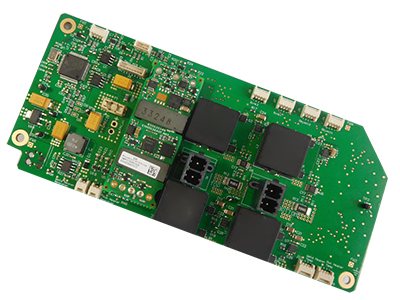

As a matter of fact, PCB experts will always know the major benefits of automated assembly processes: reduced errors, increased output and consistent quality, however, is automation always better?

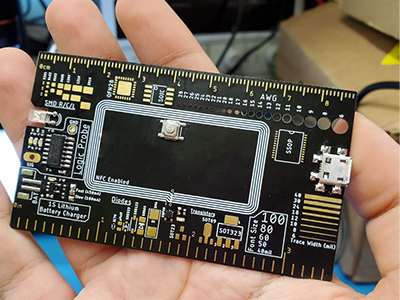

The usage of SMT line machines has become standard practice in PCB assembly and is thought to be more efficient; however, SMT machines are not appropriate for every job.ĂÂ Manual assembly is a better option for assembling boards in low quantities or low-volume orders usingĂÂ components with unique properties.

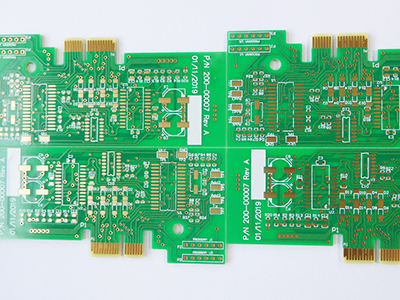

Volume Limits

Volume can be a determining factor of whether or not to assemble by hand. Orders of 10 or less boards, are often best assembled by hand- for reducing production time and faster turnaround.

Characteristics of Component Choices

The characteristics of chosen components should be taken into consideration before assembly. Careful and potentially time-consuming SMT calibration is required to minimize the risk of damage when using components with:

Heat sensitivity

Unusual shape and center of gravity

Inadequate packaging and/or documentation from the manufacturer

Therefore, low-volume orders using components with unique properties and insufficient packaging or documentation should be manually assembled by a skilled technician.

In general, it is best practice to manually assemble boards with a volume limit of 10 or less, simple technology, and when there are a few individual components per board.

SMT lines are preferred for large-volume assembly because they consistently produce quality PCBs and reduce the possibilityĂÂ of error associated with manual assembly. The key to ensuring quality of manual assembled boards is having a well-defined manual process, which is bound to passing throughĂÂ failsafe quality checks that hold hand and automated orders to the same standards.

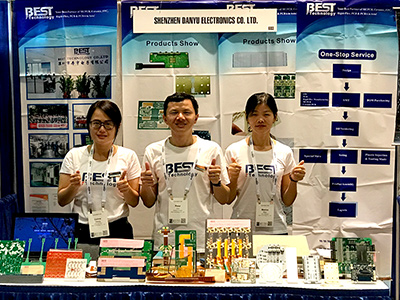

Anyway, before starting your project, it is highly recommended that you should consult with your PCB service provider regarding your PCB assembly options.