Looking for a PCB manufacturer in Singapore? If you are searching for a custom PCB manufacturer in Singapore, this guide explains the common challenges in this region and how a trusted partner can provide stable quality and faster delivery.

Are You Facing these Problems in Singapore PCB Customization?

- Insufficient prototyping accuracy leading to R&D rework? How to avoid the risk of subtle circuit short circuits/open circuits and prevent delays of over 30% in product launch cycles?

- Small-batch orders rejected? High minimum order quantities increase costs for startup teams by 50%, yet there are no alternative solutions?

- Difficulty in implementing design solutions? Lack of DFM analysis leads to pad defects, requiring secondary modifications and delaying the crucial product launch period?

- Unstable quality in high-end PCB production? Yield fluctuations in high-density HDI boards and flexible circuits â how to meet the stringent requirements of medical/automotive grades?

- Unreliable delivery commitments? Delays cause downstream production line shutdowns and losses â how to ensure high on-time delivery?

Our PCB Solutions to these Problems

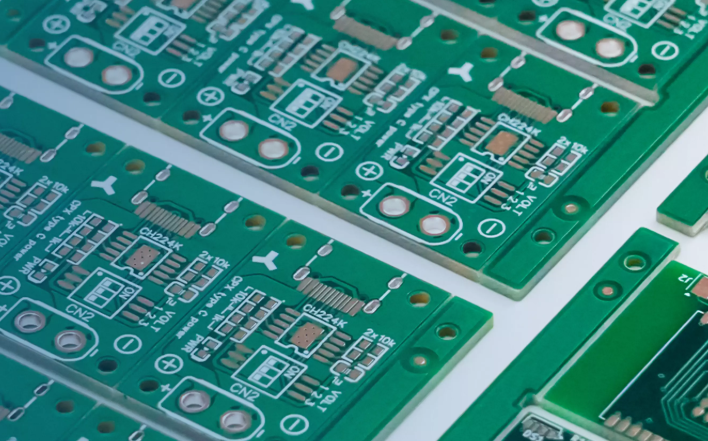

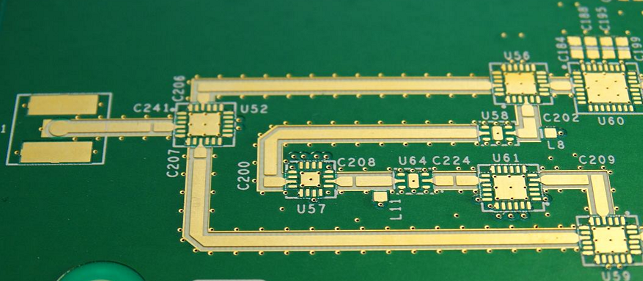

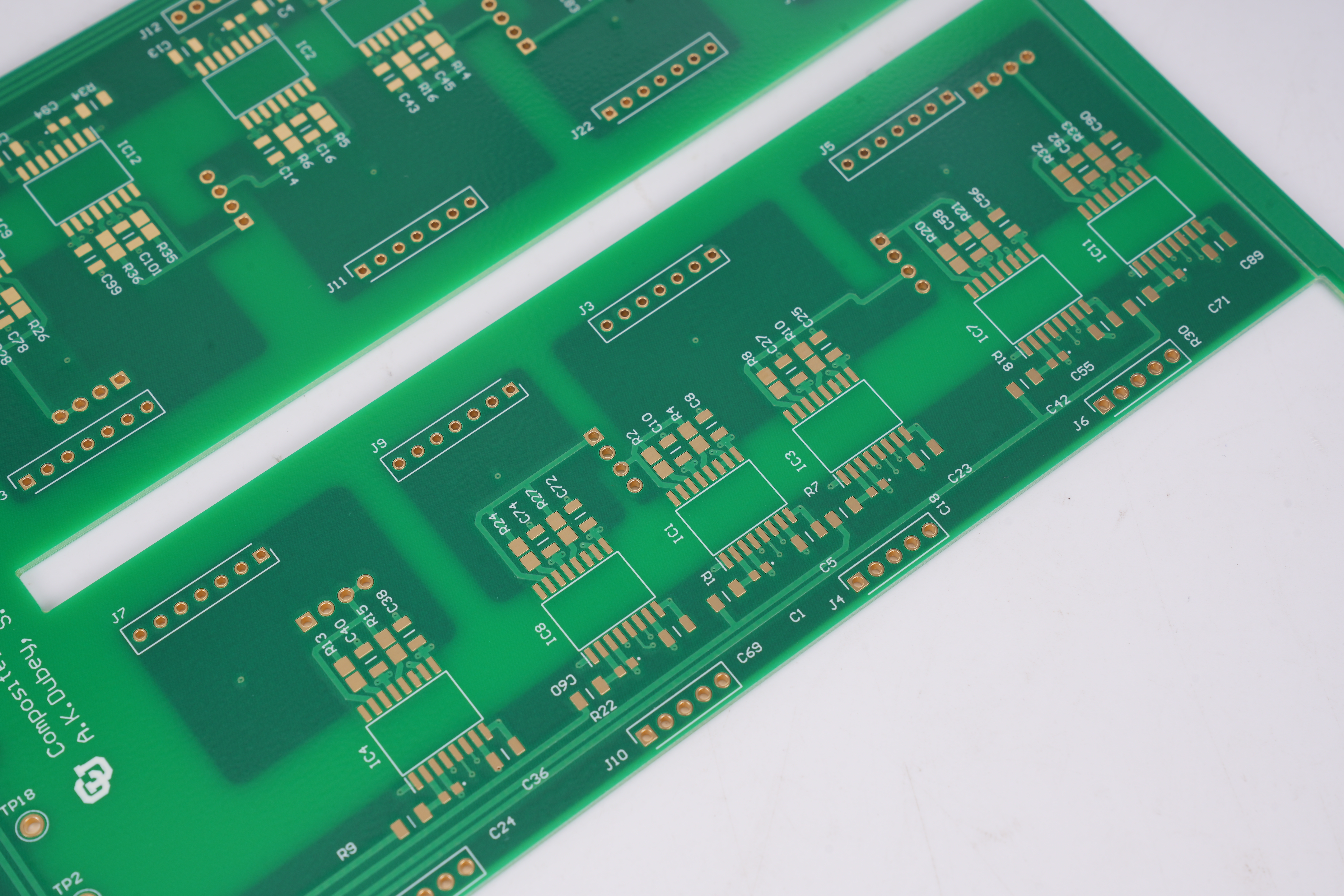

- High-precision sampling to break R&D Difficulties: Advanced laser drilling technology supports 1-64 layer PCB sampling with a minimum line width/spacing of 0.075mm±0.01mm matching micro-component soldering needs. Each batch includes free signal integrity analysis reports and X-ray inspections to proactively avoid 99% of potential defects and reduce R&D cycles by 40%.

