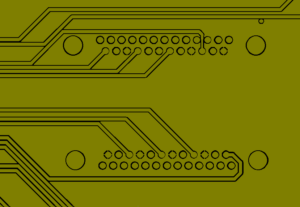

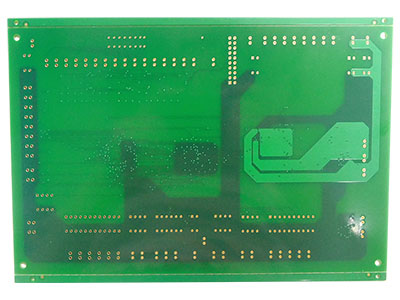

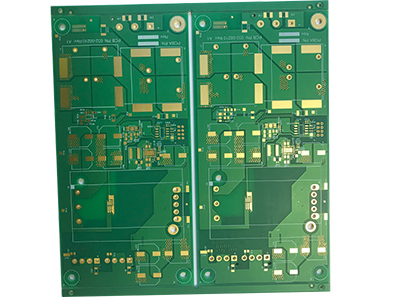

The aluminum PCB is a unique metal base copper clad laminate , it has good thermal conductivity, electrical insulation properties and machining property.

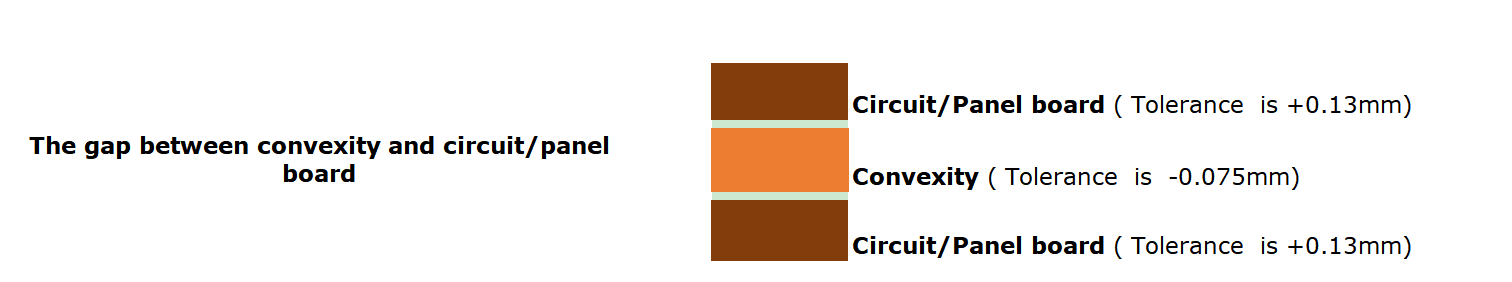

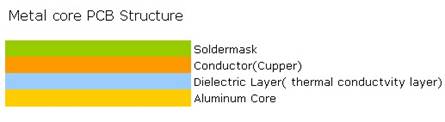

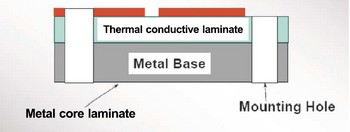

The structure of aluminum PCB is divided into three layers.

First layer: base layer, it is the metal substrate, which can choose copper or aluminum.

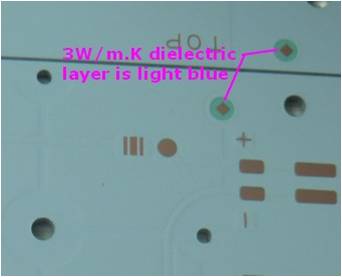

Second layer: dielectric Layer, its thickness be from 0.003 inch to 0.006 inch.

Third layer: circuit layer, the copper thickness of the circuit is from 1oz to 10oz.

The advantage of aluminum PCB:

- it has good heat radiation and better strength.

The disadvantage of aluminum PCB:

- High cost.

- The current mainstream can only do single aluminum PCB, it is difficult to do double sided aluminum PCB.

- The product will be more easily to have matter in electrical strength and pressure.

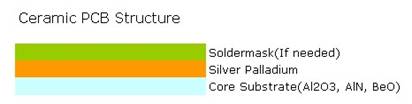

Aluminum core PCB have good thermal conductivity but Ceramic PCB will better,if you would like to know more about the different from FR4,MCPCB and Ceramic PCB,pls visit to for more information.