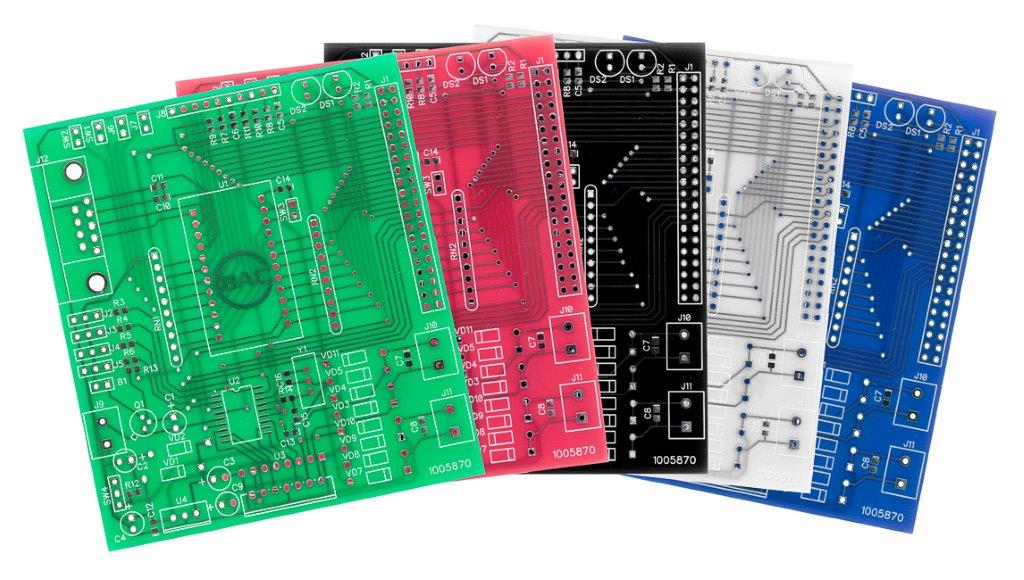

Custom PCB prototyping is the process of creating tailored printed circuit board prototypes designed to meet the unique needs of specific projects‚ÄĒwhether for consumer electronics, industrial equipment, medical devices, or aerospace applications. In Toronto‚Äôs dynamic tech ecosystem, this service isn‚Äôt just about producing a basic board; it‚Äôs about translating complex design concepts into functional, testable prototypes that align with local industry standards and project timelines. Unlike off-the-shelf PCBs, custom PCB prototyping prioritizes flexibility: from choosing materials (FR4, metal-based PCBs, ceramic PCBs, or flexible PCBs) to optimizing layer counts, trace widths, and component placements. For Toronto-based engineers and startups, this means getting a prototype that fits their exact use case‚ÄĒwhether it‚Äôs a compact board for a wearable device or a high-frequency PCB for communication equipment.

Custom PCB Prototyping vs. Standard PCB Manufacturing: Key Differences

When deciding between custom PCB prototyping and standard PCB manufacturing, understanding the core differences is critical for Toronto tech teams. Standard manufacturing focuses on mass-produced, generic boards with fixed specifications, ideal for high-volume production where consistency and cost-efficiency are top priorities. Custom PCB prototyping, by contrast, is built for low-volume, project-specific needs‚ÄĒprioritizing design flexibility, rapid iteration, and precision over scale.

In Toronto‚Äôs fast-paced innovation scene, this distinction matters: startups testing a new product concept need a prototype that can be modified quickly if adjustments are needed, while established firms might use custom prototyping to validate a complex design before full-scale production. Custom prototyping also offers tighter quality control for specialized applications (e.g., medical devices requiring ISO 13485:2016 compliance or aerospace components needing AS9100D certification)‚ÄĒa must for Toronto industries operating in regulated sectors.

Top Applications of Custom PCB Prototyping in Toronto’s Tech Industry

Toronto’s diverse tech landscape relies on custom PCB prototyping to drive innovation across key sectors. Here are the most common use cases:

- Medical Devices: Prototypes for diagnostic tools, wearable health monitors, and implantable devices‚ÄĒrequiring biocompatible materials and adherence to ISO 13485:2016 standards.

