Quick turn circuit boards‚Äč are the lifeblood of modern electronics development, enabling innovators to transform ideas into tangible prototypes and final products at unprecedented speeds. This article delves into the critical role of quick-turn PCB services, exploring how they conquer urgent deadlines and detailing what to expect from leading providers.

In the relentless race to market, engineering teams constantly face a critical bottleneck: the agonizing wait for circuit boards. How do these pressing challenges manifest?

- Prototype Delays Crippling Development Cycles:‚Äč Waiting weeks for boards brings R&D to a standstill.

- Unpredictable Costs from Iterations and Rush Fees:‚Äč Multiple design revisions and expedited shipping inflate budgets uncontrollably.

- Quality Compromises under Time Pressure:‚Äč The need for speed can sometimes lead to overlooked errors or substandard fabrication.

- Inflexible Supply Chains Halting Production:‚Äč A lack of responsive partners creates vulnerability, especially for small-batch or urgent production needs.

- Communication Gaps Causing Costly Reworks:‚Äč Misunderstandings in specifications or slow response times from suppliers result in faulty boards and wasted time.

The solution lies in partnering with a quick turn PCB manufacturer‚Äč that is architected to turn these pain points into a seamless, reliable process. An expert provider delivers a streamlined experience built on the following pillars.

- Guaranteed Accelerated Timelines:‚Äč Providing clear, reliable turnaround commitments for quick turn prototype printed circuit boards, from 24-hour fabrication to 3-5 day assembly.

- Transparent, Upfront Pricing:‚Äč Offering competitive and stable pricing for quick turn printed circuit board assembly services‚Äč without hidden fees for standard revisions.

- Speed Without Sacrificing Integrity:‚Äč Implementing robust, automated quality controls (like AOI and X-ray) at every stage of quick turn circuit board fabrication.

- Scalable and Agile Production Support:‚Äč Maintaining capacity and material inventory to smoothly transition from prototypes to low-volume production runs.

- Dedicated Engineering & Customer Support:‚Äč Assigning proactive experts to review files and communicate rapidly, ensuring designs are manufacturable and questions are answered in real-time.

As a specialized quick turn printed circuit boards supplier‚Äč and manufacturer, EBest Circuit (EBest Circuit (Best Technology)) combines state-of-the-art facilities with deep engineering expertise to deliver not just speed, but predictable success for your most urgent projects. Trust us to be your circuit board builder‚Äč under pressure. Pls feel free to contact us at sales@bestpcbs.com‚Äč to start your next quick-turn PCB circuit board project.

What Are Quick Turn Circuit Boards?

This section defines the core concept and its operational model.

Quick turn printed circuit boards‚Äč refer to PCBs manufactured and assembled on an exceptionally accelerated schedule, often ranging from 24 hours to a few days, as opposed to standard lead times of several weeks. This model is designed to support rapid prototyping, engineering testing, and urgent production needs.

- Core Service Tiers:‚Äč Services range from quick turn circuit board fabrication‚Äč only to full quick-turn circuit board assembly services USA.

- Driving Technologies:‚Äč Utilization of advanced, automated manufacturing lines and Digital Manufacturing Files (DMF) for instant processing.

- Standard Turnaround Options:‚Äč Common offerings include 24h, 48h, 72h, and 5-day turns for both fabrication and assembly.

- Material & Layer Readiness:‚Äč Keep common materials (FR-4, Rogers) and tooling for standard layer counts (1-12 layers) in ready-state to eliminate setup delays.

- The Trade-off:‚Äč While unit cost may be higher than standard production, the value lies in drastically reduced time-to-market and development cost.

In essence, quick turn PCB assembly‚Äč is a strategic service that compresses the traditional manufacturing timeline through optimized processes and dedicated capacity, making it an indispensable tool for agile development.

Why Are Quick Turn Printed Circuit Boards Essential for IoT Devices?

The IoT sector’s dynamics make fast PCB turnaround non-negotiable.

The Internet of Things (IoT) market is characterized by rapid iteration, compact form factors, and fierce competition. Quick turn prototype printed circuit boards‚Äč are crucial here because they allow developers to physically test connectivity (Wi-Fi, BLE, LoRa), sensor integration, and power management in real-world scenarios quickly, enabling rapid refinement of both hardware and firmware.

- Accelerated Hardware-Software Co-Development:‚Äč Enables parallel testing of PCB functionality and embedded code, shortening the overall development cycle.

- Form Factor & Miniaturization Validation:‚Äč Allows rapid prototyping of compact, often multilayer circuit boards quick turn‚Äč designs to fit space-constrained IoT devices.

