Swimming pool light aluminum PCBs are key to reliable and efficient underwater lighting. With RGBW LEDs becoming more popular, these boards must manage heat, moisture, and high brightness. In this guide, weâll cover the basics of swimming pool light PCBs, compare RGBW vs. regular designs, explain why aluminum PCB is preferred, and show how EBest Circuit (Best Technology) supports your lighting projects with expert manufacturing.

What is Swimming Pool Light PCB?

A swimming pool light PCB is the printed circuit board that powers and connects the components inside waterproof pool lighting fixtures. These lights are submerged in water and must operate safely and efficiently. The PCB controls the illuminationâtypically in RGB or RGBW color modesâand manages heat and power in demanding underwater environments.

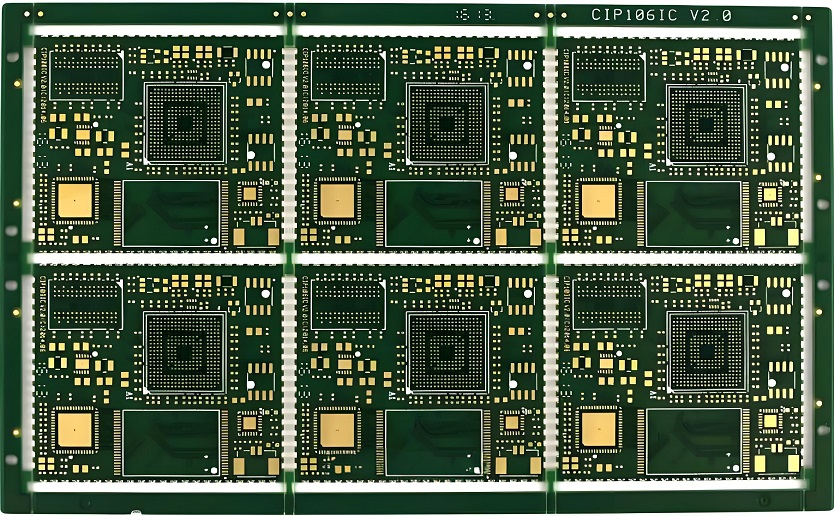

Choosing the right PCB material, design, and layout is critical to ensure long service life and consistent brightness. Because water exposure, thermal load, and sealing requirements are significant, most pool lighting PCBs are built using aluminum PCB substrates.

Regular vs. RGBW LED Swimming Pool Light PCB

When we compare standard pool light PCBs to RGBW LED swimming pool light PCBs, the difference lies in color quality, thermal management, and complexity.

Regular PCBs use RGB LEDs (Red, Green, Blue), which create color mixes but lack dedicated white light. This can limit brightness and clarity in larger pools or color-changing sequences.

RGBW LED PCBs, on the other hand, add a true white LED. This provides:

- Better color accuracy

- Enhanced brightness

- More realistic lighting for ambiance

Since RGBW LEDs generate more heat and require more current paths, they demand better thermal control. Thatâs where aluminum PCB steps inâoffering a reliable base to dissipate heat and maintain performance.

Full Design Guide to Swimming Pool Light PCB

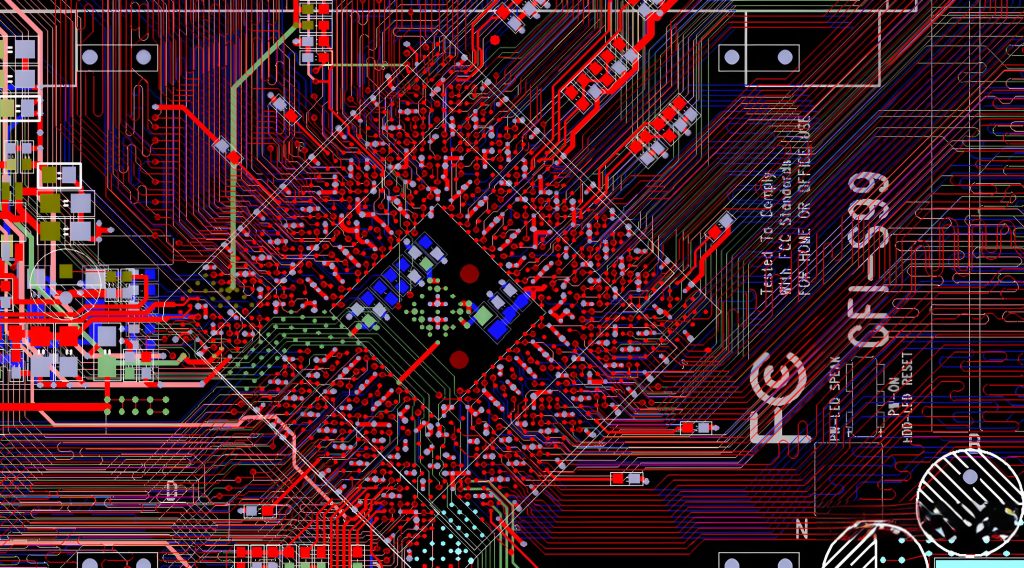

Designing a swimming pool light aluminum PCB requires a balance between thermal performance, mechanical strength, and compact layout. Here’s a step-by-step guide to get it right:

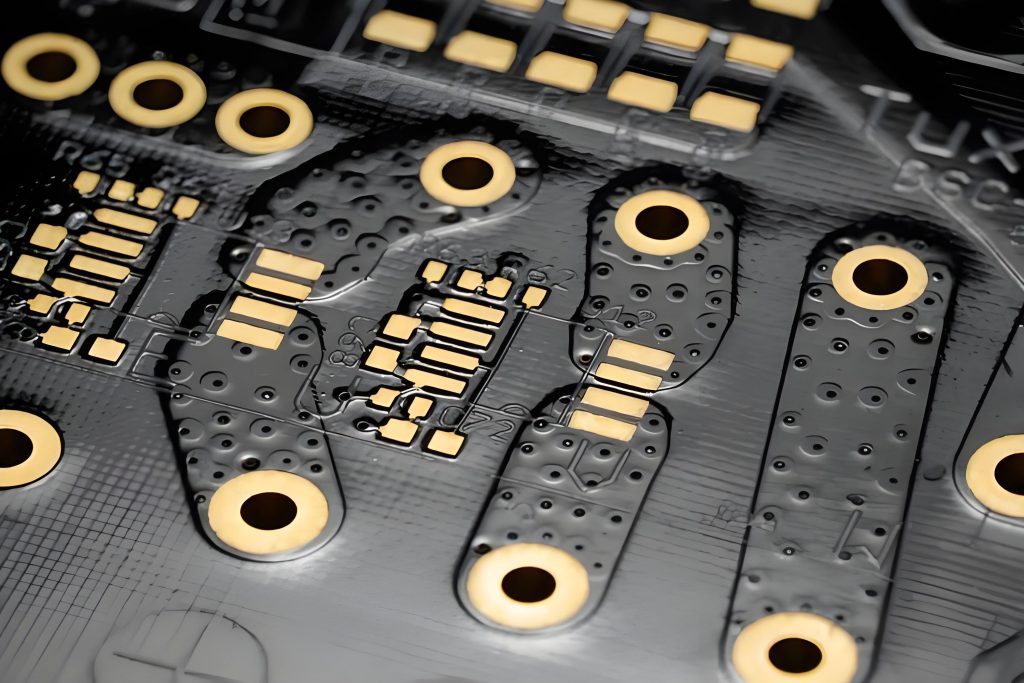

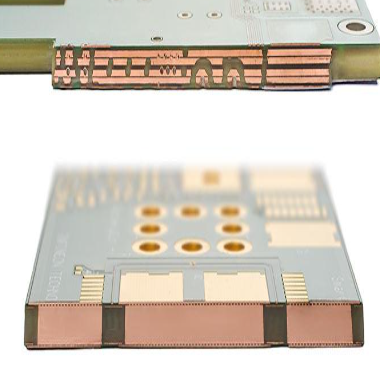

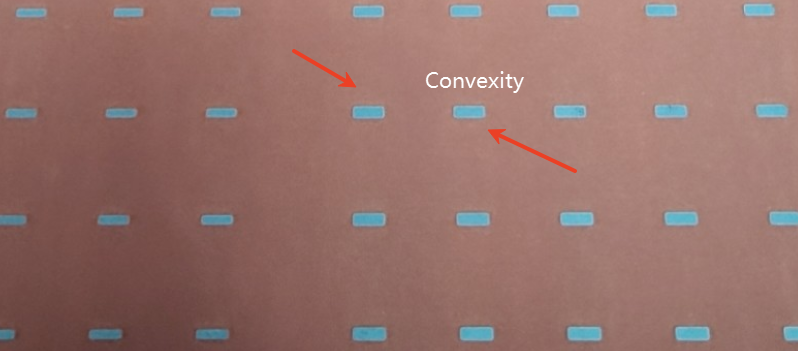

1. Choose the Right Aluminum Core

Start with selecting an appropriate aluminum base (typically 1.0â2.0 mm thickness). It should have:

- Good thermal conductivity (usually 1.0â3.0 W/m·K)

- Electrical insulation between layers

- Surface flatness for LED mounting

2. Select High-Brightness RGBW LEDs

Pick LEDs designed for underwater use. They should:

- Operate at low voltage (12V or 24V)

