How to design a cost-effective LED strip PCB board? What mass production problems can be avoided through prototyping? How do manufacturers balance cost and quality control? This article will explores the fundamentals of LED strip PCB board, their types, cost-saving design strategies, prototyping processes, and tips for selecting a reliable LED strip PCB board manufacturer.

At EBest Circuit (Best Technology), we focus on LED strip PCB board designing, prototyping and manufacturing over 18 years. The team of senior engineers provides free design support and solution optimization online 24 hours a day to ensure accurate and reliable circuit layout. The company’s original expedited proofing system can achieve 24-hour rapid delivery, relying on DMF data analysis and engineers’ manual pre-examination of drawings to ensure the first-time success of the first version. The production end is equipped with industrial-grade automated production lines, which increase the abnormal response speed by 40%, and urgent large-volume orders can be delivered within two weeks, fully meeting the rapid development and stable mass production needs of high-difficulty LED strip PCB products. Please feel free to contact us sales@bestpcbs.com

What Is LED Strip PCB Board?

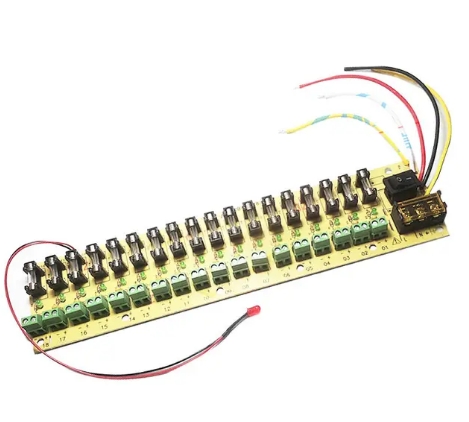

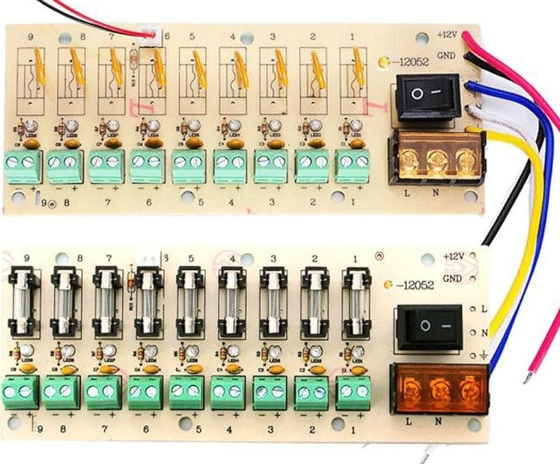

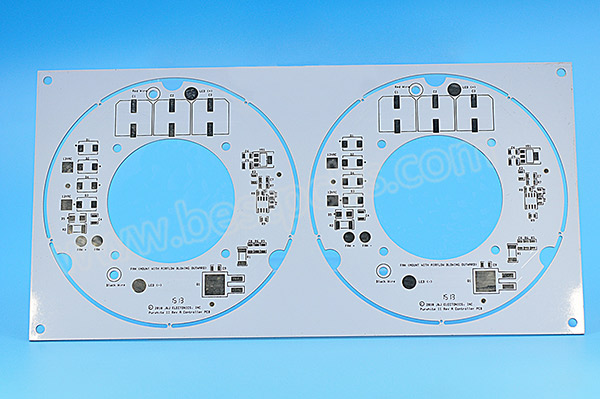

