Automotive PCB assembly is the backbone of modern vehicle electronics, powering systems such as engine control units, ADAS modules, infotainment, battery management, and body control units. Unlike consumer electronics, automotive boards must operate reliably under vibration, heat, moisture, and long service cycles.

This demands strict process control, automotive-grade components, traceable materials, and compliance with quality standards to ensure consistent performance over millions of driving miles.

What is automotive control system PCB assembly?

Automotive control system PCB assembly refers to the process of assembling printed circuit boards used in vehicle control units. These boards form the electronic backbone of automotive systems that monitor, regulate, and respond to real-time vehicle conditions.

A control system PCB does not operate in isolation. It interacts with sensors, actuators, power modules, and communication networks throughout the vehicle. The assembly process must therefore deliver electrical stability, mechanical strength, and predictable performance over many years of operation.

Automotive control system PCBs are commonly found in engine control units, battery management systems, transmission controllers, braking systems, and body control modules. Each board must withstand continuous thermal cycling, electrical noise, and mechanical stress.

Automotive PCB assembly differs from standard PCB assembly in several important ways. Materials are selected for thermal endurance. Solder joints are designed for vibration resistance. Process control is far stricter. Documentation and traceability are mandatory rather than optional.

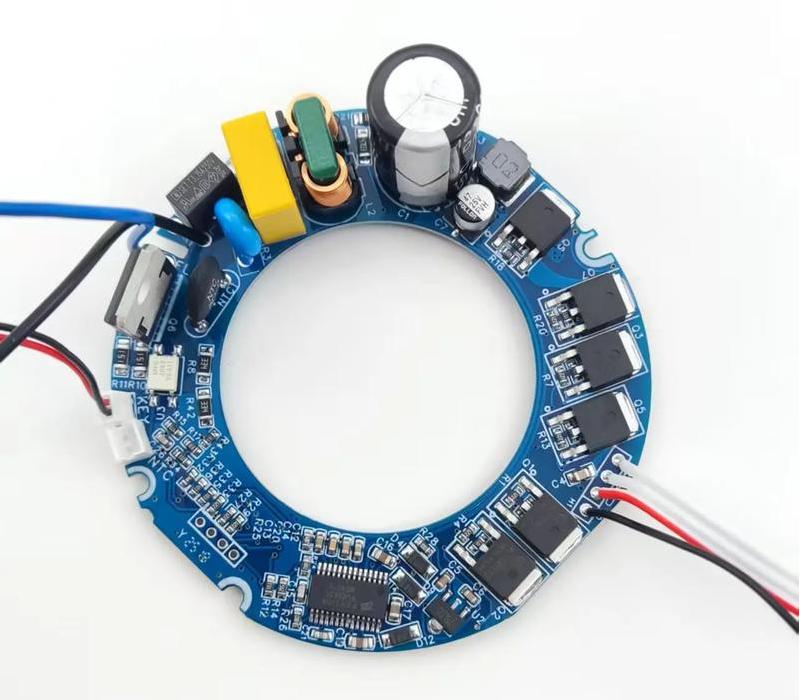

Control system PCB assembly usually involves multilayer boards with fine-pitch components, power devices, and mixed-technology assembly. Surface mount technology is widely used, while through-hole components remain common for connectors and high-power parts.

How much does automotive PCB assembly cost?

Automotive PCB assembly cost is influenced by several interrelated factors. There is no fixed price because each project carries unique technical and compliance requirements.

- Board complexity is a primary driver. Layer count, board thickness, copper weight, and impedance control all affect fabrication cost. Dense layouts increase assembly difficulty and inspection time.

- Component selection also has a major impact. Automotive-grade components are more expensive than commercial equivalents. Long-term availability and approved vendor lists further influence sourcing cost.

- Assembly process requirements shape pricing as well. Fine-pitch components, BGA packages, and mixed SMT and through-hole designs require specialized equipment and skilled operators.

- Testing and quality control contribute significantly to total cost. Automotive programs typically require multiple inspection stages and functional testing.

When evaluating automotive PCB assembly factories, cost should be viewed in context. A lower unit price may conceal risks related to yield loss, field failure, or supply instability.

Many OEMs prefer turnkey PCB manufacturing because it consolidates costs into a single controlled workflow. EBest Circuit (Best Technology) supports this model by offering turnkey PCB assembly without MOQ requirements, allowing customers to balance cost control with production flexibility.

What testing is required in automotive PCB assembly?

Testing is a defining element of automotive PCB assembly. It verifies that each assembled board meets functional and reliability expectations before entering a vehicle system.

- Visual inspection is the first layer of control. Automated optical inspection checks solder joints, component placement, and polarity. This step catches surface-level defects early in the process.

- Electrical testing follows. In-circuit testing verifies component values, connectivity, and basic electrical behavior. It helps identify assembly issues that visual inspection cannot detect.

- Functional testing is essential for control system PCBs. Boards are powered and operated under simulated conditions to confirm correct behavior. This test validates firmware interaction and signal response.

