How to choose low DK PCB materials? Let’s discover its definition, material list, selection guide, material properties, common material supplier together.

Are you troubled with these questions?

- How to overcome signal attenuation in high-frequency scenarios to break through rate bottlenecks?

- How to stabilize millimeter-wave module performance amid heat dissipation challenges?

- How to improve yield loss caused by impedance mismatch in multi-layer boards?

As a PCB material supplier, EBest Circuit (Best Technology) can provide you service and solution:

- Precision Material Tuning â Dual Dk/Df control technology for high frequencies, achieving â€0.002 loss at 10GHz, 20% speed boost, and 30% lower loss.

- Smart Process Adaptation â Full-chain process parameter database with AI matching system, cutting production line upgrade time by 40% and first-pass yield by 50%.

- Digital Twin Validation â AI-powered signal integrity simulation platform predicting 95% of impedance/crosstalk risks early, boosting yield by 50% with zero additional tuning costs.

Welcome to contact us if you have any request for PCB material: sales@bestpcbs.com.

What Are Low DK PCB Materials?

Low DK PCB materials are specifically designed for high-speed and high-frequency circuits, featuring a dielectric constant (DK) typically ranging from 2 to 4, which is lower than conventional PCB materials like FR-4. This low DK characteristic significantly enhances signal transmission speed, reduces delay and distortion, and optimizes impedance control, making them widely used in 5G communications, high-speed servers, millimeter-wave radars, and other applications demanding stringent signal integrity.

How to Choose Low DK PCB Materials?

Below is a selection guide for low DK PCB material:

1. Define Application Scenarios and Core Requirements

- High-frequency/high-speed scenarios (e.g.,RF modules): Prioritize materials with DK †3.0 and Df †0.005 (e.g., PTFE substrates with DK=2.1â2.5, ceramic-resin composites with DK=2.8). For instance, 28GHz millimeter-wave antenna PCBs require PTFE substrates, which reduce signal loss by 70% compared to FR-4 and maintain impedance stability within ±0.8%.

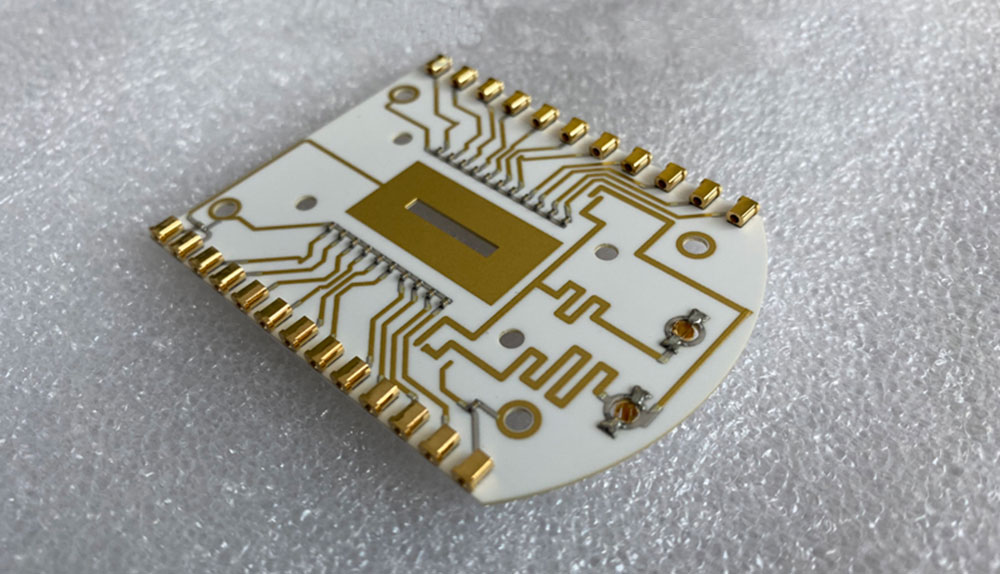

- High-power scenarios (e.g., power amplifiers): Focus on thermal conductivity and voltage resistance. Ceramic substrates (e.g., AlâOâ, AlN) offer thermal conductivity of 170â230W/m·K, far exceeding FR-4âs 0.3â0.4W/m·K, making them ideal for high-power dissipation.

- Harsh environment scenarios (e.g., automotive electronics): Select materials with high temperature resistance, moisture resistance, and chemical corrosion resistance (e.g., polyimide films with Tg ℠250°C and moisture absorption †0.6%).

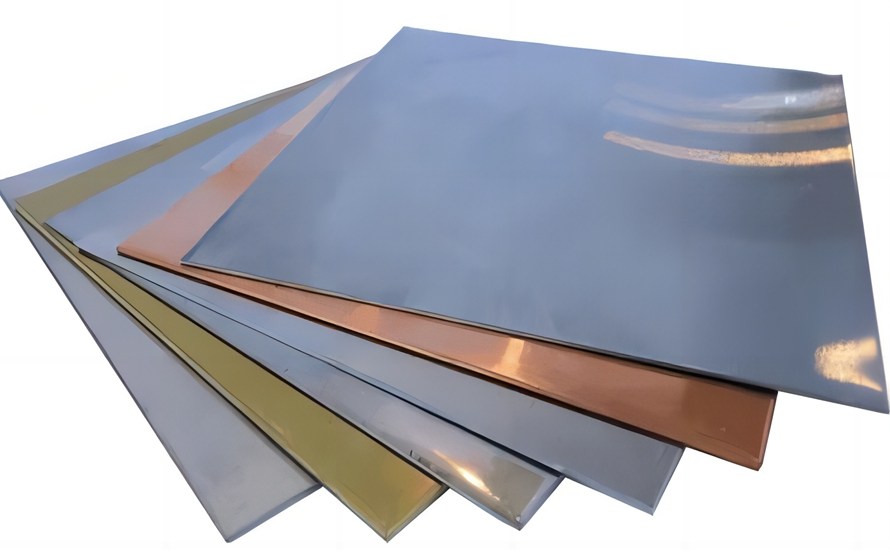

2. Screen Low DK Material Types and Characteristics

- PTFE (Polytetrafluoroethylene): DK=2.1â2.5, Df=0.0002â0.0012. Ideal for high-frequency RF circuits but requires specialized processing and has higher costs.

- Ceramic Substrates: DK=2.8â3.8, excellent thermal conductivity. Suitable for high-power and high-heat-dissipation applications but prone to brittleness, requiring mechanical strength considerations.

- Polyimide (PI): DK=3.1â3.7, Df=0.001â0.005. Combines flexibility and high-temperature resistance, ideal for flexible PCBs (e.g., wearables, automotive electronics).

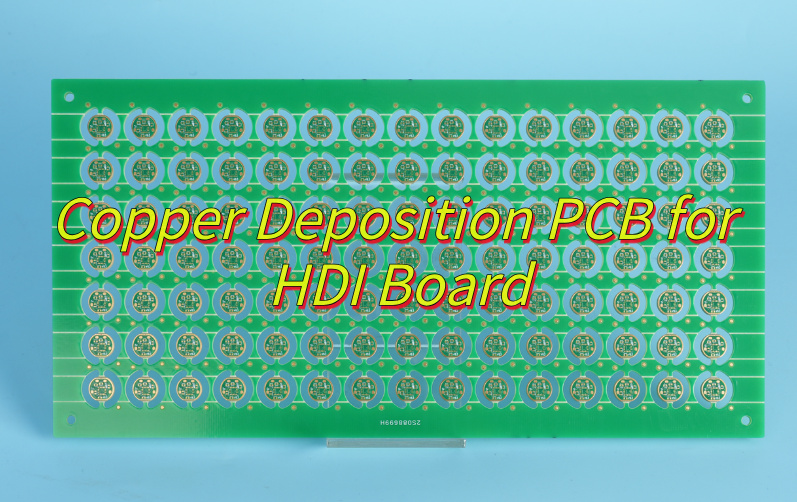

- Low DK Glass Fiber Cloth: E.g., NE glass fiber cloth (DK=3.0â3.5). Suitable for multilayere and HDI boards with moderate cost.

3. Evaluate Parameters and Technical Specifications

- DK & Df: For high-frequency scenarios, strict control of DK †3.0 and Df †0.005 is required; for mid-to-low-frequency scenarios, relaxed to DK †4.8 and Df †0.02.