- Aerospace & Defense: High-reliability PCBs for avionics systems, where resistance to extreme temperatures and vibration is non-negotiable (aligned with AS9100D requirements).

- Consumer Electronics: Compact, high-performance prototypes for smartphones, IoT devices, and home automation products‚ÄĒprioritizing miniaturization and energy efficiency.

- Industrial Automation: Robust PCBs for control systems, sensors, and manufacturing equipment, designed to withstand harsh factory environments.

- Renewable Energy: Prototypes for solar inverters, battery management systems, and wind turbine controls‚ÄĒfocused on durability and high-power handling.

For Toronto engineers, these applications demand prototypes that don‚Äôt just work‚ÄĒthey work within the city‚Äôs regulatory frameworks and industry-specific needs.

How to Choose the Right Custom PCB Prototyping Partner in Toronto

Selecting a reliable custom PCB prototyping partner in Toronto can make or break your project. Here’s what to prioritize:

Industry Certifications

Look for partners with globally recognized certifications like IATF 16949, ISO 9001:2015, ISO 13485:2016, and AS9100D. These certifications prove adherence to strict quality and safety standards‚ÄĒcritical for Toronto‚Äôs regulated industries. Additional compliance with REACH, RoHS, and UL standards ensures environmental and safety compliance.

Material & Technology Capabilities

Ensure the partner offers a range of substrates (FR4, metal-based PCBs (MCPCBs), ceramic PCBs, flexible and rigid-flexible PCBs) and can handle complex designs (multi-layer PCBs, high-frequency PCBs). Toronto projects often require specialized materials, so versatility is key.

Turnaround Time

Urgent projects need expedited service‚ÄĒlook for partners that offer 24-hour shipping for critical prototypes. In Toronto‚Äôs competitive tech scene, fast iteration can mean the difference between leading the market and falling behind.

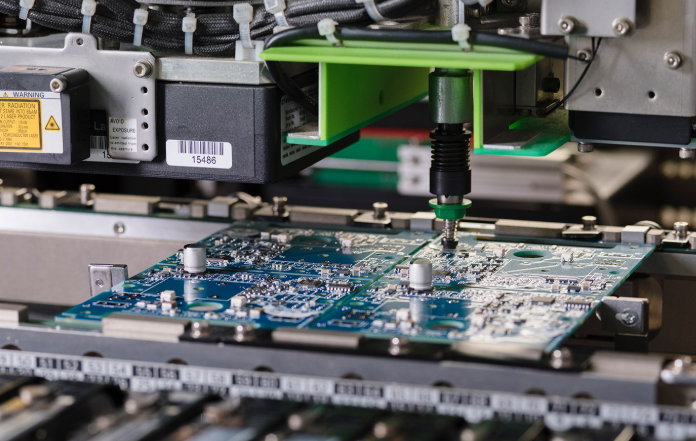

End-to-End Services

A full-service partner (offering PCB Design, PCB Prototype, Component Sourcing, PCB Assembly, and Box-Build-Assembly) streamlines the process, reducing communication gaps and ensuring consistency from concept to prototype.

Common Terms in Custom PCB Prototyping You Need to Know

Navigating custom PCB prototyping requires familiarity with key industry terms‚ÄĒessential for clear communication with your Toronto-based manufacturer:

- FR4: The most common PCB substrate (glass-reinforced epoxy resin), ideal for general-purpose applications.

- MCPCB (Metal-Core PCB): A substrate with a metal core (typically aluminum) for enhanced heat dissipation‚ÄĒused in LED lighting and power electronics.

- Rigid-Flex PCB: A hybrid board combining rigid and flexible sections, perfect for compact or foldable devices.

- Trace Width: The width of the conductive pathways on the PCB, critical for carrying electrical current without overheating.

