In medical PCBA (Printed Circuit Board Assembly), IQ, OQ, and PQ are not procedural formalities; they are foundational controls that directly support patient safety, regulatory compliance, and long-term product reliability. Together, they form a structured validation framework required by global medical regulations and expected by auditors, OEMs, and notified bodies.

Below is a clear, manufacturing-focused explanation of why IQ, OQ, and PQ are critical for medical PCBA projects.

Regulatory Compliance Is Not Optional in Medical PCBA

Medical electronic assemblies fall under strict regulatory frameworks such as ISO 13485, FDA 21 CFR Part 820, and EU MDR. These regulations explicitly require manufacturers to validate production processes, not merely inspect finished products.

IQ, OQ, and PQ collectively demonstrate that:

- The manufacturing environment is suitable

- The process is capable and controlled

- The output is consistently compliant

Without documented IQ/OQ/PQ evidence, a medical PCBA supplier will fail audits, risk regulatory findings, or cause customer design transfer delays.

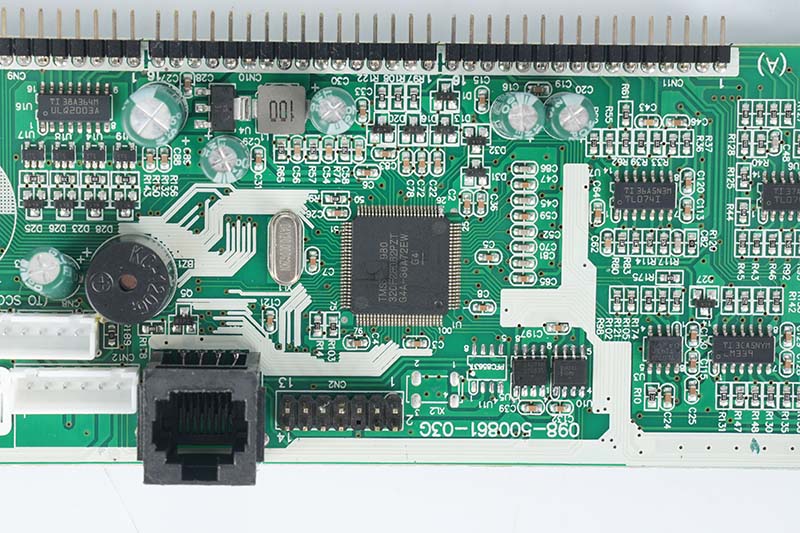

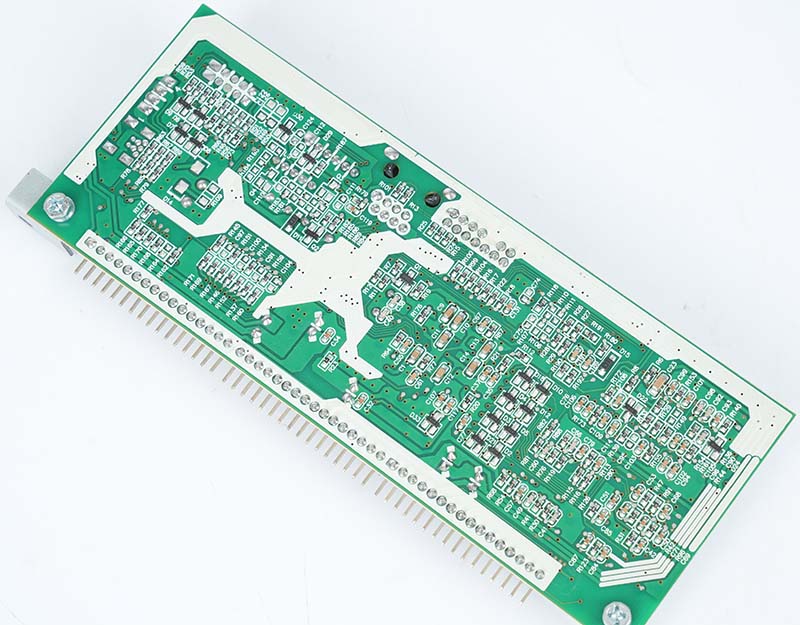

IQ (Installation Qualification): Proving the Factory Is Correctly Set Up

IQ answers one fundamental question:

Is the equipment and infrastructure installed exactly as required?