- Thermal Performance: Tg ℠150°C (FR-4) or ℠250°C (polyimide). CTE (coefficient of thermal expansion) must match copper foil (†20ppm/°C) to avoid delamination under thermal stress.

- Mechanical Performance: Tensile strength ℠80MPa, bending radius †5mm (for flexible boards).

- Environmental Reliability: Must pass RoHS compliance, moisture absorption †1%, and chemical corrosion resistance (e.g., acid/alkali environments).

4. Environmental and Sustainability Assessment

- Material Recycling and Reuse: Prioritize recyclable or biodegradable materials (e.g., polylactic acid-based composites) to minimize e-waste. For example, certain low DK glass fiber cloths achieve >90% material regeneration via chemical recycling processes.

- Regulatory Compliance: Ensure materials meet RoHS, REACH, and other environmental regulations. The EU mandates cadmium content †0.01% in PCB materials post-2025.

- Carbon Footprint and Lifecycle Analysis: Select suppliers with transparent supply chains and low carbon footprints. Localized production reduces transportation emissions. Water-soluble solder masks can cut VOC emissions by >50%.

- Circular Economy Models: Implement closed-loop systems (e.g., “design-produce-recycle-regenerate”) by partnering with professional recycling agencies to reuse copper, resin, and other materials.

5. Cost and Supply Chain Evaluation

- Premium Materials (e.g., Rogers 4003C, PTFE): High costs but essential for extreme performance scenarios (e.g., 5G base stations). Balance performance and cost.

- Mid-tier Materials (e.g., modified FR-4, low DK glass fiber cloth): Moderate costs for consumer electronics. Optimize costs via supplier collaboration (e.g., Honghe Technologyâs low DK glass fiber cloth price surge >50%).

- Supplier Selection: Prioritize certified suppliers (e.g., Japanâs Nittobo, Taiwanâs Nan Ya Plastics) for material stability and supply reliability.

6. Manufacturing Process Compatibility Verification

- HDI Boards: Use low CTE materials (†20ppm/°C) to avoid layer misalignment (±0.01mm causing DK deviation of 0.02) and ensure impedance stability.

- Flexible and Rigid-Flex Boards: Select highly flexible materials (e.g., 25Όm polyimide film with bending radius †1mm) and validate bonding strength with rigid materials.

- Processing Performance: Test drilling, etching, and plating capabilities to achieve >95% yield rates and avoid material-related defects.

7. Testing & Validation & Iterative Optimization

- Lab Testing: Validate signal loss and impedance matching via vector network analyzer S-parameter measurements (e.g., S21, S11). Verify thermal and reliability performance through thermal cycling tests.

- Field Testing: Conduct long-term tests in target environments (e.g., high temperature/humidity, vibration/impact) to confirm material stability.

- Iterative Optimization: Adjust material types or parameters (e.g., supplier changes, laminate process optimization) based on test results to finalize the optimal solution.

Common Low DK PCB Materials List

| Material Type | Representative Model | Dk Value Range | Loss Factor (Df) | Characteristics & Applications |

| PTFE-based Materials | Rogers RO3003™ | 3.00 ±0.04 | 0.0013 @10GHz | Ultra-low loss, millimeter-wave radar/satellite communications (77GHz) |

| PTFE-based Materials | Taconic RF-35™ | 3.50 ±0.05 | 0.0018 @10GHz | High frequency stability, 5G base station antennas |

| Modified Epoxy Resin | Panasonic Megtron 6™ | 3.70 @1GHz | 0.002 @1GHz | Cost-effective choice, 100Gbps server/switch motherboards |

| Modified Epoxy Resin | Isola FR408HR™ | 3.65 @1GHz | 0.010 @1GHz | Compatible with FR-4 process, medium-high speed network devices |

| Ceramic-filled Materials | Rogers RO4350B™ | 3.48 ±0.05 | 0.0037 @10GHz | Thermal conductivity 0.6W/mK, high-power RF amplifiers |

| Liquid Crystal Polymer (LCP) | Rogers ULTRALAM 3850™ | 2.90 @10GHz | 0.0025 @10GHz | Flexible substrate, 5G smartphone AiP antennas/millimeter-wave modules (<0.2% moisture absorption) |

| Polyimide (PI) | DuPont KaptonÂź HN | 3.40 @1kHz | 0.002 @1kHz | High temperature resistance (>260â), aerospace flexible circuits |

| PPO/PPE-based Materials | Nelco N7000-2HT™ | 3.20 @1GHz | 0.0015 @1GHz | Low moisture absorption (0.2%), high-speed backplanes |

Low Dielectric Constant PCB Material Properties

- Dielectric Constant (Dk): Typical range: 2.0-3.5 (e.g., PTFE substrate Dk â 2.2; PI substrate Dk â 3.0-3.5), lower than conventional FR-4 (Dk â 4.2-4.8). Reduces signal transmission delay and capacitive coupling crosstalk.

- Dissipation Factor (Df): For high-frequency materials like Rogers RO4350B, Df †0.003; PTFE substrate Df as low as 0.0002. Minimizes signal energy loss and attenuation in high-frequency scenarios.

- Frequency Band Stability: Dielectric constant remains stable across frequencies (weak dispersion effect), e.g., ceramic substrates maintain consistent Dk over wide bands, ensuring parameter consistency in high-frequency circuits.

- Coefficient of Thermal Expansion (CTE): Typical value †50ppm/â, matching silicon chip CTE. Reduces interlayer stress and solder joint failure risks caused by temperature fluctuations, suitable for extreme temperature environments.

- Thermal Resistance: Materials like PI withstand short-term peak temperatures above 250°C, compatible with reflow soldering; ceramic substrates offer superior high-temperature performance for demanding scenarios.

- Chemical Corrosion Resistance: PTFE and fluoropolymers resist acid/alkali and solvent erosion, ideal for harsh environments like industrial controls or outdoor devices, extending service life.

- Mechanical Strength & Flexibility: Rigid materials (e.g., ceramic, glass-fiber reinforced substrates) provide high bending strength and dimensional stability; flexible materials (e.g., PI, PTFE composite films) support bending needs for foldable/wearable devices.

- Low Moisture Absorption: Materials like PTFE have moisture absorption < 0.01%, preventing Dk/Df drift from humidity changes and ensuring stable signal transmission in humid environments.

Why Is Low DK So Important?

- Improving Production Efficiency: The stable dielectric properties of low DK materials optimize impedance control, streamline PCB design processes, reduce debugging and validation steps, and shorten time-to-market. This helps customers seize market opportunities faster.

- Enhancing Product Competitiveness: Utilizing low DK materials enables your end devices, such as 5G smartphones and high-speed servers to achieve faster data transmission and more stable signals. This directly elevates product performance, helping your offerings stand out in the market and attract high-end customers.

- Reducing Long-Term Operational Costs: Low DK materials minimize signal loss and equipment failure rates, lowering repair and replacement costs caused by signal distortion. Their thermal stability and low moisture absorption also reduce performance fluctuations from environmental changes, extending device lifespan and saving maintenance expenses.

- Ensuring Signal Reliability: In high-frequency scenarios like millimeter-wave radar and RF front-ends, low DK materials guarantee delay-free and distortion-free signal transmission. This prevents product failures or degraded user experiences due to signal issues, boosting customer trust.

- Adapting to Future Tech Demands: As technologies like 5G/6G, AI computing, and autonomous driving evolve, high-frequency and high-speed applications demand higher signal transmission standards. Adopting low DK materials future-proofs your devices, avoiding rapid obsolescence and protecting customer investments.

What PCB Material Has the Lowest Dielectric Constant?

Boron nitride (BN) currently has the lowest dielectric constant among PCB materials (usually less than 3.0, and some modified products can be as low as below 2.0). Its ultra-low dielectric loss characteristics make it an ideal choice for high-frequency and high-speed circuits, microwave communications, and precision sensors. The porous structure of boron nitride can also suppress electromagnetic interference, regulate radio frequency signals, and is suitable for gas sensors, pressure detectors and other scenarios.

Compared with traditional materials (such as PTFE about 2.1 and FR4 about 4.5), boron nitride performs better in low-impedance connection, signal integrity and thermal stability. It is one of the core materials for 5G base stations, aerospace electronic equipment and high-performance computing chip packaging, and meets the needs of international customers for high-precision, low-loss PCBs.

