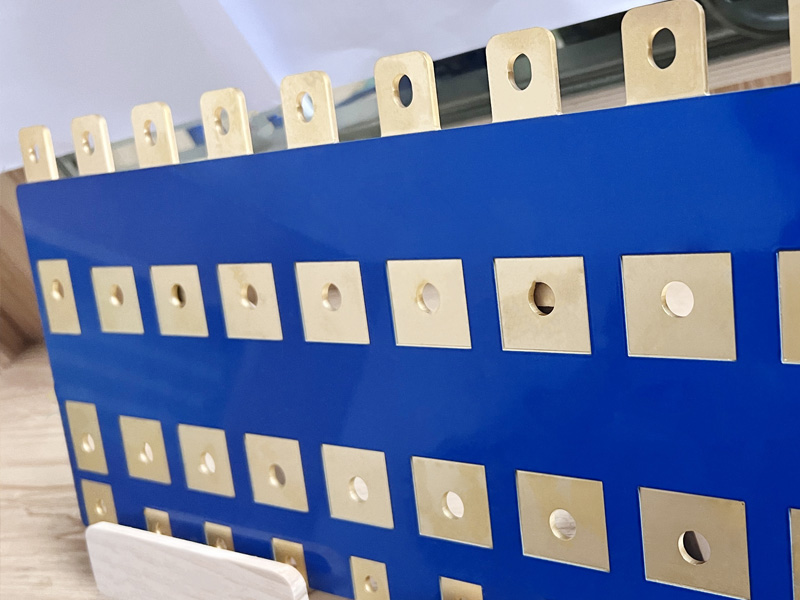

Thailand has emerged as a global hub for electronic manufacturing, with PCB assembly Thailand gaining traction due to mature industrial clusters and strategic geographic advantages. Local and international firms leverage the region’s stable supply chains and policy incentives to deliver reliable assembly services. As global demand for high-precision electronics grows, PCB assembly Thailand continues to evolve, focusing on advanced processes for automotive, medical, and AI server applications, solidifying its position as a top choice in Southeast Asia.

Top 10 PCB Assembly Manufacturer in Thailand

| Company Name | Main Business | Core Advantages | PCBA Capability | Lead Time |

| EBest Circuit Co., Limited (Best Technology Circuit Co., Limited) | High-density interconnect (HDI) PCB, SMT assembly, full-turnkey services | Global supply chain integration, advanced DFM support, ISO certifications | 2-64 layer PCB assembly, BGA/CSP reworking, precision soldering | 5-7 working days for mass production, 48hrs for urgent samples |

| Fujikura Co., Ltd. | FPC assembly for iPhone, Mac, and consumer electronics | Established 2013 in Kabinburi, Apple-certified supplier, mature process control | Precision FPC assembly, high-volume production, reliable soldering | 5-8 working days for mass production, 3 days for FPC samples |

| Compeq Co., Ltd. | FPC, rigid PCB, and HDI assembly for Apple supply chain | Global supply chain, automated production lines, BOI tax incentives | High-layer HDI (up to 24 layers), FPC integration, precision assembly | 6-9 working days for mass production, 4 days for HDI samples |

| Delta Electronics Co., Ltd. | Automotive, industrial PCB assembly and electronic integration | IATF 16949 certified, Amata Industrial Park base, local sourcing | Multi-layer PCB (2-32 layers), automotive-grade soldering, functional testing | 7-12 working days for mass production, 5 days for automotive samples |

| Unimicron Co., Ltd. (Xinxing Electronics) | High-multi-layer PCB, IC carrier board assembly for semiconductors | Advanced testing equipment, high-end product focus, stable power supply | IC carrier board assembly, high-frequency PCB processing, impedance control | 10-14 working days for mass production, 7 days for high-end samples |

| Dongshan Precision Co., Ltd. | FPC assembly for wearables, new energy vehicles and consumer electronics | 50M USD investment, 400,000„é° production area, automated SMT | Miniature FPC assembly, wearable device PCB integration, rework services | 6-9 working days for mass production, 3 days for wearable FPC samples |

