How to choose a reliable Poland PCB manufacturer? This blog is mainly about a detailed selection guide for PCB manufacturers in Poland and how to evaluate their production capabilities.

Are you struggling with these questions?

- Worried about delivery delays stalling your project timeline?

- Struggling with inconsistent quality between prototypes and mass production?

- Frustrated by design flaws causing costly rework cycles?

As a 19 year’s PCB manufacturer, EBest Circuit (Best Technology) can provide you service and solutions:

- Predictable Timelines ‚Äď 24-hour rapid prototyping paired with 15-day bulk delivery, backed by 20 years of production scheduling expertise to keep delays under 0.8%.

- Unified Quality Standards ‚Äď End-to-end quality control with real-time SPC monitoring ensures >98% consistency from samples to bulk orders, eliminating the ‚Äúprototype-to-production gap.‚ÄĚ

- Free DFM Optimization ‚Äď Free design-for-manufacturing analysis by seasoned engineers catches line width/spacing, impedance, and other hidden flaws early, slashing rework costs by 30%+ based on proven case data.

Welcome to contact us if you have any inquiry for PCB design, prototyping, bulk production, PCBA service: sales@bestpcbs.com.

Top PCB Manufacturer in Poland

1. Printor Sp. z o.o.

- Advantages: Printor is known for steady quality and smooth communication. Their internal systems support fast feedback, clear documentation, and stable production runs. They also handle complex assembly work, which helps customers reduce coordination steps.

- Production Capabilities: Single-layer to multilayer PCBs; Standard 4/4 mil lines; ENIG, HASL-RoHS, OSP finishes; SMT and THT assembly; Flying-probe testing and AOI; Product assembly and functional testing.

- Main Business: Printor works with industrial electronics, medical modules, smart controllers, and consumer devices. They serve both small R&D teams and large EU enterprises.

- Typical Lead Time: 5‚Äď10 working days for PCB prototype; 12‚Äď18 working days for PCBA assembly; 15‚Äď25 working days for serial production.

2. Elhurt EMS Group

- Advantages: Elhurt EMS delivers full electronics manufacturing solutions. Their service covers PCB sourcing, assembly, module testing, packaging, and logistics. Many EU customers prefer Elhurt because the company manages everything from materials to shipping.

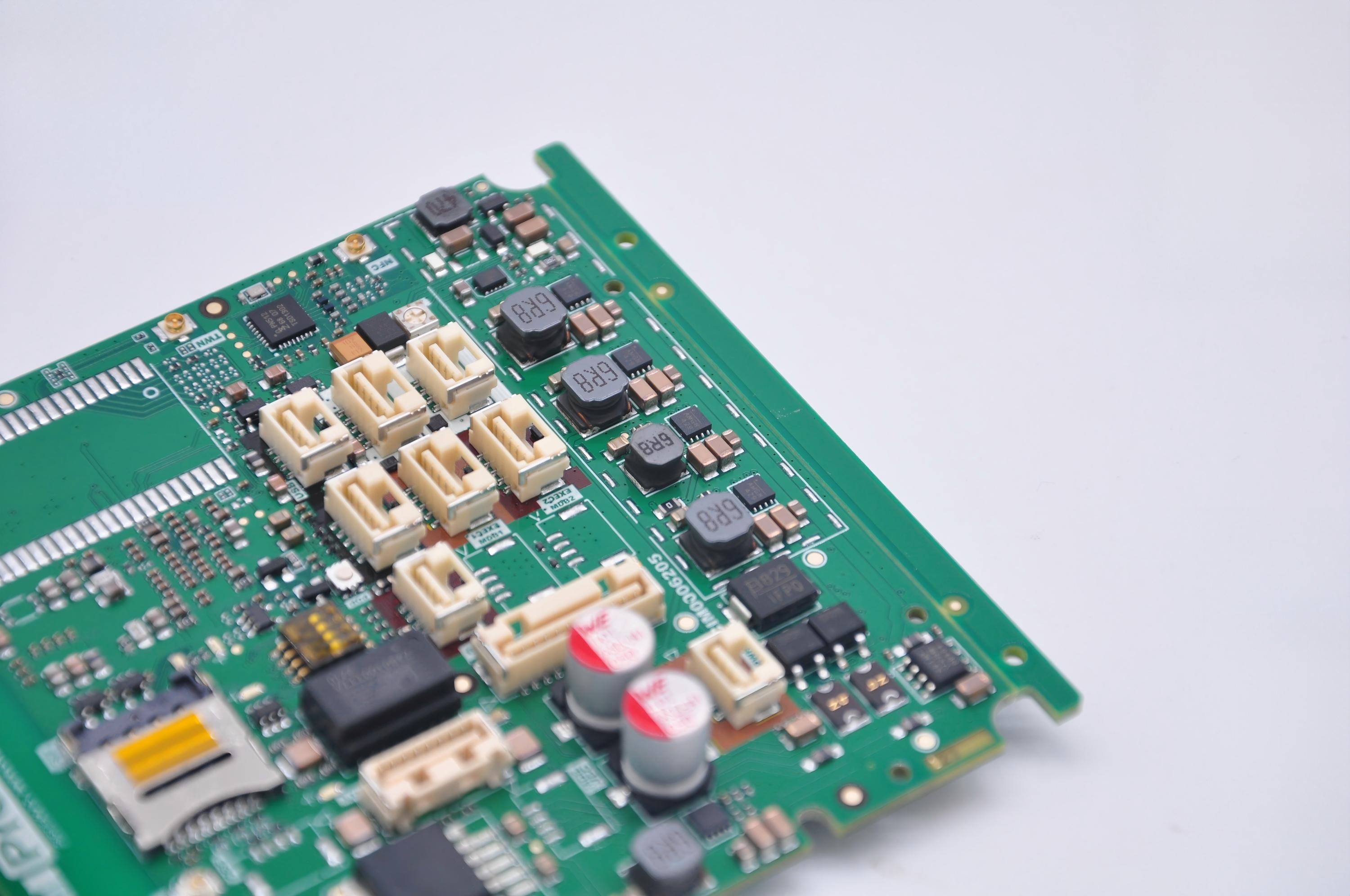

- Production Capabilities: SMT + THT assembly; Solder paste inspection; AOI, ICT, and functional testing; PCB sourcing through partner suppliers; Complete unit assembly; Large production volume capability.

- Main Business: Elhurt serves industrial control systems, consumer electronics, communication modules, and IoT hardware. They focus heavily on PCBA and complete module manufacturing.

- Typical Lead Time: 10‚Äď14 working days for PCBA prototype; 20‚Äď30 working days for mass production.

3. Lumel S.A.

- Advantages: Established industrial electronics manufacturer; strong process control; stable quality culture; full device production capabilities.

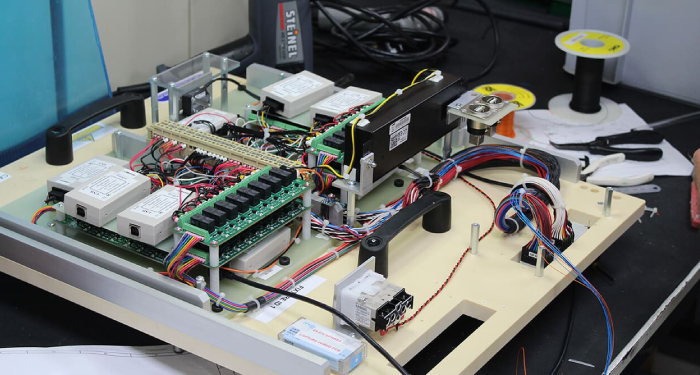

- Production Capabilities: SMT/THT assembly; conformal coating; box-build assembly; software loading/calibration; mechanical assembly; industrial-grade testing.

