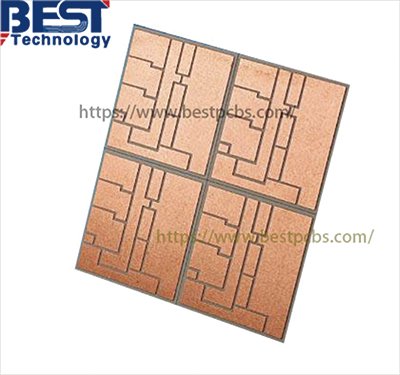

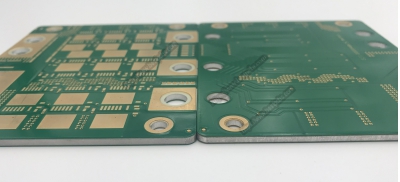

EBest Circuit (Best Technology) considers all the factors affecting the cost of MCPCB production while formulating final cost structure. Many customers contact us to know the factors which affecting the price. The factors are Size & Thickness, Number of layers, Cu Thickness, Thermal Conductivity, Surface Finishing etc.

Size & Thickness: Since larger boards require more material.

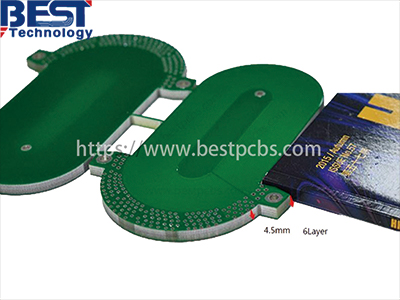

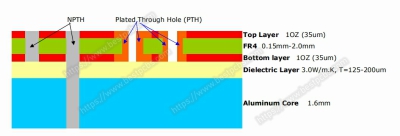

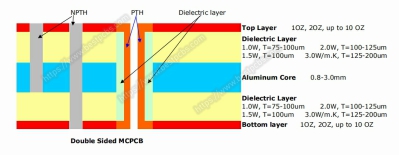

As you know, 1.6mm is the standard thickness, if you choose non-standar thickness (Thicker or thinner than 1.6mm), sometimes the price will need to increase, it depend on the layers of your MCPCB.