- Have IP68 or similar sealing ratings

- Be thermally efficient

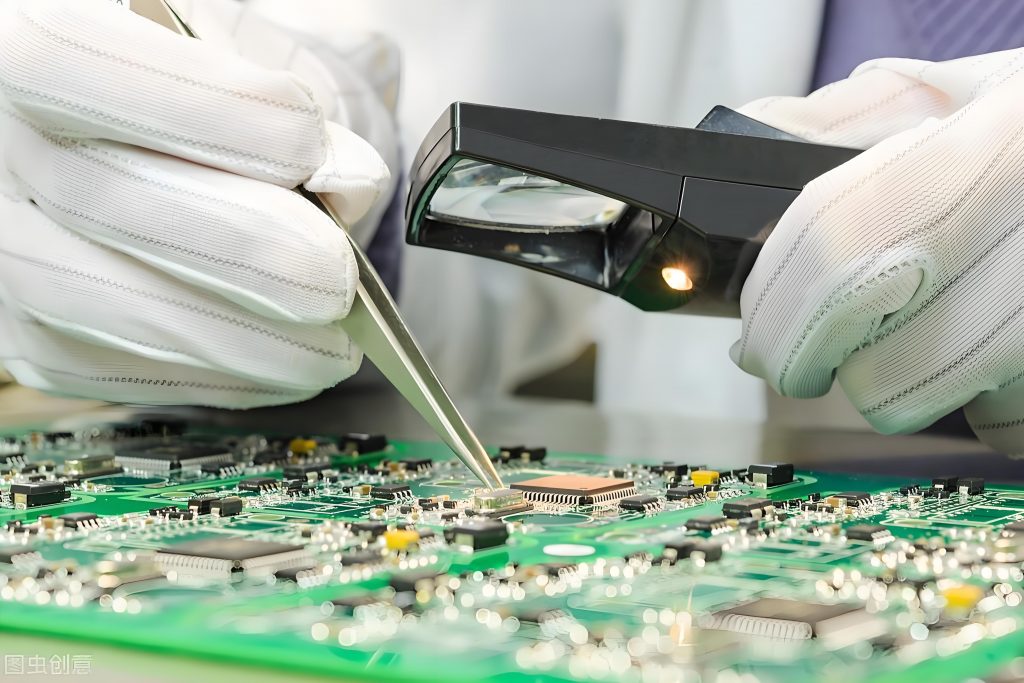

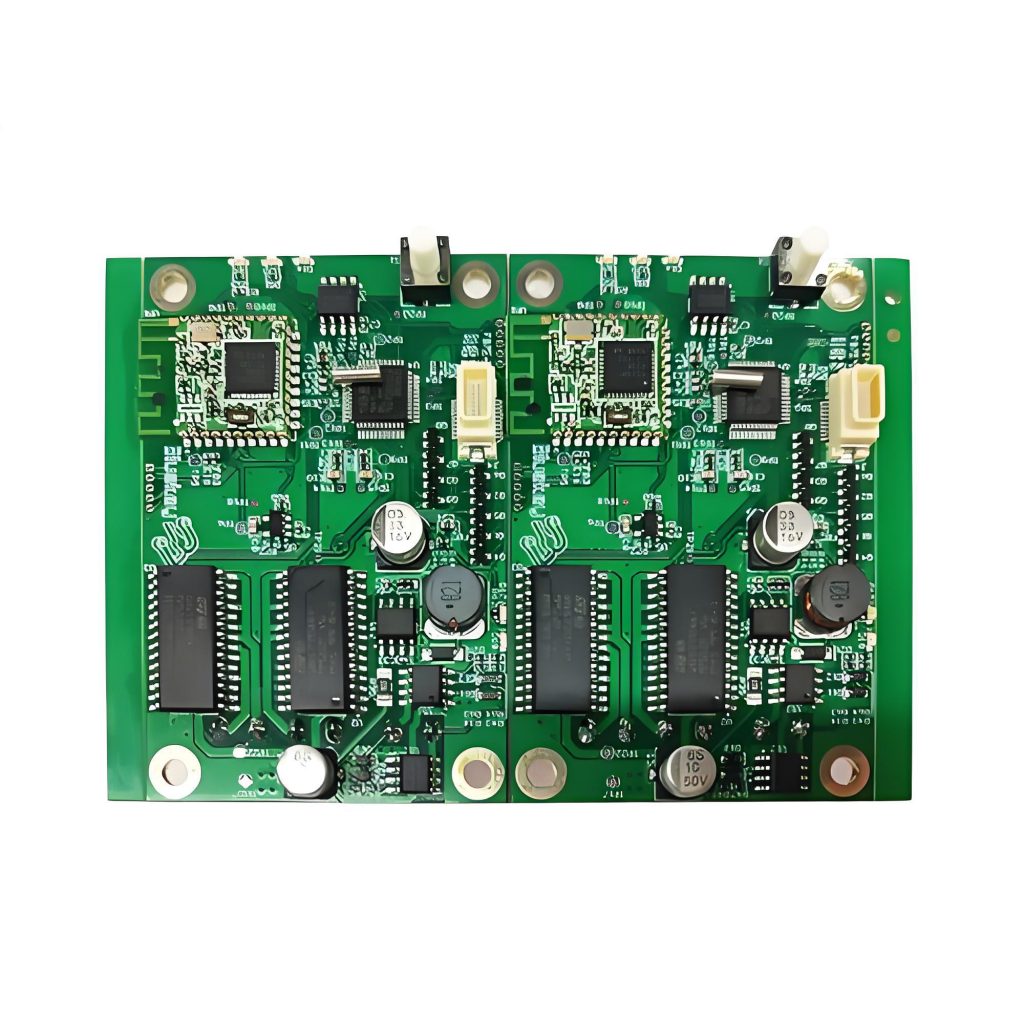

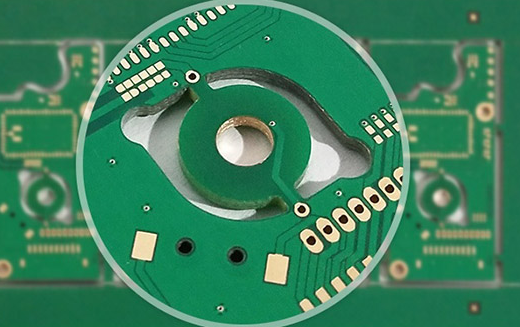

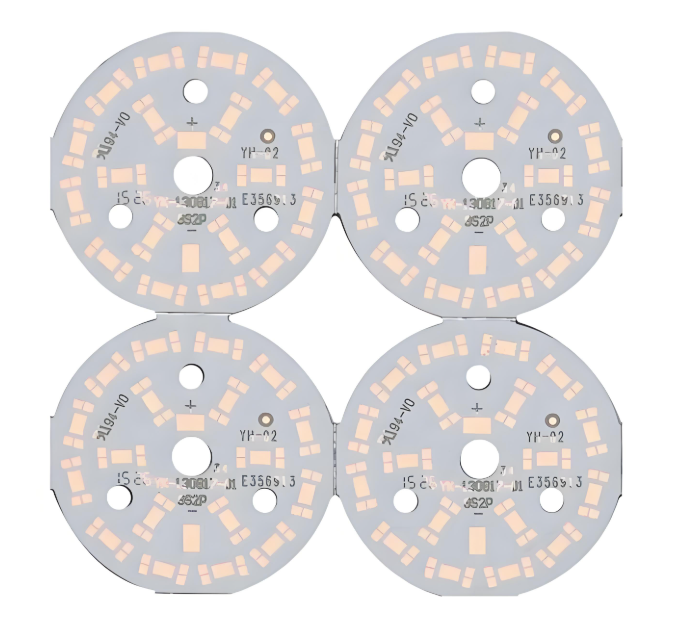

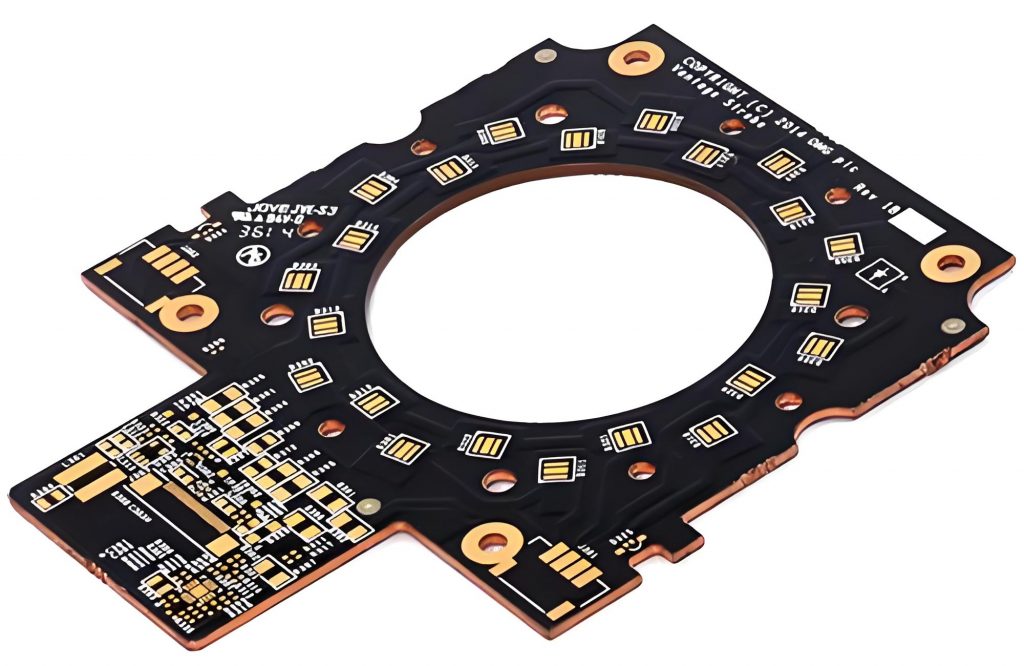

3. Layout for Symmetrical Light Distribution

The LED layout must ensure even light spread, avoiding hot spots or shadow zones. Circular or star-shaped layouts are common in pool lighting PCBs.

4. Optimize Thermal Vias and Heat Flow

Even with an aluminum base, thermal vias help move heat from the LED pads to the metal core. Use large copper pours and direct thermal paths.

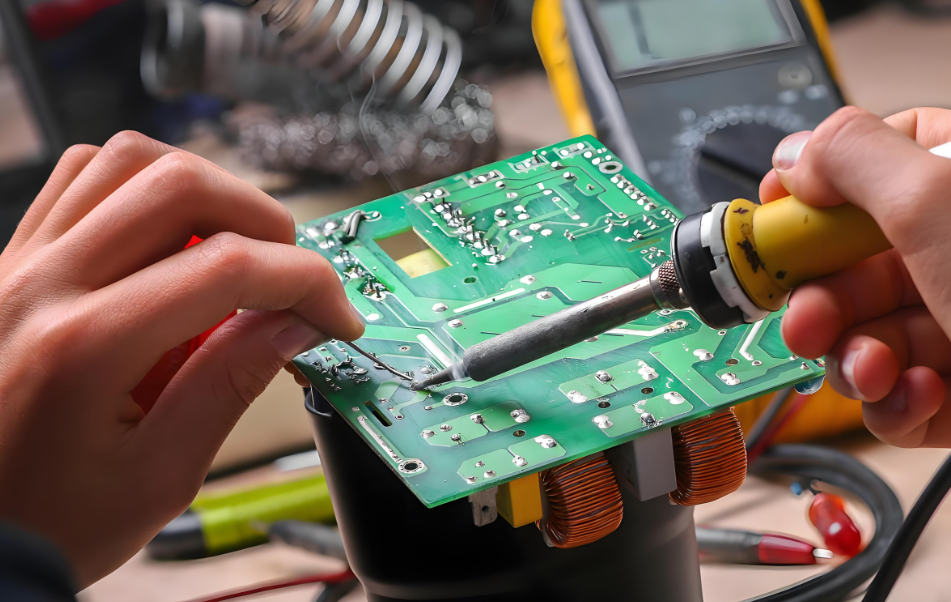

5. Surface Finishing for LED Pads

Use ENIG or OSP surface finishes to prevent oxidation and enhance solderability. These finishes are RoHS-compliant and work well with SMT LEDs.

6. Solder Mask and Silkscreen

The solder mask should withstand UV exposure and chlorinated water. White or blue masks are common for aesthetic reasons.

7. Waterproofing and Final Assembly

The PCB must integrate into a waterproof enclosure, often with potting compounds or silicone gaskets. Conformal coating adds extra protection.

Why Not Choose Copper as Swimming Pool Light PCB Base?

Many people ask: Why not just use copper PCBs for pool lights? Isnât copper more conductive? While copper indeed has better conductivity, itâs not always the right choice here. Letâs break down why:

- Cost-Effective

Copper-core PCBs are expensive due to the material cost and processing complexity. In contrast, aluminum PCBs are much more budget-friendly, especially for large lighting projects.

- Weight

Aluminum is lighter than copper. In underwater lighting, every gram matters for mounting and buoyancy. Using aluminum reduces the overall system weight, making handling and installation easier.