- Main Business: OEM/ODM for automation equipment, metering units, industrial controllers, measurement instruments.

- Typical Lead Time: PCBA prototype for 7‚Äď12 days; Full module assembly for 15‚Äď25 days.

4. Techno-Service S.A.

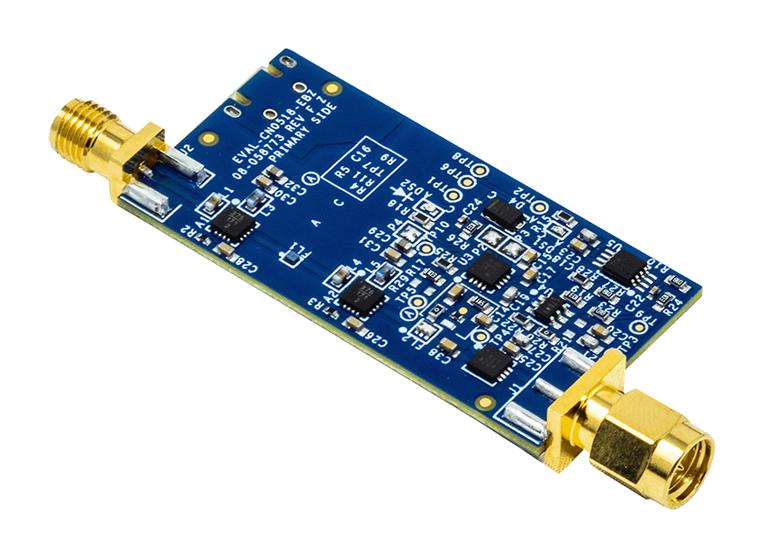

- Advantages: Advanced technical capabilities; supports high-layer counts, HDI, RF-friendly materials; modern equipment.

- Production Capabilities: Up to 20-layer PCB; HDI with laser drilling; impedance control; ENEPIG/ENIG/immersion silver; thermal cycling testing.

- Main Business: Telecom equipment, RF modules, industrial computers, automation devices, high-complexity boards.

- Typical Lead Time: Multilayer prototype for 7‚Äď12 days; HDI/RF production for 15‚Äď25 days.

5. RENEX Group

- Advantages: Stable quality; strong engineering support; SMT training centers; technical knowledge from equipment supply.

- Production Capabilities: Multilayer PCB; standard 4/4 mil; ENIG/HASL/OSP; X-ray inspection; flying-probe/AOI; assembly services.

- Main Business: Automation, robotics, education, sensors, control systems.

- Typical Lead Time: PCB prototype for 6‚Äď10 days; Production for 15‚Äď22 days.

6. DRUKOPOL

- Advantages: Precision fabrication; tight tolerance expertise; high-frequency laminate support.

- Production Capabilities: Rigid PCB; RF/microwave boards; custom thickness; ENIG/HASL; small-batch prototyping.

- Main Business: Telecom devices, RF sensors, custom industrial electronics.

- Typical Lead Time: Prototype for 5‚Äď9 days; Production for 12‚Äď18 days.