In medical PCBA, IQ typically covers:

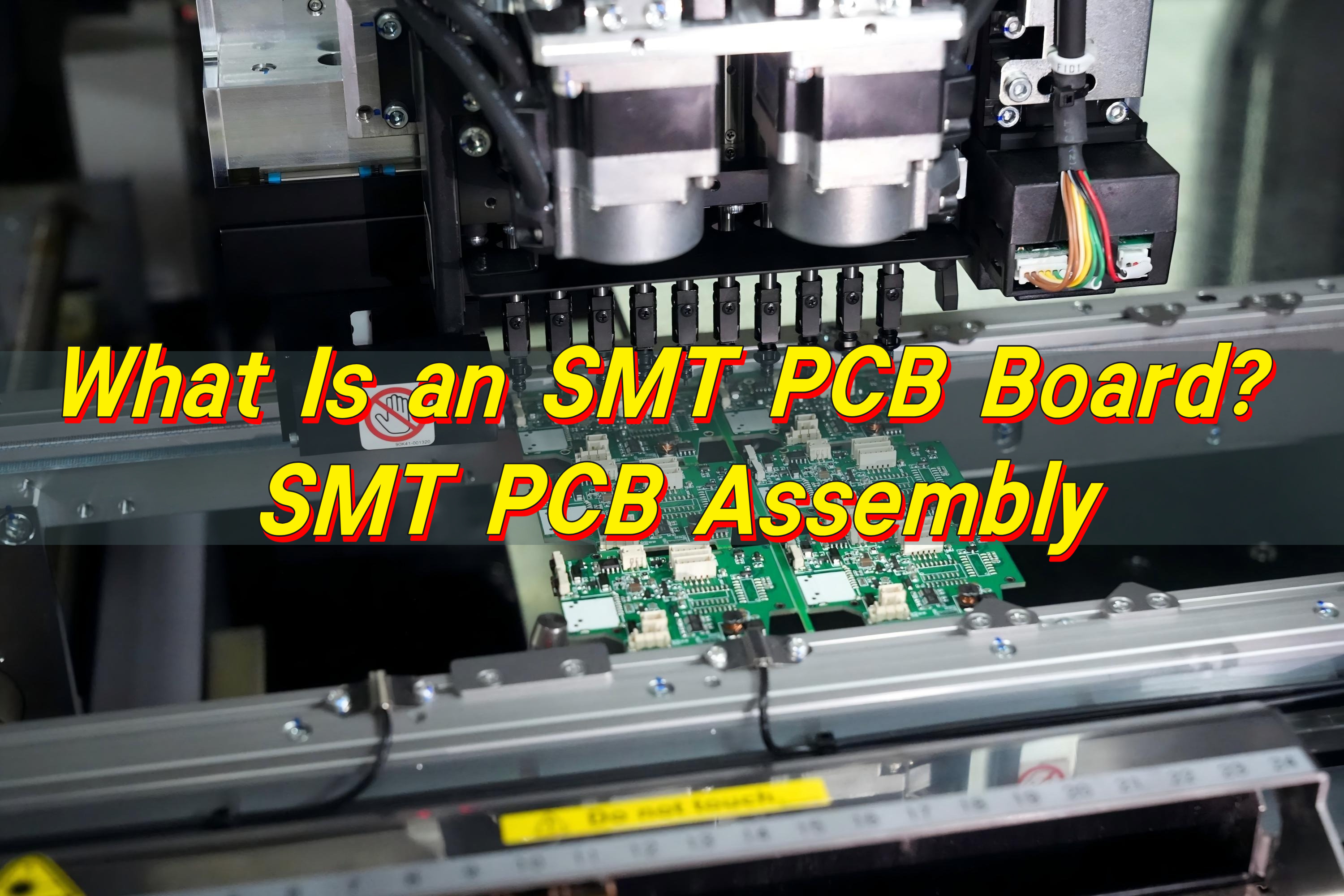

- SMT placement machines (model, accuracy, software version)

- Reflow ovens (zones, nitrogen capability, temperature uniformity)