Common Low Dielectric Constant PCB Materials Supplier

Below are suppliers list for low dielectric constant PCB materials:

Rogers Corporation

- Product Features: Leader in high-frequency materials, RO4000Ÿ series (hydrocarbon/ceramic) and RO3000Ÿ series (PTFE/ceramic) renowned for ultra-low loss factor (Df †0.003) and stable dielectric constant (Dk 2.0-3.5).

- Applications: 5G base station antennas, automotive radar, high-speed digital circuits (100Gbps+ transmission).

DuPont

- Product Features: Deep technical accumulation in low-Dk materials, fluoropolymer substrates (Dk â 2.2) with high temperature/chemical resistance.

- Applications: High-frequency PCBs, semiconductor packaging, industrial control devices.

Amphenol

- Product Features: High-performance PTFE-based materials (e.g., TacLamÂź Plus) with ultra-low loss (Df as low as 0.0002) and excellent batch consistency.

- Applications: Phased-array radars, aerospace, high-speed backplanes.

Isola

- Product Features: TachyonÂź 100G optimized for ultra-high-speed transmission (Dk 3.0-3.5); FR408HRÂź balances performance and processability.

- Applications: Data centers, 5G base stations, mixed-signal designs.

Panasonic

- Product Features: MegtronÂź series (e.g., Megtron 6/7/8) known for ultra-low transmission loss, CAF resistance (anti-chemical corrosion), Dk 3.0-4.0.

- Applications: High-end servers, data center high-speed backplanes, automotive electronics.

Hitachi/Showa Denko Materials

- Product Features: Low-Dk glass fiber formulations, high-frequency/high-speed materials (e.g., IC substrate), stable Dk and high-temperature resistance.

- Applications: Automotive electronics, telecom equipment, industrial controls.

Taconic

- Product Features: RF series (e.g., RF-35, RF-60) and TLY™ ultra-low-loss materials, PTFE-based, Dk 2.2-2.5.

- Applications: Millimeter-wave antennas, satellite communications, high-power amplifiers.

Asahi Kasei

- Product Features: Composite material technology, low-Dk glass fiber modification, optimized high-frequency performance and mechanical strength.

- Applications: Advanced packaging substrates, 5G infrastructure, automotive electronics.

Nan Ya Plastics

- Product Features: Full supply chain (glass fiber-epoxy-copper clad laminate), significant cost advantage, Dk 3.0-4.0.

- Applications: Consumer electronics, automotive electronics, industrial controls.

AT&S

- Product Features: High-end HDI and IC substrates, low-Dk materials (Dk 3.0-3.5), high-precision routing.

- Applications: Semiconductor packaging, high-end servers, medical devices.

Why Choose EBest Circuit (Best Technology) as Low DK PCB Materials Supplier?

Reasons why choose us as low DK PCB materials supplier:

- Precise Control of Material Performance: As a specialized material supplier, we focus on R&D of low DK PCB substrates with dielectric constant strictly controlled within 2.8-3.2 (tolerance â€0.05) and loss factor â€0.002. This ensures 40% improvement in signal integrity for high-frequency circuit designs, directly reducing post-debugging costs for clients.

- Supply Chain Resilience Assurance: Through exclusive partnerships with global top-tier substrate manufacturers and three intelligent warehousing centers in China, we achieve dynamic inventory management. This supports 24-hour emergency delivery with an annual supply capacity exceeding 5 million sheets, eliminating production line downtime risks caused by material shortages.

- Complimentary Technical Consulting Services: Our team of 15 senior material engineers provides end-to-end technical support covering material selection, impedance matching, and stack-up design optimization. This has helped clients reduce design iterations by 30% and shorten time-to-market by 20% on average.

- Transparent Cost Optimization Solutions: Through economies of scale and formulation optimization, we deliver 10-15% material cost savings with detailed cost-benefit analysis reports, ensuring every investment translates into performance enhancement or cost efficiency.

- Strict Batch Consistency Control: ISO 9001-certified full-process quality control includes six inspection procedures (e.g., real-time dielectric constant monitoring, thermal stress testing), ensuring batch-to-batch performance variation â€0.05. This minimizes yield fluctuations caused by material inconsistencies.

- Customized Material Development Capability: We offer tailored material development for specialized requirements such as ultra-low loss or high thermal stability. Three proprietary low DK material variants have been successfully developed, enabling technological breakthroughs in high-end applications including 5G base stations and millimeter-wave radar systems.

- Rapid-Response Technical Support: Our 24/7 technical response mechanism guarantees 2-hour initial feedback and 48-hour solution delivery for client issues. Over 200 critical technical challenges have been resolved, preventing production delays.

Welcome to contact us if you have any request for low DK PCB material: sales@bestpcbs.com.