7. CREATRONIC

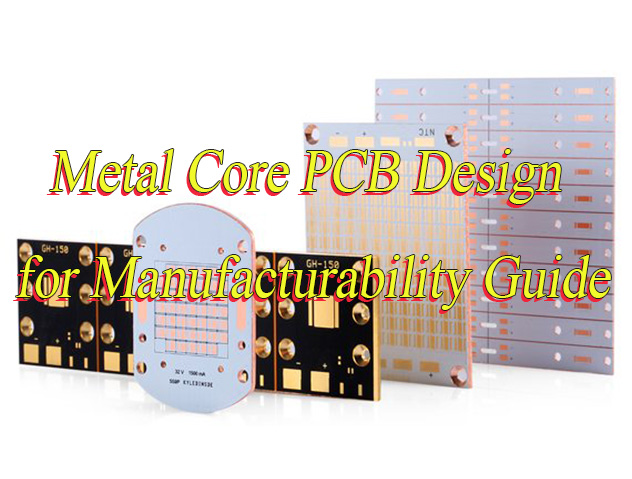

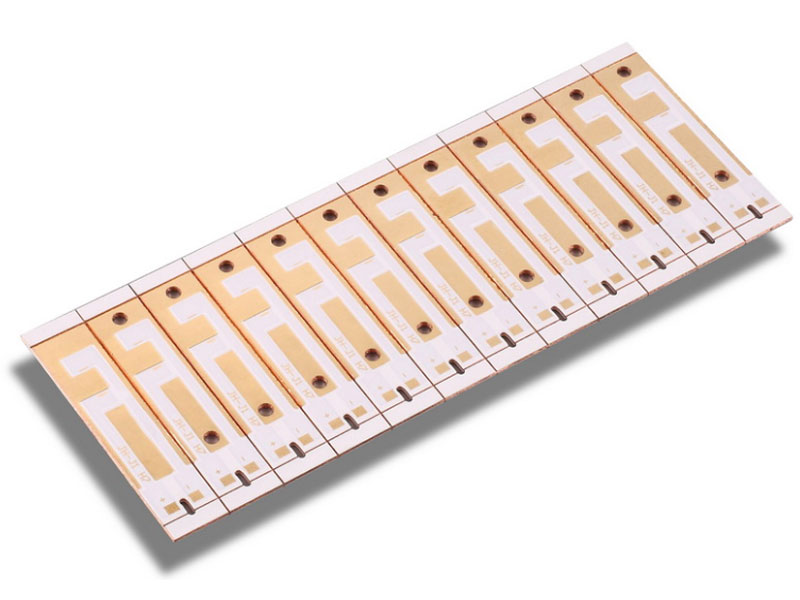

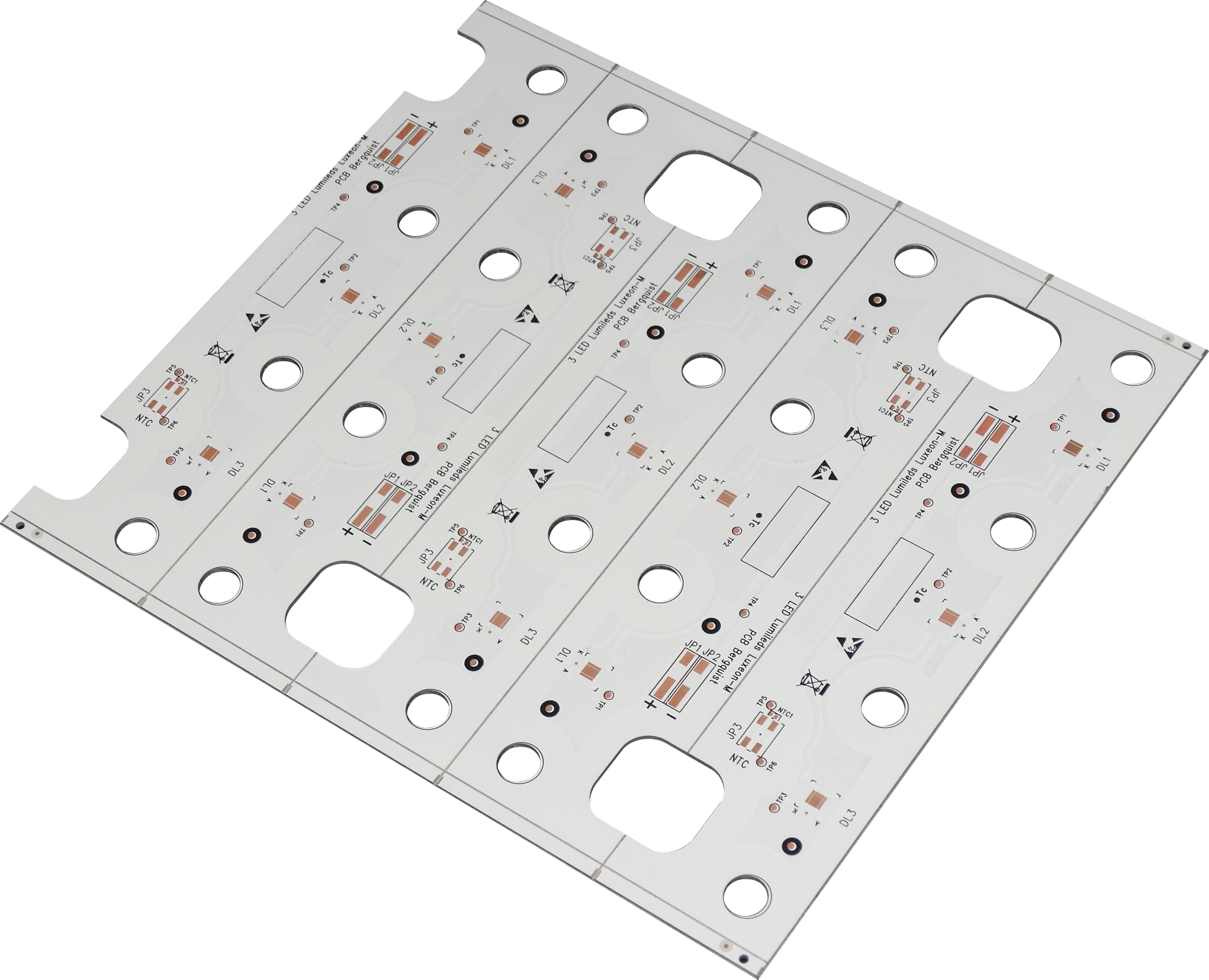

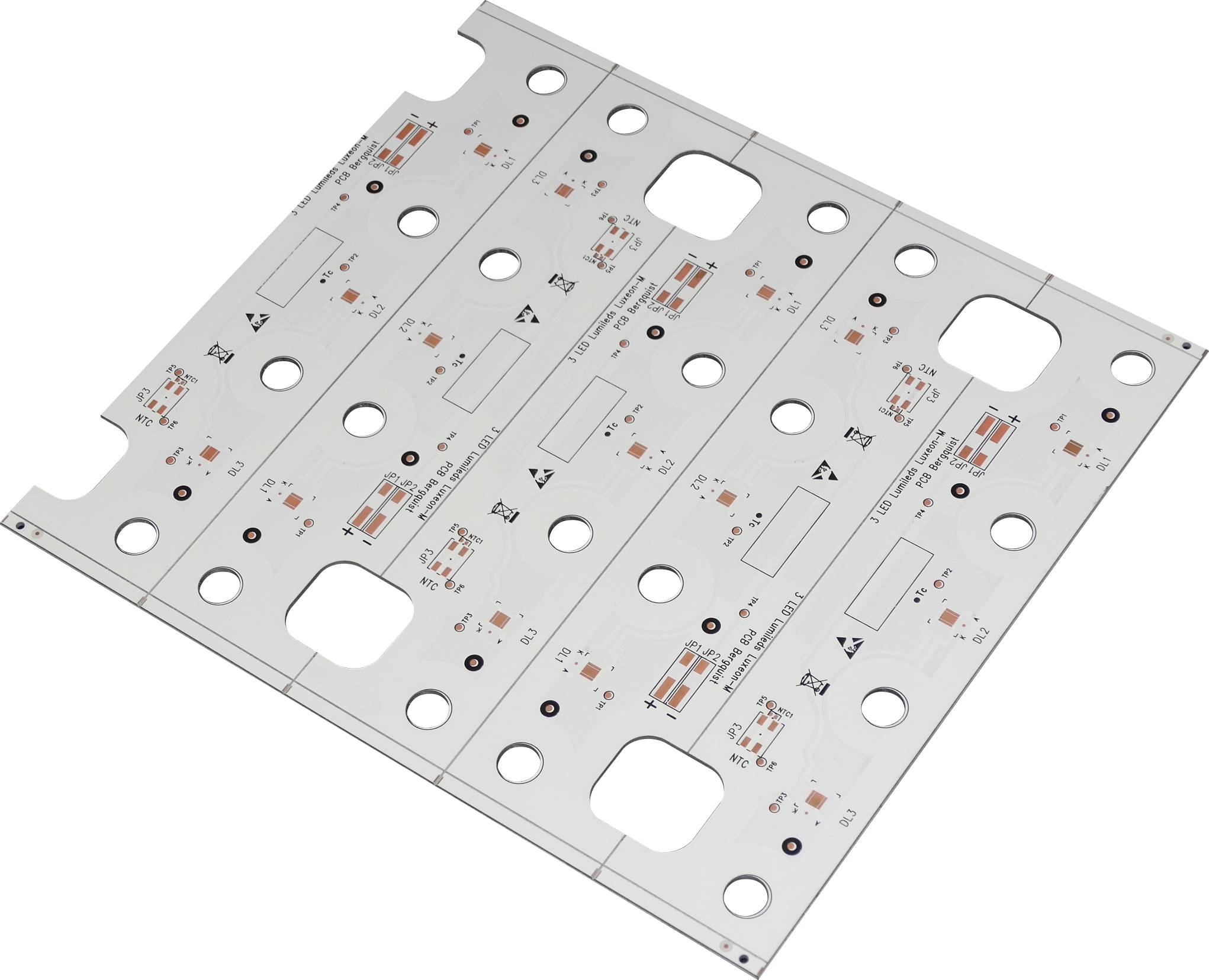

- Advantages: LED/aluminum PCB specialization; popular for lighting/large modules.

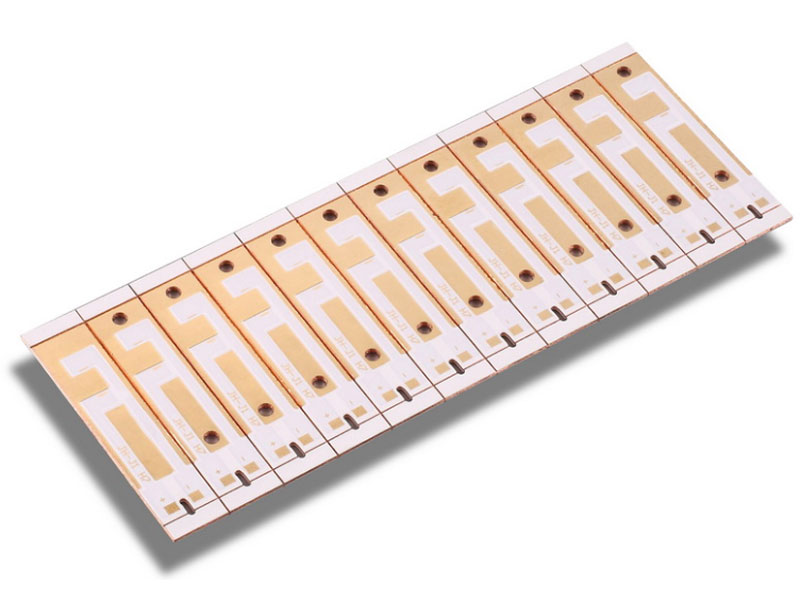

- Production Capabilities: Aluminum MCPCB; LED strip PCBs; high-power lighting boards; routing/drilling/shape profiling.

- Main Business: Lighting companies, signage manufacturers, energy-efficient devices.

- Typical Lead Time: Aluminum PCB prototype for 5‚Äď8 days; Production for 10‚Äď15 days.

8. TS Electronics

- Advantages: Rapid prototyping; close designer collaboration; error reduction.