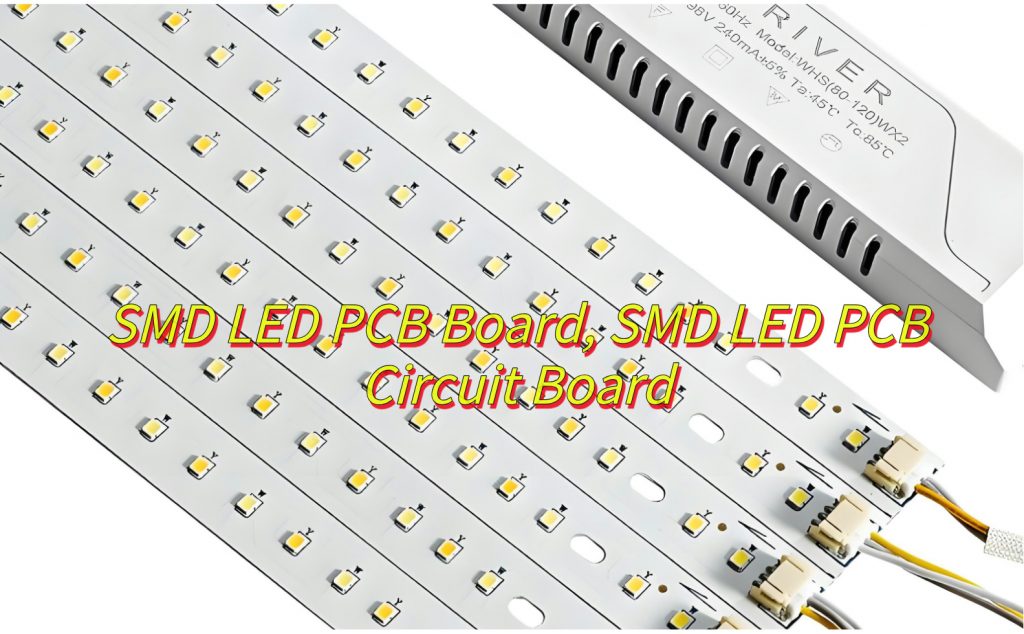

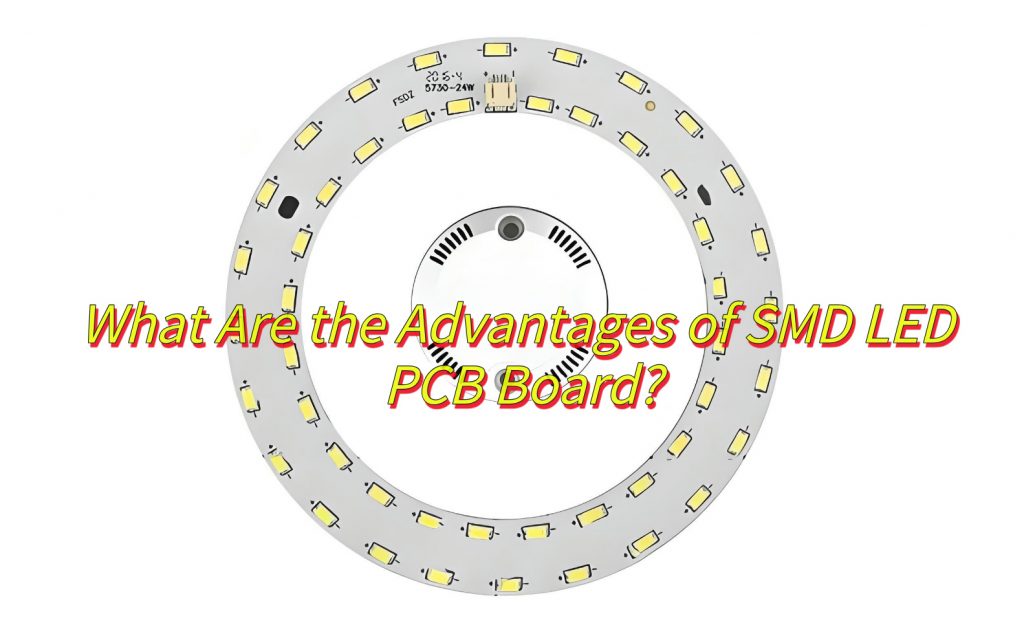

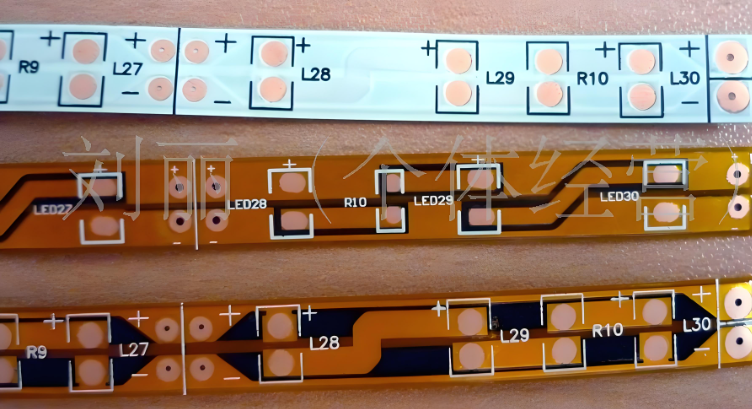

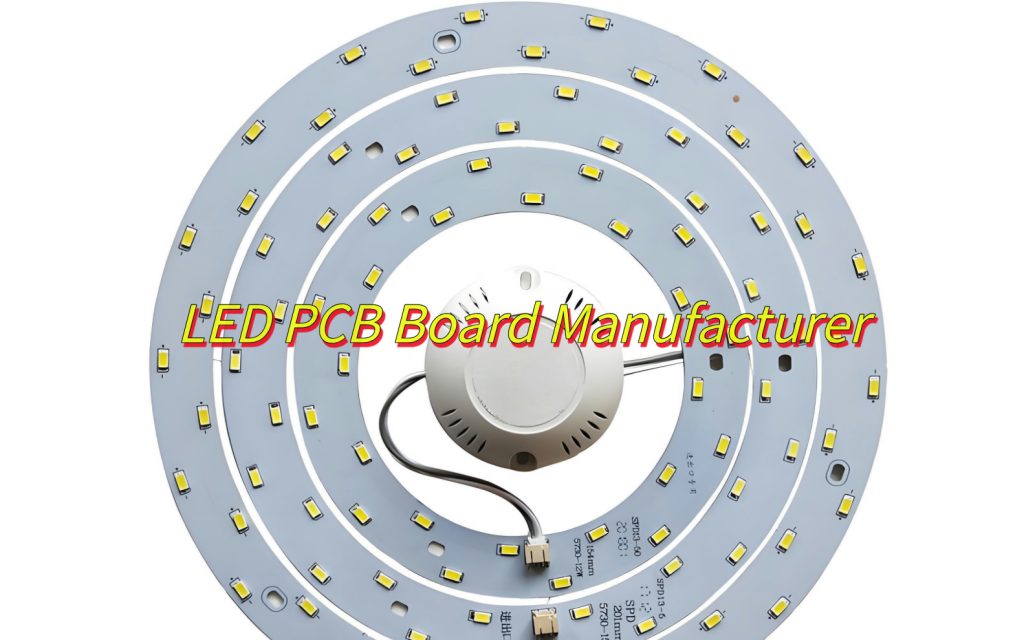

A LED Strip PCB board combines printed circuit board (PCB) technology with light-emitting diodes (LEDs) to create flexible or rigid lighting solutions. The PCB serves as the backbone, providing electrical connectivity and structural support. LED strips with PCB boards are widely used due to their compact design, high durability, and adaptability to curved surfaces. Black PCB LED strips, for instance, use dark substrates to minimize light reflection and enhance contrast in display applications.