- Delivery Time

Aluminum PCBs are faster to fabricate and assemble, so it can save much time for customers to win the market. Manufacturers like EBest Circuit (Best Technology) can offer quicker lead times with stable quality, making project deadlines easier to meet.

Swimming Pool Light RGBW LED Aluminum PCB Price

The cost of a RGBW LED swimming pool light aluminum PCB depends on several key factors:

| Feature | Impact on Price |

| Board Size | Larger boards use more aluminum and increase cost |

| LED Density | More RGBW LEDs mean tighter layout and more layers |

| Thermal Conductivity | Higher W/m·K rating substrates cost more |

| Surface Finish | ENIG is more expensive than OSP or HASL |

| Thickness | 1.6mm boards are cheaper than 2.0mm or thicker |

| Order Quantity | Higher volume reduces per-unit cost |

| Assembly | SMT components add cost depending on complexity |

On average, a single-layer aluminum PCB for RGBW pool lights ranges from $0.80 to $2.50 per piece in medium volumes. Double-layer boards may go up to $4.00 or more, depending on features.

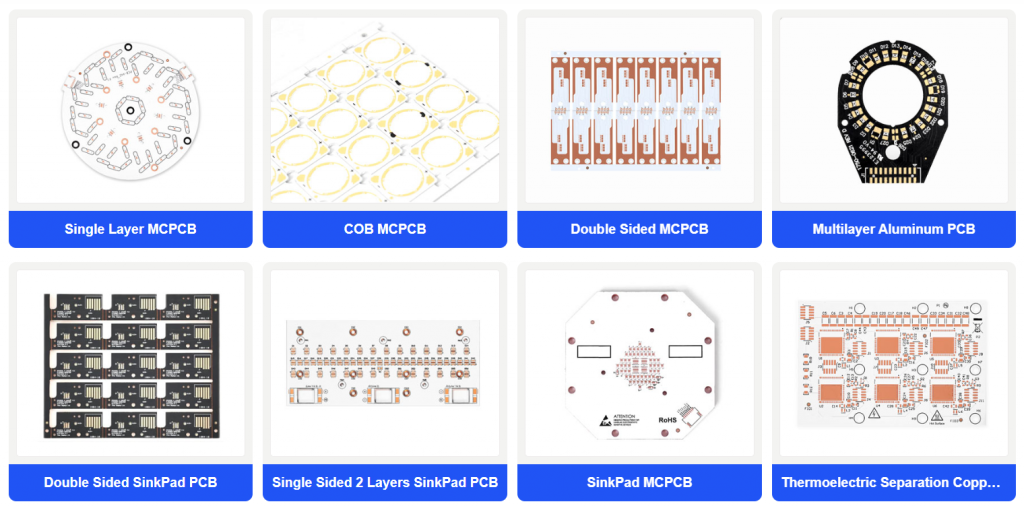

Your Best Swimming Pool Light Solution Provider â EBest Circuit (Best Technology)

When you’re looking for a trusted swimming pool light aluminum PCB manufacturer, you need more than just low prices. You need:

- Precise engineering

- Fast turnaround

- High quality and consistency

- Responsive service

Thatâs where EBest Circuit (Best Technology) shines. We specialize in LED aluminum PCB manufacturing, with tailored solutions for RGBW lighting applications in harsh environments like swimming pools.