- Production Capabilities: 1‚Äď6 layer PCBs; ENIG/HASL; flying-probe test; AOI; mixed-signal support.

- Main Business: IoT devices, automation controls, smart sensors, R&D.

- Typical Lead Time: Prototype for 5‚Äď8 days; Production for 12‚Äď18 days.

How to Choose A Reliable Poland PCB Manufacturer?

A Detailed Selection Guide to Poland PCB Manufacturer for Your Reference:

1. Verify Manufacturer’s Professional Qualifications and Certifications

- Hold ISO 9001, ISO 13485, IATF 16949, ISO 14001, and RoHS certifications

- Provide UL, IPC-A-610, IPC-A-600, and CE certifications to ensure compliance with global standards

2. Evaluate Manufacturing Capabilities and Technical Scope

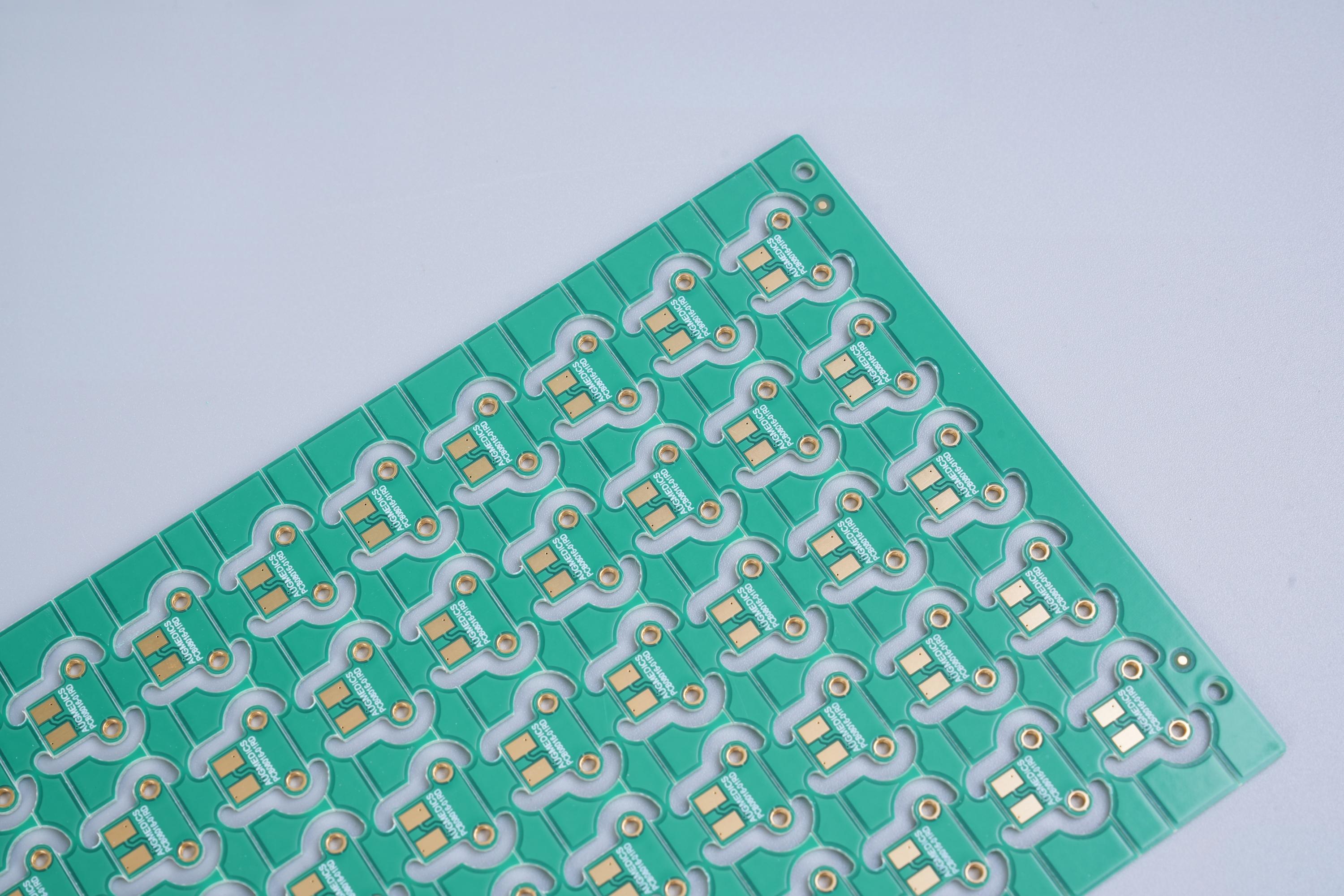