- Field Testing and Certification Prep:‚Äč Facilitates quick production of beta units for real-world testing and pre-compliance certification processes.

- Iterating on Power Architecture:‚Äč Essential for testing and optimizing low-power designs critical for battery-operated IoT devices.

- Mitigating Connectivity Issues:‚Äč Fast iterations help quickly resolve RF interference and antenna performance problems.

For IoT innovators, the ability to iterate hardware as fast as software is paramount, making a reliable quick turn PCB manufacturer for circuit board assembly‚Äč a key partner in their ecosystem.

How Do Quick Turn Printed Circuit Boards Reduce Development Lead Time?

They attack delays across the entire product development timeline.

By drastically shortening the feedback loop between design and physical validation, quick turn circuit boards‚Äč compress multiple phases of the development cycle. The lead time reduction is not merely additive; it’s multiplicative, as each iteration happens faster.

| Development Phase‚Äč | Standard Timeline (Weeks)‚Äč | With Quick-Turn PCB (Days)‚Äč | Time Saved‚Äč |

|---|---|---|---|

| Initial Prototype | 3-4 | 3-5 | ~3 weeks |

| Design Revision & Re-Spin | 2-3 | 3-5 | ~2 weeks |

| Engineering Validation | 2 | 1-2 | ~1 week |

| Total for 2 Iterations‚Äč | 7-9+ weeks‚Äč | 7-12 days‚Äč | ~6-8 weeks‚Äč |

- Parallel Development:‚Äč Software and mechanical engineering can progress using a physical board much sooner.

- Faster Failure & Learning:‚Äč Design flaws are identified and corrected in days, not weeks.

- Reduced Overall Project Risk:‚Äč Shorter cycles allow teams to adapt to changing requirements or technical challenges more agilely.

- Earlier Market Entry:‚Äč The cumulative time saving directly translates to a earlier launch date, capturing market share.

Therefore, investing in quick turn printed circuit board assembly services‚Äč is a strategic decision that reduces overall project duration and risk, not just a tactic for handling emergencies.

What Should Buyers Expect From Quick-Turn Circuit Board Assembly Services USA?

Choosing a domestic quick turn PCB USA‚Äč partner offers distinct advantages and specific expectations.

Buyers should expect a seamless, transparent, and high-quality service that leverages proximity for better communication, logistics, and control. A top-tier U.S.-based circuit card assembly manufacturer‚Äč provides more than just speed.

- Clear Communication & DFM Support:‚Äč Expect proactive Design for Manufacturability (DFM) feedback from local engineers in your timezone.

- IP Protection & Security:‚Äč Stronger legal frameworks and on-shore production offer greater peace of mind for intellectual property.

- Simplified Logistics:‚Äč Faster, cheaper domestic shipping with no customs complexities for both prototypes and small-batch production.

- Quality & Compliance Assurance:‚Äč Familiarity with and adherence to U.S. standards and certifications (e.g., for aerospace, medical).

- Scalability:‚Äč Ability to handle quick turn PCB assembly‚Äč and smoothly transition to higher-volume manufacturing locally.

In short, PCB manufacturing in USA‚Äč with a quick-turn focus should deliver speed coupled with the benefits of local partnership: superior service, reduced logistical hassle, and inherent trust.

How Do Quick Turn Prototype Printed Circuit Boards Support Rapid Engineering Validation?

They are the physical bridge between CAD models and a proven design.

Quick turn prototype printed circuit boards‚Äč enable the core activities of Engineering Validation Testing (EVT), moving theories from simulation into the tangible world where real performance is measured.

- Functional Testing:‚Äč Verifies that the circuit operates as intended under specified conditions.

- Thermal & Stress Analysis:‚Äč Allows testing of heat dissipation and mechanical robustness.

- Component Compatibility Check:‚Äč Physically validates the performance and footprint of chosen real-world components.

- Signal Integrity Verification:‚Äč Critical for high-speed designs, allowing measurement of actual signal performance on the board.

- Interfacing with Other Systems:‚Äč Tests connectors, cables, and communication with other subsystems or enclosures.

Without a fast pipeline for prototypes, the EVT phase becomes a major project bottleneck. Access to reliable quick turn printed circuit boards suppliers‚Äč keeps validation cycles tight and informative.

