PCB assembly California‚Äč refers to the specialized service of manufacturing and assembling printed circuit boards for clients located in the state of California. This article provides a comprehensive guide to navigating the California PCB assembly landscape, focusing on the stringent requirements for medical devices and how to select a reliable manufacturing partner.

Choosing a ‚ÄčPCB assembly California‚Äč partner, especially for medical applications, is fraught with challenges. What are the key hurdles?

- ‚ÄčFinding a vendor that truly understands and can consistently adhere to the rigorous quality standards (like ISO 13485) required for medical-grade electronics.‚Äč‚Äč

- ‚ÄčExperiencing costly delays and project setbacks due to a manufacturer’s unreliable communication and slow response times across different time zones.‚Äč‚Äč

- ‚ÄčFacing functional failures or premature device breakdowns in the field because of subpar assembly workmanship or the use of inferior materials.‚Äč‚Äč

- ‚ÄčStruggling with a manufacturer that lacks the expertise for complex medical prototypes, leading to inaccurate builds that don’t reflect the final design intent.‚Äč‚Äč

- ‚ÄčEncountering unexpected and inflated costs that derail the project budget, often due to a lack of transparent pricing models.‚Äč‚Äč

Overcoming these challenges requires a partner with a proven track record. Here are five core solutions that a dedicated manufacturer provides.

- ‚ÄčWe implement a certified Quality Management System, specifically for medical devices, ensuring every ‚Äčmedical PCB assembly services California‚Äč project meets the highest standards from start to finish.‚Äč‚Äč

- ‚ÄčOur dedicated project management team offers responsive communication and clear timelines, ensuring you are always informed and projects stay on schedule.‚Äč‚Äč

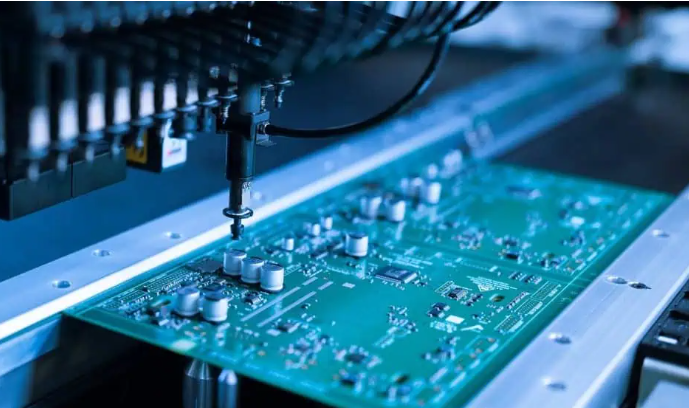

- ‚ÄčWe utilize state-of-the-art equipment and premium materials, coupled with rigorous testing protocols, to guarantee the durability and long-term reliability of every assembly.‚Äč‚Äč

- ‚ÄčOur engineering team possesses deep expertise in ‚Äčprototype PCB assembly California, ensuring your design is accurately translated into a functional prototype that validates your product concept.‚Äč

- ‚ÄčWe provide detailed and upfront ‚Äčestimating PCB assembly cost, with transparent breakdowns, so you can plan your budget with confidence and avoid surprises.‚Äč

At BEST Technology, we are a leading ‚ÄčPCB assembly manufacturer‚Äč from China with over 19 years of experience, specializing in high-reliability applications. Our core advantage lies in our rigorous quality control processes, which are tailored to meet the exacting ‚Äč‚ÄčPCB assembly requirements‚Äč of the medical industry. We are committed to being your trusted offshore partner for all your ‚Äč‚ÄčPCB assembly USA‚Äč needs, offering transparent pricing without compromising on quality. Contact us today at sales@bestpcbs.com to discuss your project.

What is PCB assembly California?

‚ÄčPCB assembly California‚Äč encompasses the entire process of populating a bare printed circuit board with components for clients and industries based in California. This section explains the core process and its local significance.

