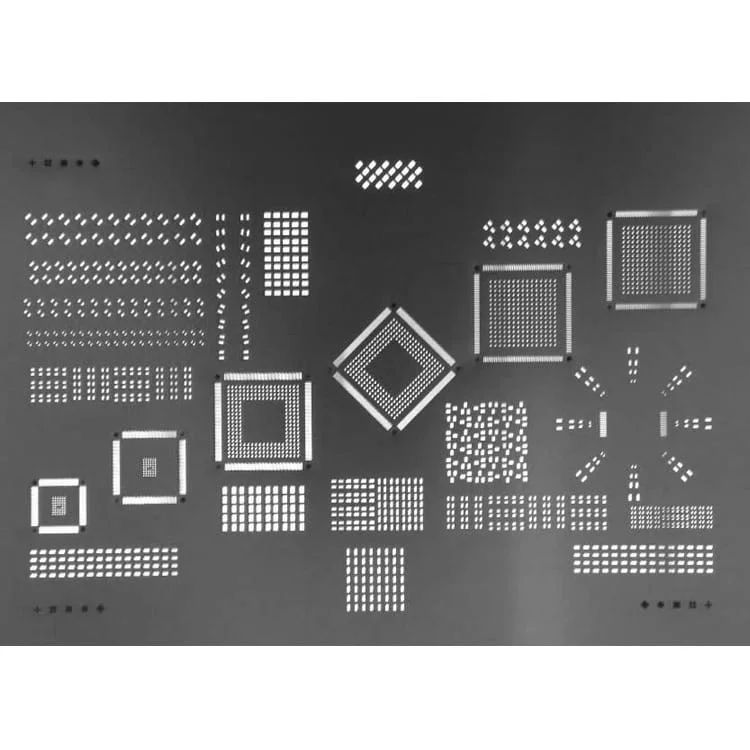

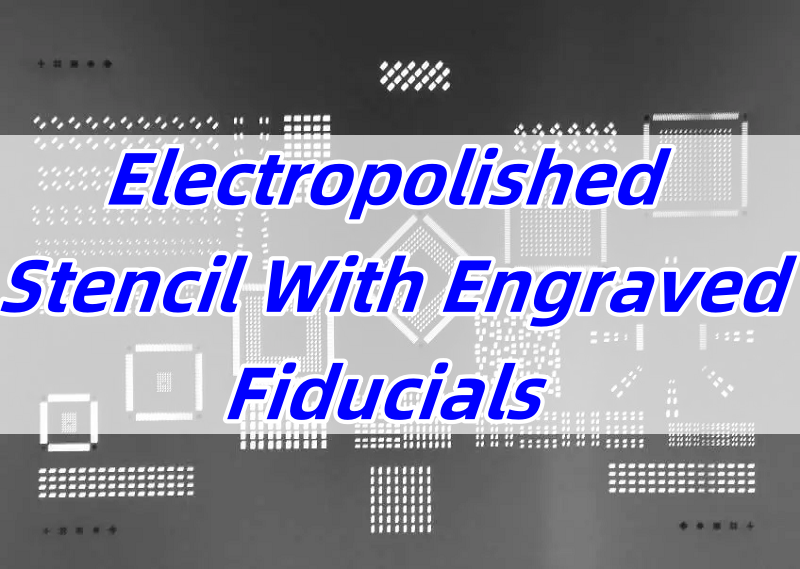

An electropolished stencil with engraved fiducials is a crucial tool for achieving precise and consistent solder paste application in surface-mount technology (SMT) assembly. These stencils help ensure that the solder paste is deposited accurately on the PCB, which is essential for the performance and reliability of the final product. By combining electropolishing with engraved fiducials, this stencil type offers superior smoothness and alignment, making it an ideal choice for complex PCB designs and high-density components. Understanding their role and benefits can significantly improve the quality of your manufacturing process.

What is an SMT Stencil?