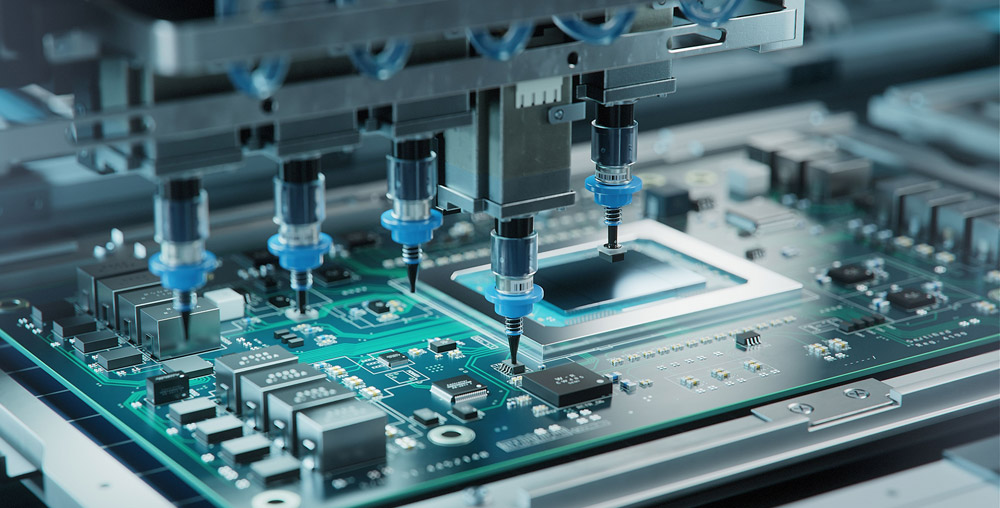

- SMT (Surface Mount Technology): A method of mounting components directly onto the PCB surface, enabling miniaturization.

- Through-Hole Technology: Components with leads inserted through holes in the PCB‚ÄĒused for high-reliability applications.

- DFM (Design for Manufacturability): The process of optimizing PCB designs to ensure efficient, cost-effective production.

Understanding these terms ensures you can articulate your project needs and evaluate prototype quality effectively.

FAQ: Common Custom PCB Prototyping Questions for Toronto Engineers

How long does custom PCB prototyping take in Toronto?

Typical turnaround time is 3‚Äď7 business days for standard prototypes, but expedited service (24‚Äď48 hours) is available for urgent projects. Factors like design complexity, layer count, and material availability can affect lead time.

What materials are best for custom PCB prototypes in Toronto?

FR4 is ideal for general-purpose projects, while MCPCBs are best for heat-sensitive applications (e.g., LEDs). Ceramic PCBs offer high-temperature resistance (for aerospace/medical use), and flexible/rigid-flexible PCBs work for compact or wearable devices.

Do I need to provide a complete design file for prototyping?

Yes‚ÄĒmost manufacturers require Gerber files (the standard PCB design format) or CAD files. Reputable partners may offer PCB Design support if you need help refining your design.

Can custom prototypes be scaled to mass production?

Absolutely. A quality custom PCB prototyping partner will ensure your prototype is designed for manufacturability (DFM), making the transition to Mass Production seamless‚ÄĒcritical for Toronto startups looking to scale quickly.

Are custom PCB prototypes compliant with Toronto/Canadian regulations?

Yes‚ÄĒif you choose a certified partner. Look for compliance with RoHS (Restriction of Hazardous Substances), REACH (Registration, Evaluation, Authorization and Restriction of Chemicals), and industry-specific standards (ISO 13485:2016 for medical, AS9100D for aerospace).

How much does custom PCB prototyping cost in Toronto?

Cost varies based on layer count, material, size, and quantity. Prototypes typically range from $50‚Äď$500 for low-volume orders. Discussing your project details with a partner will get you a precise quote.

What if my prototype fails testing?

A reliable partner will offer design reviews and DFM checks upfront to minimize failures. If issues arise, they should work with you to iterate on the design and produce a revised prototype quickly.