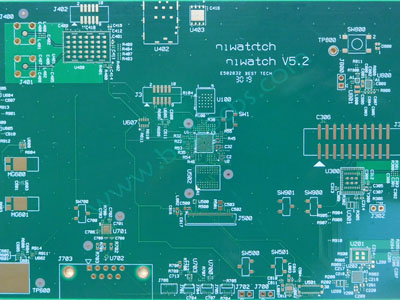

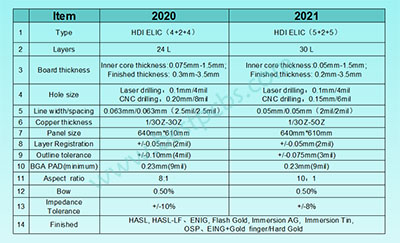

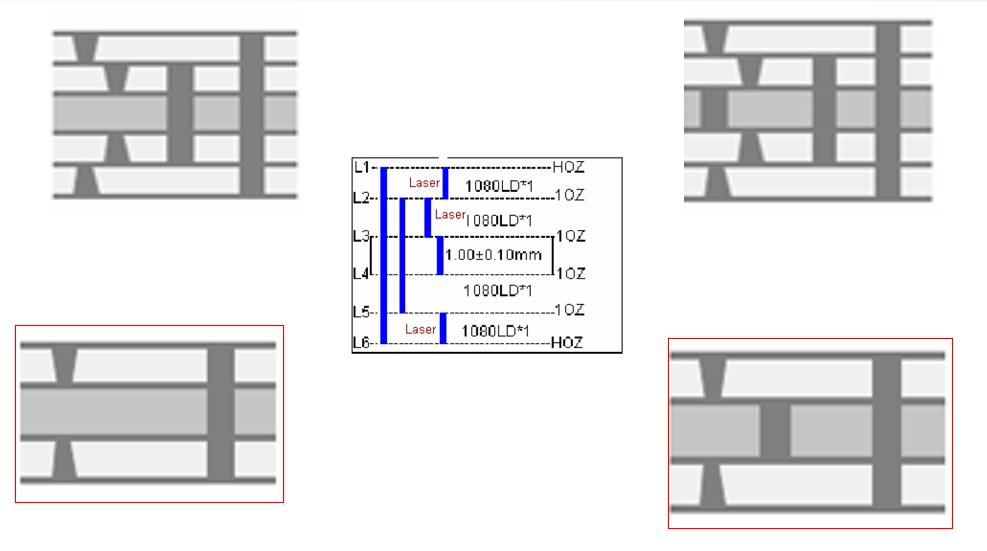

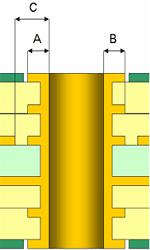

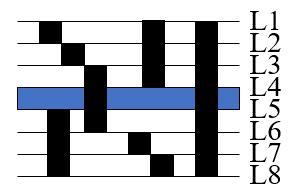

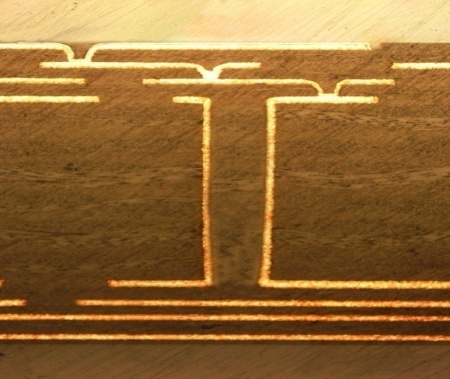

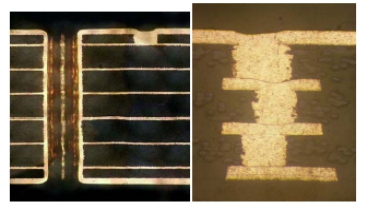

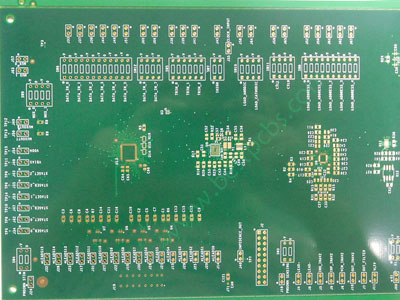

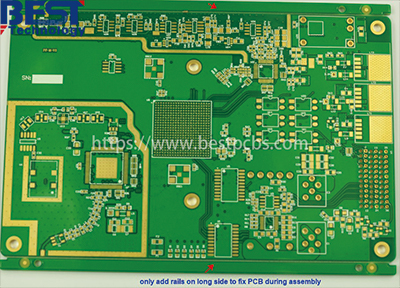

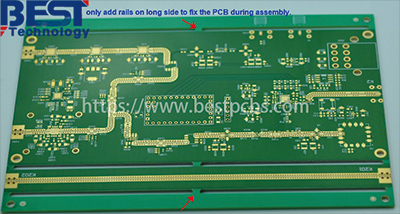

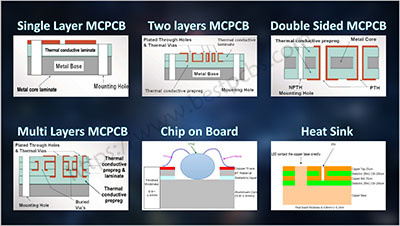

The different number of layers and manufacturer technology:Itââ¬â¢s the main factor for affecting the manufacturing price, therefore the circuit board designing is done in such a manner that it comprises a minimum number of circuit layers.ÃÂ

Thermal Conductivityis one of the most important performances of MCPCB, the higher the thermal conductivity is, the more expensive the price is. At present, the highest thermal conductivity we can provide is 8W/m.K, the commonly used thermal conductivity is 1-3W/m.K

Cu Thickness: The cost will be more expensive if the copper is thicker. We can provide 0.5 OZ, 1.0 OZ, 2.0 OZ, 3.0 OZ, up to 10 OZ.

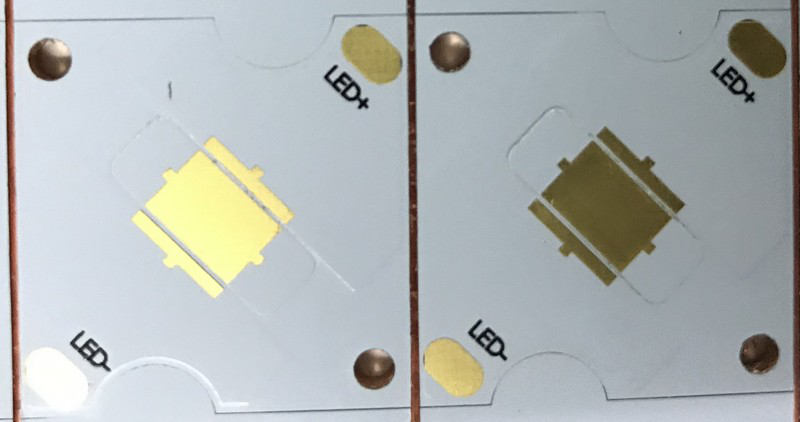

Surface Finishing: The common Surface Finishing for MCPCB is HASL_LF, OSP ENIG (The normal thickness of gold is 1uââ¬â¢Ã¢â¬â¢). ENIG is more expensive since the gold is expensive and it with good performance for protecting the surface from oxidized.

ENIEPIG is good for wire bonding (the normal thickness of gold is 3uââ¬Â).

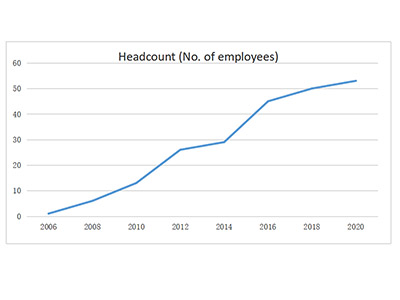

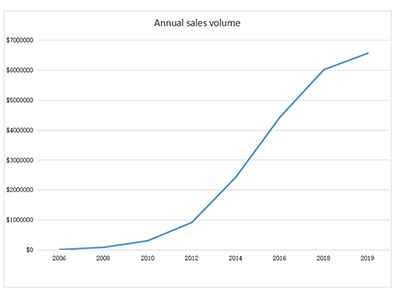

We always strive to formulate a competitive price structure for our customers, this enables to have a considerable reduction in the total prices and deliver superior quality services to them. If you would like to know more about MCPCB, please directly contact our sales Tammy