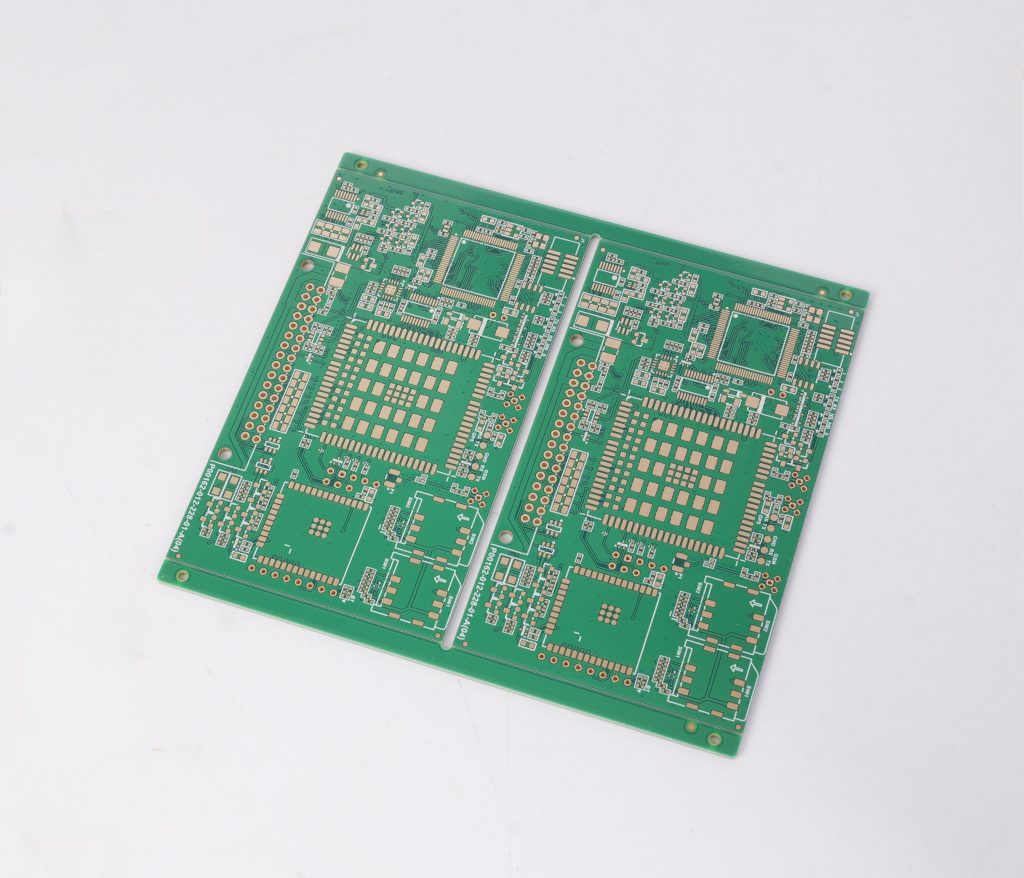

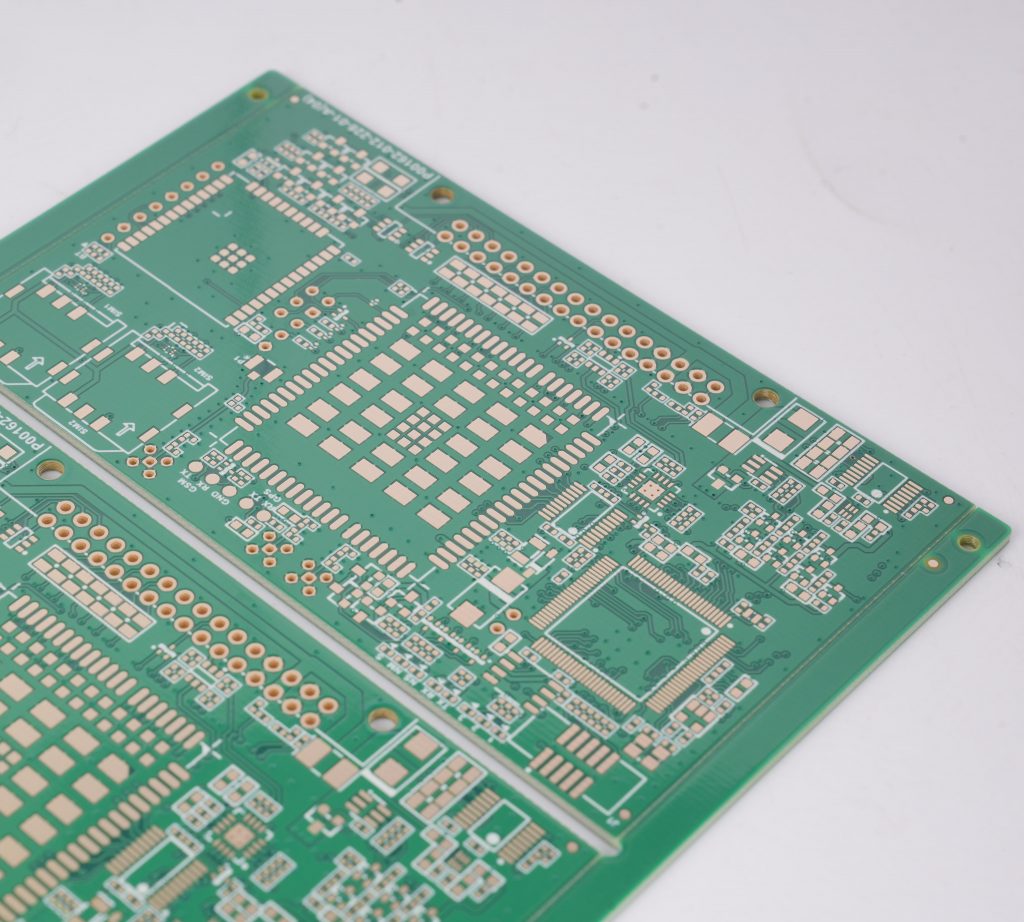

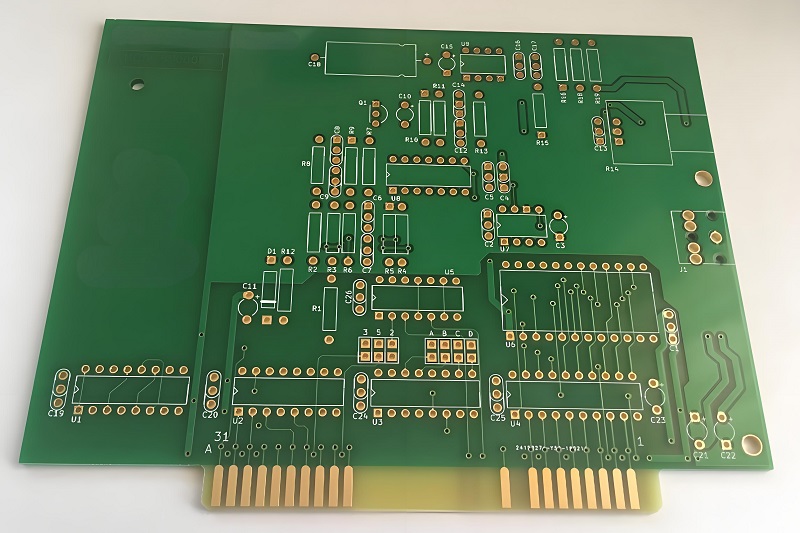

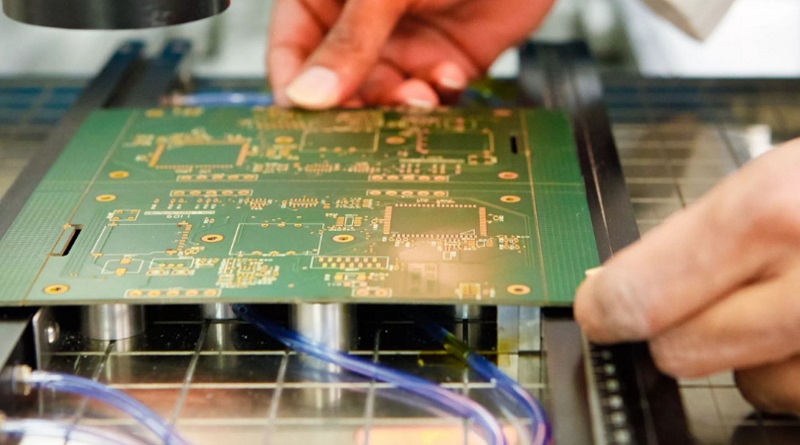

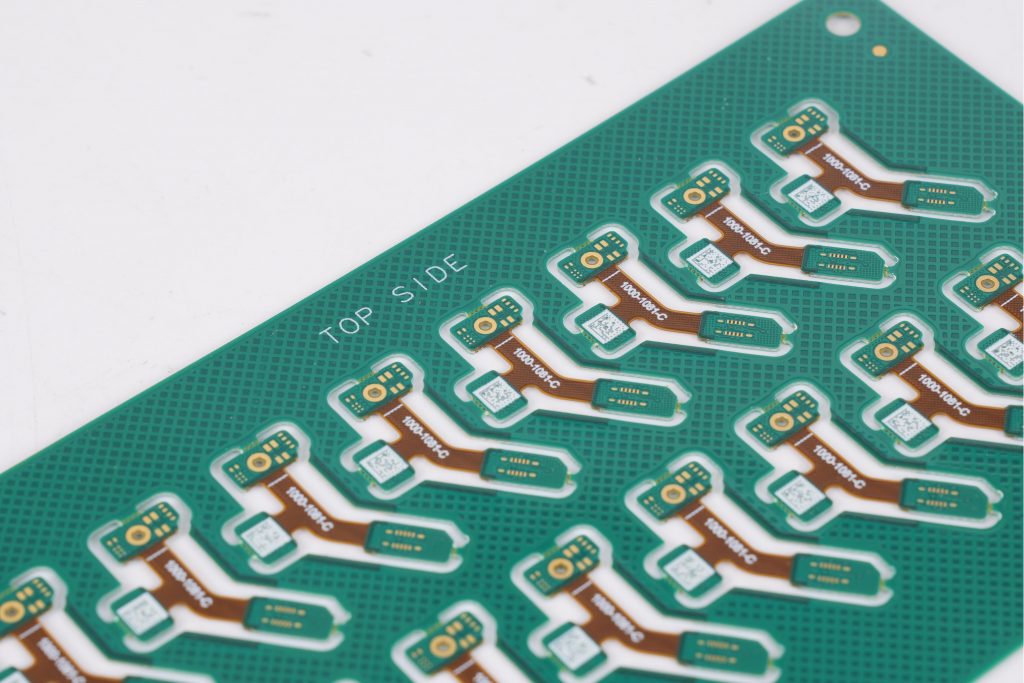

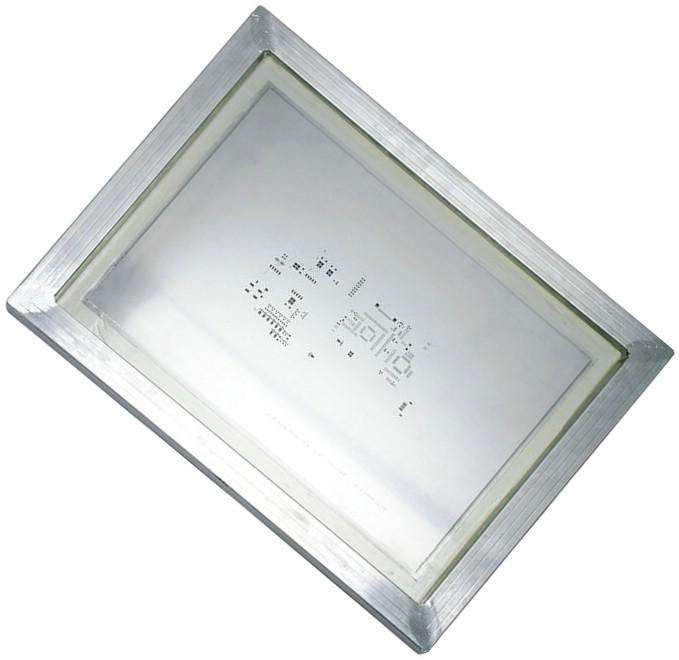

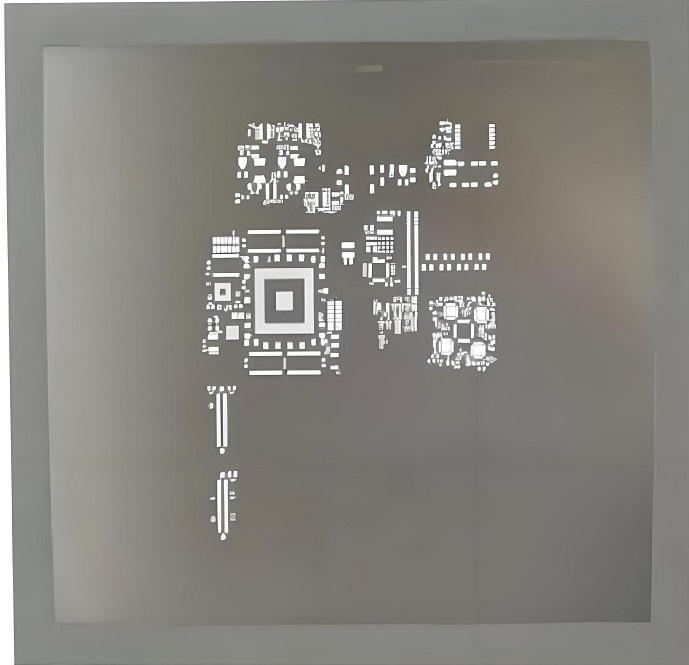

An SMT stencil is a thin sheet of stainless steel used in the surface-mount assembly process to apply