- For certain applications, environmental testing is required. Thermal cycling exposes boards to repeated temperature changes. Vibration testing evaluates mechanical robustness.

- Traceability supports all testing activities. Each board is linked to material batches, process records, and test results.

A reliable automotive PCB assembly factory integrates testing into production rather than treating it as a final checkpoint. EBest Circuit (Best Technology) applies multi-stage inspection and testing as part of its turnkey PCB manufacturing process, supporting stable quality without unnecessary delay.

How long does PCB assembly take?

PCB assembly lead time depends on project scope, supply chain conditions, and testing requirements. Automotive projects often prioritize consistency over speed, yet efficient scheduling remains important.

- Prototype assembly usually takes longer than consumer electronics prototypes. Engineering review, process setup, and validation testing add time but reduce downstream risk. For small-volume production, lead times typically range from one to three weeks. This includes material preparation, assembly, inspection, and functional testing.

- Mass production lead times depend on order size and production planning. Once a process is validated, cycle times become more predictable. Long-term agreements often allow for stable scheduling.

- Component availability plays a major role. Automotive-grade components may have longer lead times. A turnkey PCB assembly partner can mitigate this risk through proactive sourcing and inventory planning.

EBest Circuit (Best Technology) supports flexible lead times by integrating PCB fabrication, component sourcing, and assembly under one system. This approach reduces coordination delays and helps maintain predictable delivery schedules.

What is automotive PCB assembly used for?

Automotive PCB assembly supports a wide range of vehicle systems. Each application has its own technical focus, yet all share a need for dependable electronic control.

- Powertrain systems rely on PCBs to manage engine performance, fuel delivery, and emissions. These boards must operate reliably under high temperature and electrical load.

- Safety systems depend on precise signal processing. Airbag controllers, braking systems, and stability control units use PCBs that must respond instantly and accurately.

- Body electronics manage lighting, climate control, and access systems. While operating conditions may be less severe, long-term reliability remains essential.

- Electric and hybrid vehicles introduce new requirements. Battery management systems and power control units rely on PCBs that handle high currents and monitor complex parameters.

- Infotainment and connectivity systems also use automotive PCB assembly. These boards integrate communication interfaces while meeting automotive durability standards.

Across all these uses, automotive PCB assembly ensures that electronic systems perform consistently throughout the vehicle’s service life.

What challenges exist in automotive control system PCB assembly?

Automotive control system PCB assembly presents technical and operational challenges. These challenges require careful planning rather than reactive problem solving.

- Thermal management is a constant concern. Control systems often operate near heat sources. Poor thermal design or assembly can lead to premature failure.

- Vibration and mechanical stress affect solder joint integrity. Assembly processes must account for continuous movement and shock.

- Component lifecycle management adds complexity. Automotive programs often last many years. Ensuring component availability requires strategic sourcing.

- Process consistency is another challenge. Automotive quality expectations leave little room for variation. Assembly parameters must remain stable over long production runs.

- Compliance requirements introduce additional workload. Documentation, traceability, and audit readiness are not optional in automotive manufacturing.

Despite these challenges, structured manufacturing processes can mitigate risk. Working with an experienced automotive PCB assembly manufacturer helps translate design requirements into stable production outcomes.

How to choose an automotive control system PCB assembly factory?

Selecting the right automotive control system PCB assembly factory is a strategic decision. It affects product reliability, supply continuity, and total cost of ownership.

- Experience in automotive projects matters. A factory familiar with automotive standards understands the importance of process discipline.

- Manufacturing capability should align with product requirements. This includes multilayer PCB fabrication, fine-pitch assembly, and power electronics handling.

- Quality systems are critical. Look for structured inspection, testing, and traceability practices. These systems support long-term program stability.

- Supply chain management is equally important. Automotive components require careful sourcing and lifecycle planning.

- Communication and engineering support often determine project success. A responsive partner helps resolve issues early and supports design optimization.

EBest Circuit (Best Technology) positions itself as a professional PCB manufacturer offering PCB prototyping, design, and assembly services. Its turnkey PCB assembly model without MOQ requirements supports both development and production stages.

Why select a professional automotive PCB assembly factory?

A professional automotive PCB assembly factory provides more than production capacity. It delivers process control, accountability, and confidence.

Professional manufacturers invest in equipment, training, and quality systems. These investments reduce variation and improve long-term reliability.

Turnkey PCB manufacturing further strengthens this approach. By managing the entire process, risks related to handoffs and miscommunication are reduced.

For automotive programs, reliability is not negotiable. Choosing a professional automotive PCB assembly factory supports consistent performance throughout the vehicle lifecycle.

EBest Circuit (Best Technology) offers turnkey PCB assembly services without MOQ requirements, supporting automotive customers from early prototypes to stable production.

Conclusion:

Automotive PCB assembly plays a central role in modern vehicle electronics. Control system PCBs support safety, performance, and efficiency across many applications.

For professional support in automotive PCB assembly and turnkey PCB manufacturing, contact sales@bestpcbs.com to discuss your project requirements.