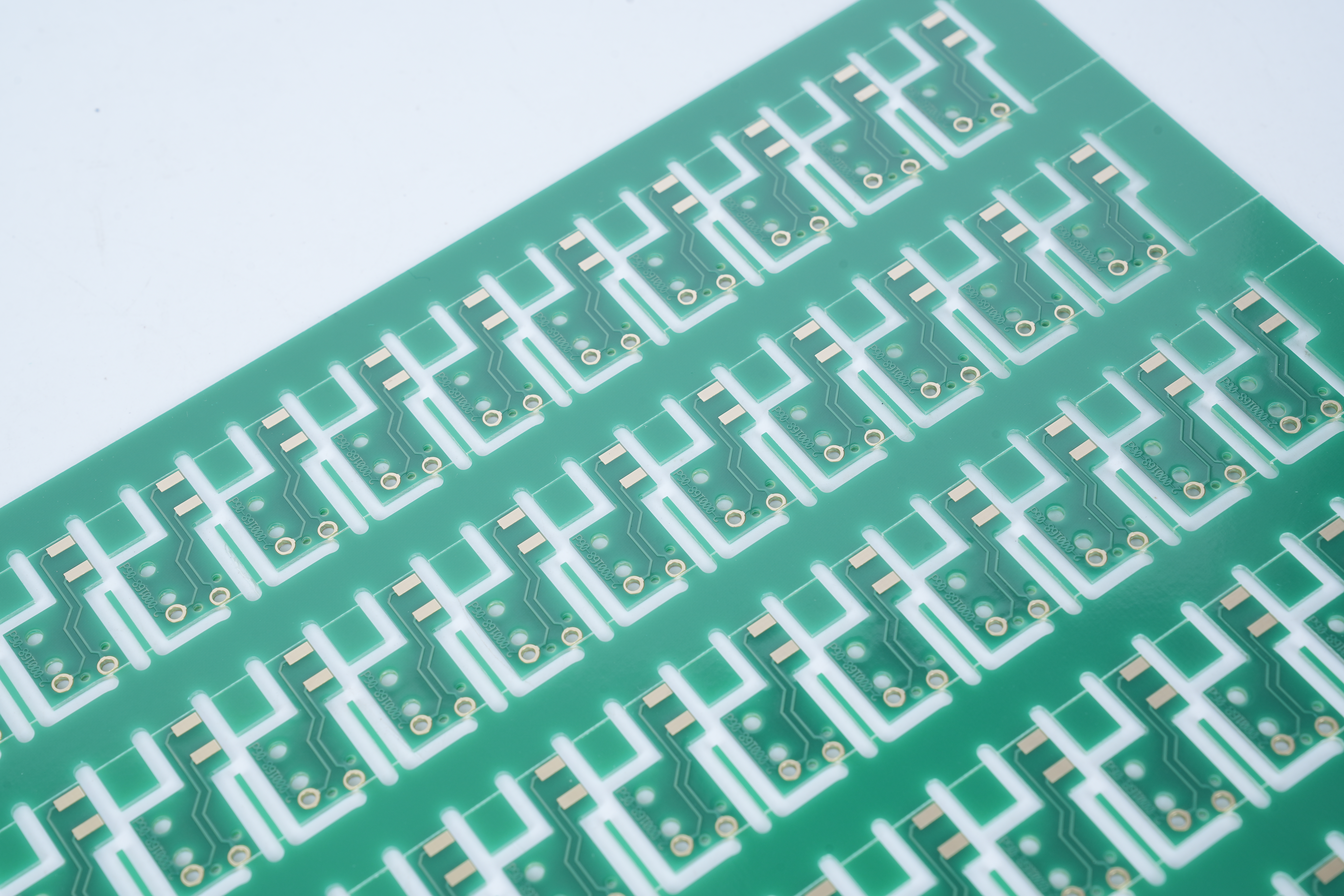

- Zero-threshold small batch customization: No minimum order quantity restrictionsâenjoy mass production-grade processes starting from 1 piece. For startups, we offer cost-sensitive schemes that reduce per-piece costs by 35% (approximately $5 USD/piece) through material panel optimization. Supports fine soldering like BGA ball placement and QFN packaging for consumer electronics/IoT validation needs.

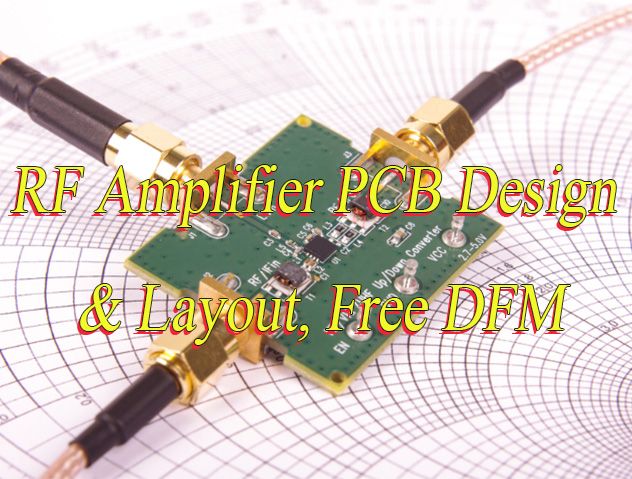

- Free DFM design optimization to ensure landing: Complimentary professional DFM analysis automatically verifies 18 parameters including trace layout and impedance control. Optimized schemes show significant improvement in first-pass success rates reducing average client design iterations by 2 times and saving over $20K USD per project in R&D costs.