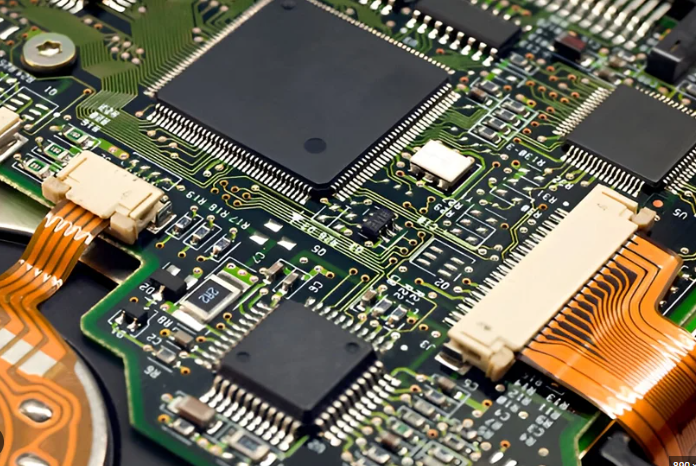

- ‚ÄčThe Process:‚Äč‚Äč It involves several key steps: sourcing components, applying solder paste, placing components via sophisticated machinery, soldering (often through reflow ovens), and rigorous inspection and testing.

- ‚ÄčCalifornia Context:‚Äč‚Äč For California’s thriving tech and biotech sectors, this service is critical. It supports innovation from ‚ÄčSan Jose‚Äč tech startups to ‚ÄčSan Diego‚Äč medical device companies, requiring suppliers who understand fast-paced, high-stakes environments.

In summary, ‚ÄčPCB assembly California‚Äč is a vital service that fuels innovation across the state’s key industries, demanding precision, reliability, and speed from its providers.

Why Choose PCB Manufacturing California Services?

Opting for a service branded as ‚ÄčPCB manufacturing California‚Äč often implies benefits like local support and fast turnaround. This section explores the perceived advantages and how offshore partners can deliver comparable value.

- ‚ÄčProximity and Communication:‚Äč‚Äč The primary appeal is geographical proximity, which suggests easier communication and logistics.

- ‚ÄčThe Global Standard:‚Äč‚Äč However, leading international manufacturers like BEST Technology have closed this gap. We offer English-speaking project managers, overlapping communication windows, and highly efficient shipping logistics to California, ensuring a seamless experience.

- ‚ÄčBroader Capabilities:‚Äč‚Äč Often, an offshore specialist like us has a larger scale, allowing for more comprehensive services from ‚Äčprototype PCB assembly California‚Äč to high-volume production, all under one roof.

Therefore, while “local” has its appeal, the key is choosing a partner that delivers “local-like” responsiveness with global manufacturing capabilities and cost-effectiveness.

Top Manufacturers for PCB Assembly San Diego

San Diego’s thriving innovation ecosystem, particularly in biotech, telecommunications, and defense, creates a strong demand for high-quality PCB assembly. This section explores the landscape of top-tier manufacturers that serve the San Diego area, highlighting key players that combine technical expertise with reliable service to meet the region’s unique needs.

‚Äč1. BEST Technology‚Äč

As a specialized PCB and flexible circuit manufacturer, BEST Technology offers significant value to San Diego’s advanced industries. While headquartered in China, the company has cultivated a strong client base in Southern California by providing robust engineering support and specializing in complex, high-reliability products like rigid-flex PCBs and medical electronics. Their focus on rigorous quality control and competitive pricing makes them a strategic offshore partner for companies looking to balance innovation with cost-effectiveness.

‚Äč2. APEC‚Äč

Located in the nearby City of Industry, California, APEC (American PCB Engineering & Manufacturing Corp.) provides a true local manufacturing option for San Diego companies requiring quick-turn services and domestic production. With over 30 years of experience, APEC specializes in quick-turn prototype through mid-volume production, offering services from design for manufacturability (DFM) to final box-build assembly. Their proximity allows for easier collaboration and faster logistics, which can be critical for rapid prototyping cycles.

‚Äč3. Screaming Circuits‚Äč

A division of PCB manufacturer Millennium Circuits Limited, Screaming Circuits focuses exclusively on rapid prototype and low-volume PCB assembly. While not based in California, their business model is built around speed and accessibility, making them a popular choice among San Diego startups and engineering teams needing fast turnarounds. Their online quoting system and extensive component library streamline the process for designers and engineers working on tight deadlines.

In summary, San Diego’s top PCB assembly partners range from local quick-turn specialists like APEC to rapid-prototype experts like Screaming Circuits and high-reliability offshore manufacturers like BEST Technology. The best choice depends on specific project requirements for speed, complexity, volume, and budget, with each manufacturer offering distinct advantages for the region’s diverse technological demands.

Top Manufacturers for PCB Assembly San Jose

San Jose, located at the heart of Silicon Valley, represents one of the most demanding markets for PCB assembly services globally. Companies in this region require manufacturers capable of supporting cutting-edge technologies, from high-performance computing and networking to advanced consumer electronics. This section highlights leading PCB assembly providers that have demonstrated the technical expertise, rapid prototyping capabilities, and quality standards necessary to serve San Jose’s innovation-driven ecosystem.