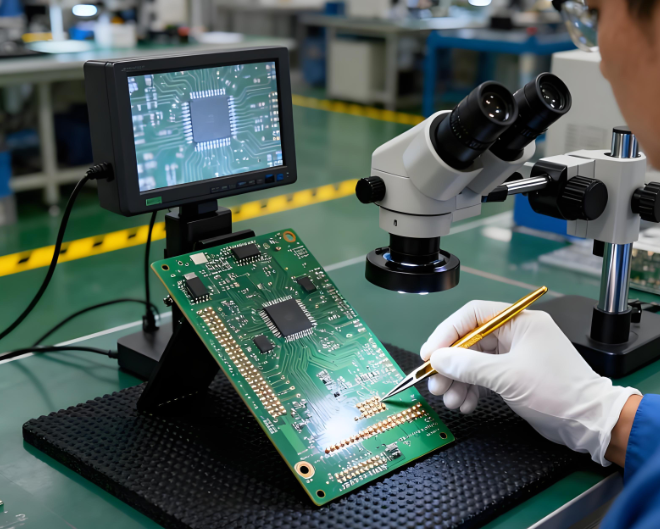

- AOI, SPI, X-ray systems

- ESD control systems

- MES and traceability systems

- Calibration status of measurement equipment

Why IQ matters for medical PCBA:

- Ensures no unauthorized equipment substitutions

- Prevents undocumented machine changes that invalidate builds

- Establishes a baseline configuration for future audits

- Supports traceability for long-life medical devices

Without IQ, even a ‚Äúgood‚ÄĚ PCBA build can be regulatorily unacceptable.