| NOK Corporation Co., Ltd. | Display touch FPC, module PCB assembly for iPhone and consumer devices | Ayutthaya base, dual-site layout (Thailand/Vietnam), Apple-certified | Display module PCB integration, precision connection processing, FPC assembly | 7-11 working days for mass production, 4 days for touch FPC samples |

| Sumitomo Electric Co., Ltd. | High-frequency PCB, automotive PCB assembly for telecom/automotive | JIS certified, long-term SEA presence, high-frequency technology expertise | High-frequency PCB processing, automotive-grade assembly, reliability testing | 8-13 working days for mass production, 6 days for high-frequency samples |

| AKM Meadville Co., Ltd. | HDI PCB assembly for automotive and consumer electronics | Rojana Industrial Park (port proximity), logistics efficiency, IATF 16949 | Automotive-grade HDI assembly, high-reliability soldering, batch optimization | 7-10 working days for mass production, 4 days for automotive HDI samples |

| TTM Technologies Co., Ltd. | Aerospace, industrial PCB assembly and high-precision manufacturing | AS9100D certified, advanced testing, global quality system | Multi-layer PCB (2-48 layers), aerospace-grade assembly, full traceability | 10-15 working days for mass production, 8 days for aerospace samples |

Quality Standard of PCB Assembly Thailand

- IPC-A-610: Acceptability standard for electronic assemblies, covering soldering quality, component placement, and mechanical integrity.‚Äč

- IPC-6012: Specification for rigid printed boards, ensuring material performance and structural reliability for Thailand PCB assembly.‚Äč

- ISO 13485: Mandatory for medical device-related PCB assembly Thailand, governing quality management systems.‚Äč

- IATF 16949: Required for automotive PCB assembly, focusing on defect prevention and continuous improvement.‚Äč

- RoHS & REACH Compliance: Restricting hazardous substances, mandatory for all export-oriented PCB assembly in Thailand.

Pain Points of PCB Assembly Supplier Thailand

- Capacity and yield ramp-up takes 12 months on average, affecting production stability for new facilities.

- Fluctuations in raw material prices, especially copper, impact profit margins without effective hedging.

- Shortage of specialized components delays production, with limited local alternative sources.

- Logistics bottlenecks for international component sourcing, leading to unpredictable lead times.

- High cost of advanced testing equipment, restricting small to medium firms from high-end markets.

- Compliance complexity across multiple standards (automotive, medical) increases administrative burden.

- Energy supply stability risks, despite industrial parks’ robust infrastructure.

- Difficulty in balancing cost efficiency with premium quality requirements for global clients.

Why Choose EBest( Best Technology) for PCB Assembly Thailand?

Reasons Why Choose EBest(Best Technology) for PCB Assembly Thailand:

- 19 years of production experience with extensive Thailand PCBA projects, mastering cross-regional supply chain management to mitigate local component shortages.

- Full suite of certifications including IATF 16949, ISO 9001:2015, ISO 13485:2016, AS9100D, REACH, RoHS, and UL, simplifying compliance for diverse industries.

- 24-hour prototype delivery and efficient mass production lead times, addressing yield and ramp-up delays faced by local manufacturers.

- One-stop PCB assembly Thailand services, covering component sourcing, assembly, testing, and delivery to reduce logistics bottlenecks.

- Free DFM analysis to optimize design for manufacturability, lowering production costs and improving yield rates.

- MES system integration enables full-process traceability, resolving quality control and accountability challenges.

- Dedicated component alternative sourcing team, providing reliable backups for scarce parts to avoid production halts.

- In-house advanced testing equipment, eliminating the need for third-party services and reducing quality control costs.