solder paste to specific areas on a PCB. The stencil aligns with the PCB’s surface, ensuring that solder paste is deposited only where needed. The paste is then used to attach components to the board during the reflow soldering process.

These stencils are essential for high-volume PCB manufacturing, especially when dealing with intricate designs and small components. The precision they provide can make or break the quality of the finished product.

What Are the Different Types of PCB Stencils?

There are a few different types of stencils used in the SMT process, each with specific applications.

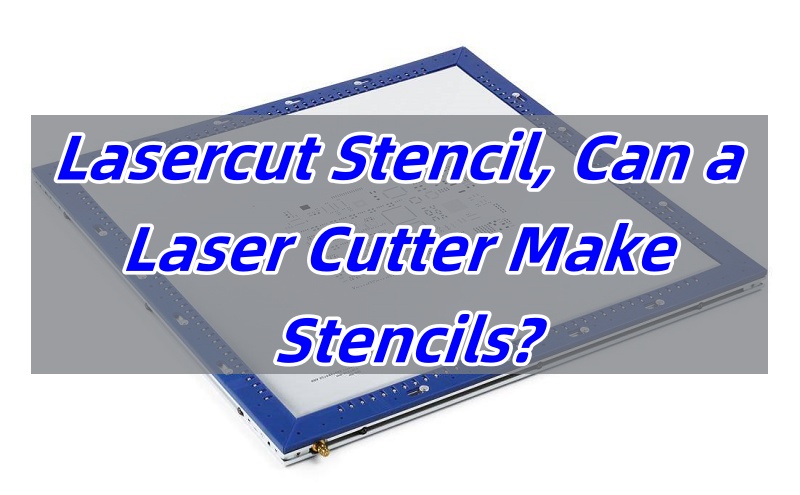

Laser-cut stencils: These are the most common type, known for their high precision and flexibility. Laser-cut stencils are ideal for most PCB designs and offer a high degree of accuracy with sharp, clean apertures.

Etched stencils: Etching is a more traditional method, often used for thicker stencils or specific applications where laser cutting may not be suitable.

Step-up and step-down stencils: These stencils have varying thicknesses in different areas, allowing for optimized solder paste deposition for components with varying heights.