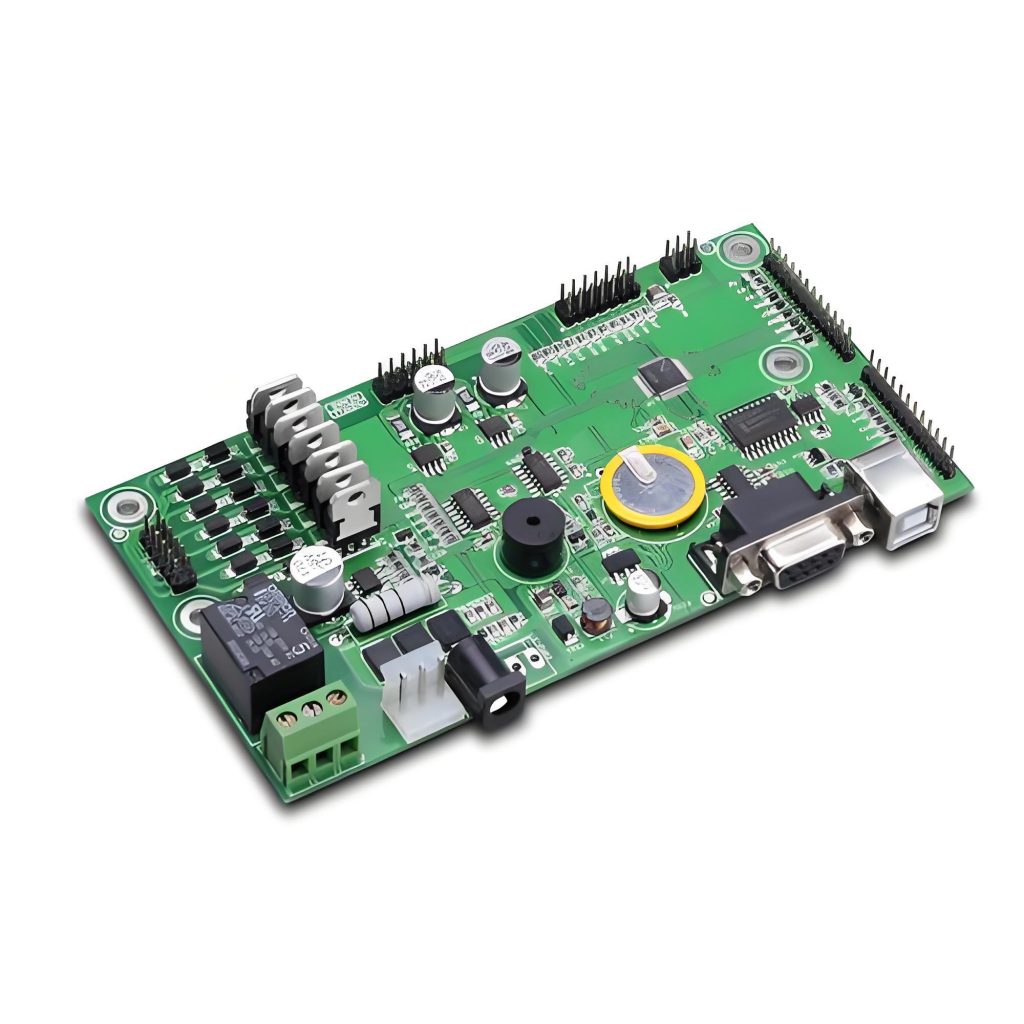

We support:

- Custom thermal designs

- PCB + PCBA service

- UV-resistant materials

- RoHS & REACH compliance

- Rapid prototyping to mass production

Our team works closely with lighting brands, OEMs, and system integrators to deliver high-reliability pool lighting PCBs on time and within budget.