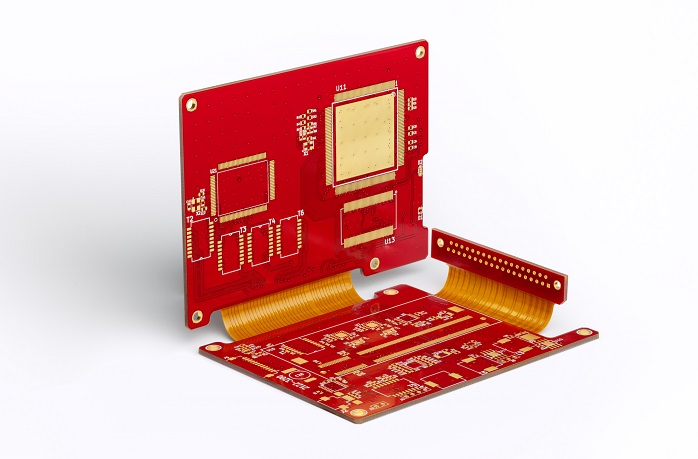

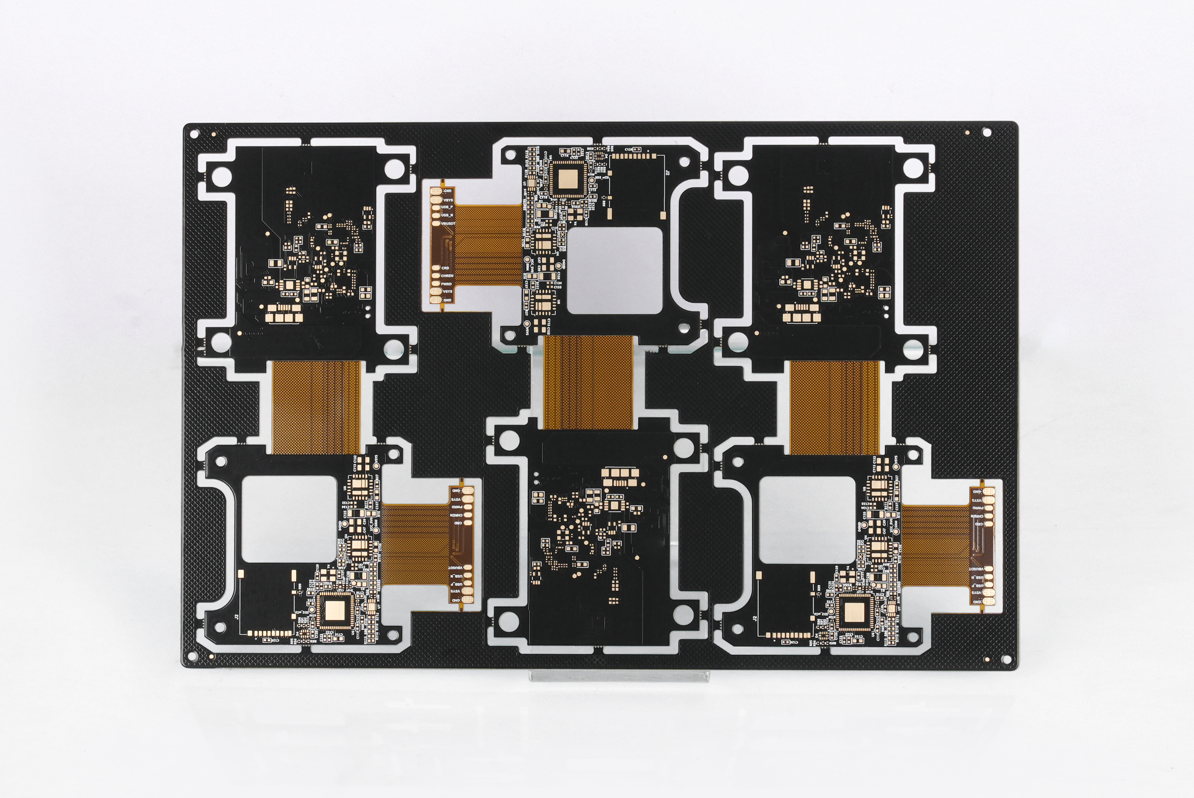

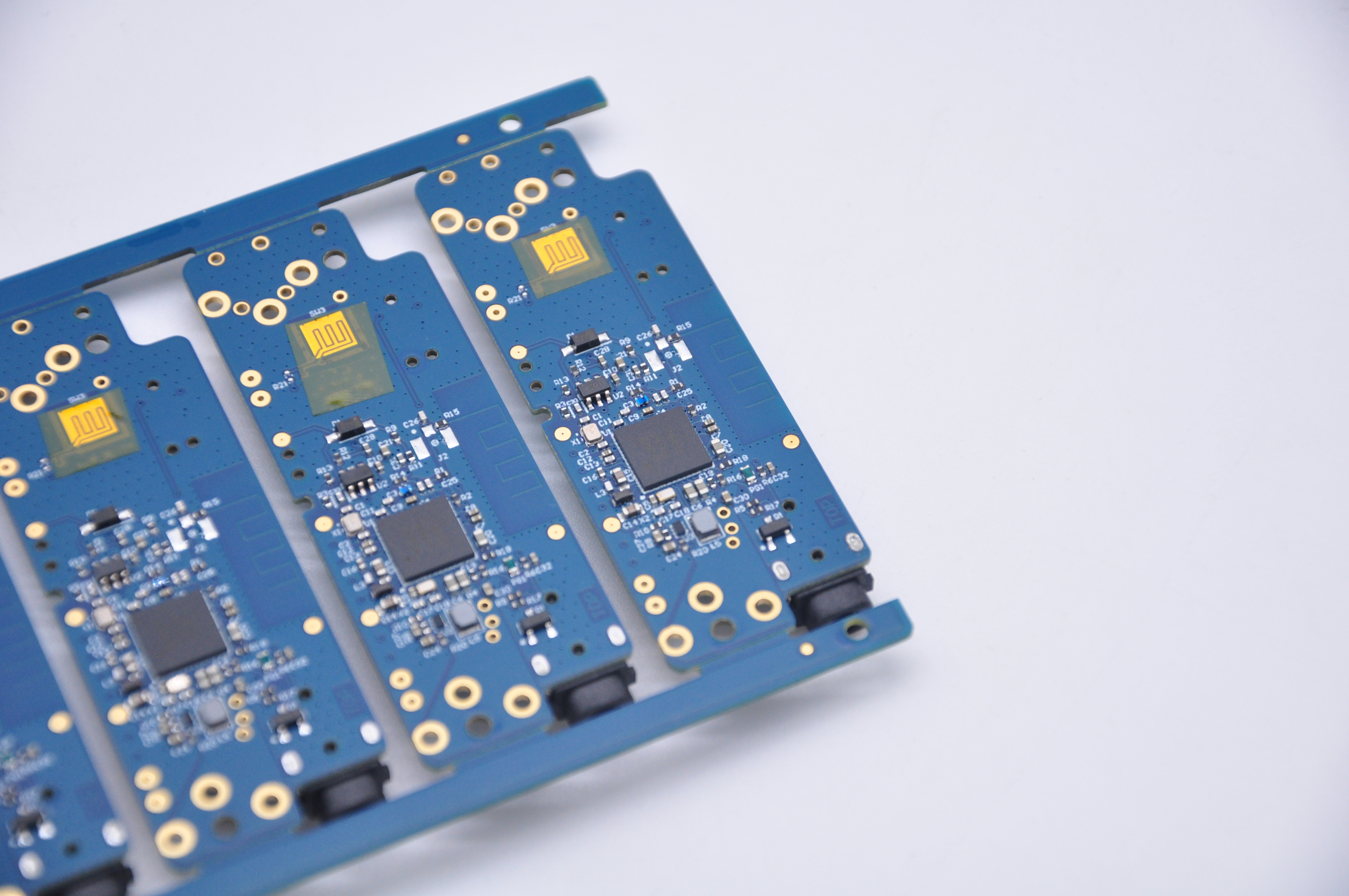

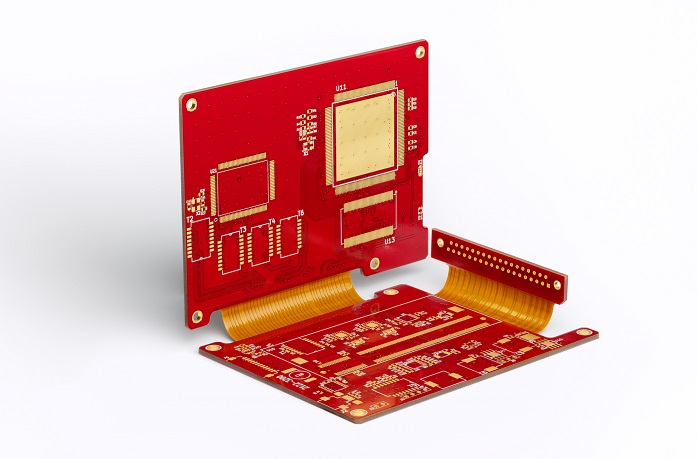

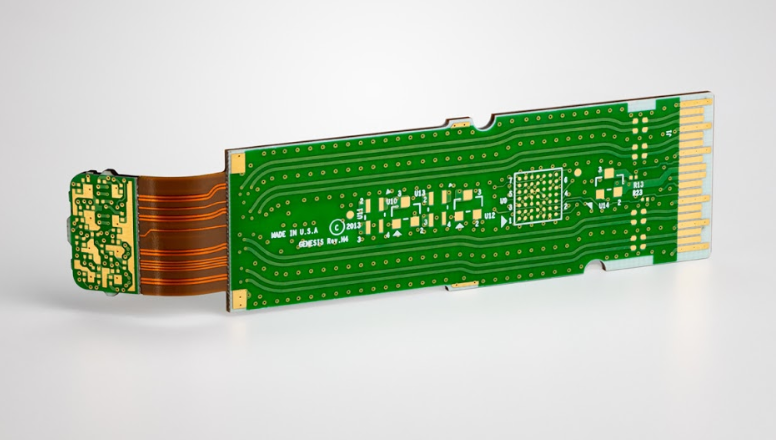

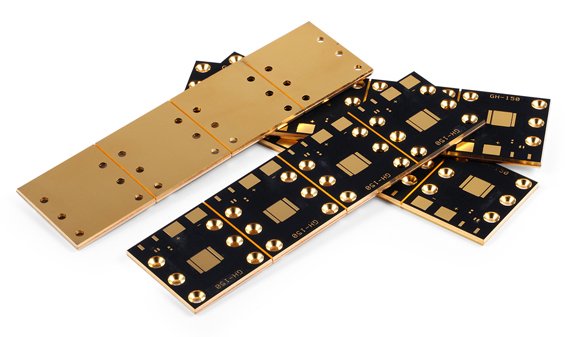

- Authoritative certifications for high-end manufacturing capabilities: Mastered high-density HDI (minimum blind/buried via 0.1mm), rigid-flex boards (bend radius â€1mm), and high-frequency material processes. Certified with ISO 9001, IATF 16949 automotive grade, medical ISO 13485 standardsâproducts meet 5G base stations, surgical robotics and other demanding scenarios with yield stability above 99.8%.

- Guaranteed delivery control across the entire process: Standard orders delivered in 7-10 business days with 24-hour expedited sampling for urgent needs. On-time delivery rate reaches 99%. For delayed orders we activate a double compensation mechanism paired with dedicated customer service for 48-hour on-site resolution of unexpected issues.

Why Choose EBest Circuit (Best Technology) for Global PCB Manufacturer?

Reasons Why Choose EBest Circuit (Best Technology) for Global PCB Manufacturer:

- Comprehensive certification coverage: Holds ISO 9001 IATF 16949 RoHS 2.0 and medical ISO 13485 certificates meeting European-American environmental safety mandates.

- 19 years of PCB manufacturing expertise: Served 600+ global enterprises built a production error database and saved clients 18% average rework costs through process improvements.

- Competitive pricing without hidden cost: Global supply chain integration provides 15%-20% below market average quotes with tiered pricing for cost-sensitive projects.

- 24-hour rapid prototyping for urgent orders Dedicated fast-track lines support 24-hour turnaround from file review to finished product for urgent prototyping and exhibition needs.