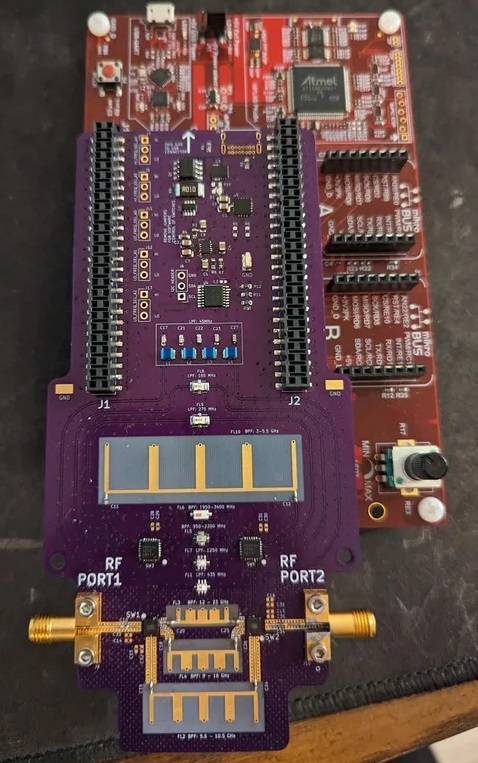

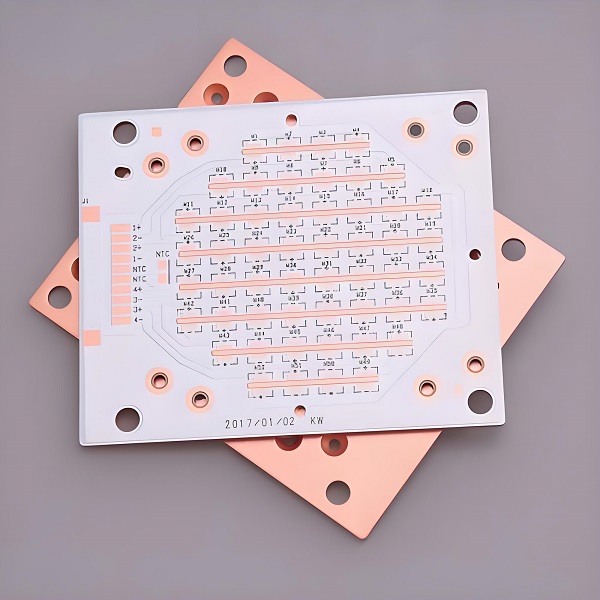

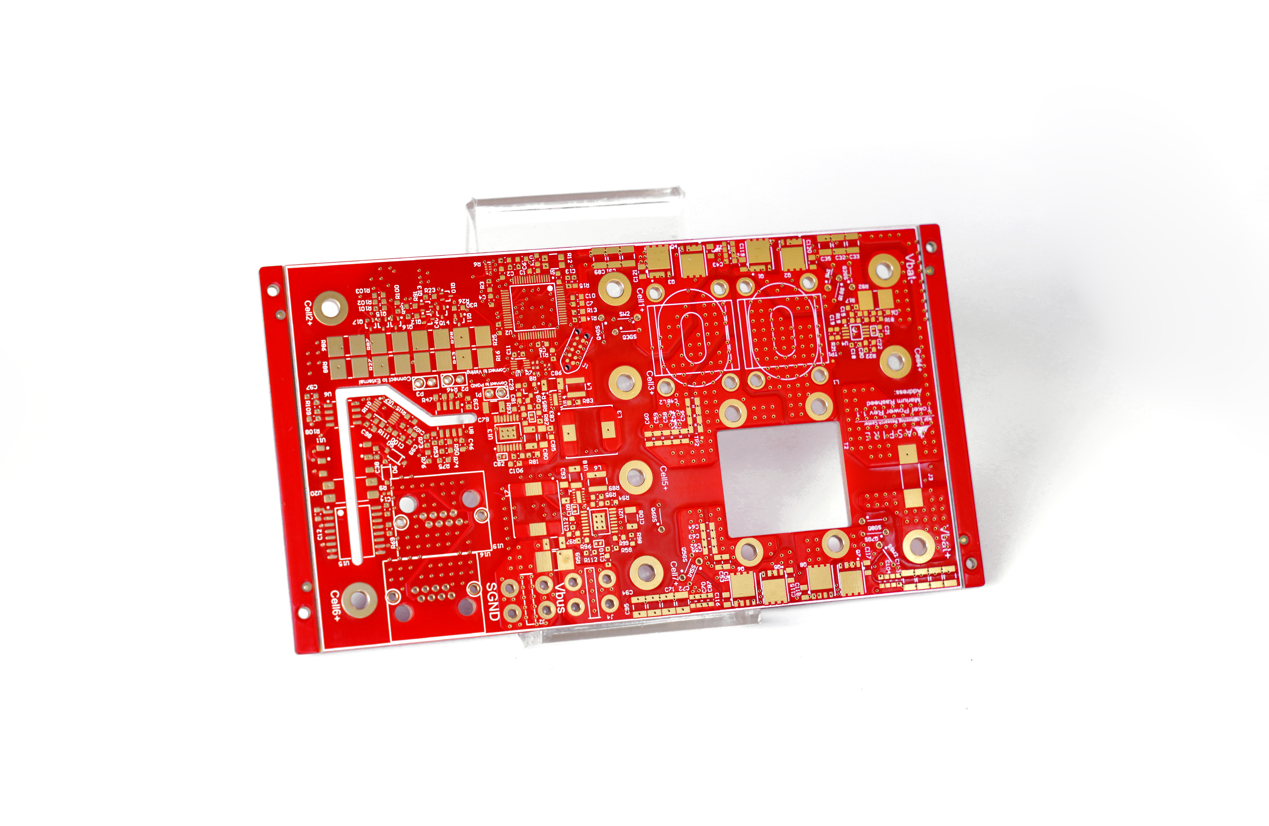

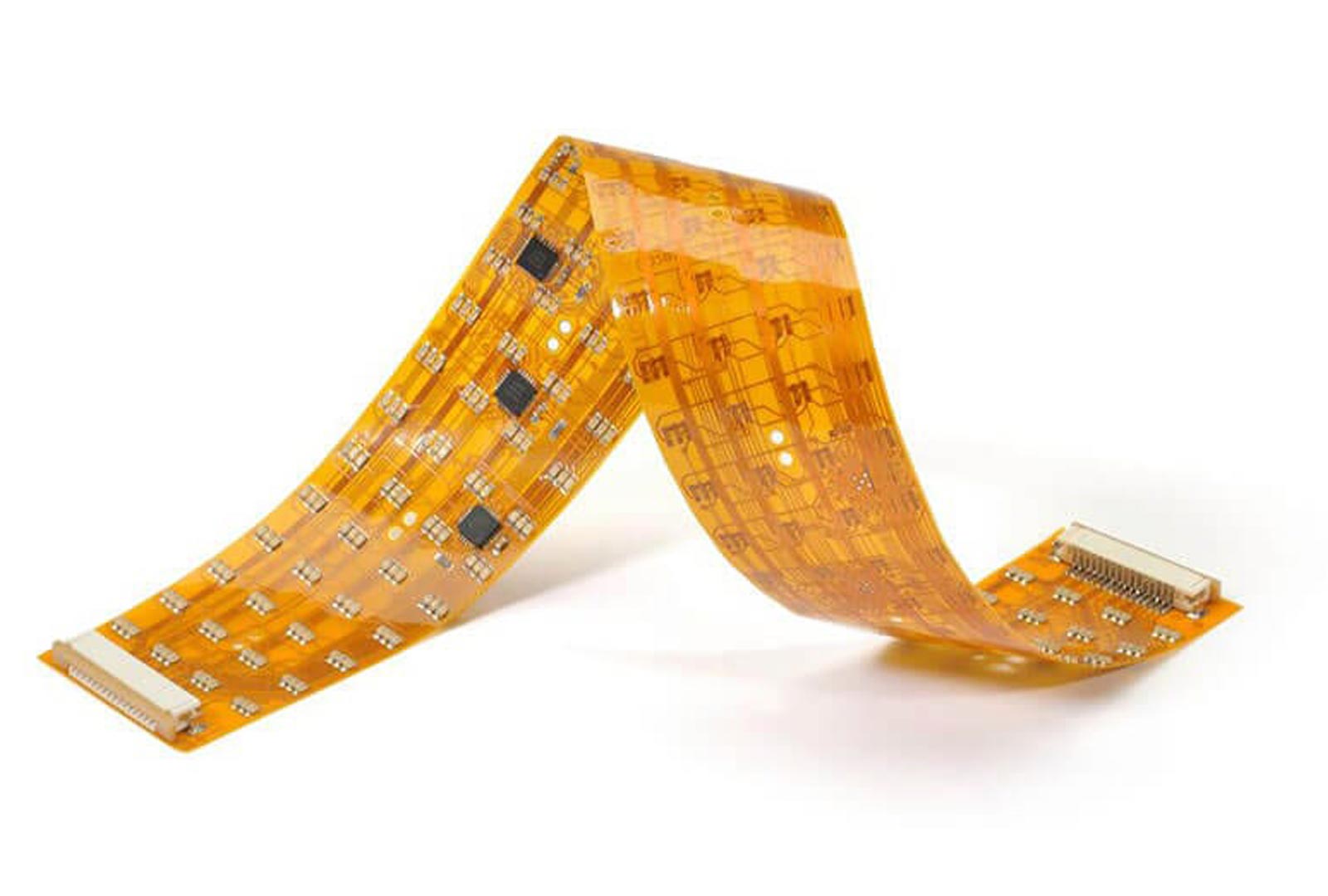

- Support production of single/double-sided, 4-32 layer multilayer, HDI (1-3 stage microvias), flexible/rigid-flex, RF microwave (PTFE/FR4 substrate), and metal-core (aluminum/copper) boards

- Master special processes including blind/buried vias (minimum hole size 0.1mm), high-TG materials (Tg 170-220¬įC), back drilling, impedance control (¬Ī5%), embedded capacitors/resistors

- Specify parameters such as minimum trace width/spacing (0.075mm/0.075mm), hole size (0.1mm), maximum layer count (32 layers), surface finishes (ENIG/ENEPIG/HASL/OSP), and material thickness (0.1-3.2mm)