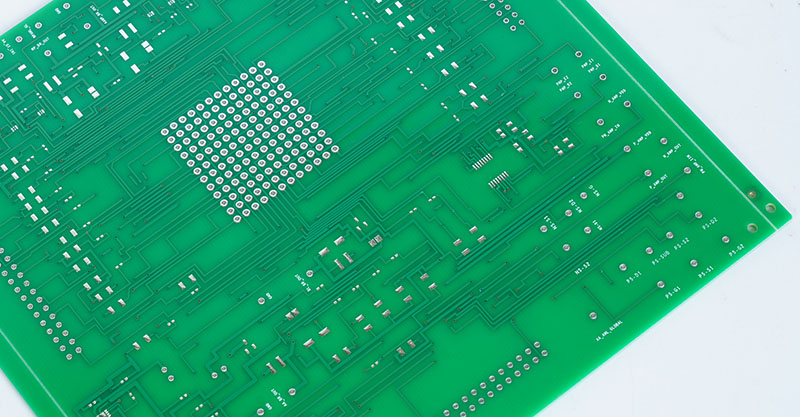

What Drives Quality in Quick Turn Circuit Board Fabrication for Multi-Layer Builds?

Speed must not come at the expense of reliability, especially for complex multilayer circuit boards quick turn‚Äč projects.

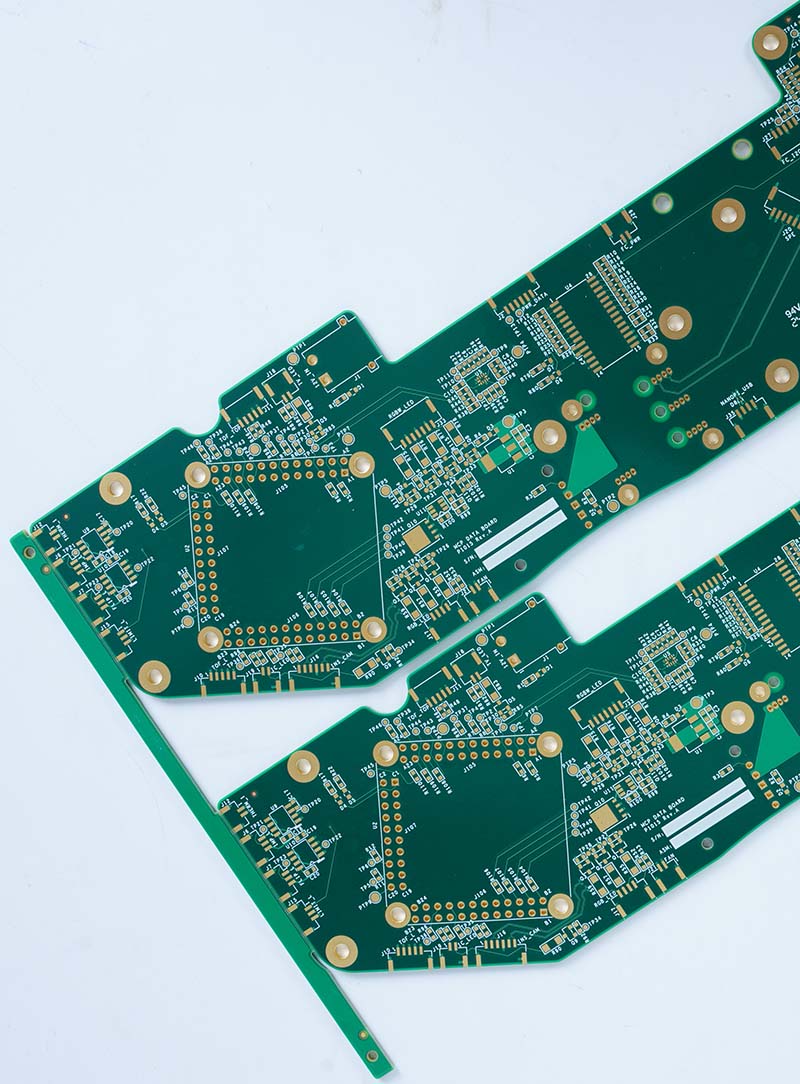

Quality in expedited quick turn multilayer circuit board PCB assembly‚Äč is driven by automated processes, stringent process controls, and experienced oversight, ensuring that the compression of time does not introduce defects.

- Advanced, Automated Equipment:‚Äč Use of laser direct imaging (LDI), automated optical inspection (AOI), and flying probe testers ensures precision and catches errors instantly.

- Controlled Impedance & Layer Alignment:‚Äč Critical for multilayer boards; achieved through precise material control and registration systems.

- Robust Lamination Process:‚Äč Ensures perfect bonding between layers without delamination, even on fast-turn schedules.

- Through-Hole & Via Reliability:‚Äč Ensured by proper drilling, plating, and inspection techniques (like X-ray for blind/buried vias).