- Full-inspection quality control: Each PCB undergoes triple verification via AOI automated optical inspection fly-probe testing and manual final checks achieving 99.8% pass rates with traceable quality reports attached.

- Free DFM optimization: Expert teams provide complimentary manufacturability analysis to preempt 90% of design flaws and reduce post-modification costs.

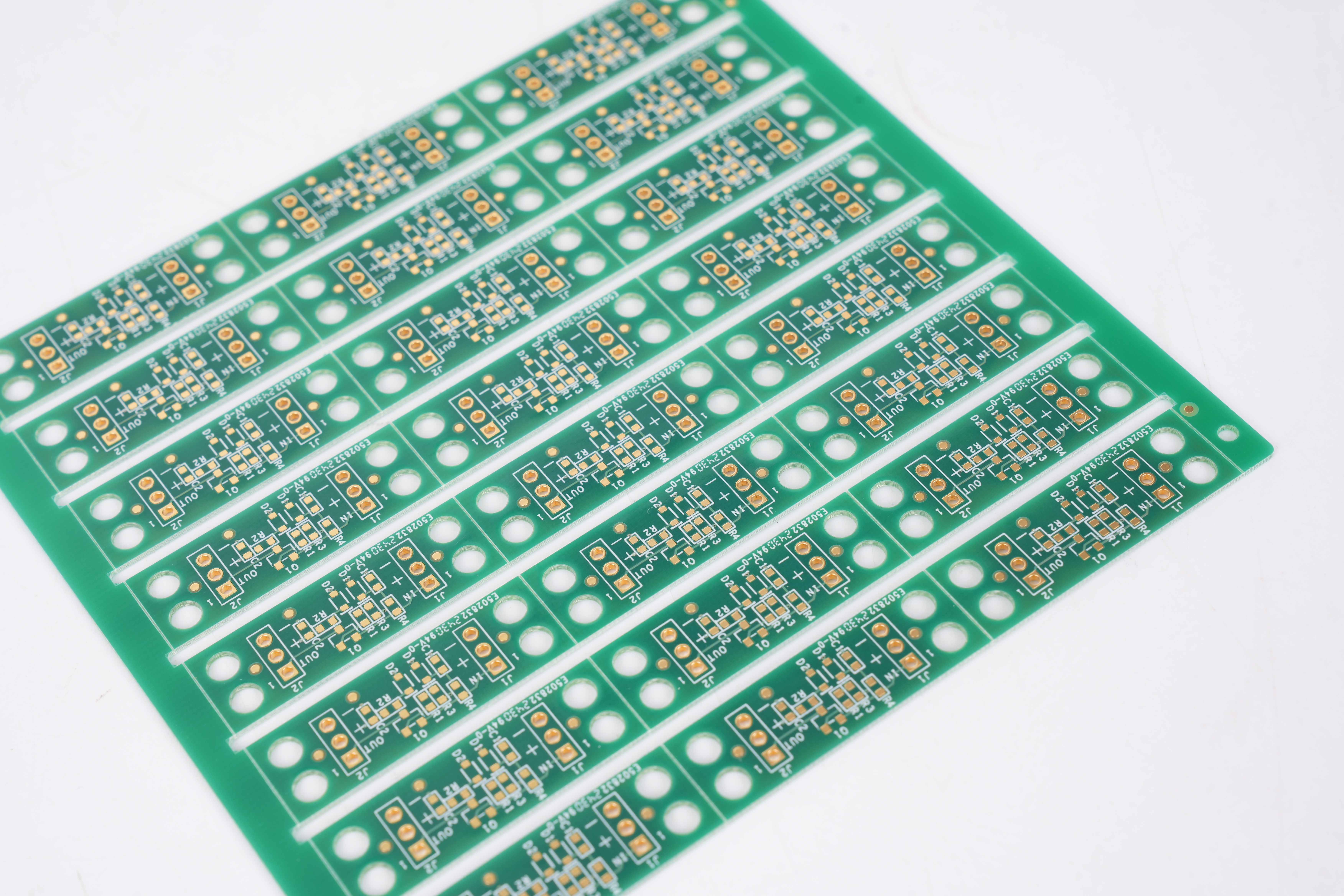

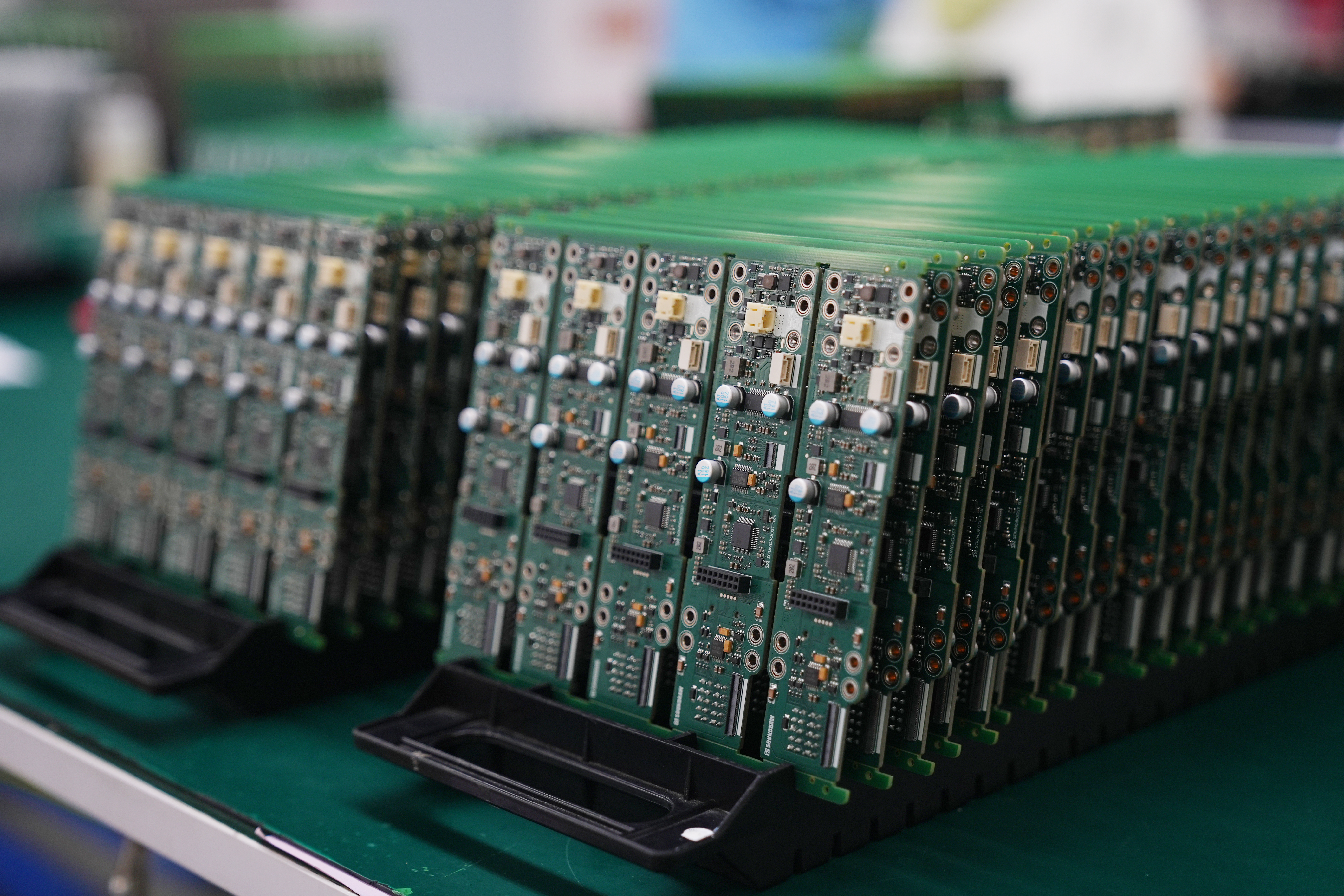

- Flexible service models: Supports full-stage needs from 1-piece prototypes to 100k+ volume production with value-added services like custom packaging and specialty logistics.

- Support customization solutions: Including raw material customization, surface treatment customization, solder mask customization, and many other service types.