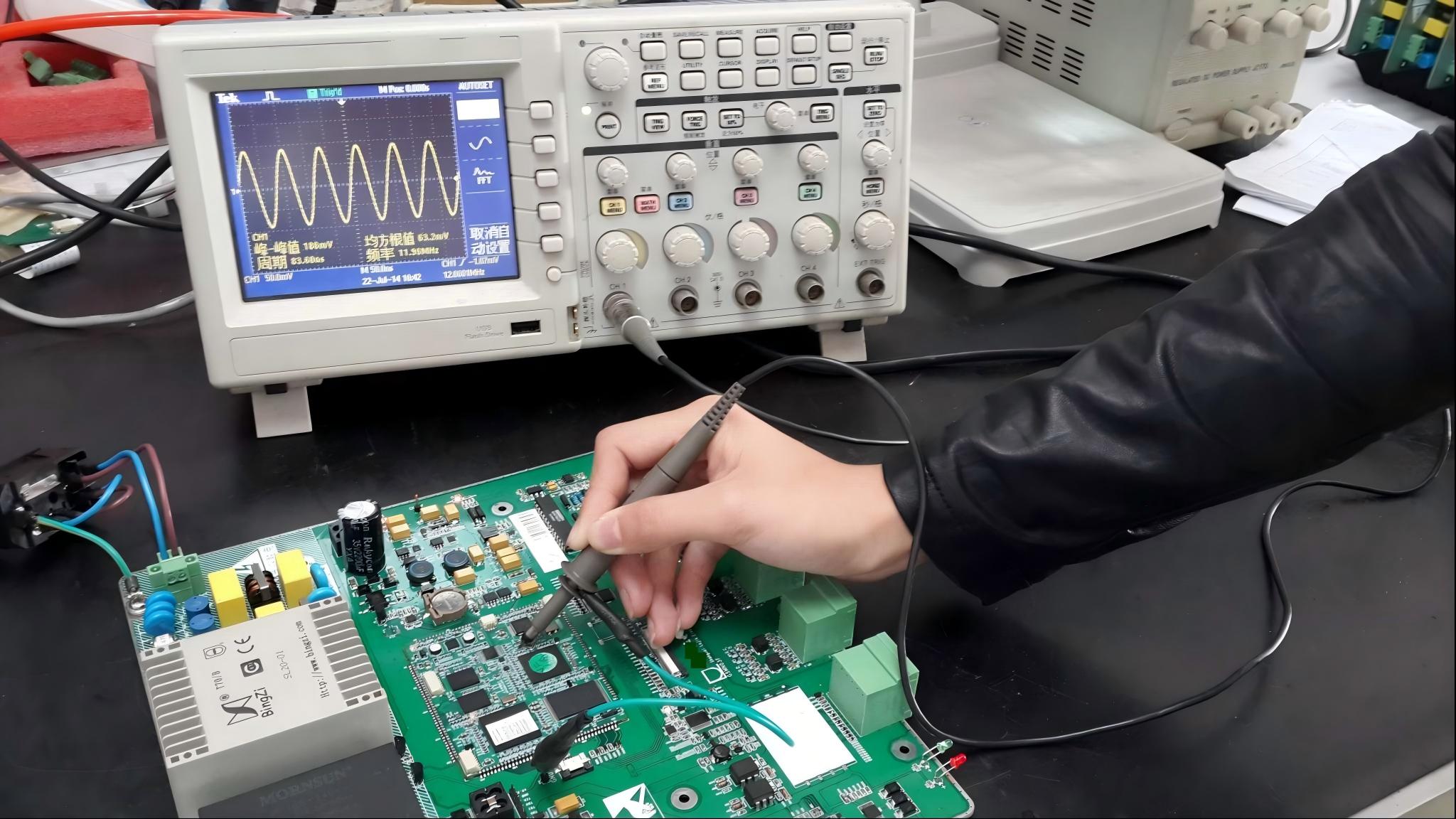

OQ (Operational Qualification): Proving the Process Works Under Defined Limits

OQ focuses on process capability, not just setup.

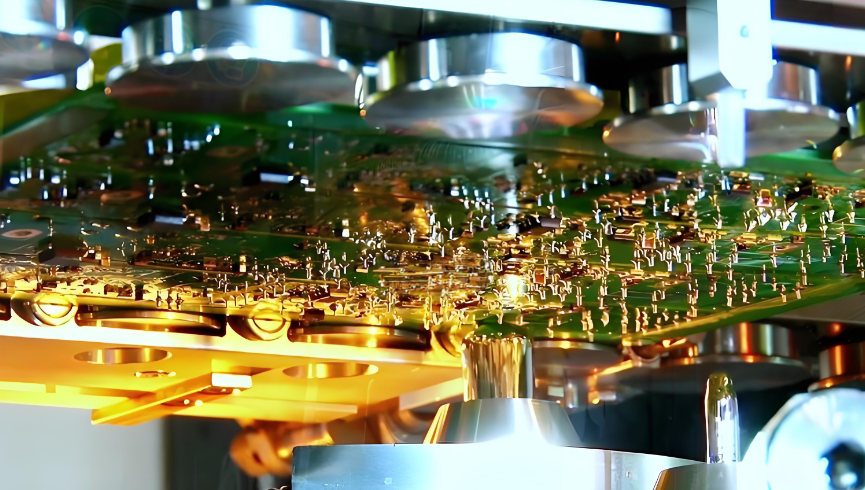

It verifies that each PCBA process step performs reliably within specified operating ranges, such as:

- Solder paste printing pressure, speed, and alignment

- Pick-and-place accuracy at min/max component sizes

- Reflow temperature profiles and thermal margins

- Cleaning effectiveness for ionic contamination limits

- Conformal coating thickness consistency (if applicable)

Why OQ is essential in medical PCBA:

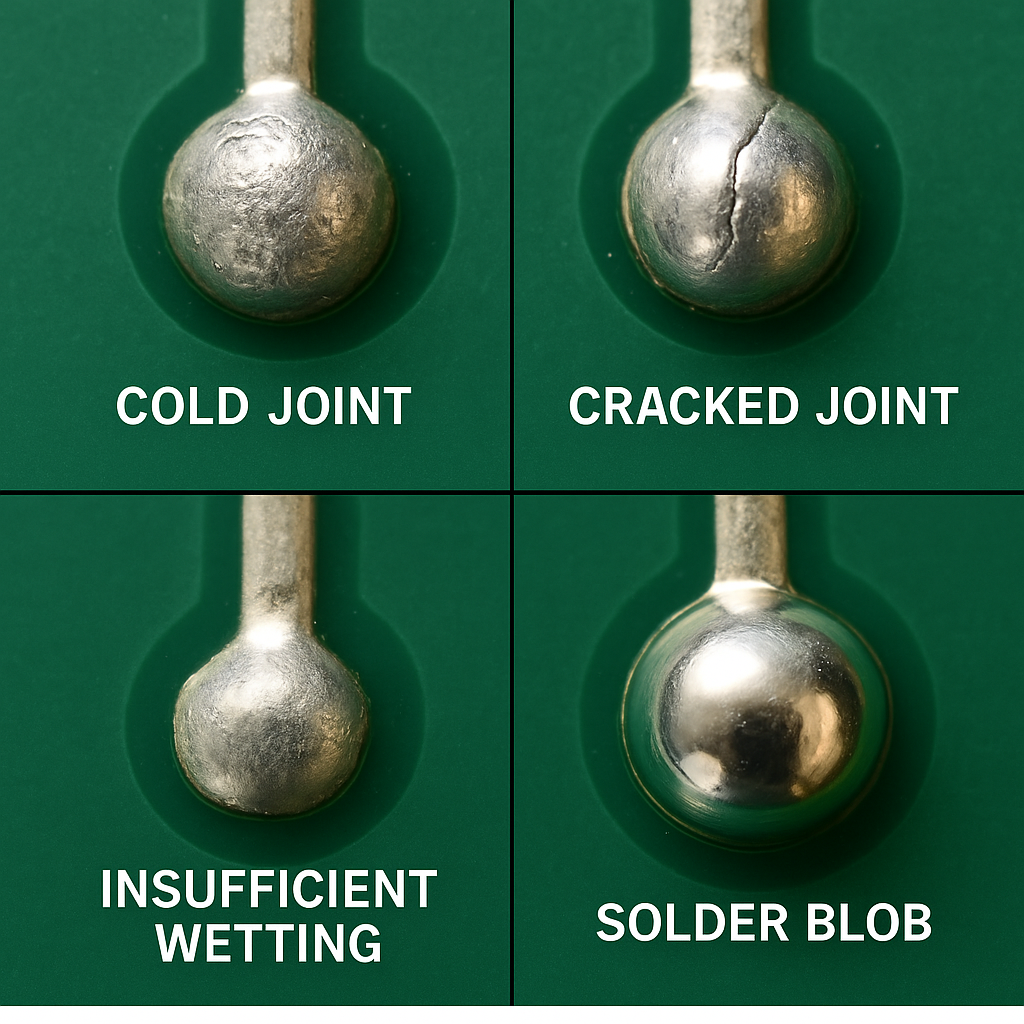

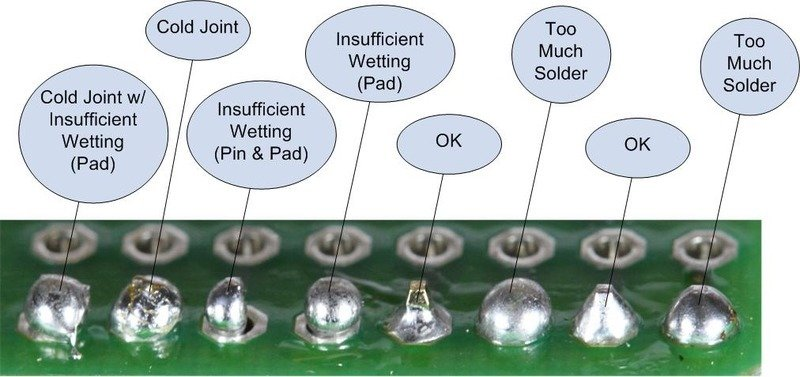

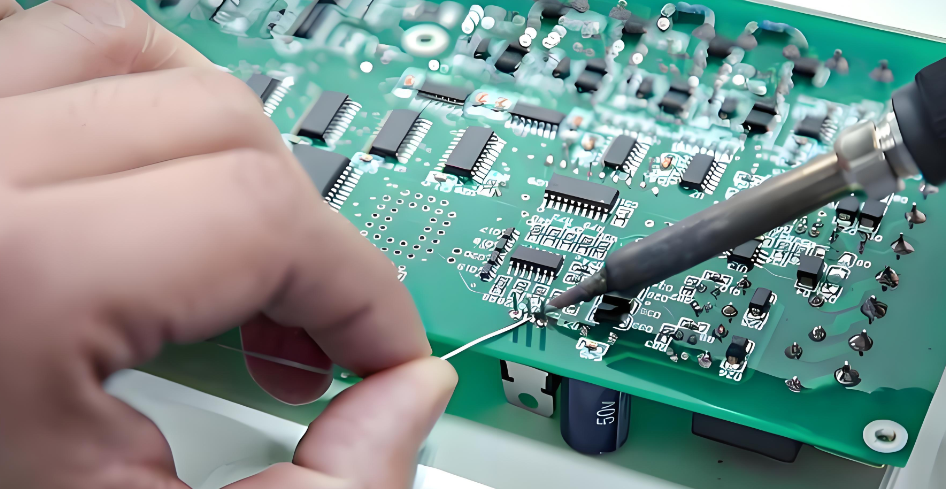

- Medical electronics often have tight solder joint reliability requirements

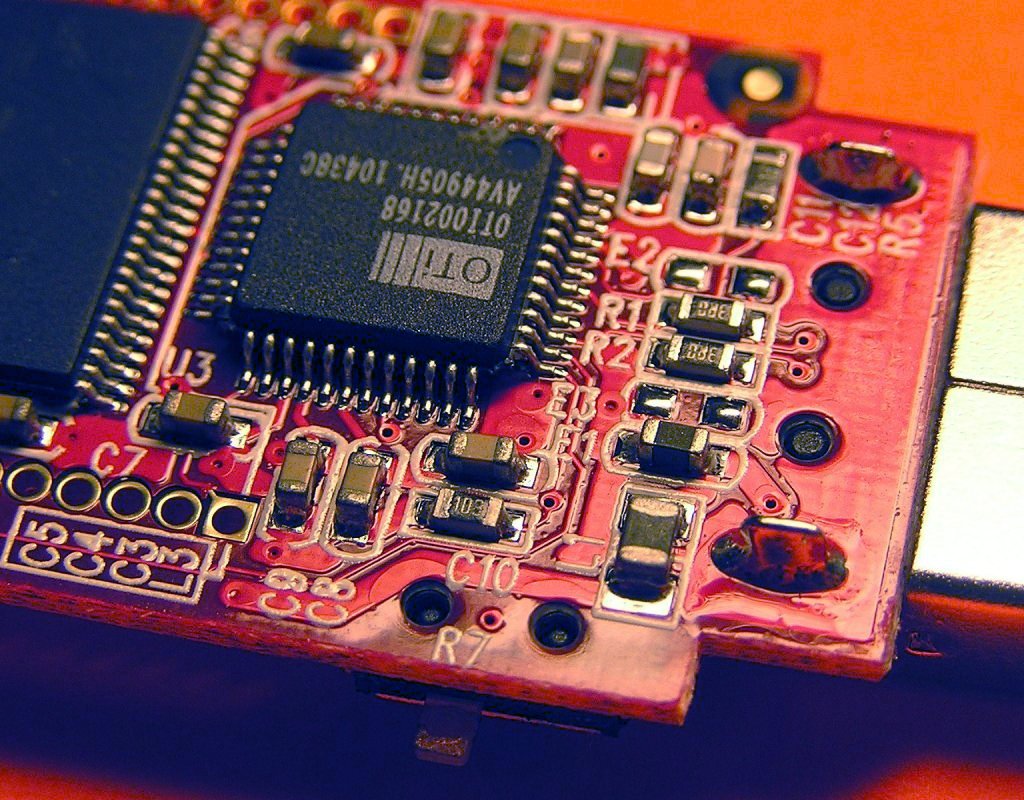

- High-density, fine-pitch, or mixed-technology boards amplify risk

- Many medical failures are process-induced, not design-induced

- OQ establishes defensible process windows

Auditors often focus heavily on OQ because it proves engineering control, not operator dependence.