‚Äč‚Äč1. BEST Technology‚Äč

While geographically located in China, BEST Technology has established itself as a valuable partner for numerous San Jose-based technology companies. The company specializes in advanced PCB technologies, particularly in rigid-flex and multilayer board manufacturing, making them well-suited for the complex designs common in Silicon Valley. Their engineering team provides comprehensive design for manufacturability (DFM) feedback, helping clients optimize designs for performance and cost-effectiveness. BEST Technology’s competitive pricing structure and experience with high-complexity boards make them a strategic choice for startups and established companies alike.

‚Äč2. Sierra Circuits‚Äč

As a California-based PCB solutions provider with over 35 years of experience, Sierra Circuits has deep roots in serving the Silicon Valley market. They offer comprehensive services from design support and prototyping to full-scale production, with particular expertise in high-speed, HDI, and impedance-controlled boards. Their online platform provides instant quotes and design analysis, streamlining the process for engineers working under tight deadlines. Sierra Circuits’ proximity to San Jose enables faster turnaround times and closer collaboration on critical projects.

‚Äč3. MacroFab‚Äč

Operating a distributed manufacturing platform across North America, MacroFab brings a unique cloud-based approach to PCB assembly that resonates well with San Jose’s tech culture. Their platform allows engineers to upload designs, receive instant quotes, and manage production through an intuitive online interface. MacroFab’s network of manufacturing facilities provides scalability from prototyping to medium-volume production, with strong capabilities in both PCB assembly and enclosure integration. This model offers flexibility and transparency particularly valued by hardware startups and research institutions in the San Jose area.

‚ÄčTo conclude, the PCB assembly landscape serving San Jose reflects the innovative spirit of Silicon Valley itself, featuring both established local experts and technologically advanced offshore partners. While Sierra Circuits offers deep local expertise and rapid turnaround, and MacroFab provides a modern, platform-based approach, BEST Technology stands out for handling the most complex technical challenges at transparent price points. The optimal choice depends on specific project requirements regarding technical complexity, timeline, budget, and desired level of collaboration, with all three manufacturers offering distinct advantages for San Jose’s diverse and demanding market.

How to Select Prototype PCB Assembly California?

Selecting a partner for ‚Äčprototype PCB assembly California‚Äč is a critical decision that can make or break a product’s development. Here is a structured approach.

- ‚ÄčAssess Technical Capability:‚Äč‚Äč Review their experience with boards similar to yours, especially in terms of complexity, layers, and materials.

- ‚ÄčVerify Quality Certifications:‚Äč‚Äč Ensure they hold relevant certifications (e.g., ISO 9001, ISO 13485 for medical devices) that validate their quality processes.

- ‚ÄčEvaluate Communication and Support:‚Äč‚Äč Gauge their responsiveness and willingness to offer Design for Manufacturability (DFM) feedback. A good partner acts as a consultant.

- ‚ÄčScrutinize their Testing Protocol:‚Äč‚Äč For a prototype, understanding how it fails is as important as knowing it works. Ensure they have in-circuit testing (ICT) and functional testing capabilities.

- ‚ÄčRequest Clear Quotations:‚Äč‚Äč Obtain detailed quotes that break down ‚ÄčPCB assembly cost‚Äč for the prototype, avoiding hidden fees.

Following these steps will guide you to a prototype partner that ensures your design is validated accurately and efficiently.

What are the Advantages of EBest Circuit (Best Technology) in Medical PCB Assembly Services California?

The advantages of BEST Technology in ‚Äčmedical PCB assembly services California‚Äč stem from our dedicated focus on quality, reliability, and compliance, which are paramount in this field.

- ‚ÄčMedical-Grade Certification:‚Äč‚Äč ‚ÄčWe are ISO 13485 certified, ensuring a systemic approach to quality that goes beyond standard electronics.

- ‚ÄčTraceability and Documentation:‚Äč‚Äč We provide complete material traceability and detailed documentation packages, which are critical for medical device validation.

- ‚ÄčExperience with Biocompatible Materials:‚Äč‚Äč We have expertise in assembling PCBs that use specialized, biocompatible materials and conformal coatings often required for medical applications.

- ‚ÄčReliability Engineering:‚Äč‚Äč Our processes are designed to maximize the Mean Time Between Failures (MTBF) of the assemblies, a key metric for medical device longevity.