Welcome to contact us if you have any issues about PCB design, prototyping, mass production and assembly: sales@bestpcbs.com.

List of PCB Manufacturers in Singapore

1. Circuits Plus Pte Ltd

- Main business: PCB manufacturing for industrial and electronic equipment.

- Manufacturing capabilities: Single/double-sided PTH boards, multilayer rigid PCBs (general electronics/industrial control).

- Advantages: Established Singaporean manufacturer with stable cross-industry collaboration experience.

- Lead time: Standard orders 7-15 working days, project-based scheduling for large volumes.

2. MFS Technology (S) Pte Ltd

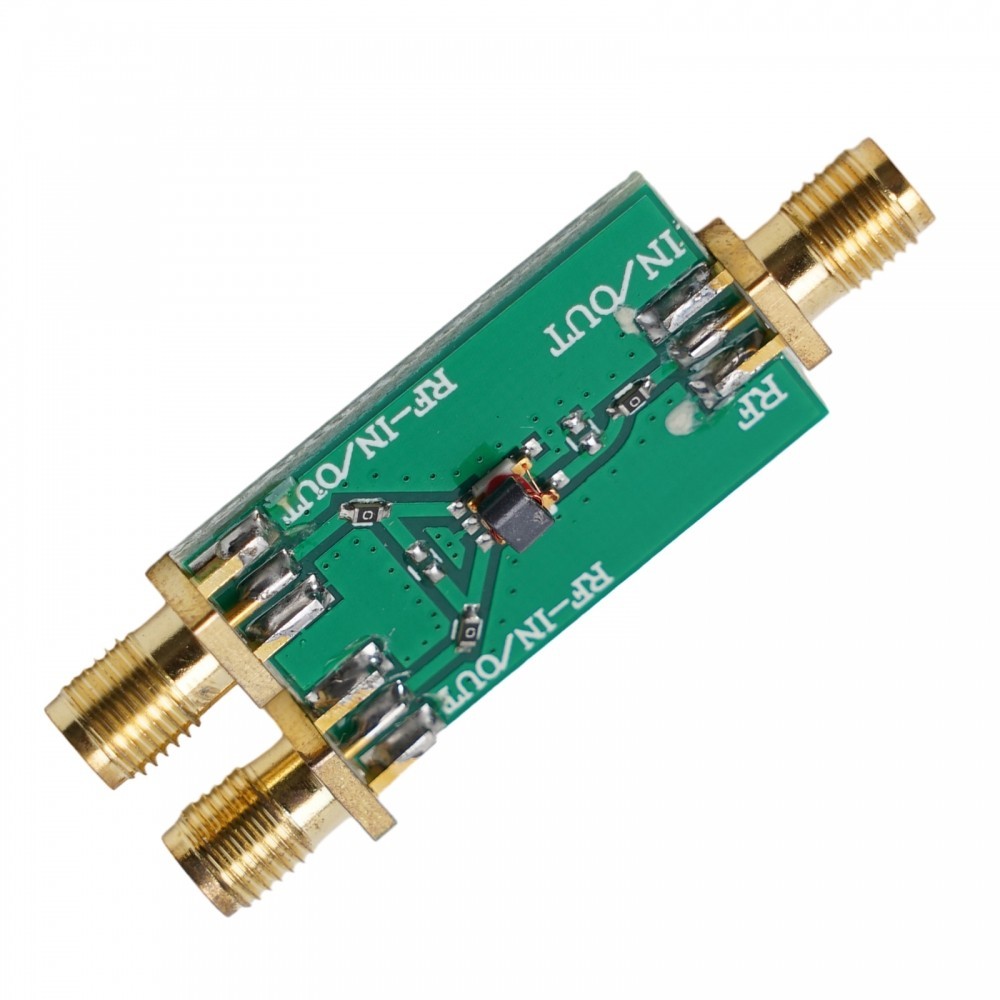

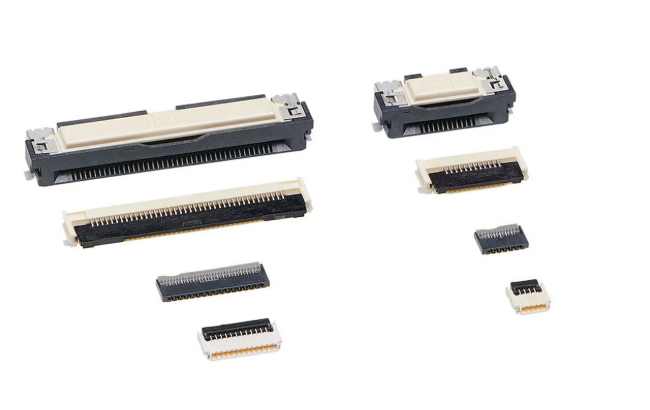

- Main business: Flexible circuits, rigid-flex PCBs, and specialty substrates.