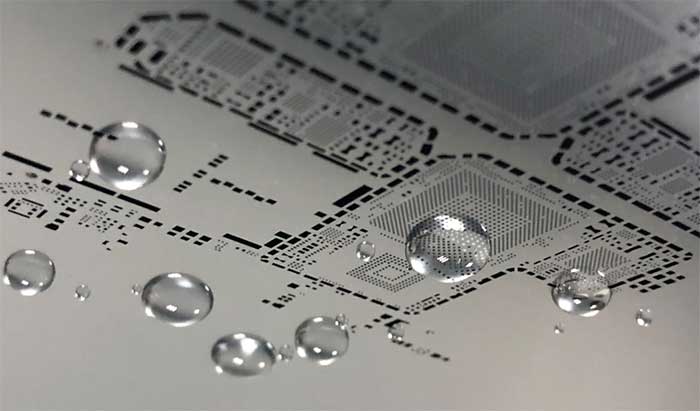

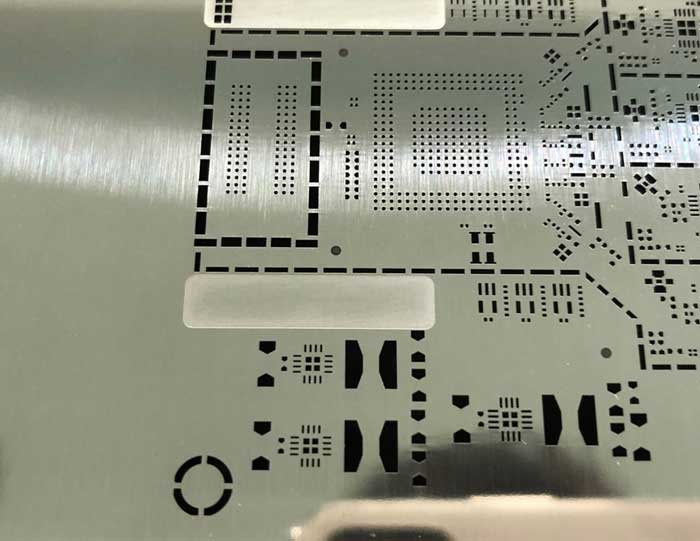

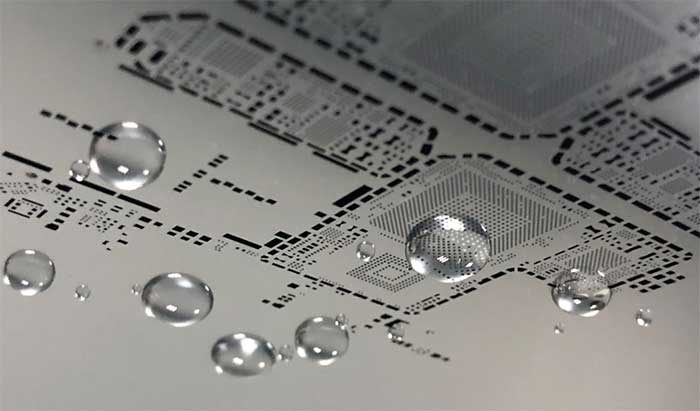

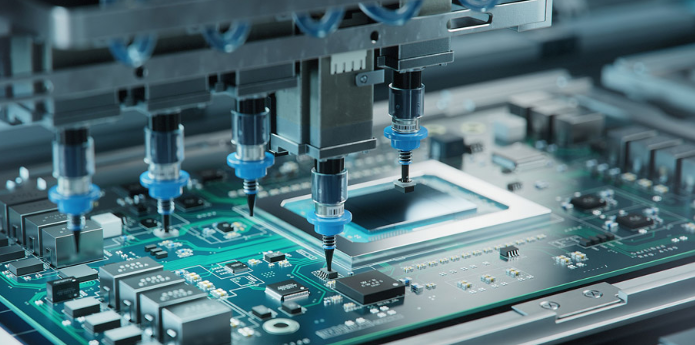

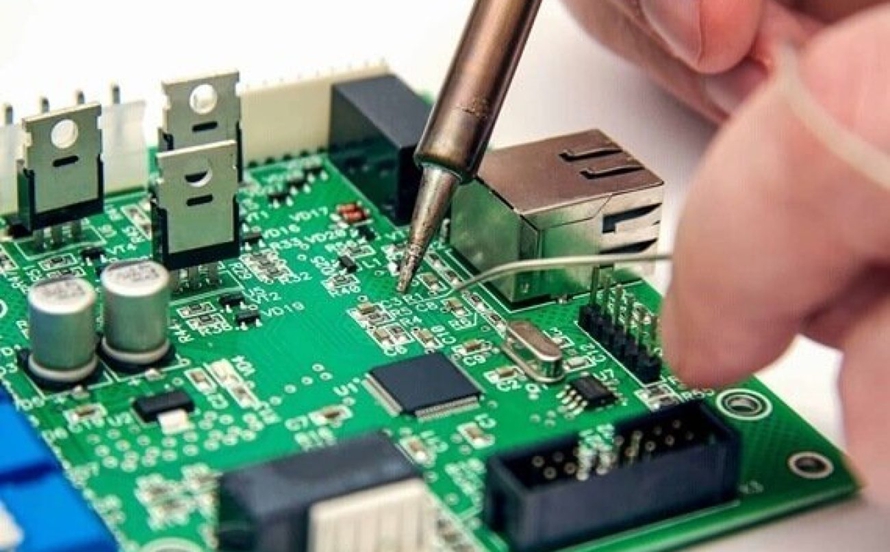

Our PCB Assembly Quality Control Process

- Incoming material inspection: 100% screening of components against BOM lists and IPC-A-610 standards, combining X-ray detection, high-magnification visual inspection, and electrical testing (LCR measurement). We verify component values, specifications, and integrity to eliminate oxidation, damage, or counterfeit parts before warehouse storage, laying a solid foundation for PCB assembly Thailand quality. ‚Äč

- In-process inspection: Conducts fixed-point checks every 2 hours at printing, mounting, and soldering stages, paired with random sampling reviews. MES system synchronously logs all data, including solder paste thickness, component placement accuracy, and soldering parameters, triggering real-time alerts for anomalies to enable immediate correction and prevent batch defects. ‚Äč

- Finished product testing: Integrates ICT (circuit continuity testing), FCT (functional performance verification), and X-ray tomography. This covers 100% of hidden soldering defects (e.g., voids, cold joints) and validates product performance against design requirements, ensuring consistency for high-precision Thailand PCB assembly applications. ‚Äč

- Traceability system: Full-lot tracking from raw materials to delivery via unique batch codes. Records include component supplier info, production station, testing data, and operator details, enabling rapid root-cause analysis for any issues. This meets strict compliance requirements for medical, automotive, and aerospace industries, reinforcing accountability.