In short, our advantage lies in building quality and reliability into every step of the ‚Äčmedical PCB assembly‚Äč process, ensuring that our California clients‚Äô devices meet the highest standards of safety and efficacy.‚Äč

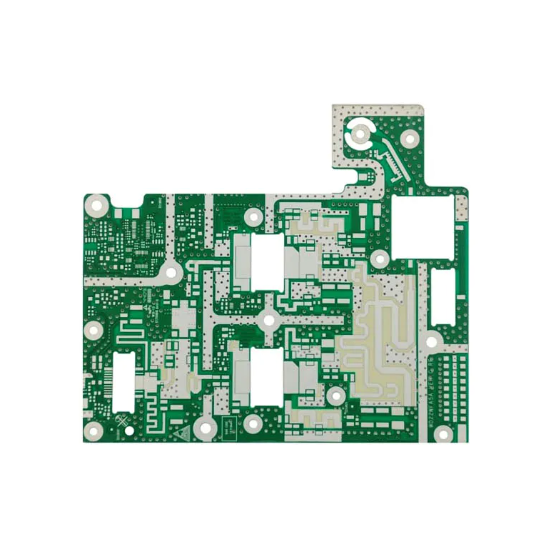

Case of Supporting PCB Assembly California Project at BEST Technology

A recent project for a biomedical startup based in California exemplifies our ability to meet the stringent requirements of the medical technology sector. The client was developing a next-generation portable diagnostic device for clinical use, requiring a highly reliable main control board.

‚ÄčThe client needed a complex 6-layer PCB that would serve as the brain of their device. The key challenges included:

- ‚ÄčHigh Reliability:‚Äč‚Äč The board had to function flawlessly in a clinical environment, with zero tolerance for failure.

- ‚ÄčStrict Compliance:‚Äč‚Äč The product required certification to medical standards, necessitating full documentation and traceability.

- ‚ÄčDurable Finish:‚Äč‚Äč The surface finish needed to be suitable for repeated connection cycles and resistant to oxidation in storage.

- ‚ÄčComplex Assembly:‚Äč‚Äč The board would host a mix of fine-pitch BGAs and sensitive analog components, demanding precise assembly and inspection.

‚ÄčBEST Technology was selected to manufacture and assemble this critical board. The board’s specifications were meticulously chosen to meet the application’s demands.

‚ÄčThis printed circuit board is designed as the main control board for a ‚Äčportable medical diagnostic device. It is responsible for processing signals from various sensors, controlling the device’s user interface, and managing data communication. Its high reliability makes it suitable for critical applications in ‚Äčpatient monitoring equipment, portable diagnostic analyzers, and other medical electronic devices‚Äč where consistent performance is non-negotiable.

‚ÄčBoard Parameters:‚Äč‚Äč

- ‚ÄčLayer Count:‚Äč‚Äč 6 Layers

- ‚ÄčBase Material:‚Äč‚Äč FR-4

- ‚ÄčBoard Thickness:‚Äč‚Äč 1.64mm +/-10%

- ‚ÄčGlass Transition Temperature (Tg):‚Äč‚Äč 170¬įC

- ‚ÄčCopper Thickness (Inner/Outer):‚Äč‚Äč 1 OZ

- ‚ÄčSurface Finish:‚Äč‚Äč ENIG (Gold Thickness: 1U”)

- ‚ÄčSolder Mask / Silkscreen:‚Äč‚Äč Green Solder Mask, White Silkscreen

- ‚ÄčCompliance Standards:‚Äč‚Äč UL, RoHS, IPC-6012 Class 2

- ‚ÄčTesting & Documentation:‚Äč‚Äč 100% Electrical Test, Continuity Test. Reports include: COC, Cross-Section Report, Electrical Test Report, Solderability Test Report, Copper Thickness Report.

‚ÄčWe delivered the fully assembled and tested boards on schedule. Each unit passed our stringent quality checks, including AOI and X-ray inspection for BGAs. The comprehensive documentation package provided ensured a smooth and fast audit process for the client’s medical device certification. The project was a success, enabling the client to move seamlessly into the final testing and regulatory approval phase for their innovative product. This case underscores our commitment to providing ‚Äčrigorous quality medical PCB assembly‚Äč for our clients in California and beyond.

‚ÄčIn summary, PCB assembly California‚Äč is a critical service for the state’s innovative industries, particularly medical technology, where quality is non-negotiable. This guide has outlined the key considerations for selecting a manufacturing partner who can meet these high standards. BEST Technology stands out as a provider of ‚Äčrigorous quality medical PCB assembly‚Äč by combining certified processes, engineering expertise, and a commitment to reliability. For a partner you can trust with your most critical projects, contact us at sales@bestpcbs.com.