- Manufacturing capabilities: FPC, rigid-flex boards (automotive/industrial/medical/consumer electronics).

- Advantages: Expertise in flexible and rigid-flex solutions, multi-site production (Malaysia/China) for high-reliability programs.

- Lead time: 2-4 weeks (varies by complexity/volume/plant allocation).

3. Promax Technology Integration Pte Ltd

- Main business: Contract PCB manufacturing + assembly + engineering support.

- Manufacturing capabilities: 1-24 layer PCBs, prototyping to mass production, design development, component sourcing & turnkey assembly.

- Advantages: One-stop service (manufacturing + assembly + R&D support), ISO 9001 certified.

- Lead time: Prototypes 7-12 working days, production orders project-scheduled.

4. Precision Circuit Manufacturers Pte Ltd

- Main business: Rigid/rigid-flex/flexible PCB manufacturing.

- Manufacturing capabilities: Specialized boards for industrial/automotive/communication applications.

- Advantages: Focus on high-value flexible technologies for compact/complex assemblies.

- Lead time: 2-3 weeks (varies by technology tier/order size).

5. Kentronics Engineering

- Main business: PCB design/layout + manufacturing + assembly.

- Manufacturing capabilities: Local prototyping/small-batch production & assembly.

- Advantages: Design-manufacturing integration for early-stage hardware projects.

- Lead time: 10-20 days from design to finished boards (varies by design complexity).

6. ANZ Electric Pte Ltd

- Main business: PCB-related manufacturing & electronics services.

- Manufacturing capabilities: General industrial/commercial PCBs & electrical products.

- Advantages: Local coordination advantage, regionally listed supplier.

- Lead time: Standard boards ~2-3 weeks (varies by order volume).

7. MPN TECH Pte Ltd

- Main business: PCB & electronics solutions provider.

- Manufacturing capabilities: Multi-market PCB supply & electronics manufacturing services.

- Advantages: Regional electronics service network member, local outsourcing coordination.

- Lead time: 2-4 weeks (varies by product type/sourcing route).

8. PIC-CONTROL Pte Ltd

- Main business: Electronic design + control solutions (including PCB development).

- Manufacturing capabilities: Electronic design, custom control boards, small-batch manufacturing coordination.

- Advantages: System-level design capability (hardware + firmware + PCB).

- Lead time: 2-6 weeks (includes design validation + production phases).

Custom Service Types Offered by Singapore PCB Manufacturers

- High-precision prototype customization: For R&D phase needs, provides small-batch (1-100 units) high-precision PCB prototyping with rapid iteration support to shorten development cycles.

- High-density PCB customization: Meets 5G & AI device requirements via â€0.1mm line/space high-density PCB production, enhancing component integration and signal efficiency.

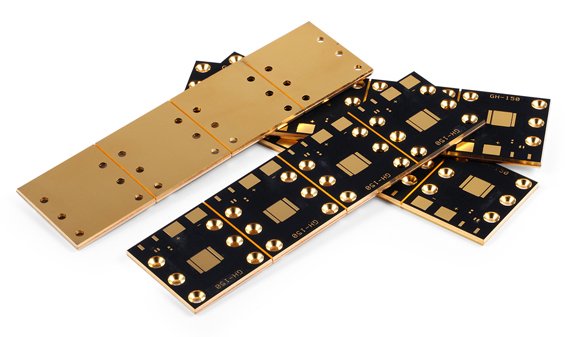

- Special material customization: Offers tailored PCBs using ceramic substrates, aluminum CCL, polyimide flexible materials for extreme conditions (high temp/humidity/flexure).

- Industry-specific customization: Delivers dedicated solutions for automotive (AEC-Q grade heat-resistant PCBs), medical (biocompatible PCBs), industrial control (EMI-resistant PCBs).

- Surface finish customization: Provides HASL, immersion gold, ENIG, OSP and other finishes to address diverse soldering and oxidation protection needs.

- Integrated assembly customization: Combines PCB manufacturing with component sourcing, SMT assembly for “one-stop” delivery, reducing supply chain management costs.

- Aesthetic & packaging customization: Supports PCB color, silkscreen marking, contour routing, plus ESD/moisture-resistant packaging for secure transit.

- Eco-compliance customization: Uses RoHS/REACH-compliant materials (lead-free solder, eco-substrates) and processes to meet global environmental regulations.

How to Choose the Right PCB Manufacturer in Singapore?

Guide to Selecting a Reliable Singapore PCB Manufacturer:

1. Core Certifications and Standard Verification

- Prioritize International Authoritative Certifications: Select manufacturers certified with ISO 9001 (Quality Management), ISO 14001 (Environmental Management), UL (US Safety Certification), IPC Standards (Association Connecting Electronics Industries), and RoHS/REACH compliance. These certifications serve as the default “quality benchmark” for European and American clients.

- Specialized Process Certifications: For niche areas like high-frequency high-speed boards, HDI (High-Density Interconnect), rigid-flex boards, verify certifications such as NASA, AS9100 (Aerospace), or IATF 16949 (Automotive), demonstrating technical depth.

2. Technical Capability and Capacity Alignment

- Equipment and Process Transparency: Request a list of production line equipment (e.g., LDI Laser Direct Imaging, VCP Vertical Continuous Plating, AOI Automated Optical Inspection) and process parameter ranges (line width/spacing accuracy, layer count capability, minimum hole size) to ensure alignment with project requirements.

- Rapid Prototyping and Small Batch Capability: European-American clients often require fast design validation. Choose manufacturers offering 24-48 hour rapid prototyping and small batch delivery within 7 days to shorten R&D cycles.