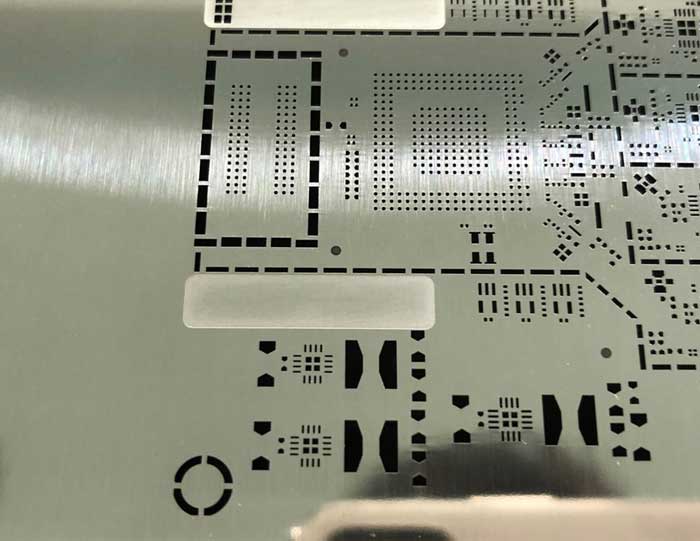

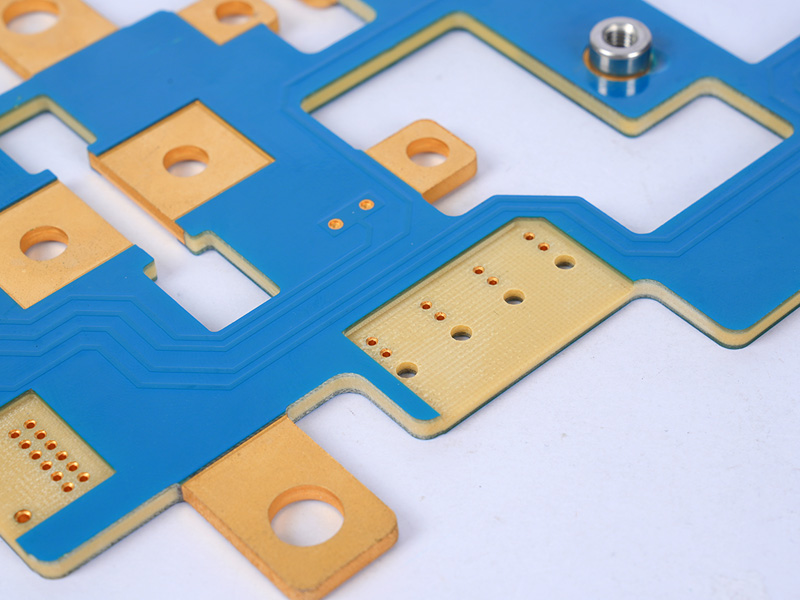

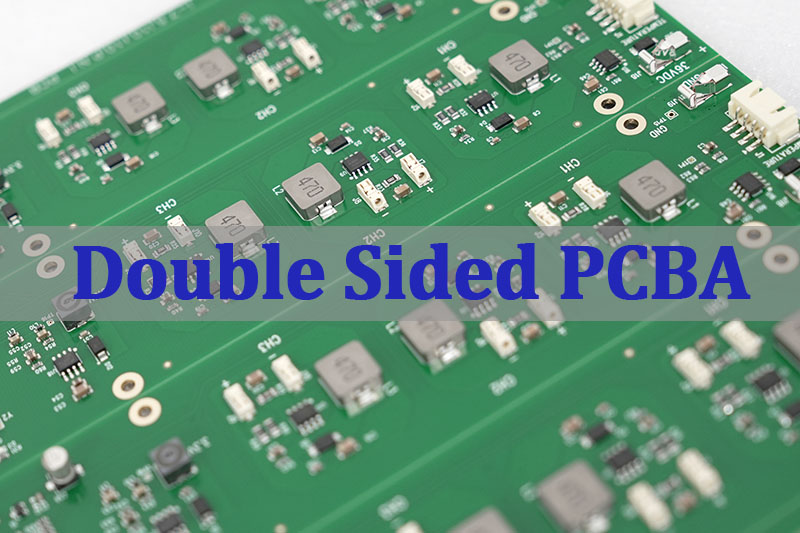

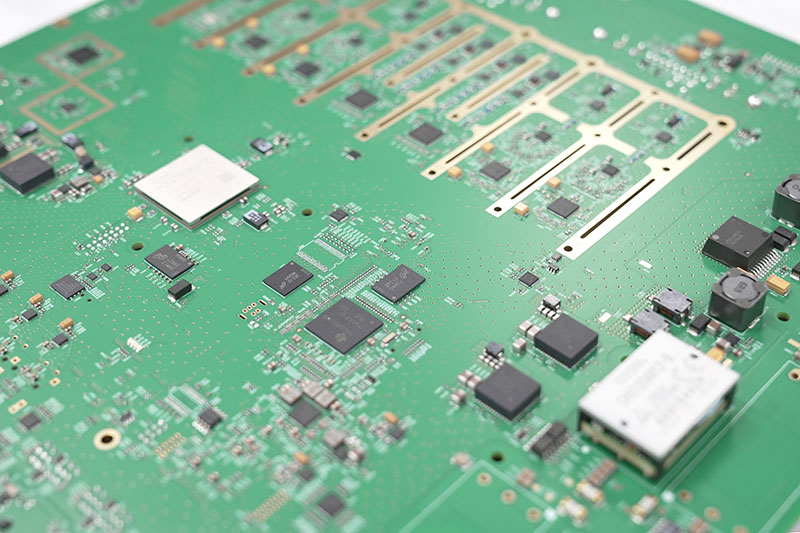

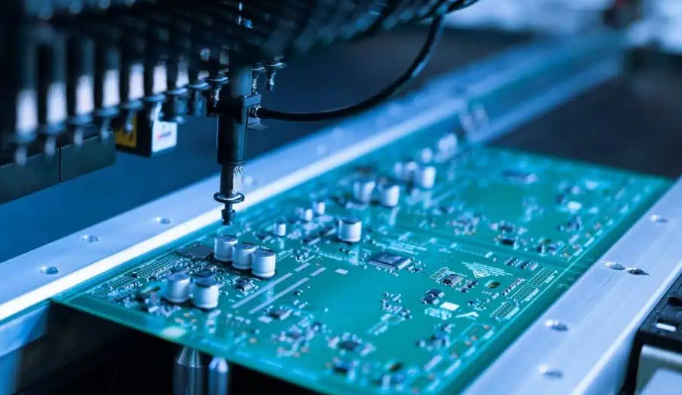

Our PCB Assembly Capabilities

| Item | Capabilities |

| Placer Speed | 13,200,000 chips/day |

| Bare Board Size | 0.2 x 0.2 inches – 20 x 20 inches/ 22*47.5 inches |

| Minimum SMD Component | 01005 |

| Minimum BGA Pitch | 0.25mm |

| Maximum Components | 50*150mm |

| Assembly Type | SMT, THT, Mixed assembly |

| Component Package | Reels, Cut Tape, Tube, Tray, Loose Parts |

| Lead Time | 1 – 5 days |

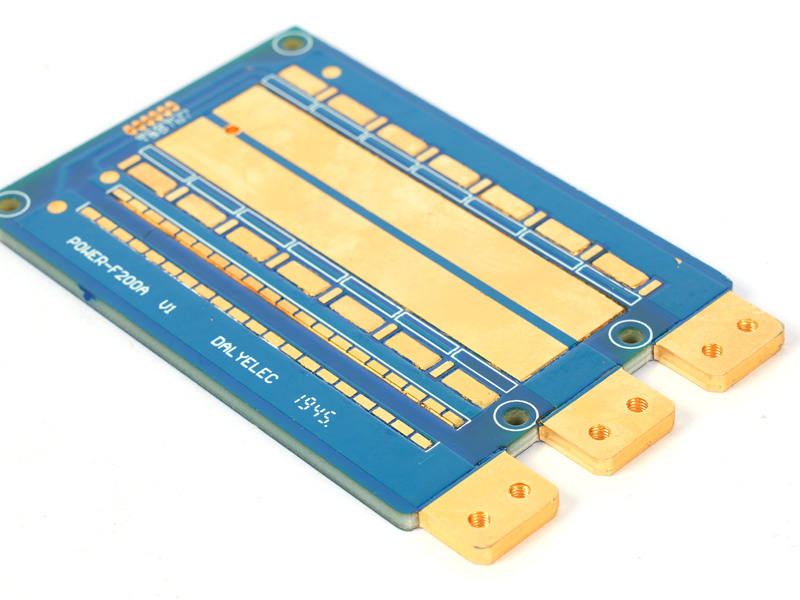

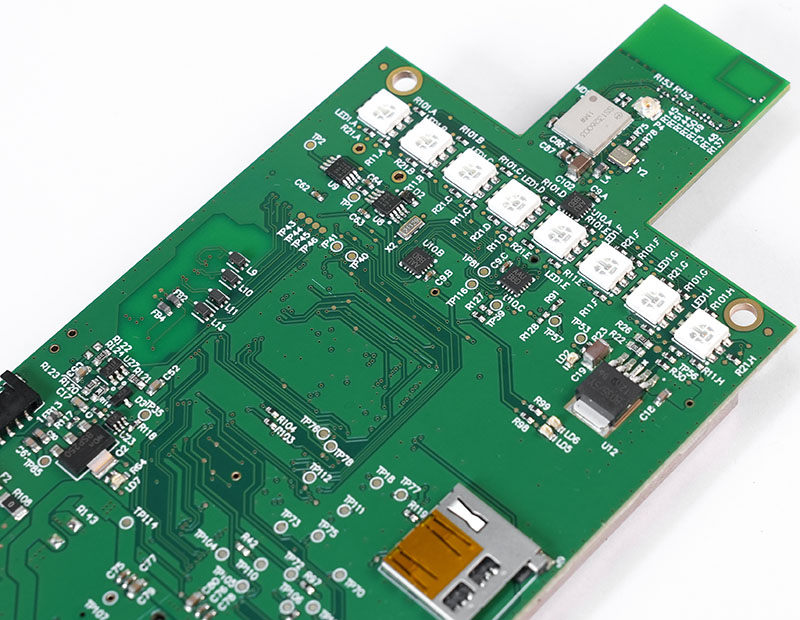

Case Studies of Our Medical PCB Assembly Thailand

Project Background: A Thai-based medical device company specializing in portable diagnostic equipment sought a reliable Thai PCB assembly partner for its newly developed blood analyzer. The analyzer was designed for primary healthcare facilities and mobile clinics. Project requirements included strict adherence to ISO 13485 standards, material biocompatibility (to avoid adverse reactions upon contact with the human body), and compliance with the Thai Food and Drug Administration (TFDA) medical device regulations.

Project Requirements: Precision assembly of 01005 size micro-components (core sensors and connectors), a yield rate of over 99.95% to ensure clinical reliability, a 15-day delivery time for 5000 units (to meet the deadline for a Southeast Asian medical exhibition), and batch-level comprehensive traceability for TFDA submission, including component origin and production parameters.