3. Inspect Quality Control Systems

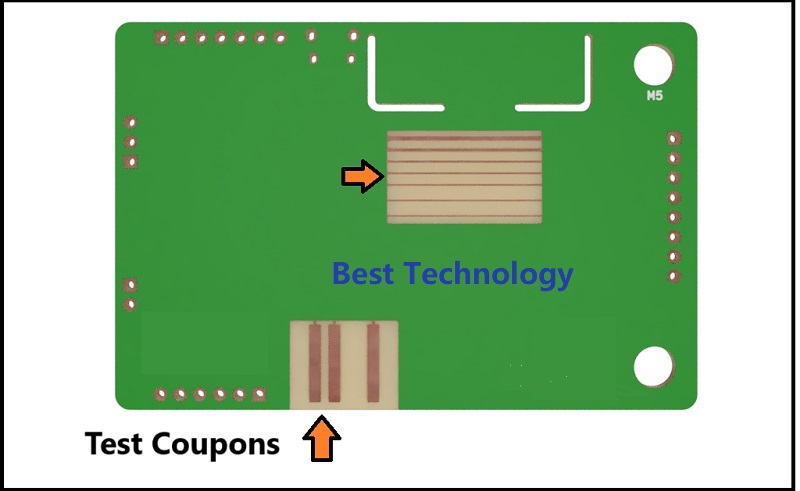

- Equipped with 3D AOI, inline SPI, flying probe test, X-ray inspection, ICT/FCT, and other full-process inspection equipment

- Adhere to IPC Class 2/3 standards, provide first article inspection reports, reliability test data (e.g., 1000-cycle thermal cycling at -40~125¬įC, 168-hour 85¬įC/85%RH testing, 96-hour salt spray test), and traceability systems

4. Verify Supply Chain Stability and Delivery Capability

- Source raw materials from renowned suppliers including Shengyi, Kingboard (FR4), Rogers (high-frequency materials), and DuPont (solder masks), with dual-sourcing strategies to mitigate supply risks

- Prototype lead time 3-5 days (including engineering confirmation), volume production 7-14 days (standard), expedited delivery within 24/48 hours, with delivery guarantee agreements

5. Obtain Customer References and Market Reputation

- Provide case studies in automotive (ECU/BMS), medical (patient monitors/ultrasound devices), industrial (PLC/inverters), and consumer electronics (5G modules), with verification methods (customer interviews/site visits)

- Check third-party reviews on CPCA, industry publications (Printed Circuit Information), and B2B platforms (Alibaba International) for on-time delivery rates, response times (‚ȧ24 hours), and after-sales efficiency

6. Test Service and Communication Efficiency

- Technical teams provide DFM recommendations (trace optimization/impedance matching/testability design) within 48 hours during quoting to avoid mass production risks

- Commercial teams offer clear contract terms (payment/delivery/liability), proactive NDA signing (confidentiality period ‚Č•3 years, clear breach penalties), and traceable communication records

7. Compare Cost and Value

- Detailed quotes break down material (substrate/copper/ink), process (drilling/plating/finishing), testing (AOI/flying probe/reliability), shipping (air/sea/courier), and other costs (engineering/tooling), with no hidden fees

- Evaluate comprehensively based on quality (defect rate ‚ȧ0.1%), reliability (MTBF ‚Č•500,000 hours), and service (technical support response ‚ȧ24 hours), prioritizing cost-effectiveness over lowest price

8. Conduct On-Site Audits for Critical Orders

- Audit production environments (Class 10000 cleanroom, 22¬Ī2¬įC/55¬Ī5%RH), equipment status (brands/models/maintenance records), management processes (5S/visualization/traceability), and operator standards (IPC-certified training) to ensure alignment with advertised capabilities

How to Evaluate a Poland PCB Manufacturer’s Production Capability?

Methods About Evaluating A Poland PCB Manufacturer’s Production Capability:

1. Confirm Technical Specifications and Process Scope

- Review publicly available parameters such as layer count, trace width/spacing, hole size, substrate types, and surface finishes. Most Polish manufacturers support 2‚Äď32 layers; higher layer counts require confirmation of outsourcing or limitations.

- Verify capabilities for specialized processes like high-frequency/high-speed substrates, HDI (microvias), impedance control, and rigid-flex boards.

2. Audit Quality Systems and Industry Certifications

- Request certificates including ISO 9001, IATF 16949 (automotive), ISO 13485 (medical), UL, and aerospace standards (e.g., ECSS-Q-70).

- Assess quality management completeness using Poland‚Äôs “initial factory production control inspection + continuous supervision” model.

3. Evaluate Production Equipment and Capacity Data

- Obtain equipment lists (laser drilling, LDI, AOI, flying probe testing, SMT lines) with brands and age.

- Inquire about monthly capacity (m²/month), lead times (prototypes/bulk), and support for urgent orders (e.g., 72-hour rapid delivery).

4. Request Samples and Conduct Assessment Testing

- Require samples using standard materials/processes, incorporating highest-difficulty features (minimum trace width, smallest hole size, impedance traces).

- Commission third-party or in-house labs for cross-section analysis, solderability, thermal stress, insulation resistance, and voltage withstand tests per IPC-A-600.

5. Conduct On-Site or Video Factory Audits

- Inspect production environment (cleanliness, temperature/humidity control), material storage, process cards, and traceability systems.

- Review quality control points (e.g., inner-layer AOI, electrical test coverage, final inspection) and SPC data availability.

6. Assess Supply Chain and Material Security

- Inquire about suppliers for critical substrates, copper foil, and chemicals, and confirm partnerships with brands like Isola, Rogers, Panasonic.

- Confirm raw material inventory strategies and contingency plans for shortages.

7. Analyze Technical Team and Customer Support

- Evaluate DFM (Design for Manufacturing) capabilities to identify pre-production design risks and provide optimization suggestions.

- Test engineering support response times and language proficiency (English/Polish).

8. Review Existing Customer Cases and Industry Reputation

- Request client reference lists for similar products (e.g., automotive electronics, industrial controls, communication devices).

- Check Polish industry platforms and B2B sites for feedback on on-time delivery, quality consistency, and issue resolution efficiency.

9. Confirm Environmental Compliance and Regulations

- Ensure compliance with RoHS, REACH, halogen-free directives, and possession of relevant test reports.

- Verify Polish environmental permits (e.g., wastewater/air emission compliance).

10. Conduct Small-Batch Trial Production

- Place a trial order of 50‚Äď100 pcs, tracking production progress, quality control records, and final yield rates.

- Compare actual yield rates, delivery cycles, and issue responses across multiple manufacturers for final selection.

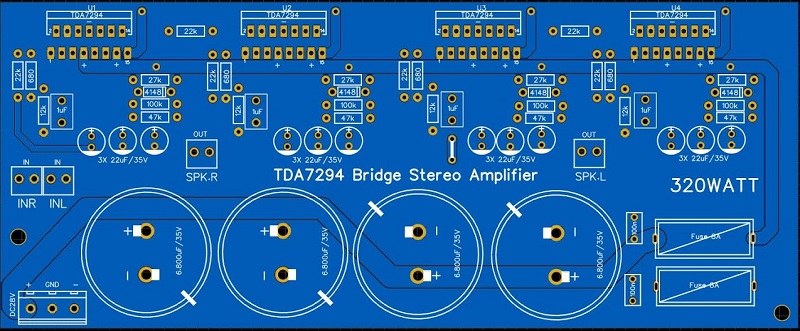

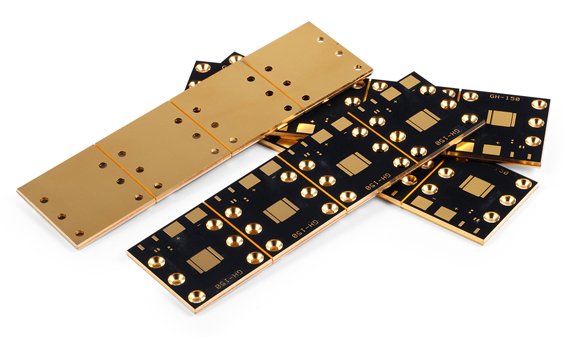

What Types of PCBs Can You Get from Poland Manufacturing Companies?