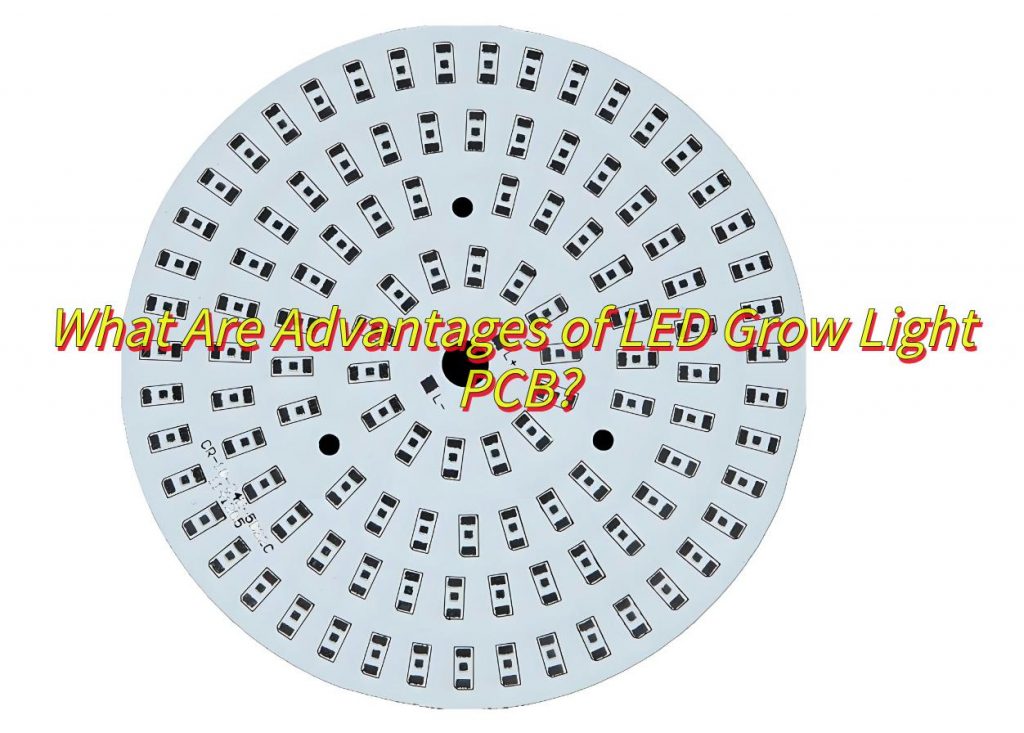

What Advantages of LED Strip PCB Board?

Here are advantages of LED strip PCB board:

- Flexible design for easy installation at various angles

- Displays 1600+ colors with dynamic lighting effects

- Superior heat dissipation, lifespan exceeding 50,000 hours

- Eco-friendly materials, 12V low-voltage safety certified

- Shock-resistant for indoor/outdoor durability

- Precision machine soldering ensures consistent quality

- Customizable RGB lighting systems

- Moisture/static-proof (suitable for bathrooms/outdoors)

How to Choose Professional LED Stripe PCB Board Design Service?

Selecting a professional LED strip PCB board design service ensures optimal performance and cost efficiency. Important factors include:

- âTechnical expertise in LED stripe PCB design:â Look for teams proficient in thermal management, circuitry layout, and material selection.

- âCustomization capabilitiesâ: Providers should tailor designs to voltage, brightness, and form factor requirements.

- âPrototyping Support âServices: Offering LED stripe PCB design help validate designs before mass production.

- âCost Transparencyâ: Clear pricing models prevent budget overruns.

âHow to Design LED Strip Flexible PCB to Reduce Production Cost?

LED strip flexible PCBÂ design minimizes costs without compromising quality. Strategies include:

- âSimplifying circuitryâ: Reduce complex traces to lower material waste.

- âUsing standardized componentsâ:Off-the-shelf LEDs and resistors cut procurement costs.

- âOptimizing panel utilizationâ:Arrange multiple PCBs on a single panel to reduce fabrication expenses.

- âSelecting cost-effective materialsâ:Flexible PCBs with polyimide substrates balance durability and affordability.

What Is Prototyping Process of LED Strip Flexible PCB Board?