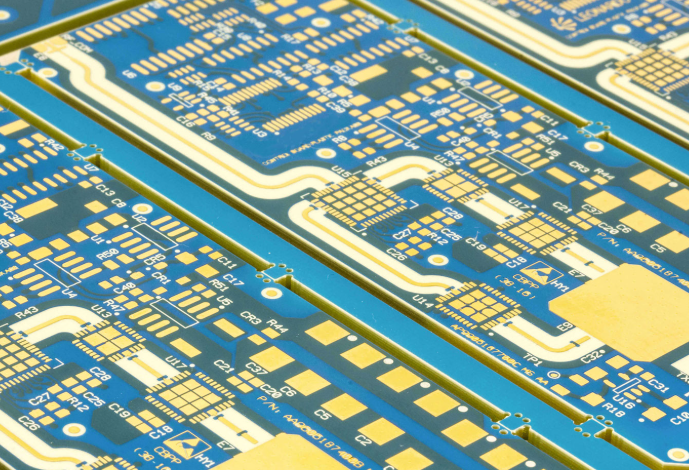

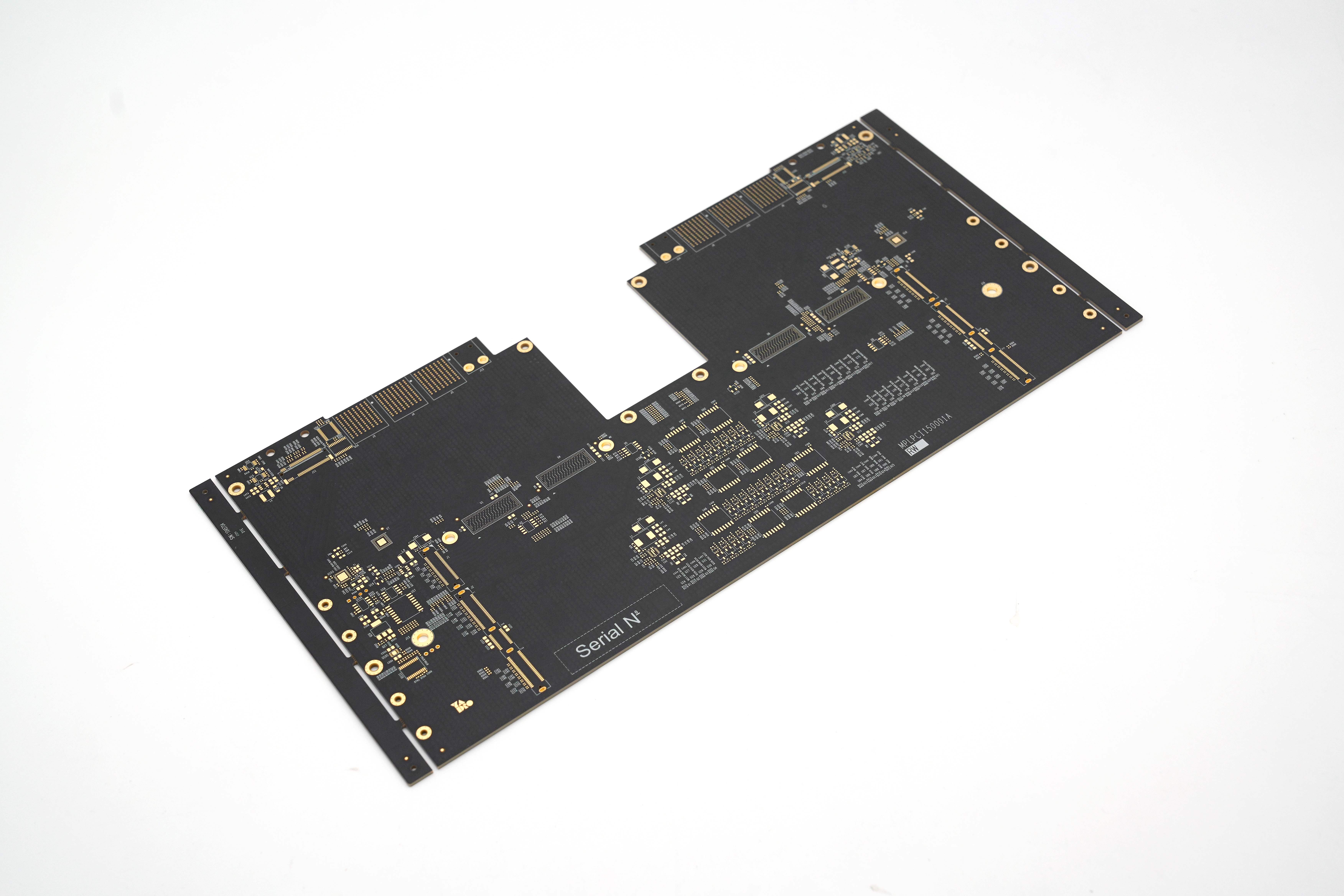

HDI Rigid PCB for AI Hardware Accelerator

October 9th, 2025Why choose HDI rigid PCB for AI hardware accelerator? Let’s discover benefits, applications, power integrity design, thermal solution, cost-performance balancing strategies for HDI rigid PCB for AI accelerator.

Are you troubled with these problems?

- How can high-frequency signal transmission in AI acceleration hardware avoid interference loss?

- How does high-density HDI wiring solve heat dissipation challenges?

- How can complex HDI designs shorten production cycles?

As a HDI Rigid PCB Manufacturer, EBest Circuit (Best Technology) can provide you service and solutions:

- Lossless signal transmission: â€50ÎŒm line width/space + 6-layer blind and buried vias reduce signal loss by 30%, ensuring uncompromised computing power in high-frequency scenarios.

- 3D heat dissipation architecture: A combination of thermal channels, metal base, and heat dissipation vias supports stable operation with a heat flux density of â„5W/cmÂČ.

- Rapid mass production delivery: 48-hour rapid prototyping + 7-day mass production, with full process visualization, shortening AI hardware time-to-market.

Welcome to contact us if you have any request for rigid HDI PCB: sales@bestpcbs.com.

Why is HDI Rigid PCB Important for AI Hardware Accelerator?

Benefits of HDI Rigid PCB in AI Hardware Accelerator:

- High-Density Routing & Micro-Via Technology: HDI PCBs achieve high-density routing through microvias (diameter â€0.006 inches), blind/buried vias, and ultra-fine traces (<3 mils), reducing signal path length and latency. For example, in Transformer-based AI chips, data transmission latency decreases from 1ns to 0.7ns, with routing density increasing 5-fold.

- Signal Integrity Optimization: Low-Dk/Df materials (e.g., M7, Rogers 4350B) combined with differential signal design ensure 10GHz signal insertion loss of only 0.5dB. Eye diagram opening improves by 20%, with bit error rates as low as 1e-15, meeting PCIe 5.0 specifications.

- Thermal Management: Ultra-thin 0.1mm substrates paired with high-thermal-conductivity resins (1W/m·K) and nickel-gold plating (90W/m·K) shorten heat dissipation paths by 40%. This reduces junction temperature by 10°C, lowers fan speeds by 20%, and decreases noise by 5dB.

- Manufacturing Precision: UV laser drilling achieves â€3ÎŒm positioning accuracy, while X-ray alignment systems control lamination deviations <5ÎŒm. Layer-to-layer connectivity reaches 99.99%, and pad flatness is maintained below 1ÎŒm, ensuring robust connections for high-reliability applications.

- Cost Efficiency & Long-Term Value: Despite higher upfront costs, HDIâs integration density reduces power waste and enhances efficiency. For AI servers, HDI PCB value increases from $500 to $2,500, with margins improving by 15â20 percentage points. Total Cost of Ownership (TCO) decreases over the product lifecycle.

- High-Speed Interface & High-Frequency Support: Low-Dk/Df substrates (e.g., Megtron 8, Tachyon 100G) minimize signal loss and improve electromagnetic compatibility for high-speed digital interfaces, enabling seamless integration with PCIe 5.0 and beyond.

- Miniaturization & High Reliability: HDIâs compact form factor suits constrained devices like 5G base stations and smartphones, while withstanding harsh environments (-40°C to 125°C) for automotive and aerospace applications.

- Advanced Manufacturing Innovations: Laser drilling, sequential lamination, and automated optical inspection (AOI) ensure precision for advanced HDI stages (e.g., â„4-layer), supporting future technologies like 3D ICs and chiplet-based designs.

Applications of Rigid HDI PCB in AI Hardware Accelerator

Applications of AI accelerator rigid HDI PCB:

- AI Server GPU Accelerator Cards

- Edge AI Accelerators

- Autonomous Driving Platforms

- Data Center Compute Modules

- 5G Base Station Acceleration Modules

- Aerospace Computing Units

- Smart Security Cameras

Signal Integrity Optimization in HDI Rigid PCB for High Frequency AI Accelerator

Precise Impedance Control

- For critical signal lines (e.g., clocks, data buses) in HDI rigid PCBs for high-frequency AI accelerators, use TDR (Time-Domain Reflectometry) simulation and real-world measurements to ensure single-ended line impedance is strictly controlled at 50±5Ω and differential pair impedance at 100±10Ω. Prevent signal reflection exceeding 3% due to impedance mismatch.

- During layer stack design with tools like Polar SI9000, specify parameters such as substrate thickness, copper foil thickness (â„18ÎŒm), dielectric layer Dk/Df values (e.g., Megtron 6: Dk=3.9±0.05), and prioritize embedded capacitance/inductance technologies to minimize via counts.

Crosstalk Suppression Strategy

- Apply the “3W rule” (trace spacing â„3Ă trace width) for high-speed signal lines. Maintain differential pair inner spacing within 2Ă trace width and adjacent signal spacing â„5Ă trace width.

- Deploy isolated ground planes in critical areas (e.g., around CPUs) and add grounding vias (spacing â€200mil) to form Faraday cages, limiting crosstalk noise to â€5% of signal amplitude. For signals above 10GHz, use shielded differential pairs (e.g., trace structures with ground shields).

Power Integrity Optimization

- Adopt a “power plane + decoupling capacitor” dual approach. Segment the main power plane into independent regions (e.g., AI chip core voltage 1.2V, I/O voltage 3.3V) and connect via â„50mil/200mil via arrays.

- Place decoupling capacitors following the “proximity principle”: 0.1ÎŒF/0.01ÎŒF capacitor combinations â€5mm from chip pins. Use tools like Ansys SIWave for PDN (Power Distribution Network) analysis to determine capacitor quantities and values, ensuring power noise â€2% voltage ripple.

Precision Layout and Routing

- Follow “short and straight” principles for critical signal paths, avoid 90° bends (use 45° chamfers or arc transitions) and minimize via counts (â€2 vias per trace).

- For BGA packages, use “dog-bone routing” with blind/buried via technologies (e.g., HDI 2nd-order vias) to achieve smooth transitions from chip pins to PCB outer layers. Implement length matching (error â€50mil) and use serpentine routing for timing adjustment.

Material and Process Selection

- Prioritize low-loss substrates (e.g., Panasonic Megtron 7: Dfâ€0.002) with thin dielectric layers (â€3mil) to reduce signal delay.

- For surface finishes, use ENIG (Electroless Nickel Immersion Gold) or OSP (Organic Solderability Preservative) to avoid HASL (Hot Air Solder Leveling)-induced surface roughness increasing signal loss.

- For microvia filling, adopt high-reliability electroplating processes to ensure void-free via interiors and IST (Interconnect Stress Test) certification for reliability.

Efficient Power Integrity Design in HDI Rigid PCB for AI Accelerators

1. Refined Modeling of Power Distribution Network (PDN)

- Implementation Steps: Utilize 3D electromagnetic simulation tools (e.g., Ansys HFSS/SIwave) to construct a PDN model, focusing on simulating impedance characteristics at AI chip power pins. Target impedance should be controlled within 2%-5% of the target voltage (e.g., â€20mΩ for 1V power supply).

- Critical Parameters: Determine via simulation the impact of power plane thickness (â„1oz recommended), dielectric layer thickness (â€0.1mm for HDI boards), and via dimensions (blind via diameter â€0.2mm) on impedance.