- Single-layer and double-layer boards

- FR-4 multilayer boards

- Simple HDI boards

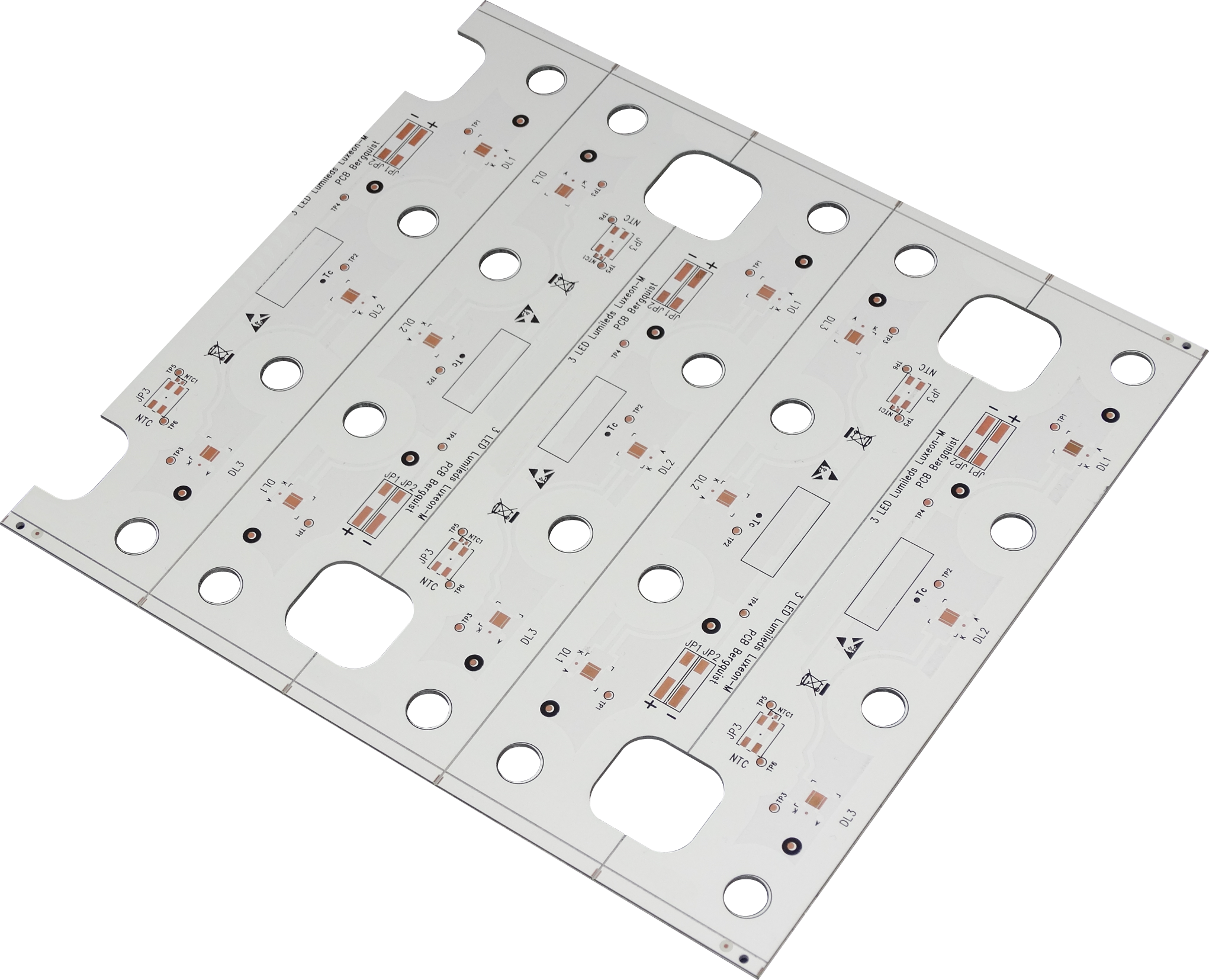

- Metal Core PCB( Aluminum PCB and Copper PCB)

- RF laminates (in limited factories)

- PCBA services

- Functional testing

- Industrial PCB assemblies

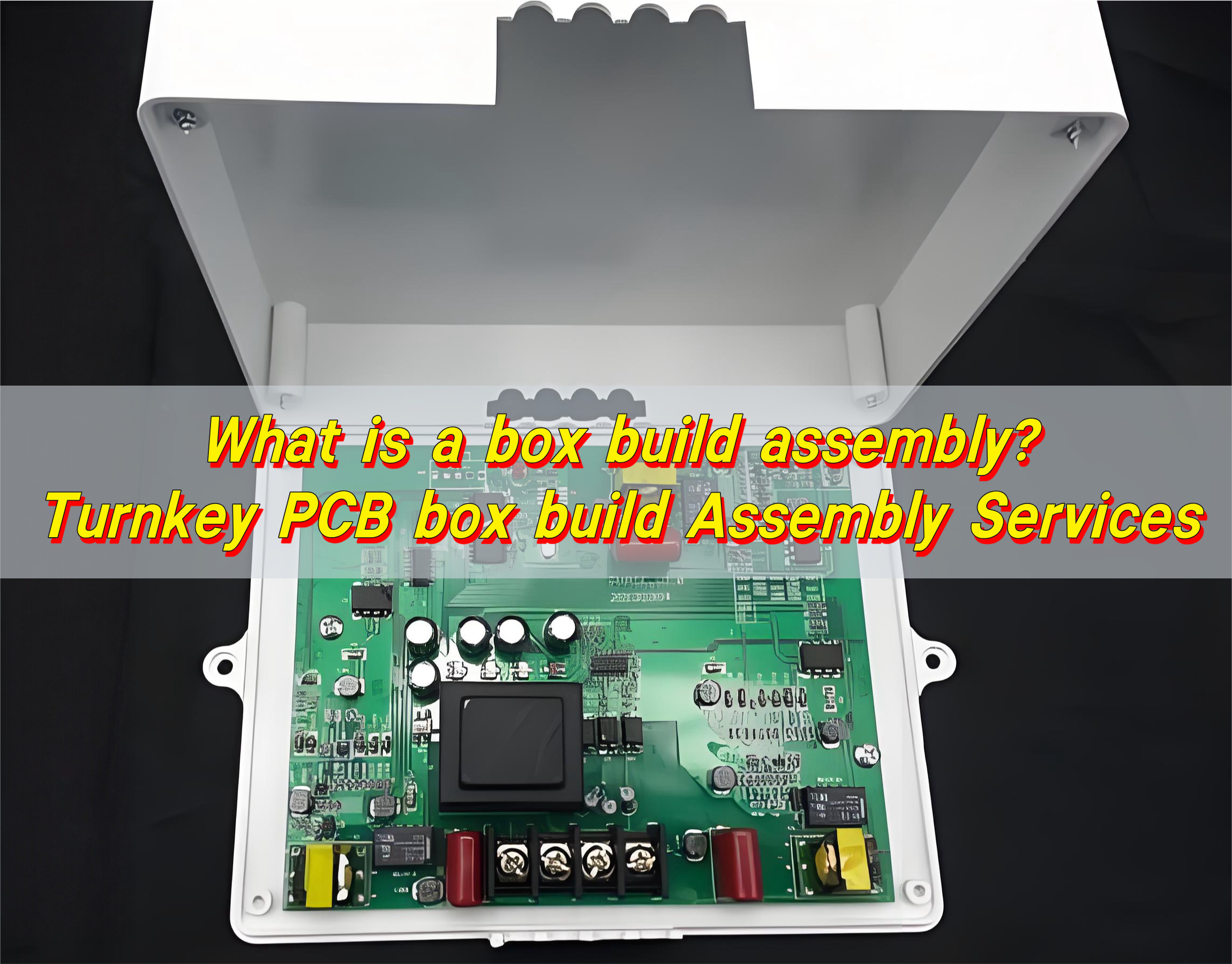

- Turn-key box-build modules

Challenges Faced by Poland PCB Manufacturers

Delivery Delays Cause Customer Loss:

- Lead times commonly extend beyond 6 weeks: Compared to Asian manufacturers’ standard 5‚Äď7-day lead times, some Polish vendors frequently require over 6 weeks from order confirmation to delivery, disrupting clients’ product development and launch schedules.