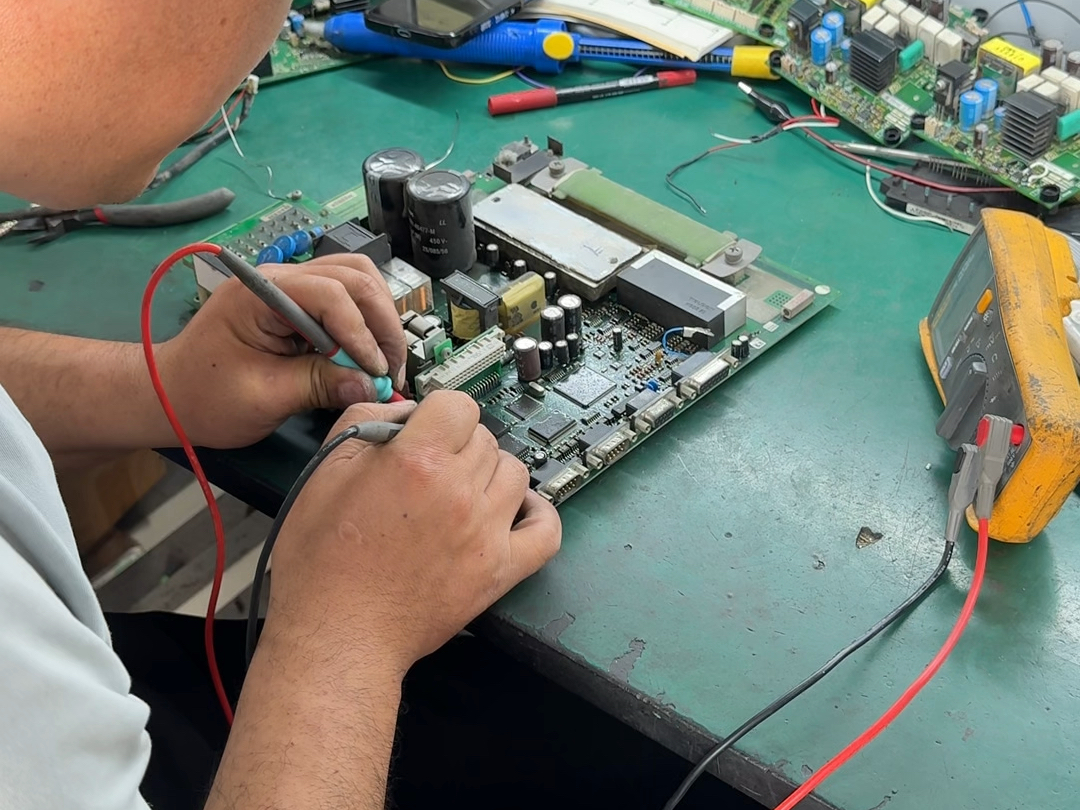

PQ (Performance Qualification): Proving Consistent, Repeatable Output

PQ answers the most important question:

Can we repeatedly build compliant medical PCBAs under real production conditions?

PQ involves:

- Running multiple production lots

- Using trained operators

- Normal shift conditions (not engineering trials)

- Measuring yields, defects, and key quality metrics

Typical PQ evidence includes:

- First-pass yield (FPY)

- Defect per million (DPMO)

- Functional test pass rates

- Reliability screening results (as applicable)

Why PQ is critical for medical PCBA programs:

- Confirms stability over time, not just once

- Supports design transfer from prototype to volume

- Reduces field failure risk

- Protects OEMs from recalls and liability exposure

For implantable, life-support, or diagnostic devices, PQ is often scrutinized line-by-line during audits.

Risk Reduction and Patient Safety

Medical PCBAs frequently operate in:

- Life-critical systems

- Continuous-use environments

- High-reliability diagnostic platforms

IQ/OQ/PQ validation directly reduces:

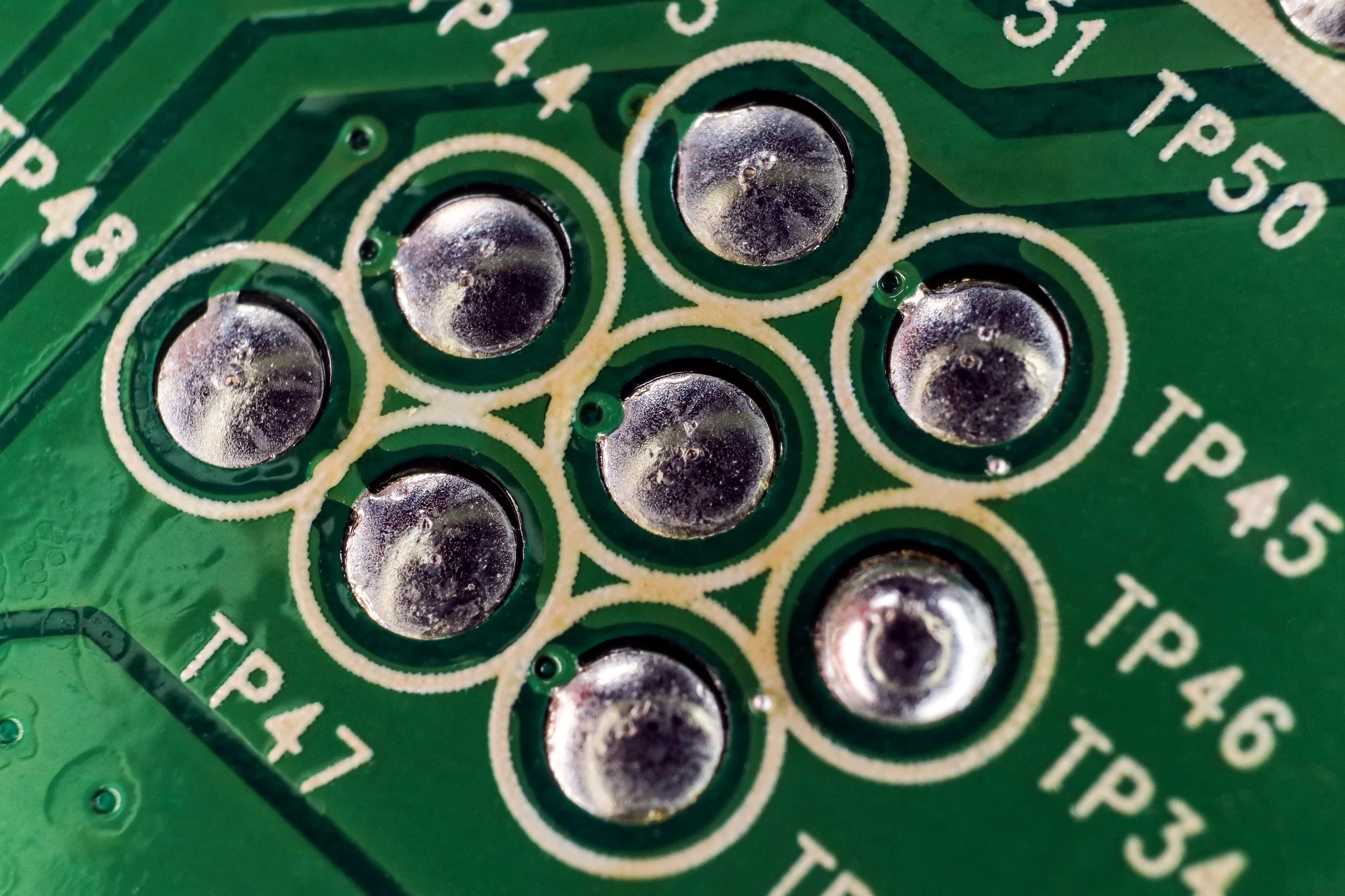

- Latent solder joint defects

- Intermittent electrical failures

- Process drift over long production cycles

- Human variability in assembly steps

In medical applications, a single uncontrolled process variable can translate into patient harm. Validation converts unknown risks into controlled, documented ones.

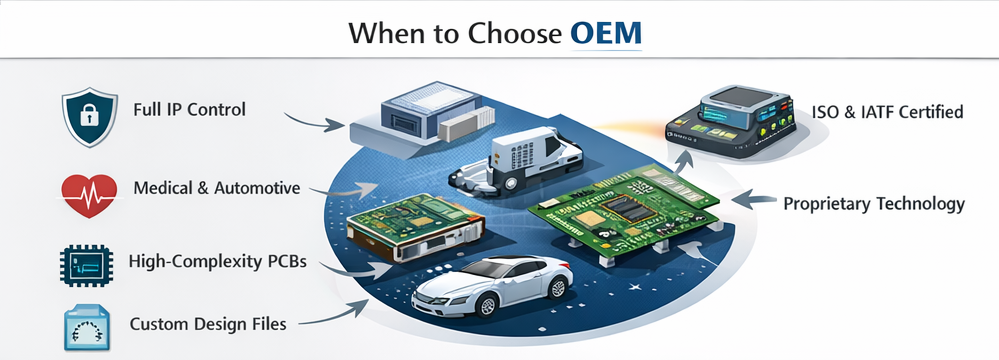

OEM Confidence and Long-Term Supply Stability

From a customer perspective, IQ/OQ/PQ:

- Shortens supplier qualification timelines

- Simplifies regulatory submissions

- Enables faster scale-up

- Reduces ongoing audit burden

Medical OEMs increasingly select PCBA partners based on validation maturity, not just price or capacity.

A supplier that can present complete IQ/OQ/PQ documentation is signaling long-term manufacturing discipline and regulatory readiness.

Why IQ, OQ, PQ Are Non-Negotiable for Medical PCBA?

In medical PCBA manufacturing:

- IQ proves the factory is correctly installed

- OQ proves the process is technically capable

- PQ proves consistent, real-world performance

Together, they ensure:

- Regulatory compliance

- Process stability

- Product reliability

- Patient safety

Medical electronics demand more than ‚Äúworking boards.‚ÄĚ They demand validated processes that work every time.