- Validation Method: Measure impedance at key nodes using a network analyzer to ensure deviation from simulation results is <5%.

2. Hierarchical Layout Strategy for Decoupling Capacitors

- Near-Chip Layer: Deploy 0.1ÎŒFâ10ÎŒF high-frequency decoupling capacitors (X7R material) within a 5mm radius of AI chip power pins, adhering to the “minimized loop area” wiring principle.

- Intermediate Layer: Insert a 0.01ÎŒFâ0.1ÎŒF capacitor layer between power and ground planes to form a “capacitor-plane sandwich” structure, reducing inter-plane resonance frequency.

- Bottom Layer: Place large-capacity (â„100ÎŒF) low-frequency decoupling capacitors, using multiple parallel vias to minimize ESL (equivalent series inductance).

- Execution Standard: Conduct PDN impedance scanning post-layout to ensure resonance peaks do not exceed 50Ω within the target frequency band (e.g., <1GHz).

3. Collaborative Segmentation Design for Multi-Power Domains

- Segmentation Principles: Divide power planes into “island” segments based on AI accelerator voltage domains (e.g., core 1.2V, I/O 3.3V), with adjacent domains spaced â„2mm apart and separated by â„20mil-wide ground plane isolation strips.

- Via Bridging: Implement “cross-segment capacitor bridging” by placing 2â4 0.01ÎŒF capacitors along segment boundaries to reduce cross-segment noise.

- Simulation Verification: Validate signal integrity across segmentation boundaries via SI/PI co-simulation, ensuring crosstalk <5% of signal amplitude.

4. HDI Microvia Power Plane Optimization

- Blind/Buried Via Design: Use a hybrid “blind via + buried via” structure for interlayer power connections, minimizing via-induced plane segmentation. Recommended blind via diameter: 0.15â0.2mm, aspect ratio â€1:6.

- Microvia Filling: Electroplate copper-filled microvias on high-frequency current paths to reduce via resistance (target â€0.5mΩ).

- Thermal Via Design: Add thermal via arrays (spacing â€1mm, diameter 0.3mm) beneath high-heat regions (e.g., under chips) to connect to bottom-layer thermal layers.

5. Dynamic Power Noise Suppression System

- Real-Time Monitoring: Integrate voltage sensors at AI chip power pins, using FPGA or dedicated chips for real-time voltage fluctuation monitoring.

- Dynamic Compensation: Adjust decoupling capacitor array switching states or dynamically regulate supply voltage via LDO regulators (accuracy ±1%) based on monitoring data.

- Execution Case: Validate the dynamic compensation system on test boards to ensure voltage fluctuations <2% during load step changes (e.g., 1A/ÎŒs).

6. Material and Process Selection Specifications

- Substrate Selection: Use low-loss HDI substrates (e.g., Panasonic M7N) with dielectric constant â€4.5 and loss tangent â€0.005.

- Surface Treatment: Apply ENIG (electroless nickel gold) to power planes for low contact resistance; use OSP (organic solderability preservative) on ground planes for reliable conduction.

- Manufacturing Control: Maintain layer-to-layer alignment accuracy â€Â±50ÎŒm during HDI board lamination to ensure microvia alignment with pads.

7. Thermal Management and Heat Dissipation Co-Design

- Thermal Layer Layout: Deploy a â„2oz copper thermal layer at the PCB bottom, connected via thermal vias (diameter 0.5mm, spacing 5mm) to power planes under chips.

- Thermal Simulation Verification: Use thermal simulation tools (e.g., FloTHERM) to analyze heat dissipation paths, ensuring chip junction temperature <105°C at 40°C ambient.

- Practical Testing: Perform infrared thermal imaging tests on prototypes to validate thermal path effectiveness.

8. Standardized Verification and Debugging Process

- Simulation Phase: Complete PDN impedance, signal integrity, and thermal simulation validations; generate and archive simulation reports.

- Testing Phase: Measure power noise (bandwidth â„1GHz) using oscilloscopes to ensure peak-to-peak noise <50mV; scan EMI emissions with near-field probes to comply with FCC Class B standards.

- Debugging Phase: Iteratively optimize issues identified during testing (e.g., adjust decoupling capacitor positions, add thermal vias) until all design requirements are met.

Thermal Management Solutions for HDI Rigid PCB in AI Accelerator

- High Thermal Conductivity Material Application: Utilize ceramic-filled epoxy substrates, aluminum-based composites, or metal-core materials (e.g., copper/aluminum) to achieve thermal conductivity of 5â10 W/(m·K). Integrate embedded copper heat blocks or graphene coatings to reduce thermal resistance between high-power chips (e.g., GPU/ASIC) and PCB, enabling efficient lateral heat diffusion in hotspots.

- Multi-layer Thermal Channel Construction: Implement 20+ layer stack-up designs with dedicated thermal layers embedded between high-speed signal and power layers. Leverage blind/buried via technology to form vertical thermal pathways, paired with thermal via arrays (0.3mm diameter, 1mm pitch) to efficiently transfer heat from 300â500W high-power devices to metal backplates or liquid cooling systems, reducing thermal resistance by over 40%.

- Layout Zoning & Airflow Optimization: Segment layout by power density, position high-power components (â„50W, e.g., GPU/ASIC) at PCB edges/top, and thermally sensitive devices at cold air inlets. Optimize airflow paths via CFD simulation to prevent local hotspots and enhance convective cooling efficiency, ensuring unobstructed airflow paths.

- Active Cooling System Integration: Deploy microchannel cold plates directly bonded to high-power chips with fluorinated fluid cooling for 130W/cmÂČ heat flux dissipation. Immersion cooling enhances thermal conductivity by 10Ă for ultra-high-performance AI clusters. Integrate backside mini-fan arrays and heat pipes with PWM-controlled speed regulation to balance cooling and noise, maintaining operating temperatures â€85°C.

- Thermal Simulation & Reliability Validation: Use ANSYS Icepak or equivalent tools for thermal modeling to predict hotspot distribution and optimize layouts. Validate solder joint reliability via accelerated thermal cycling (-40°C to 125°C) and monitor thermal distribution in real-time via infrared thermography for stable AI inference operations.

- EMI Shielding & Safety Protection: Maintain â„2mm clearance between cooling structures and high-speed traces (e.g., PCIe 5.0/DDR5) to avoid EMI. Use dielectric coolants (e.g., 3M Novec) to prevent electrical shorts. Incorporate temperature sensors and over-temperature protection circuits for automatic throttling or cooling mode switching during faults.

- Advanced Process & Material Innovation: Employ HDI microvia technology (â€0.1mm diameter) to enhance routing density. Adopt high-Tg substrates (Tg â„170°C) for thermal stability. Apply phase-change materials or thermal interface materials (e.g., thermal grease) on PCB surfaces to reduce interfacial thermal resistance and improve overall cooling efficiency.

Cost-Performance Balancing Strategies for HDI Rigid PCB in AI Accelerators

Material Selection & Cost Optimization

- Prioritize low Dk/Df materials (e.g., MEGTRON 6, Rogers 4350B) to reduce dielectric loss by 25% for â„10Gbps signal integrity. Reduce copper thickness from 2oz to 1oz to cut material costs by 23% for modules with current density â€1A/mmÂČ. Standardize board thickness to 1.6mm to lower processing costs by 15% and enhance batch production efficiency.

Symmetrical Stackup Design

- Adopt an 8-layer symmetrical “signal-ground-power-signal” stackup with alternating power/ground planes to balance CTE and minimize warpage. Maintain signal-layer to reference-plane coupling distance within ±0.05mm to reduce crosstalk by 15%.

High-Speed Signal Path Optimization

- Implement strict impedance control (85Ω/100Ω) for differential pairs with equal-length serpentine routing (â€5mil error) for PCIe 5.0/6.0 signals. Use backdrilling to eliminate via stubs and reduce reflections. For HBM-AI chip interconnections, adopt TSV short-path design to limit latency to â€50ps.

Power Integrity (PI) Enhancement

- Deploy multi-layer power/ground plane stackups with zoned power islands for Vcore/Vmem rails. Place 0201-sized high-frequency decoupling capacitors (100nF+10nF) beneath BGA packages, paired with low-ESL/ESR capacitors to suppress power noise to â€5mV.