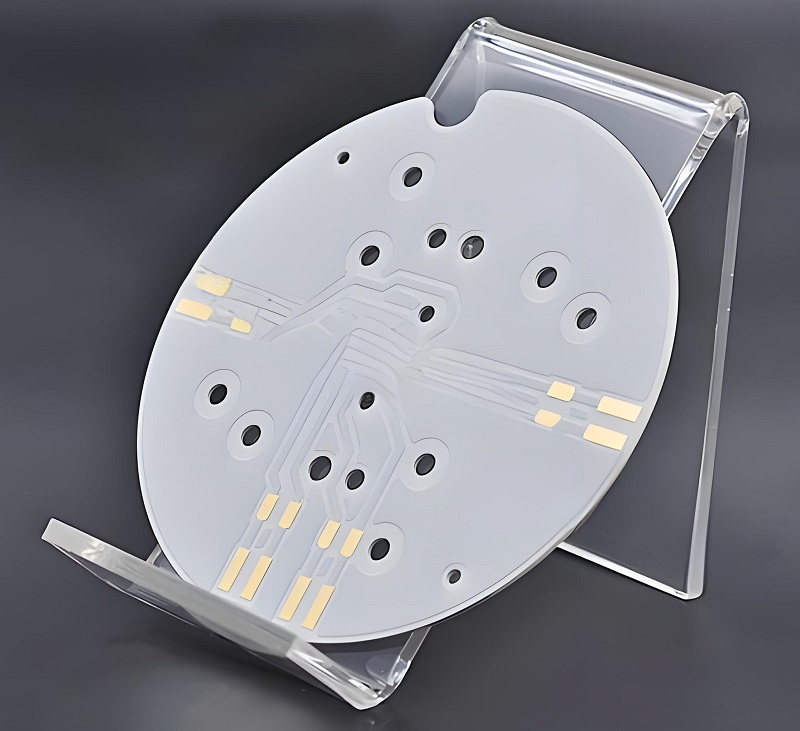

Electropolished stencils: These are laser-cut stencils that have undergone an electropolishing process. The electropolishing smooths out the rough edges of the stencil, improving solder paste release and reducing cleaning time.

Electropolished stencils with engraved fiducials are a premium option, especially for complex PCBs with high-density components. The fiducials help align the stencil perfectly with the PCB, ensuring precise paste placement.

Are Stencils Reusable?

Yes, stencils are reusable, which makes them a cost-effective choice for manufacturers. With proper care, a stencil can be used for hundreds, or even thousands, of PCB assemblies. However, the lifespan of the stencil will depend on the type of stencil, the material used, and how well it is maintained.

What Are Solder Stencils Made Of?

Most solder stencils are made from stainless steel, which offers durability, flexibility, and resistance to corrosion. Stainless steel stencils are ideal for high-volume production as they provide precise solder paste deposits and are easy to clean. However, other materials such as polyethylene (PE) may be used in specific applications, depending on the requirements.

What Is the Stencil Life of Solder Paste?

The life of solder paste on the stencil depends on several factors, including the type of paste, the environment, and the frequency of use. In general, solder paste on a stencil can remain viable for hours before it needs to be cleaned off. Proper storage and handling are critical to extending paste life and preventing contamination.

What Happens if You Donât Refrigerate Solder Paste?

Solder paste contains flux and metal powders that can degrade if not stored correctly. If solder paste is left out in a warm environment for too long, it can lose its viscosity, making it difficult to apply. Refrigerating solder paste when it’s not in use helps maintain its consistency and ensures reliable soldering results.

How Long Does an SMT Stencil Last?

The lifespan of an SMT stencil depends on several factors, including the material, type of stencil, and frequency of use. Specifically, for electropolished stencils with engraved fiducials, their lifespan is generally longer due to the smooth surface, which reduces wear and tear during the paste printing process. Moreover, proper cleaning and maintenance are essential, as they can significantly extend the stencil’s life.

How Do You Get Crisp Lines When Stenciling?

Getting crisp lines when using a stencil involves using high-quality stencils, like those that are electropolished. The smoother surface of these stencils helps the solder paste release more evenly, reducing the chances of smudging or uneven paste deposition. Additionally, ensuring the stencil is well-aligned and using the right paste consistency can help achieve cleaner lines.

What Is the Trick to Using Stencils?

The key to using stencils effectively lies in alignment and paste control. First, ensure the stencil is aligned properly with the PCB using fiducials. Then, apply the solder paste evenly across the stencil, making sure the paste is of the right viscosity. Finally, avoid using too much paste, as this can lead to bridging and other defects.

Why Choose BEST Technology for Your SMT Stencils?