Challenges: Shortage of locally available FDA-certified medical-grade connectors and micro-sensors, requiring 2-3 weeks for international procurement; tight delivery schedule conflicting with traditional prototyping cycles; ensuring solder joint void rate (‚ȧ3%) and impedance stability (¬Ī5%) to prevent signal interference during clinical use.

Solution: We leveraged our global supply chain to source FDA-certified components from pre-certified European suppliers, completing delivery within 72 hours. 24-hour prototype production was initiated for design verification, combined with MES-driven process control to monitor solder paste thickness (0.12-0.15mm) and placement accuracy (¬Ī0.02mm). Free DFM analysis was provided to optimize component layout, avoid heat concentration areas, and improve impedance consistency.

Project Results: A yield rate of 99.98% was achieved (only 10 defective units out of 5000), with delivery completed 3 days ahead of schedule (total 12 days). Clinical trials confirmed 100% signal stability and no biocompatibility issues; TFDA traceability documentation was approved on the first submission. The client expanded the scope of cooperation, designating us as the exclusive Thai PCB assembly supplier for two new product lines (portable ultrasound equipment and blood glucose meters).

FAQs of PCB Assembly Thailand

Q1: Do you meet the compliance certifications required for PCB assembly in Thailand?‚Äč

A1: Yes, we hold IATF 16949, ISO 9001:2015, ISO 13485:2016, AS9100D, REACH, RoHS, and UL certifications, fully complying with local and global industry standards for PCB assembly Thailand.‚Äč

Q2: What payment methods do you accept for Thailand clients?‚Äč

A2: We offer flexible payment terms including T/T (30% deposit, 70% before delivery), L/C at sight, and monthly payment plans for long-term partners, adapting to local financial practices.‚Äč

Q3: How do you protect intellectual property for Thailand-based clients?‚Äč

A3: We sign NDA agreements before project initiation, restrict internal access to design files, and implement secure data storage systems, ensuring full IP protection throughout the PCB assembly process.‚Äč

Q4: What after-sales services do you provide for PCB assembly in Thailand?‚Äč

A4: We offer 12-month warranty for all products, provide technical support within 24 hours, and conduct root cause analysis for any quality issues, with free rework for non-client-related defects.‚Äč

Q5: What is the minimum order quantity (MOQ) and component alternative solutions?‚Äč

A5: Our MOQ is 10 units for prototypes and 500 units for mass production. For component shortages, our engineering team provides verified alternatives with equivalent performance, ensuring production continuity without quality compromise.