Thermal Co-Design

- Integrate high-thermal-conductivity substrates (>5W/m·K) with copper heat sinks and thermal via arrays to form 3D heat dissipation channels. For >300W AI core areas, embed liquid-cooling plates with TIM materials to boost thermal conductivity by 40%. Optimize thermal paths via simulation to eliminate hotspots.

Manufacturing Cost Control

- Maximize material utilization to >90% through panelization. Balance test coverage and cost by setting test point density to 0.8/cmÂČ. Enlarge solder mask openings by 0.1mm to improve soldering yield by 5% and reduce rework costs.

HDI Structure Selection

- Evaluate cost increments (40%-200%) for Type I/II/III HDI structures, prioritizing Type II for cost-performance balance. Avoid â€0.3mm special via designs; use laser microvia technology (3mil/3mil line/space) for high-density routing.

Power Path Optimization

- Utilize â„100mil wide copper traces for key power paths to limit current density to â€3A/mmÂČ. Deploy â„6 parallel vias to reduce power loop inductance and enhance current capacity. Position VRM modules near high-power regions to shorten power paths.

AI-Driven Design Tools

- Leverage AI algorithms for component placement (e.g., UCIe Chiplet modules) to minimize EMI and shorten signal paths by 20%. Use AI-based autorouting to reduce via count by 15% and lower crosstalk. Implement AI defect detection for early fault warning to prevent production losses.

DFM Integration

- Incorporate DFM validation during design to assess manufacturability parameters (line/space, via size, layer alignment). Ensure layer precision via AOI/X-Ray inspection to minimize rework. Collaborate with suppliers for material/process optimization and long-term cost reduction.

Why Choose EBest Circuit (Best Technology) as HDI Rigid PCB Manufacturer?

Reasons why choose us as HDI rigid PCB manufacturer:

- Competitive Pricing with Value Optimization: Leveraging dynamic cost modeling and bulk procurement advantages, we offer 8%-15% lower quotes than industry averages. Combined with tailored design optimization, we help reduce material costs by over 20% during the design phase, delivering both cost efficiency and technical excellence.

- 24-Hour Rapid Prototyping for Market Leadership: Our dedicated express channel delivers prototypes from design confirmation to sample in just 24 hoursâ60% faster than standard lead times. This accelerates product iteration and ensures you capture critical market windows without delay.

- 99.2% On-Time Delivery: Powered by intelligent ERP systems and flexible capacity allocation, we achieve a 99.2% on-time delivery rate, far exceeding industry benchmarks. This minimizes production delays, reduces inventory risks, and safeguards your supply chain stability.

- Strict Quality Control System: Triple-layer inspection (AOI + AI visual review + manual final check) ensures 100% batch inspection with defect rates below 0.03%. This exceeds industry standards, enhancing product reliability and reducing post-sale costs.

- Global Compliance with Premier Certifications:Certified with ISO 9001, ISO 13485 (medical), IATF 16949 (automotive), and RoHS, we meet stringent global market requirements. This facilitates seamless entry into regulated markets like EU, North America, and beyond.

- 19-Year Process Database for Risk Mitigation: Backed by 19 years of manufacturing data and a million-case error library, our intelligent alarm system predicts 98% of potential process risks. This reduces trial production rework and cuts hidden costs by over 30%.

- Free DFM Analysis for Design Excellence: Complimentary Design for Manufacturability (DFM) reviews cover 20+ critical dimensionsâincluding trace width/spacing, impedance matching, and testability. This preempts 90% of manufacturing risks and shortens time-to-market by 2-4 weeks.

- End-to-End One-Stop Solutions: From design consultation and engineering validation to mass production and global logistics, we provide a single-window service. This reduces supply chain coordination costs by over 30% and simplifies project management.

Welcome to contact us if you have any inquiry for rigid HDI PCB: sales@bestpcbs.com.

HDI Printed Circuit Board for Smart POS | EBest Circuit (Best Technology)

October 2nd, 2025Why choose HDI printed circuit board for smart POS? Let’s discover its benefits, applications, technical parameter, how to balance cost and performance, signal integrity optimization solutions for HDI PCB through this blog.

Are you worried about these problems?

- Does your POS mainboard freeze frequently in extreme environments?

- Are traditional PCBs holding back your device’s slim design?

- Poor circuit board reliability driving up after-sales costs?

As a HDI PCB manufacturer, EBest Circuit (Best Technology) can provide you service and solutions:

- High-Stability HDI Stack-up: Materials resistant to low/high temps, reducing failure rates by 60%.

- Any-Layer Interconnect Tech: Enables 0.8mm ultra-thin 8-layer boards.

- Enhanced Surface Treatment: Passes 48-hour salt spray test, doubling product lifespan.

Welcome to contact us if you have any request for HDI printed circuit board: sales@bestpcbs.com.

Why Choose HDI Printed Circuit Board for Smart POS?

Benefits of HDI Printed Circuit Board for Smart POS

- Ultimate Miniaturization: Adopts sub-0.1mm microvias, blind/buried via technology, and thin interlayer dielectric design, boosting wiring density by 30%-50% per unit area. Enables compact integration of multi-modules (processor, communication chip, security chip, etc.) and supports device slimming.

- High-Frequency Signal Integrity: Short-path routing + low-impedance copper layer reduces signal transmission delay by 40% and crosstalk by 50%. Ensures zero data loss in high-frequency interactions (5G/4G, NFC payment) and error-free transaction processing.

- Multi-Function Integration & Scalability: 8+ layer fine routing directly integrates processor, memory, biometrics, power management modules. Embedded capacitors/resistors cut external components by 30%. Reserved interfaces support AI algorithm/blockchain security module upgrades.

- Efficient Thermal Management: High-Tg substrate + thermal via/layer design doubles thermal conductivity, rapidly dissipates heat from chips/power modules. Reduces thermal stress risk by 50% for 24/7 operation, extending device lifespan by 20%.

- Cost-Benefit Optimization: Higher per-board cost offset by 15% reduction in overall materials (connectors, cables). Automated production (laser drilling, precision lamination) improves efficiency by 30%, shortens time-to-market by 20%, and lowers lifecycle cost by 10%.

- Future-Proof Tech Compatibility: Naturally compatible with 5G high-frequency RF circuits (low-loss microstrip transmission), AI chip high-density computing needs, and biometric module fine routing. Maintains device adaptability to rapid payment scenario evolution.

Applications of HDI Printed Circuit Board in Smart POS

- Integrate processor, communication module, security chip, touchscreen driver.

- Optimize 5G/4G, NFC, Wi-Fi high-frequency signal transmission.

- Integrate fingerprint recognition and facial recognition modules.

- Carry financial-grade security chip and encryption module.

- Dissipate heat from processor and power module.

- Integrate power management module and reduce power impedance.

- Reserve interfaces to support AI algorithms and blockchain module expansion.

- Each point directly maps to the core application scenarios of HDI PCB in smart POS devices, ensuring technical accuracy and concise expression.

Technical Parameter for Smart POS HDI Printed Circuit Boards

| Parameter | Specification |

| Substrate Material | High-frequency FR4 or polyimide materials; Tg value â„170°C; Low dielectric constant (Dk â€3.8) |

| Layer Count | 4-12 layer HDI structure with blind/buried via design |

| Line Width/Spacing | Minimum line width: 50ÎŒm; Minimum line spacing: 50ÎŒm |

| Drilling Specifications | Mechanical drilling: â„0.15mm; Laser drilling: 0.05-0.1mm; Aspect ratio â€10:1 |

| Surface Finish | ENIG (chemical nickel gold); Optional immersion silver/tin; Thickness: Nickel 3-5ÎŒm, gold 0.05-0.1ÎŒm |

| Impedance Control | Single-ended impedance: 50Ω±10%; Differential impedance: 90Ω±10% |

| Copper Thickness | Outer layer: 1/2oz-2oz (17-70ÎŒm); Inner layer: 1/3oz-1oz (12-35ÎŒm) |

| Solder Mask | LPI liquid photoimageable solder mask; Thickness: 15-25ÎŒm; Minimum opening: 75ÎŒm |

How HDI PCB Optimize High Frequency Signal Transmission Performance in Smart POS?

1. Precision Low-Loss Substrate Selection

- Material Specifications: Utilize high-frequency low-loss substrates such as Rogers RO4350B (Dk=3.48, Df=0.0021) and Panasonic MEGTRON 6 (Dk=3.7, Df=0.002), ensuring Dk †3.5 and Df †0.0025.