- Material Supply Chain Transparency: Confirm key material brands (e.g., Panasonic M-Series, Shengyi Technology high-frequency materials) and traceability for substrates, solder masks (e.g., Taiyo Ink), avoiding substandard substitution risks.

3. Client Case Studies and Industry Reputation

- Verify Case Authenticity: Request references to past European-American client projects (e.g., German industrial control, US medical devices, Singapore 5G communications). Validate technical challenges solved (e.g., impedance control, thermal design) and final product performance.

- Third-Party Evaluations: Cross-reference delivery punctuality, yield rates, and after-sales responsiveness through industry forums (EE Times, EDN), supply chain rating platforms (Dun & Bradstreet), or independent audit reports.

4. Communication and Collaboration Efficiency

- Multilingual Support and Immediate Response: Engage manufacturers with multilingual teams (English/German/French) ensuring seamless design communication, technical issue feedback, and order status updates within 24 hours (European-American working hours).

- Digital Collaboration Tools: Prioritize manufacturers using direct EDA file integration (Altium, OrCAD), online quoting systems, and real-time production tracking platforms (ERP/MES integration) for enhanced collaboration efficiency.

5. Cost Efficiency and Long-Term Partnership

- Transparent Pricing and Cost Analysis: Request itemized quotes (material costs, processing fees, testing, shipping) and compare cost differentials between Singapore and Southeast Asian neighbors (Malaysia, Thailand). Clarify the added value of “Made in Singapore” (technical premium, logistics convenience).

- Long-Term Cooperation Mechanisms: Establish annual framework agreements defining price lock-in periods, priority capacity guarantees, and technology sharing (e.g., new material applications, process optimization) to mitigate long-term risks.

6. Environmental and Sustainability Practices

- Green Production Commitments: Confirm adoption of lead-free processes, wastewater treatment systems, energy-efficient equipment (LED curing), and published carbon footprint data to meet European-American ESG procurement requirements.

- Circular Economy Measures: Assess support for old board recycling and material reuse programs, reflecting emphasis on resource efficiency.

7. Site Visits and Risk Mitigation

- Factory Site Audits: For critical projects, arrange on-site inspections focusing on production environment (cleanroom class), quality control processes (first-article inspection, outgoing quality checks), employee training records, and safety protocol compliance.

- Third-Party Audit Options: If on-site visits are infeasible, commission international agencies (SGS, TĂV) for remote audits and detailed evaluation reports to inform decision-making.

How to Evaluate Production Capacity of PCB Manufacturers in Singapore?

Methods about how to evaluate production capacity of PCB manufacturers in Singapore:

1. Evaluate production equipment setup: Check for advanced equipment like high-precision laser drills, automated etching lines, and AOI inspection systems, equipment sophistication directly impacts manufacturing precision.

2. Confirm capacity scale: Inquire about peak/monthly capacity and maximum concurrent order capacity to align with long-term/batch needs.

3. Assess process coverage: Verify capability to produce PCBs of varying layers, materials, structures, and handle complex techniques like fine-pitch soldering or blind/buried vias.

4. Review technical team expertise: Gauge engineer team size, experience, and backgroundsâcritical for tackling custom tech challenges and DFM optimization.

5. Analyze raw material supply chain: Ensure stable partnerships with global suppliers of premium substrates (e.g., FR-4) and copper foil, raw material quality underpins production capability.

6. Examine production standardization: Check for standardized SOPs across operations to minimize quality variance from human factors.

7. Understand capacity flexibility: Assess ability to scale production or handle urgent orders amid demand fluctuations.

8. Validate quality consistency: Request 3-6 months of yield rate data and customer-reported defect stats to evaluate process control.

How to Evaluate Lead Time of PCB Manufacturing Companies in Singapore?

Methods about how to evaluate lead time of PCB manufacturing companies in Singapore:

1. Clarify standard lead time benchmarks: Request lead time tables for different PCB types (e.g., single-layer, multi-layer, flexible) as reference.

2. Understand production scheduling system: Check if orders are managed via digital systems with real-time status tracking to avoid manual scheduling errors.

3. Verify urgent order handling: Confirm priority tiers, capacity buffers, and minimum turnaround for rush orders.

4. Assess supply chain coordination efficiency: Evaluate component sourcing timelines (if outsourced) and logistics models impacting overall lead time.

5. Confirm progress communication protocol: Define update frequency (daily/weekly) and format (system alerts/emails) for transparency.

6. Review on-time delivery history: Request last 6 monthsâ OTIF (on-time-in-full) data to assess actual vs. promised lead times.

7. Define delay mitigation terms: Include liability and compensation clauses (e.g., daily deductions) in contracts to protect interests.

8. Evaluate force majeure preparedness: Inquire about contingency plans for supply shortages or equipment failures to gauge risk resilience.

Frequently Asked Questions

Q1: PCB prototypes deviate from design drawings, affecting assembly?

A1: Choose manufacturers supporting DFM pre-analysis. Before placing orders, professional engineers conduct manufacturability reviews of design drawings to correct layout, hole positions, etc., in advance. After prototyping, detailed inspection reports are provided to ensure consistency with drawing parameters.

Q2: Small-batch orders frequently experience delivery delays and poor communication feedback?

A2: Prioritize manufacturers with dedicated customer service mechanisms and assign clear order follow-up personnel. Sign contracts with delivery guarantee clauses requiring regular production progress updates. In case of delays, provide clear reasons and resolution measures.

Q3: PCB products exhibit instability in high-temperature environments?

A3: Specify the product’s operating temperature range when ordering. Manufacturers recommend high-temperature-resistant substrates (e.g., high-Tg FR-4) and corresponding processes. Conduct high-temperature environmental simulation testing post-production to ensure compliance with usage requirements.

Q4: Partial PCB electrical performance fails to meet standards during mass production?

Solution: Select manufacturers with full-process quality inspection systems and request batch sampling reports. In case of issues, the manufacturer must respond within 24 hours, analyze failure causes, provide return/replacement/replenishment solutions, and bear associated losses.

Q5: Complex design schemes raise uncertainty about mass production feasibility?

A5: Seek manufacturers with experienced technical teams offering design evaluation services. First conduct small-batch pilot production to verify process feasibility and product stability before initiating mass production, reducing risks.