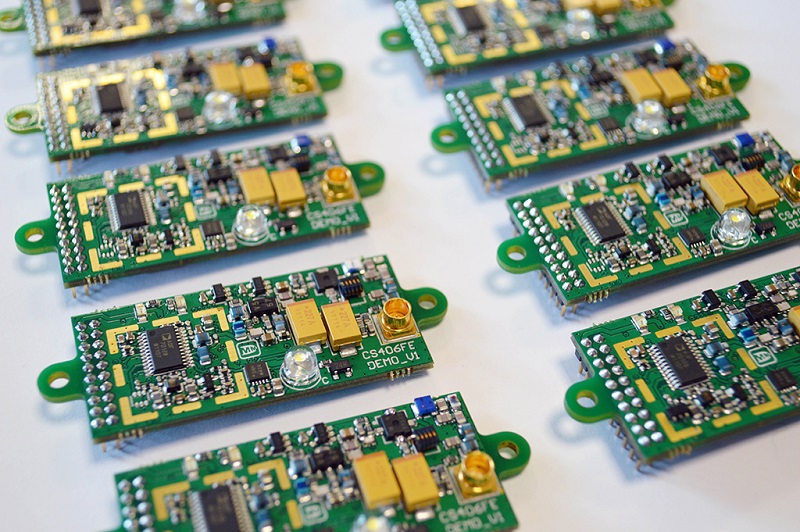

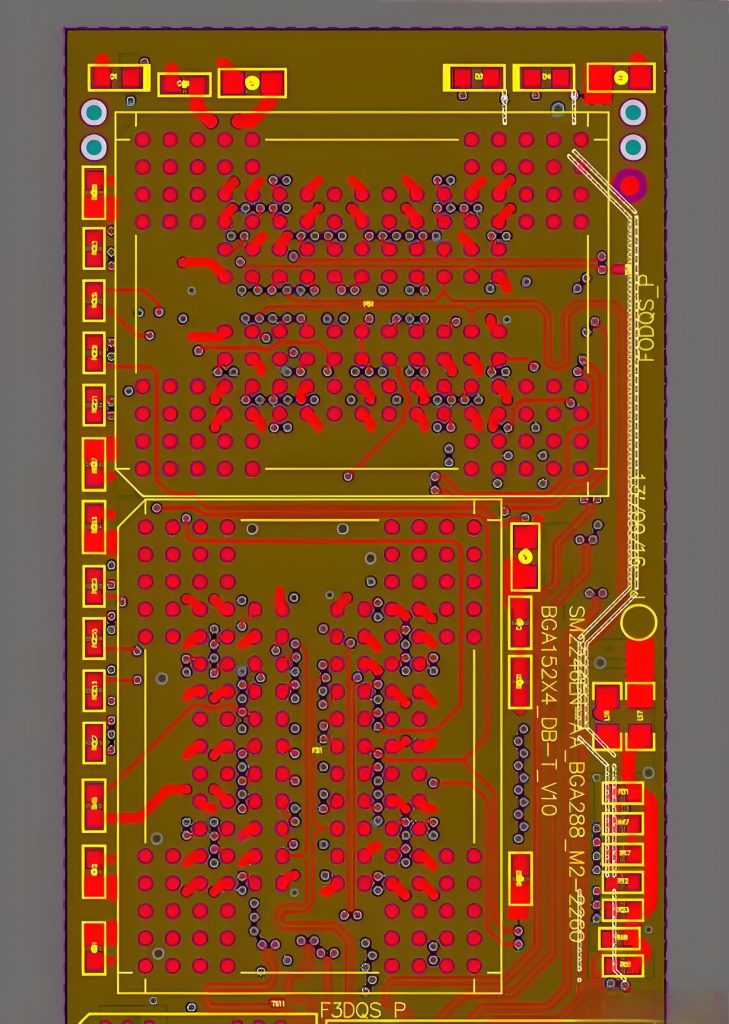

At EBest Circuit (Best Technology), we provide top-tier SMT stencils, including electropolished stencils with engraved fiducials, designed for precision and durability. With over 18 years of experience in the PCB manufacturing industry, weâve built a reputation for excellence with clients like Emerson and Flextronics. Our advanced laser-cut technology guarantees high accuracy with a tolerance of †±4 ÎŒm, ensuring your solder paste is applied with perfect precision.

Our stencils are made from high-quality stainless steel and are available in various thicknesses, ranging from 0.10mm to 0.60mm. Additionally, we offer both framed and unframed stencils to suit a variety of needs. Furthermore, with step-up and step-down technology, we can create stencils that are specifically optimized for different component sizes. This helps reduce printing errors and, ultimately, increases the efficiency of your SMT assembly.

In summary, electropolished stencils with engraved fiducials are essential for achieving high-quality SMT assembly with minimal errors. They provide unmatched precision and smooth solder paste release, making them an ideal choice for complex PCB designs. Choosing the right stencil vendor, like EBest Circuit (Best Technology), can significantly enhance your PCB production process. With fast delivery, affordable pricing, and cutting-edge technology, we ensure that your PCB manufacturing needs are met with the highest standards of quality and efficiency. For more information or inquiries, feel free to contact us at sales@bestpcbs.com.