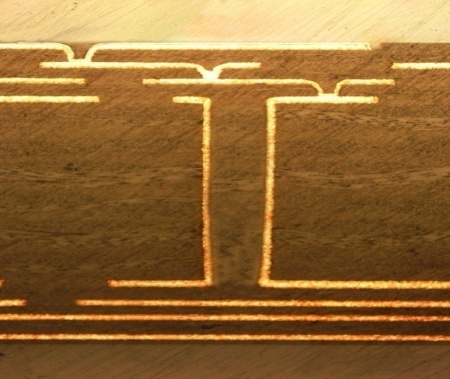

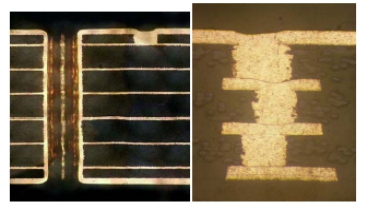

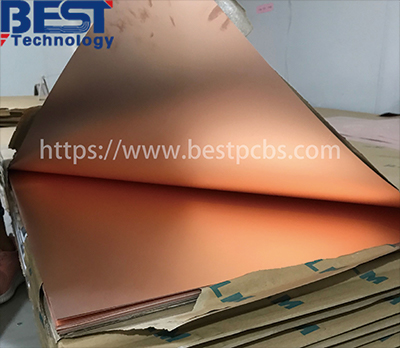

Core is with certain hardness and specified thickness, and with copper foil in both sides.

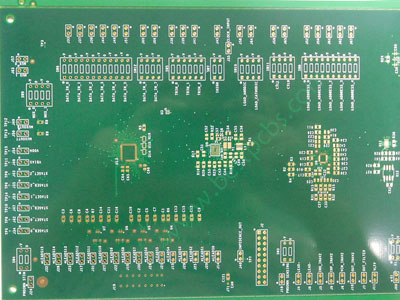

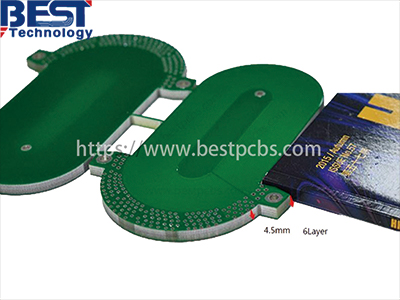

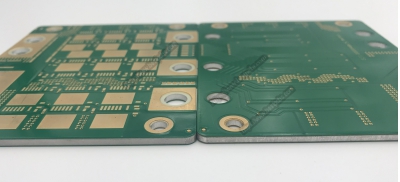

It is the basic material for making printed circuits boards, and the multilayer PCB board is actually made by pressing Core and Prepreg.

Sometimes, when people are talking about the Copper Clad Laminate (CCL), they also refer to the CORE.

And here is the major difference for the PP and Core:

- Prepreg is stayed with a semi-solid material in a PCB, similar to cardboard. But core is different, core is hard, similar to copper;

- Prepreg is similar to adhesive + insulator; while Core is the basic material of PCB, they have completely different functions;

- PCB Prepreg can curl, but PCB Core cannot bend;

- Prepreg is non-conductive, and the core has a copper layer on both sides, which is the conductive medium for a PCB board.

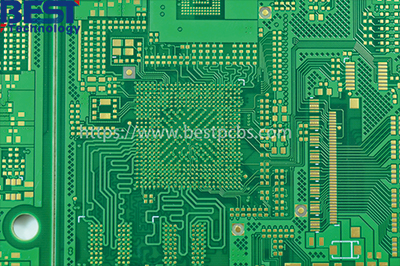

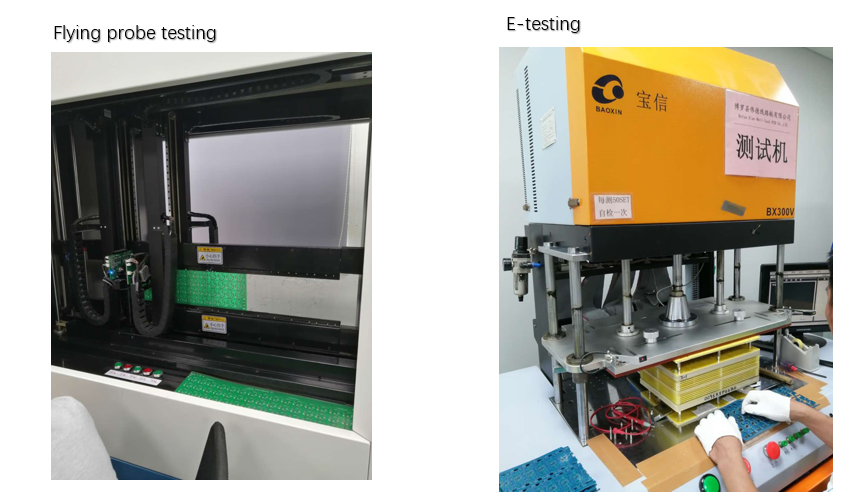

As an PCB manufacturer with more than 15 years experiences in China, EBest Circuit (Best Technology) insists on using the best Copper Clad Laminate ( CCL) materials to make the PCB, no matter Prepreg or CORE, we will select the best FR4 materials for the PCB manufacturing, to make sure all the PCB boards we supplied to customers are with qualified materials and to be your best PCB suppliers in China.