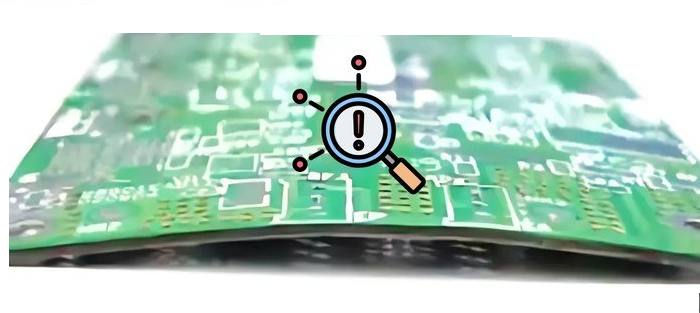

Key Challenges in Custom PCB Prototyping (and How to Overcome Them)

Even with a great design, custom PCB prototyping can present challenges‚ÄĒhere‚Äôs how to address them for Toronto projects:

Design Complexity

Complex layouts (e.g., multi-layer PCBs, high-frequency traces) can lead to signal interference or manufacturing errors. Solution: Work with a partner that offers DFM reviews to identify issues early and optimize your design for production.

Material Shortages

Global supply chain issues can delay prototype production. Solution: Choose a partner with established Component Sourcing networks‚ÄĒthey can secure rare materials or suggest suitable alternatives without compromising quality.

Tight Timelines

Urgent projects (e.g., product launches, client demos) require fast turnaround. Solution: Prioritize partners with expedited services and efficient production capabilities‚ÄĒavoiding long shipping times from international manufacturers.

Regulatory Compliance

Meeting industry standards (e.g., ISO 13485:2016, AS9100D) can be daunting. Solution: Select a certified partner that understands Toronto‚Äôs regulatory landscape‚ÄĒthey‚Äôll ensure your prototype meets all necessary compliance requirements (including REACH, RoHS, and UL).

The Importance of DFM (Design for Manufacturability) in Custom PCB Prototyping

Design for Manufacturability (DFM) is a critical step in custom PCB prototyping‚ÄĒyet it‚Äôs often overlooked. DFM involves optimizing your design to ensure it can be manufactured efficiently, reliably, and cost-effectively. For Toronto engineers, this means reducing the risk of production delays, costly reworks, and prototype failures.

A strong DFM process includes checking for trace width consistency, component placement (to avoid soldering issues), and material compatibility. Reputable prototyping partners will conduct DFM reviews as part of their service, flagging potential issues (e.g., overly narrow traces, incompatible components) and suggesting adjustments. This proactive approach saves time and money‚ÄĒespecially for Toronto startups and small teams with limited resources.