- Comprehensive Final Testing:‚Äč Electrical testing and final visual inspection remain non-negotiable final checkpoints.

Hence, a leading quick turn PCB manufacturer for circuit board assembly‚Äč invests in the technology and processes that make speed and quality for complex boards not mutually exclusive, but standard.

How to Select a Reliable Quick Turn PCB Manufacturer for Circuit Board Assembly?

Choosing the right partner is critical. Look beyond the advertised turnaround time.

When evaluating a potential quick turn PCB manufacturer, consider a holistic set of criteria that guarantees not just a fast first board, but a smooth, reliable path to production.

- Proven Track Record & Capabilities:‚Äč Seek documented experience with your board’s complexity (layer count, materials, fine-pitch components).

- Transparent Processes & Communication:‚Äč Assess their responsiveness and clarity during the quoting and DFM feedback stage.

- Quality Certifications & Infrastructure:‚Äč Look for certifications like ISO 9001, ISO 13485, or IATF 16949, and inquire about their in-house quality control equipment.

- Scalability and Material Sourcing:‚Äč Ensure they can support your journey from prototype to pilot runs and have stable supply chains for components.

- Value-Added Services:‚Äč Consider if they offer full-service support like quick-turn PCB circuit board‚Äč design, component sourcing, and comprehensive testing.

Selecting a manufacturer is about building a partnership for your product’s entire lifecycle, starting with the urgent prototype.

What Makes China Leading Quick Turn 24Hours PCB Circuit Board Assembly Manufacturer?

The model of a China leading quick turn 24hours PCB circuit board assembly manufacturer‚Äč is built on massive scale, vertical integration, and a highly competitive cost structure.

Chinese manufacturers dominate the cheap PCB fabrication‚Äč landscape and have adapted to offer extremely aggressive quick-turn services by leveraging unique advantages.

| Factor‚Äč | Advantage for Quick-Turn‚Äč |

|---|---|

| Vertical Integration‚Äč | Controls material production, fabrication, and assembly in one location, minimizing hand-off delays. |

| Massive Scale & Dedicated Lines‚Äč | Can allocate entire high-speed production lines exclusively for 24-hour turn orders. |

| Large Local Supply Chain‚Äč | Immediate access to a vast inventory of common components and raw materials. |

| Highly Competitive Pricing‚Äč | Offers cheap PCB‚Äč options even on expedited schedules due to lower operational costs. |

For global buyers focused primarily on maximum speed at the lowest possible cost for standard technology boards, these manufacturers are a compelling option when navigating where to buy circuit boards‚Äč for prototyping.

Why Many OEMs Select EBest Circuit (EBest Circuit (Best Technology)) for Quick Turn PCB Assembly?

OEMs choose EBest Circuit (EBest Circuit (Best Technology)) because we deliver a balanced, reliable equation of Speed, Quality, and Partnership.

We understand that an urgent deadline cannot compromise the foundation of a good product. Our commitment goes beyond being just another quick turn printed circuit boards factory.

- Predictable Speed with Precision:‚Äč We offer guaranteed, reliable turnarounds (e.g., 24h fab, 3-day assembly) backed by our state-of-the-art facility and don’t cut corners on our rigorous quality checks.

- Engineering Partnership:‚Äč Our team provides expert printed circuit board service quick turns, including proactive DFM analysis to prevent delays from design flaws.

- Seamless Scalability:‚Äč We are your single partner from quick turn prototype printed circuit boards‚Äč through to mid-volume production, ensuring consistency.

- Transparent Communication:‚Äč You get direct access to project managers and engineers, ensuring clear, timely updates and collaboration.

- Commitment to Quality Standards:‚Äč Our processes are certified and designed to meet stringent international quality demands, even on the fastest turns.

For OEMs who view their PCB builders‚Äč as a strategic extension of their team, EBest Circuit (EBest Circuit (Best Technology)) provides the dependable agility needed to meet urgent deadlines without sacrificing the integrity of the final product.

To conclude, quick turn circuit boards‚Äč are the strategic accelerator for electronics development, transforming urgent deadlines from a source of stress into a manageable, competitive advantage. This article has explored their critical role across industries, the expectations from top services, and the key factors in selecting a manufacturer.

When every day counts, partnering with a provider that balances unwavering speed with unwavering quality is essential. EBest Circuit (EBest Circuit (Best Technology)) is committed to being that partner, offering reliable, high-quality quick-turn printed circuit board‚Äč solutions that support your innovation from the first prototype to final production. For more information or if you would like to send us any inquiry, please send us an email through the contact form at the bottom of our Contact Page.