- Performance Enhancement: Achieves 70%+ reduction in 60GHz signal loss compared to FR-4, maintaining signal attenuation â€2.5dB/cm for 5G/Wi-Fi 6/4G modules.

- Application Compatibility: Specifically designed to meet the high-frequency requirements of smart POS modules, ensuring robust anti-interference capabilities and stable communication links.

2. Stackup Structure Optimization

- Layer Configuration: Implement alternating “signal-ground-power” stackup (e.g., L1: Signal, L2: GND, L3: Power, L4: Signal) to minimize return path discontinuity.

- Noise Mitigation: Grid-like power plane design reduces power noise fluctuations to <50mV, while avoiding cross-split routing preserves signal integrity for DDR4/PCIe interfaces.

- Structural Advantage: Maintains unbroken reference planes under high-speed traces, critical for minimizing electromagnetic interference (EMI) and crosstalk.

3. Hierarchical Blind/Buried Via Application

- Via Type Selection: Deploy blind vias (1-2 layers) for fine-pitch BGA regions and buried vias (3-6 layers) for internal layer connections, optimizing routing density.

- Innovative Structure: The “1+2+1” blind via stack (top-layer blind via + internal buried via + bottom-layer blind via) increases routing density by >30% while reducing signal path length and transmission delay.

- Space Optimization: Minimizes through-hole space occupation, enabling compact layout design for high-density POS motherboards.

4. Precision Impedance Control & Matching

- Impedance Standards: Strictly control single-ended impedance to 50±10Ω and differential impedance to 100±3Ω via line width/spacing tuning (e.g., 0.1mm/0.1mm differential pairs).

- Verification Method: TDR (Time-Domain Reflectometry) simulations validate impedance continuity, ensuring 60GHz signal return loss †-28dB to minimize reflection losses.

- Design Compliance: Adjusts dielectric thickness and copper weight to meet impedance targets, critical for maintaining signal integrity at high frequencies.

5. Differential Signal & Shielding Design

- Differential Pair Routing: High-speed signals (USB3.0/HDMI) are routed as differential pairs with length matching error <5mil to reduce common-mode noise.

- Shielding Implementation: Ground vias spaced <0.5mm alongside critical signal traces form electromagnetic shielding strips, suppressing crosstalk to <-70dB.

- Anti-Interference Enhancement: Creates a protective barrier against EMI, ensuring signal purity and reliability in dense POS environments.

6. EMI/Thermal Co-Design

- Electromagnetic Isolation: Ground planes segregate digital/analog domains with single-point grounding, while 0.01ÎŒF high-frequency decoupling capacitors suppress power noise.

- Thermal Management: Densely arranged thermal vias (0.3mm diameter, 1mm pitch) under power devices (e.g., LDOs/MOSFETs) form heat pathways to bottom-layer thermal pads, reducing single-via thermal resistance by 40%.

- Synergistic Effect: Prevents thermal concentration from degrading signal performance, ensuring system stability and longevity.

7. Simulation Verification & Process Control

- Simulation Tools: HyperLynx/Allegro perform time/frequency domain simulations to validate eye diagram margin (>20%), crosstalk (<5%), and impedance matching.

- Manufacturing Standards: Adheres to IPC-2221 specifications for minimum trace width/spacing (4mil/4mil), blind via diameter (â„0.1mm), and layer alignment tolerance (±50ÎŒm).

- Quality Assurance: X-ray drilling inspection ensures blind via positioning accuracy, boosting first-pass yield to >95% and ensuring design manufacturability and reliability for volume production.

How to Balance the Performance and Cost of HDI Printed Circuit Boards in Smart POS?

Layer and Structure Refinement Design

- Adopt symmetric stack-up structures from 1+N+1 to 3+N+3, achieve 0.1mm-level high-density wiring in the BGA region via laser microvia technology, and optimize signal path length.

- PWR/GND pins penetrate 1-2 layers via microvias, freeing up inner layer wiring space, reducing layer count by 20% compared to original design, and minimizing material usage.

- Wiring density increases by 40%, signal integrity improves by 12%, supports multi-layer any-layer interconnection design, and adapts to future functional expansion requirements.

- Optimize interlayer coupling capacitance, reduce crosstalk, enhance high-frequency signal transmission quality, and ensure stable 5G/NFC communication.

Material Grading Selection Strategy

- For high-frequency scenarios, select low Dk/Df materials (Dk †4.5, Df †0.005) such as PTFE substrate to reduce 5G signal loss by over 25%.

- For conventional scenarios, use high-Tg FR-4 (Tg â„ 170â) to balance cost and heat resistance, preventing substrate deformation under high temperatures.

- Hybrid outer-layer low-loss substrate with inner-layer conventional FR-4, achieving â€5% performance loss, significant cost optimization, and suitability for mid-range POS devices.

- Select materials with low coefficient of thermal expansion (CTE) to reduce interlayer delamination risk caused by thermal stress and improve long-term reliability.

Manufacturing Process Adaptability Enhancement

- Implement mSAP/MSAP process to achieve 2mil/2mil line width, increasing wiring density by 30% and adapting to high-density wiring requirements.

- Control laser drilling precision to ±0.05mm, plating void ratio â€3%, ensuring no short/open defects in microvias.

- Achieve 100% AOI inspection coverage, complemented by X-ray inspection, to identify interlayer alignment deviations and microvia filling quality.

- Optimize plating uniformity to avoid excessive copper thickness variation in microvia inner walls, preventing reliability issues and extending product lifespan.

Thermal and Heat Management Co-Design

- Metal substrate + buried copper block technology achieves thermal resistance â€1.5â/W, reducing processor area temperature by 20â and improving heat dissipation efficiency.

- Thermal via array density â„20/cmÂČ, combined with thermal vias to form efficient heat conduction paths and reduce thermal hotspots.

- Embed liquid cooling microchannels between layers to reduce thermal stress risk by 50%, extend device lifespan by 20%, and support 24/7 high-load operation.

- Use high thermal conductivity (â„2W/m·K) thermal adhesive to enhance interfacial heat conduction efficiency and reduce thermal resistance.

Power and Signal Integrity Optimization

- Control PDN impedance â€0.5Ω@100MHz and power noise â€50mV to ensure power stability.

- Ground via spacing â€0.2mm to form low-impedance return paths, reducing ground bounce noise impact on signals.

- Differential pairs adopt 4mil spacing + 50Ω impedance design, achieving â„20dB crosstalk suppression and improving signal noise immunity.

- Optimize power plane partitioning to reduce power plane resonance, enhance power integrity, and support high-speed signal transmission.

Extensibility and Maintainability Design

- Reserve standardized interfaces (e.g., ZIF connectors) to support hot-swapping of AI algorithm modules and adapt to future functional upgrade requirements.

- Modular stack-up structure facilitates maintenance and component replacement, reducing total lifecycle cost by 15% and improving maintainability.

- Design DFT (Design for Testability) interfaces to support boundary scan and in-circuit testing, simplifying fault localization and repair processes.

- Adopt removable connector design to reduce on-site repair difficulty and time, improving device availability.

Why Choose EBest Circuit (Best Technology) as HDI Printed Circuit Board Supplier?

Reasons why choose us as HDI printed circuit board supplier:

- 19-Year Expertise for Risk Reduction: Leverage 19 years of HDI technology accumulation to provide expert consultation, reducing customer R&D trial costs by 30% and ensuring one-time certification approval for complex products like smart POS, minimizing rework expenses.

- Full-Inspection Quality Assurance: Implement 100% batch inspection + UL/IPC dual certification with defect rate â€0.03%, directly safeguarding customer terminal products’ zero-fault rate, enhancing brand reputation, and reducing after-sales recall risks.

- 24-Hour Rapid Prototyping Service: Complete emergency order prototyping within 24 hours, accompanied by free DFM analysis reports to preemptively resolve 90% of potential production issues, accelerating product launch by 40% and securing market opportunities in emerging fields like 5G/mobile payments.

- Custom Material & Process Optimization: Select high-frequency low-loss substrates + ENIG surface treatment combined with laser microvia forming (â€100ÎŒm aperture) to boost signal transmission speed by 15% and reduce power consumption by 20% for smart POS, meeting high-speed payment scenario requirements.

- End-to-End Integrated Solutions: Cover full-process services from PCB design to SMT and PCBA assembly, reducing customer supply chain coordination efforts by 15%, expediting product commercialization, and supporting rapid iteration demands.