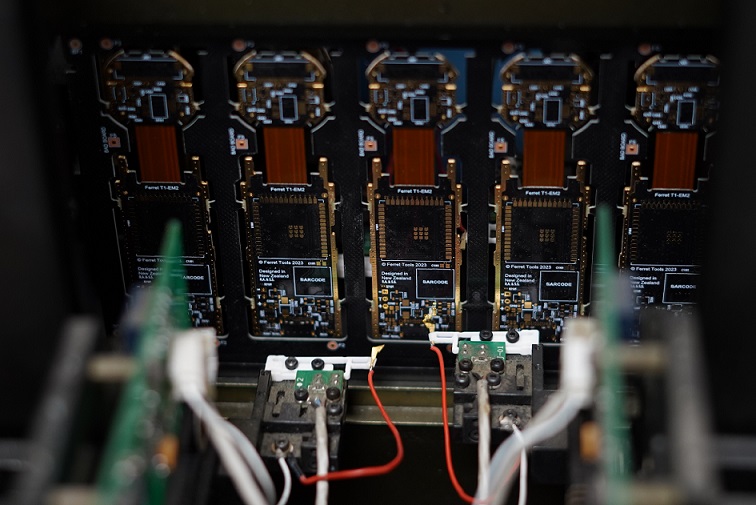

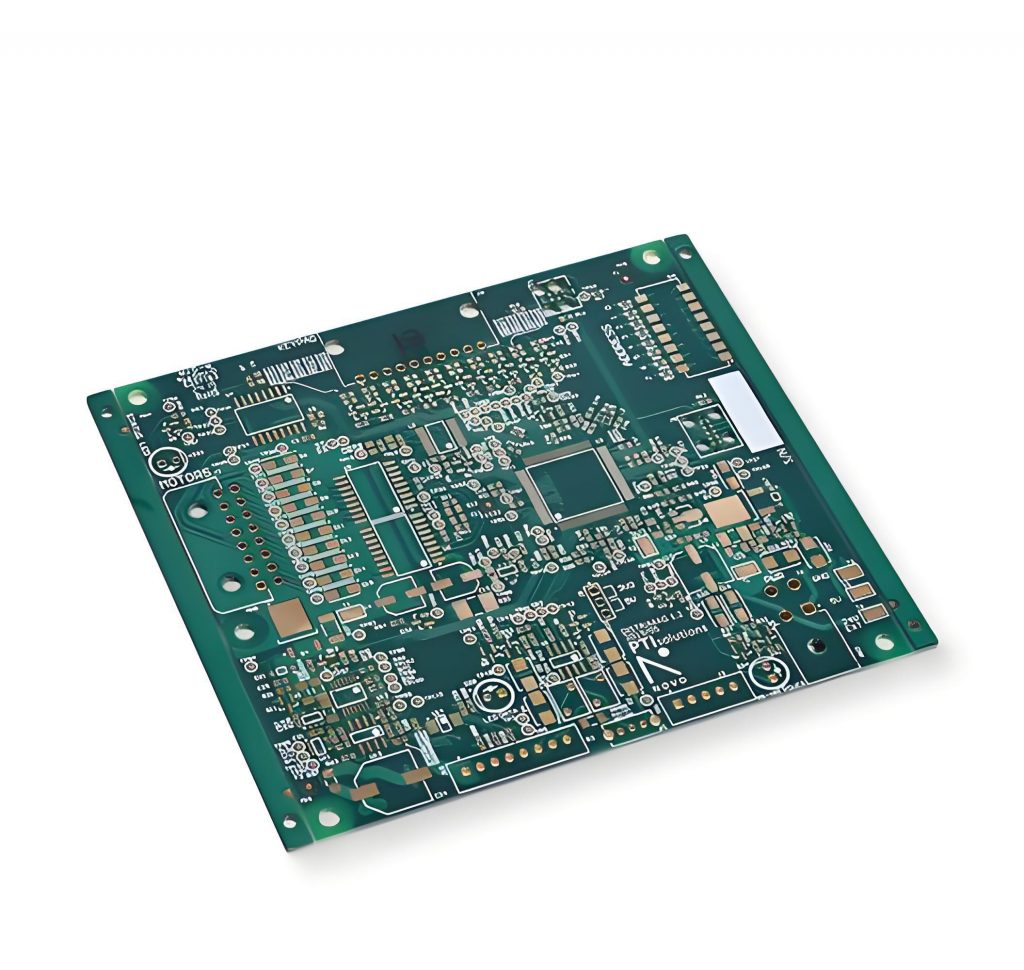

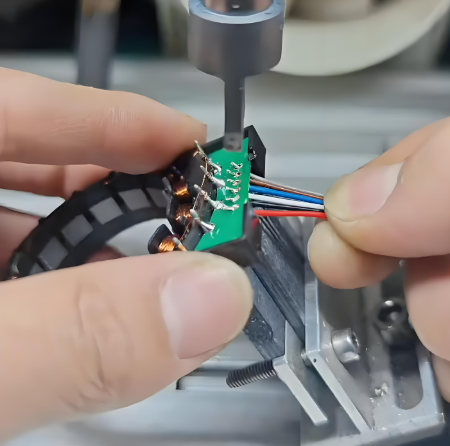

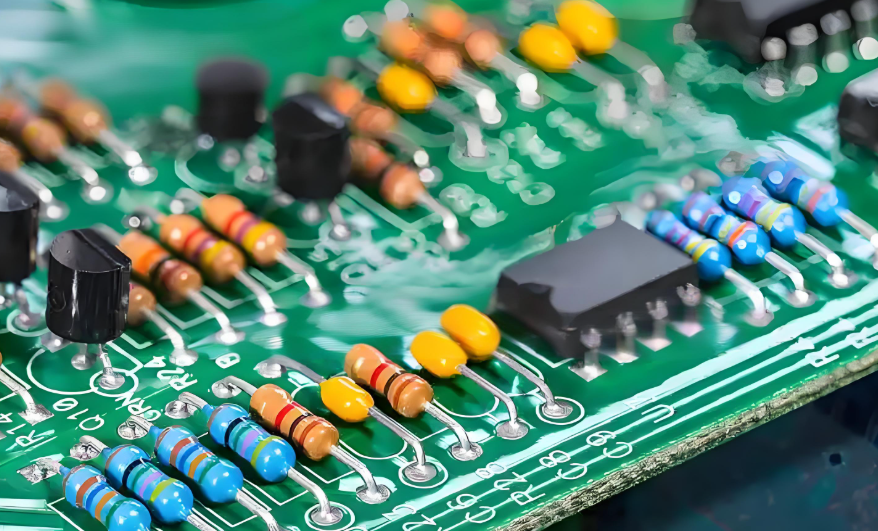

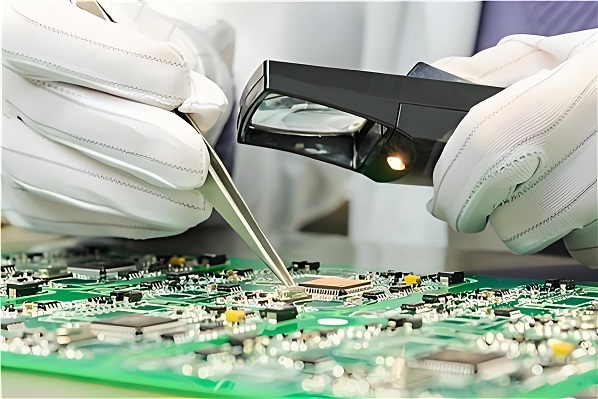

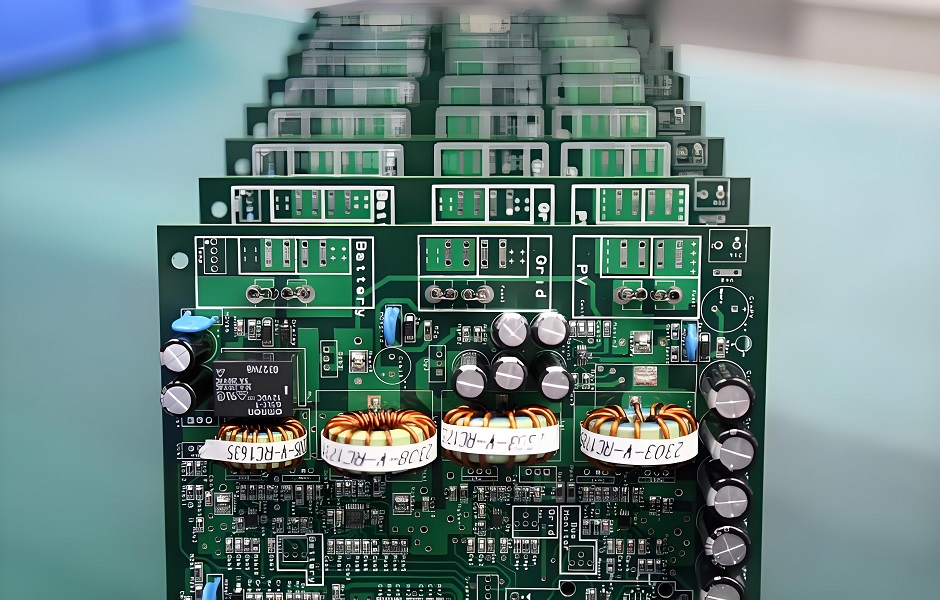

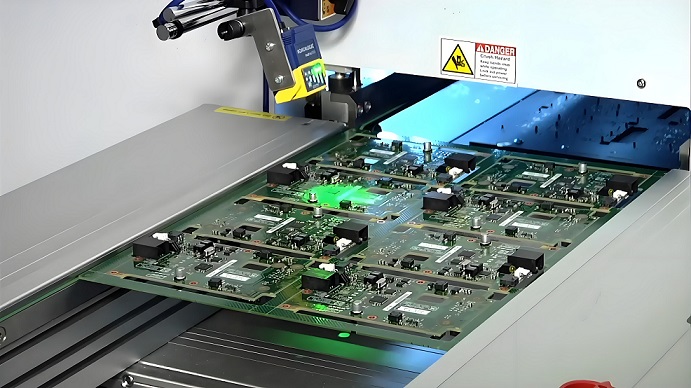

Our Aluminum PCB & PCBA Process Capability

EBest Circuit (Best Technology) is not only a PCB manufacturerâwe also offer full PCBA (PCB assembly) services. Our capabilities include:

| Item | Capability |

| PCB Layers | 1 to 10 layers for aluminum PCB |

| Board Thickness | 0.4mm to 3.2mm |

| Max Board Dimension | 610*1625mm |

| Conductor Thickness | 0.5oz-10oz |

| Min Line Width/Line Space | 4/4mil |

| Min Solder Mask Bridge | 8mil |

| Thermal Conductivity | Up to 3.0 W/m·K |

| Surface Finish | ENIG, OSP, HASL, Imm Silver, Imm Tin |

| Solder Mask Color | White, Black, Green (others are available) |

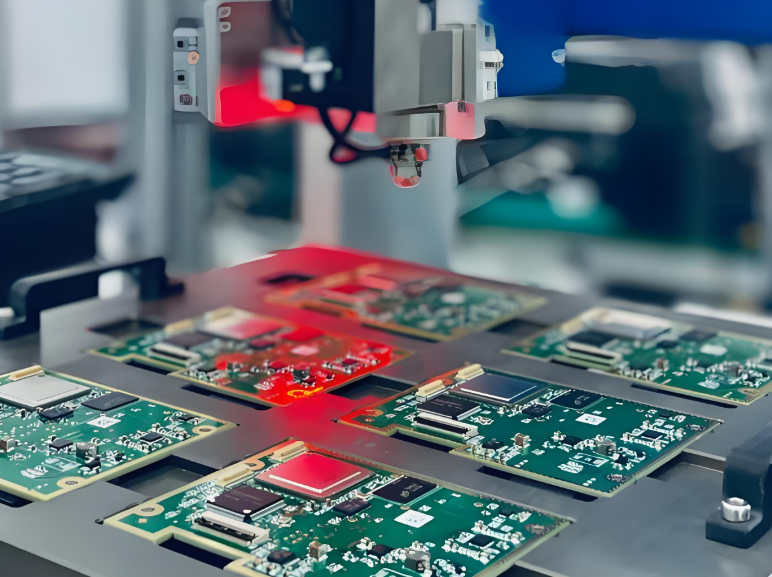

| Component Placement | 01005, QFN, BGA |

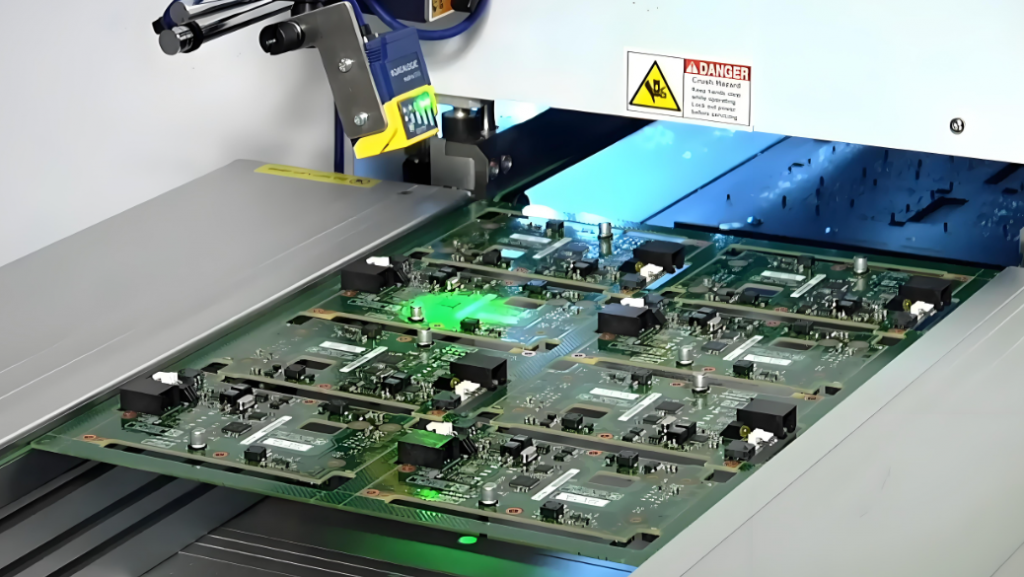

| Assembly Type | SMT, Through-hole, Hybrid |

| Testing | AOI, X-ray, ICT, Functional Testing |

FAQs

Q1: Whatâs the difference between RGB and RGBW in pool lighting PCBs?

RGB uses three LEDs to create colors, while RGBW adds a dedicated white LED, offering better clarity and light balance underwater.

Q2: Can aluminum PCBs handle the heat from high-power LEDs?

Yes. With a good layout and high thermal conductivity aluminum, these PCBs effectively dissipate heat from RGBW LEDs.

Q3: How long does it take to manufacture swimming pool light aluminum PCBs?

Standard lead time is 3â5 working days for bare PCBs, and 5â7 working days for PCB + assembly, depending on complexity. Expedited service available for aluminum PCB.

Q4: Can EBest Circuit (Best Technology) help with LED selection and layout optimization?

Absolutely. Our engineering team offers DFM (Design for Manufacturability) reviews, LED sourcing, and thermal simulations.

Q5: Do aluminum PCBs support double-sided assembly?

While aluminum PCBs are mainly single-sided, hybrid double-layer designs are possible with proper insulation and structure.

Want to bring your RGBW swimming pool light project to life with the right aluminum PCB?

Contact EBest Circuit (Best Technology) todayâweâll help you build efficient, cost-effective, and beautiful underwater lighting systems. If you want to copper metal core PCB fabrications, we are also here.