Hereâs a simplified overview of the LED strip flexible PCB prototyping process, focusing on sampling and production steps:

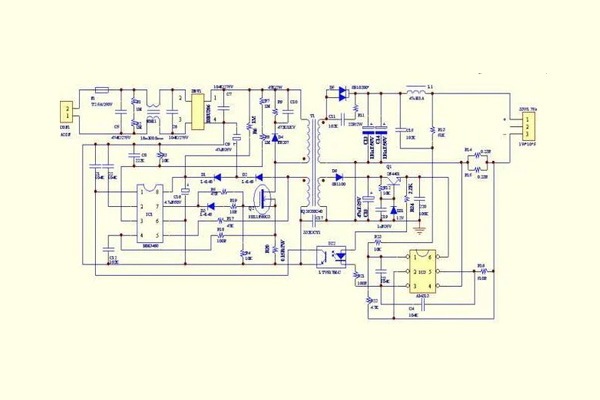

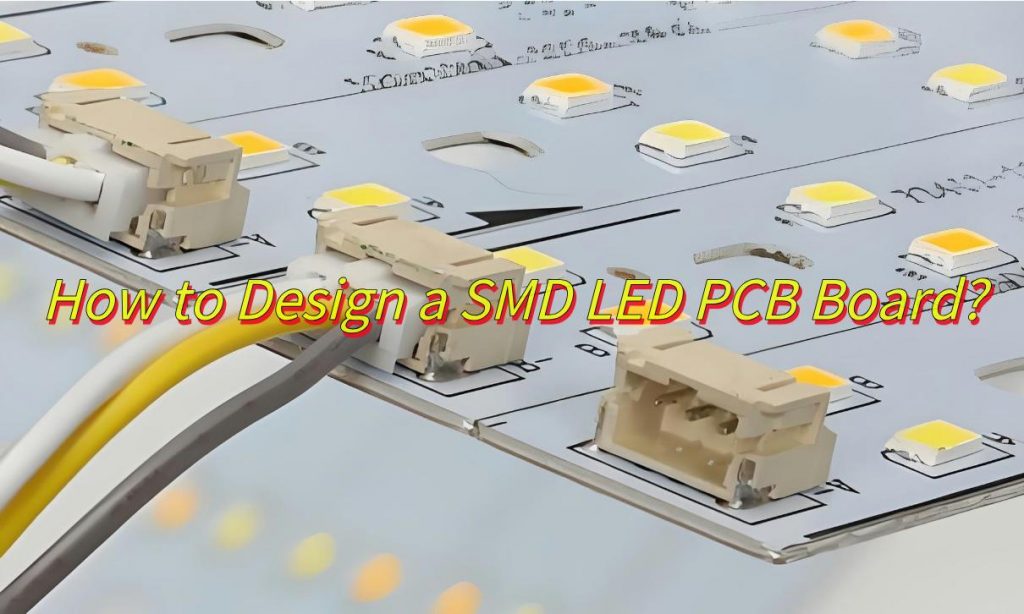

1.Circuit Design & Layout

- Circuit Designâ: Create schematics for LED placement, driver integration, and power distribution.

- Layoutâ: Plan bendable PCB dimensions, cut points, and connector placements.

2.Material Selectionâ

- Base Materialâ: Flexible polyimide substrate (heat-resistant, bendable).

- Conductive Layerâ: Thin copper foil for circuitry.

- Encapsulationâ: Silicone or TPU for protection.

3.Conductive Layer Processingâ

- Laser Cuttingâ: Precision-etch copper traces to form circuits.

- Platingâ: Apply anti-oxidation coatings (e.g., nickel/gold) on copper.