Custom PCB Prototyping for High-Frequency Applications in Toronto

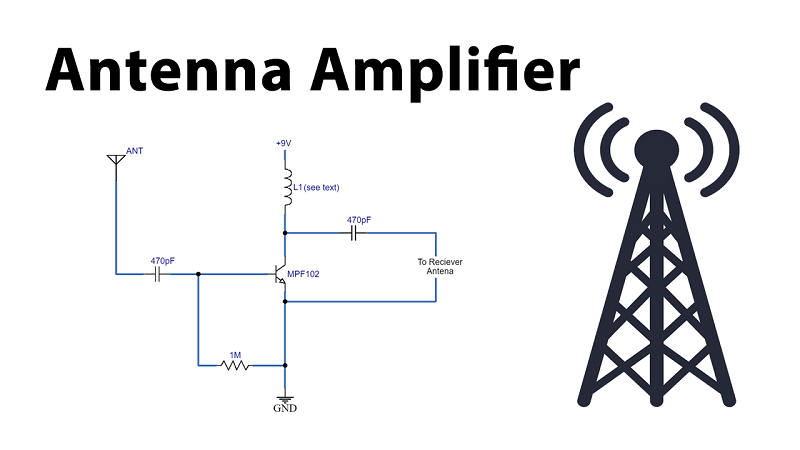

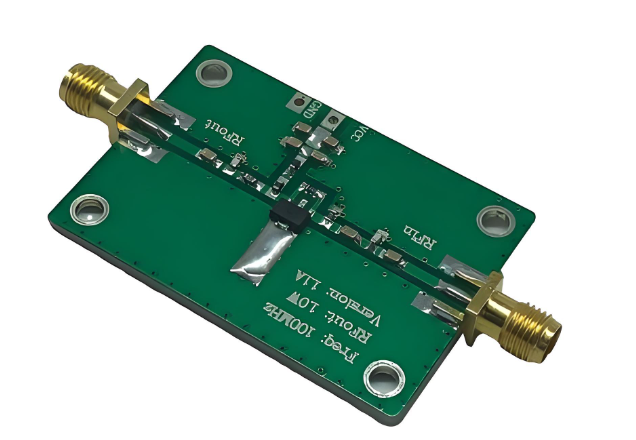

High-frequency PCBs (used in communication systems, radar, and IoT devices) require specialized custom PCB prototyping‚ÄĒand Toronto‚Äôs tech industry is increasingly demanding this expertise. High-frequency prototypes need substrates with low dielectric loss (e.g., PTFE) to minimize signal degradation, as well as precise trace spacing to avoid interference.

Manufacturers with experience in high-frequency prototyping understand the unique challenges: maintaining signal integrity, controlling impedance, and ensuring thermal management. Whether you’re developing a 5G device or a satellite communication system, a specialized partner will tailor the prototype to your frequency requirements (typically 1 GHz and above) and validate performance through testing.

How Custom PCB Prototyping Supports Toronto’s Startup Ecosystem

Toronto‚Äôs startup scene thrives on innovation‚ÄĒand custom PCB prototyping is a cornerstone of that success. Startups often have limited budgets and tight timelines, making prototyping a make-or-break step. Custom prototyping allows them to test ideas quickly, iterate on designs without committing to Mass Production, and validate product-market fit before scaling.

For example, a wearable tech startup can use a custom prototype to test a new sensor integration, while a cleantech startup can validate a battery management system design. Local prototyping partners offer the agility startups need: fast turnaround, flexible order quantities (even 1‚Äď10 boards), and personalized support. This accessibility levels the playing field, allowing Toronto startups to compete with larger firms and bring innovative products to market faster.

Quality Control in Custom PCB Prototyping: What Toronto Engineers Should Expect

Quality is non-negotiable in custom PCB prototyping‚ÄĒand Toronto engineers should demand rigorous quality control (QC) from their partner. A robust QC process includes:

- Visual inspections to check for soldering defects, trace damage, or component misalignment.

- Electrical testing (e.g., continuity testing, impedance testing) to ensure the prototype functions as intended.

- Material verification to confirm substrates and components meet specified standards (e.g., RoHS compliance).

- Environmental testing (for specialized applications) to validate performance in extreme temperatures, humidity, or vibration.

Certified partners (ISO 9001:2015, IATF 16949) follow standardized QC protocols, providing documentation to prove compliance. This transparency is critical for Toronto projects in regulated industries‚ÄĒensuring your prototype is reliable, safe, and ready for testing.