- Supply chain and internal coordination issues: Unstable raw material procurement, overly tight production scheduling, and unexpected order insertions delaying existing orders due to lack of priority management systems.

- Opaque communication exacerbates waiting: Clients struggle to obtain clear production updates post-order, with delays often communicated only near the agreed delivery date, pushing some to switch suppliers due to time-cost pressures.

PCB Quality Instability Impacts Product Reliability

- Inconsistent process control: Deviations in solder mask coverage, hole metallization, and trace width/spacing control lead to shorts, opens, or impedance mismatches, resulting in high rework costs.

- Material and finish issues: Use of substandard substrates or non-compliant gold/HASL plating thickness causes oxidation or delamination in high-temperature/humidity environments, affecting solder joint reliability and long-term performance.

- Inspection gaps: Small-to-medium manufacturers lacking adequate AOI or flying probe testing rely on visual checks, missing micro-defects that surface during client assembly.

PCB Solution We Can Offer You

Solutions for Delivery Delays

- Refined production scheduling and capacity reservation: Implement compact production planning with dedicated time slots for small and medium orders to prevent delays from large order insertions, maintaining a stable lead time of 3‚Äď4 weeks.

- Multi-source supplier collaboration and material stocking: Sign long-term agreements with verified local and European material suppliers, maintain safety stock for commonly used substrates and inks, and reduce material waiting times.

- Proactive communication and progress transparency: Send weekly production update emails with photos of key process completions; notify clients 3‚Äď5 days in advance of potential delays with explanations and collaborate on adjustment plans.

Solutions for Quality Instability

- Dual inspection for critical processes: Implement self-inspection + mutual inspection for solder mask coverage, hole copper thickness, and circuit etching, using portable measurement tools for sampling verification to meet IPC-A-600 standards.

- Deep collaboration with quality material suppliers: Insist on mid-to-high-tier substrates (e.g., FR-4 TG130) and sign quality agreements with suppliers to ensure consistency from the source.

- Client involvement in final inspection: Provide high-resolution photos or videos of boards before shipment for client review of appearance, silkscreen, etc., avoiding disputes from visual standard differences upon delivery.

Case Studies of Our Poland PCB Manufacturing Projects

Project Background: The client is a Poland agricultural IoT startup focused on developing precision agriculture smart irrigation systems.

Project Requirements:

- Long-term stable operation in harsh outdoor environments (-25¬įC to +70¬įC, humidity up to 95%RH) with a failure rate below 0.1% over 5 years

- Signal integrity supporting 4G/LTE-M communication modules, GNSS positioning, and multi-channel soil moisture/temperature sensors with ¬Ī10% impedance control tolerance

- Power management with wide voltage input (9-36V DC), reverse connection protection, overvoltage/overcurrent protection, and standby power consumption below 1mA

- Environmentally friendly processes compliant with RoHS and EU REACH regulations, using lead-free soldering

Solution Implementation:

- Stack-up and materials: Core FR-4 Tg 150¬įC, thickness 1.6mm, copper thickness 1oz (outer layer)/1oz (inner layer); surface finish ENIG with nickel layer >3őľm and gold layer 0.05-0.1őľm for solderability and corrosion resistance

- Impedance control and routing: 50ő© single-ended impedance control for 4G module RF lines and GNSS antenna feeders, 90ő©¬Ī10% differential pairs; “GND-signal-power-GND” stack-up sequence to reduce crosstalk and power noise

- Protection design: TVS diodes and self-recovering fuses at power input ports for ¬Ī30kV ESD protection and 4A overcurrent protection; conformal coating (acrylic-based) passing 168h humidity cycling (85¬įC/85%RH) test

- Manufacturing and inspection: LDI (Laser Direct Imaging) process ensuring trace width/spacing ‚Č•4mil; 100% flying probe testing + AOI + X-Ray inspection for zero shorts/opens.

Output Results:

- Electrical performance: Impedance measurement deviation below 8%, continuous 720h operation in -30¬įC to +75¬įC chamber without abnormalities

- Communication stability: 4G module signal sensitivity -108dBm with packet loss rate below 0.5% under Polish major operator networks

- Reliability data: Passed 1000 thermal cycles (-25¬įC?+70¬įC) and 96h salt spray test with no coating corrosion or solder joint cracks

- Client feedback: Deployed in Poznan smart farms for 6 months with zero field failures, achieving 98% customer satisfaction

Why Choose EBest Circuit (Best Technology) as Your PCB Manufacturer?

Reasons Why Choose EBest Circuit (Best Technology) As PCB Manufacturer:

- 99.2% Proven On-Time Delivery Rate ‚Äď Based on three-year order tracking data, 99.2% of orders are delivered strictly within contract deadlines, with only 0.8% experiencing minor delays due to force majeure. This exceeds the industry average of 92%, ensuring zero supply chain risk for clients.

- Quadruple International Certification Backing ‚Äď Certified with ISO9001:2015 (Quality Management), ISO13485:2016 (Medical Devices), IATF16949 (Automotive Standards), and REACH/RoHS compliance. Product pass rate reaches 99.8% with a first-pass yield of 98.5%, meeting strict EU and Polish market entry requirements.

- Free DFM Analysis Reduces Costs by 30% ‚Äď Our team of engineers with over 10 years of experience provides free Design for Manufacturability analysis. Historical cases show an average 68% reduction in design defects, 40% shorter mass production debugging cycles, and over RMB 3 million annual cost savings for clients.

- 24-Hour Rapid Prototyping Verification ‚Äď Utilizing optimized production lines, we deliver prototypes within 24 hours from design confirmation ‚Äď 80% faster than the industry average 5-day cycle, accelerating product iteration for clients.

- Batch Order Lead Time Reduced to 7-15 Days ‚Äď Through lean production scheduling and parallel multi-line processes, small batches (‚ȧ500 pieces) are delivered in 7 days, while large-scale orders (10,000+ pieces) take just 15 days ‚Äď 50% faster than traditional manufacturers.

- Turnkey Solutions Saves 40% Costs ‚Äď Integrating design optimization, rapid prototyping, volume production, and SMT assembly services, clients avoid multi-vendor coordination, reducing total costs by 40% and project timelines by 35%.

- 100% Environmental Compliance with Advanced Materials ‚Äď Using lead-free and halogen-free materials, third-party annual testing confirms heavy metal residues are 90% below EU RoHS limits, fully compliant with Polish EPR environmental regulations.

- Price Competitiveness Analysis ‚Äď Market research shows our prices are 15-20% lower than German and Italian counterparts in the 2024 EU market. Cost control is achieved through scale procurement and process optimization, ensuring optimal market pricing.

- Advanced Process Capabilities for High-End Demands ‚Äď Supporting HDI blind/buried vias, 100GHz high-speed boards, rigid-flex PCBs, MCPCB and achieving minimum trace width/spacing of 3mil (0.076mm) with 98% yield, meeting precision requirements for 5G, medical electronics, and automotive applications.

Welcome to contact us if you have any request for PCB design, prototyping, mass production and assembly: sales@bestpcbs.com.