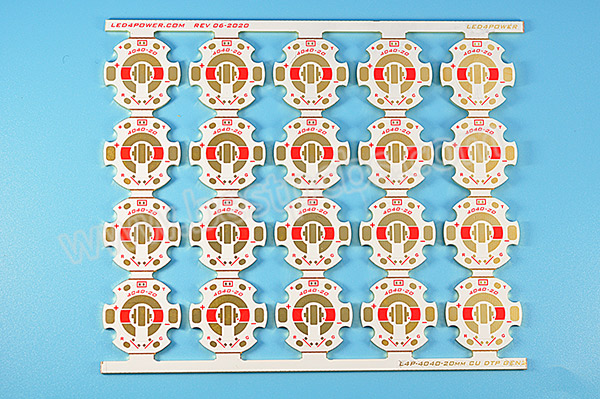

4.Component Assemblyâ

- SMT (Surface Mount Technology)â: Machine-mount LEDs, resistors, and drivers onto the PCB.

- COB (Chip-on-Board)â: Directly bond LED chips to the PCB for high-density strips.

- Solderingâ: Use reflow ovens for secure electrical connections.

5.Encapsulationâ

- Coatingâ: Apply silicone or TPU evenly over the PCB to waterproof and diffuse light.

- Curingâ: Harden the coating under UV light or heat.

- Heat Sinksâ: Attach aluminum strips to high-power LED sections for cooling.

6.Prototype Testing & Final Samplingââ

- Electrical Testsâ: Verify voltage stability, current flow, and color consistency.

- Flex Testâ: Bend the strip repeatedly to check for circuit integrity.

- Environmental Testsâ: Expose to humidity, heat, and cold to validate durability.

- Adjustmentsâ: Optimize trace thickness, LED spacing, or heat dissipation based on test results.

- Final Samplingâ: Produce revised prototypes for client approval before mass production.

Why Do We Need to Make A LED Strip PCB Prototype Before Mass Production?

Making a LED Strip PCB prototype before mass production can identify design flaws early, preventing costly revisions before formal production. Benefits include:

- âRisk mitigationâ Fix issues like overheating or poor solder joints before scaling up.

- âPerformance verificationâ Ensure the strip meets brightness, color, and lifespan standards.

- âClient approvalâ Prototypes help clients visualize the final product and request adjustments.

How to Find A Reliable LED Strip PCB Board Manufacturer?

To Find a Reliable LED Strip PCB Manufacturer:

- Verify Material Qualityâ: Ensure the manufacturer uses heat-resistant polyimide substrates and rolled copper for flexibility and durability.

- Check Technical Capabilitiesâ: Look for expertise in laser etching, SMT assembly, and waterproof encapsulation (e.g., silicone/TPU coatings).

- Review Certificationsâ: Confirm compliance with ISO, UL, or RoHS standards for safety and environmental practices.

- Request Prototypesâ: Test samples for bend durability, color consistency, and thermal performance.

- Evaluate Customizationâ: Prioritize manufacturers offering tailored designs (length, density, connectors) and low MOQ options.

- Assess Production Capacityâ: Confirm ability to scale from prototyping to bulk orders without quality loss.

- Read Client Feedbackâ: Check reviews for on-time delivery, post-sales support, and defect resolution.

EBest Circuit (Best Technology) can meet all above requirements. If you’re interested in our LED strip PCB board design, prototyping and manufacturing service, welcome to leave a message below this blog.

How to Keep Costs Low and Quality High in LED Strip PCB Board Manufacturing?

Here are some tips for how to keep costs low and quality in LED strip PCB board manufacturing:

- Simplify Designâ: Minimize layers, use standard specs.

- âMaterial Selectionâ: Thin polyimide (0.1-0.2mm), pre-bonded copper.

- âAutomate Production:â SMT assembly, laser cutting.

- âEfficient Testingâ: Automated electrical checks, durability tests.

- âBulk Buy Materialsâ: Negotiate volume discounts.

- âTest Prototypesâ: Refine design before mass production.

In conclusion, thatâs all about LED strip PCB Board design, prototyping and how to select a reliable LED strip PCB manufacturer. If you have any other issues about LED strip PCB board need our help, please feel free to contact us.( The email is at the beginning of this blog)