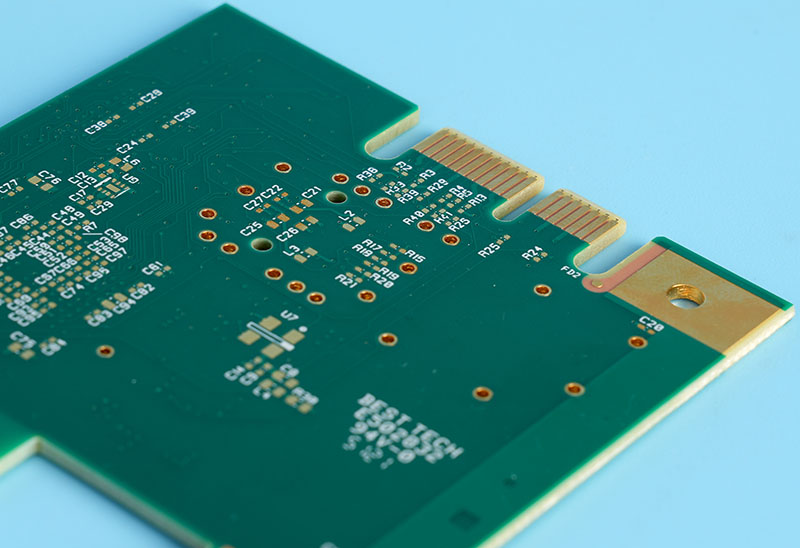

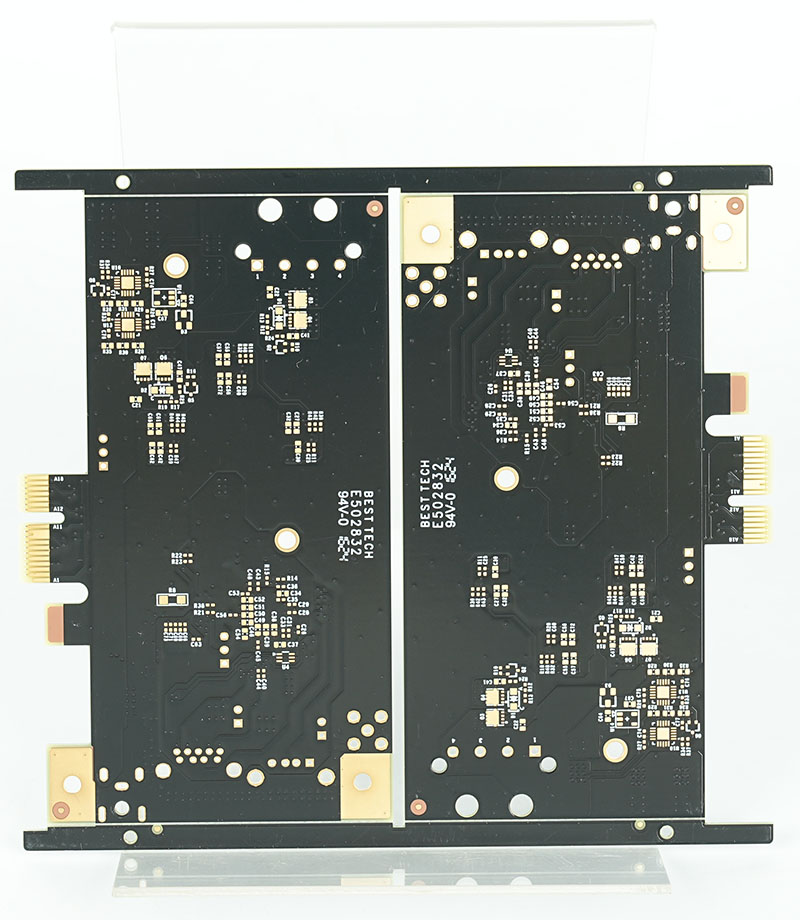

Why Choose EBest Technology for Custom PCB Prototyping in Toronto

When it comes to custom PCB prototyping in Toronto, EBest Technology brings over 20 years of expertise, industry-leading certifications, and a customer-centric approach that sets us apart. Founded in 2006, we specialize in tailored solutions‚ÄĒfrom standard FR4 prototypes to complex multi-layer PCBs, high-frequency PCBs, metal-based PCBs (MCPCBs), ceramic PCBs, and flexible/rigid-flexible PCBs‚ÄĒall manufactured to meet IATF 16949, ISO 9001:2015, ISO 13485:2016, and AS9100D standards, with full compliance to REACH, RoHS, and UL. Our monthly production capacity of 260,000 square feet (28,900 square meters) means we can handle both small-batch prototypes and scale-up orders, while our 24-hour expedited service ensures your urgent projects stay on track.

We don‚Äôt just produce prototypes‚ÄĒwe offer one-stop PCB solutions, partnering with you every step of the way: from PCB Design support and DFM reviews to Component Sourcing, PCB Assembly, and Box-Build-Assembly. Our team of engineers invests heavily in research and development to stay ahead of industry trends, focusing on product quality and customer satisfaction. We understand Toronto‚Äôs tech ecosystem and regulatory requirements, ensuring your prototype is not just functional, but optimized for your specific application. Whether you‚Äôre a startup testing a new concept or an established firm validating a complex design, we deliver reliable, high-quality prototypes that drive your project forward.

Don‚Äôt let prototyping delays or subpar quality hold you back. Contact EBest Technology today to discuss your custom PCB prototyping needs‚ÄĒwe‚Äôll provide a tailored quote, fast turnaround, and the expertise you need to turn your design into a successful product. With our personalized support and proven track record as a trusted global partner, we‚Äôre here to help you innovate with confidence. Let‚Äôs build something great together.