- Cost Optimization Guarantee: Offer 10%-15% lower custom quotes than industry averages through scaled production and material supply chain integration, while maintaining premium material usage to enhance customer profit margins and product competitiveness.

- Quick-Response Delivery Service: Ensure 7-day delivery for standard orders and 5-day expedited delivery for urgent orders, enabling customers to flexibly adapt to market fluctuations and avoid order loss or market share erosion due to delays.

- Multi-Scenario Reliability Validation: Conduct customized wide-temperature (-40°C~125°C) and humidity (95% RH) tests to ensure stable operation of smart POS in extreme environments, reducing customer return rates and after-sales costs by 30%.

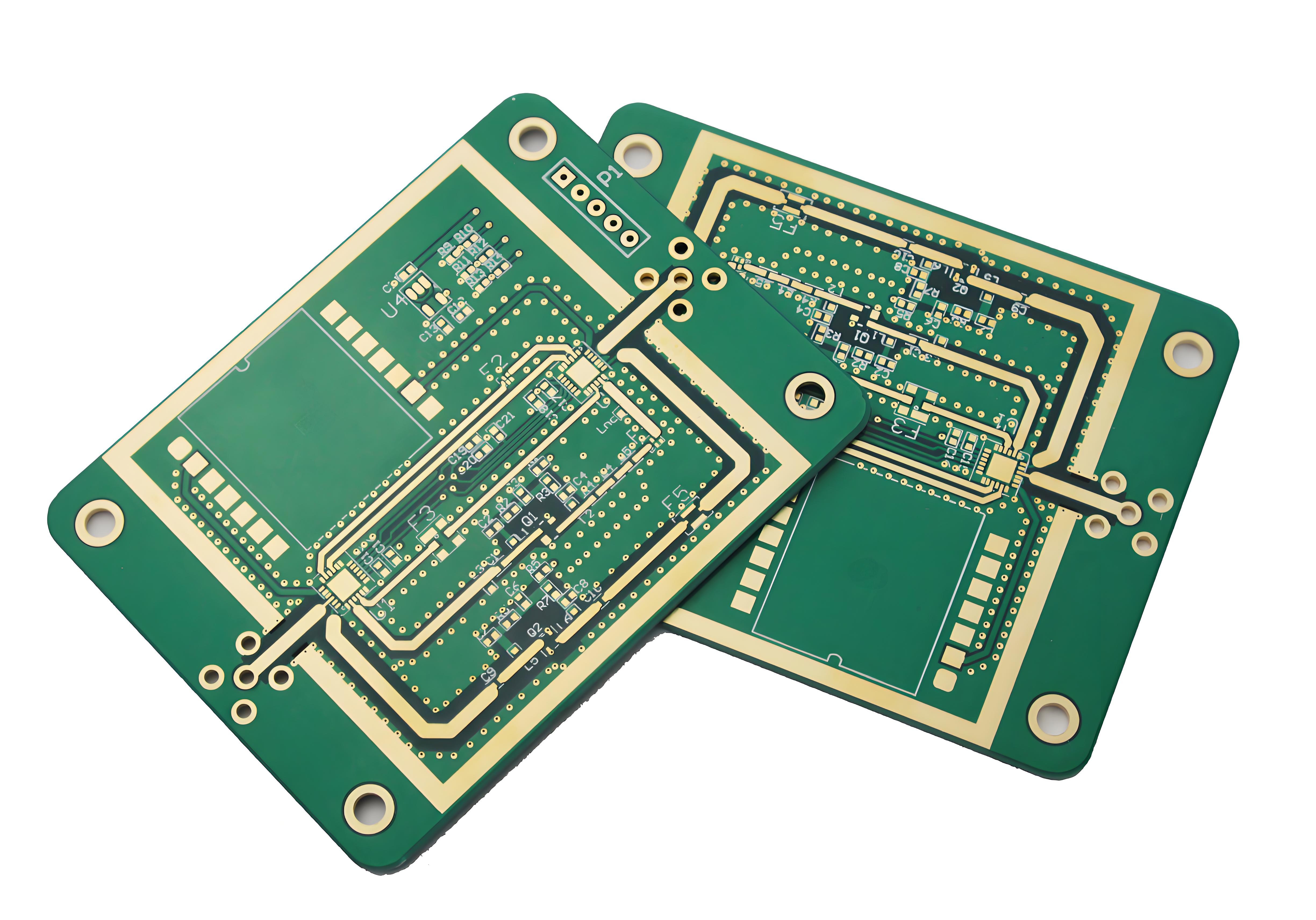

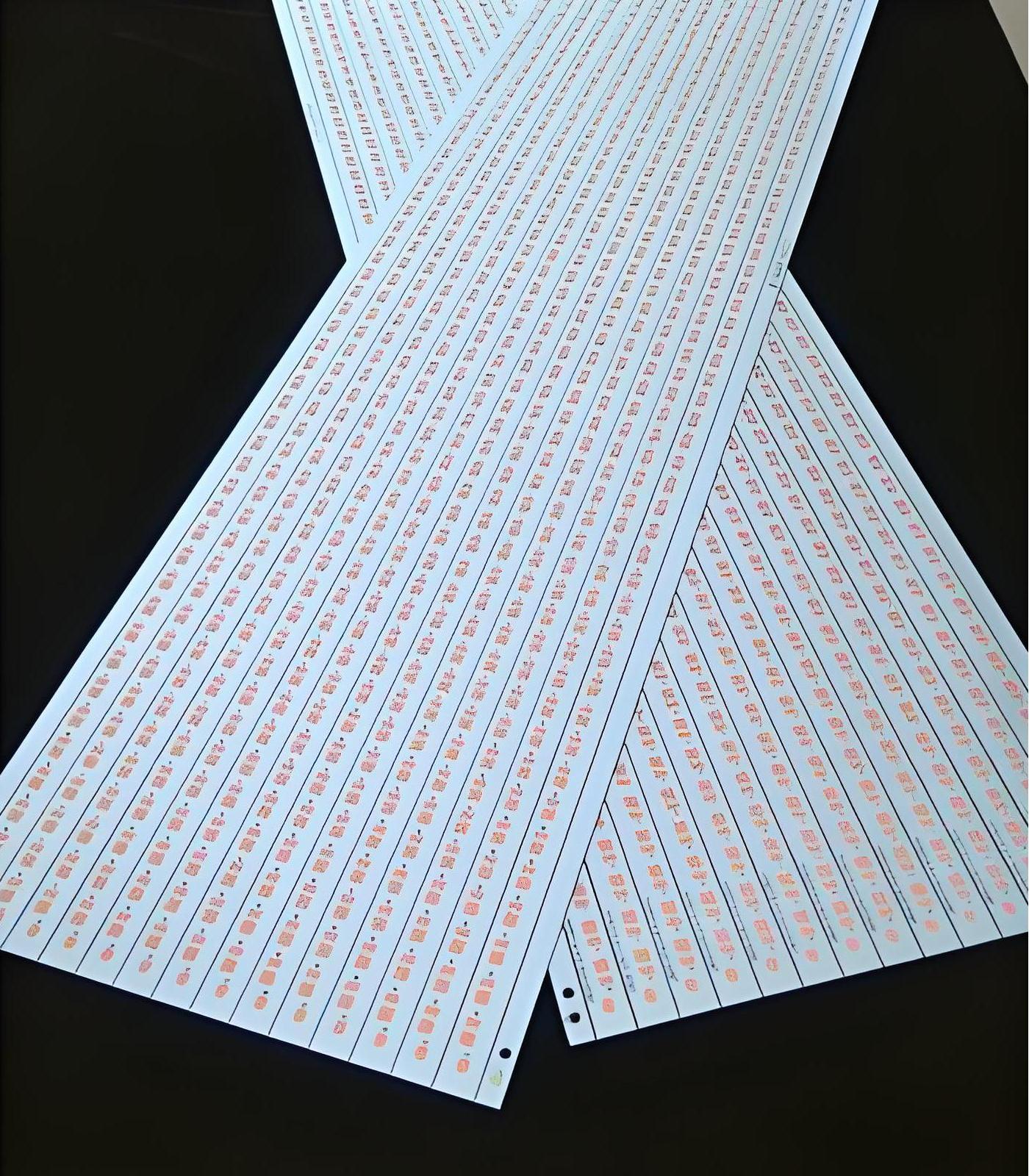

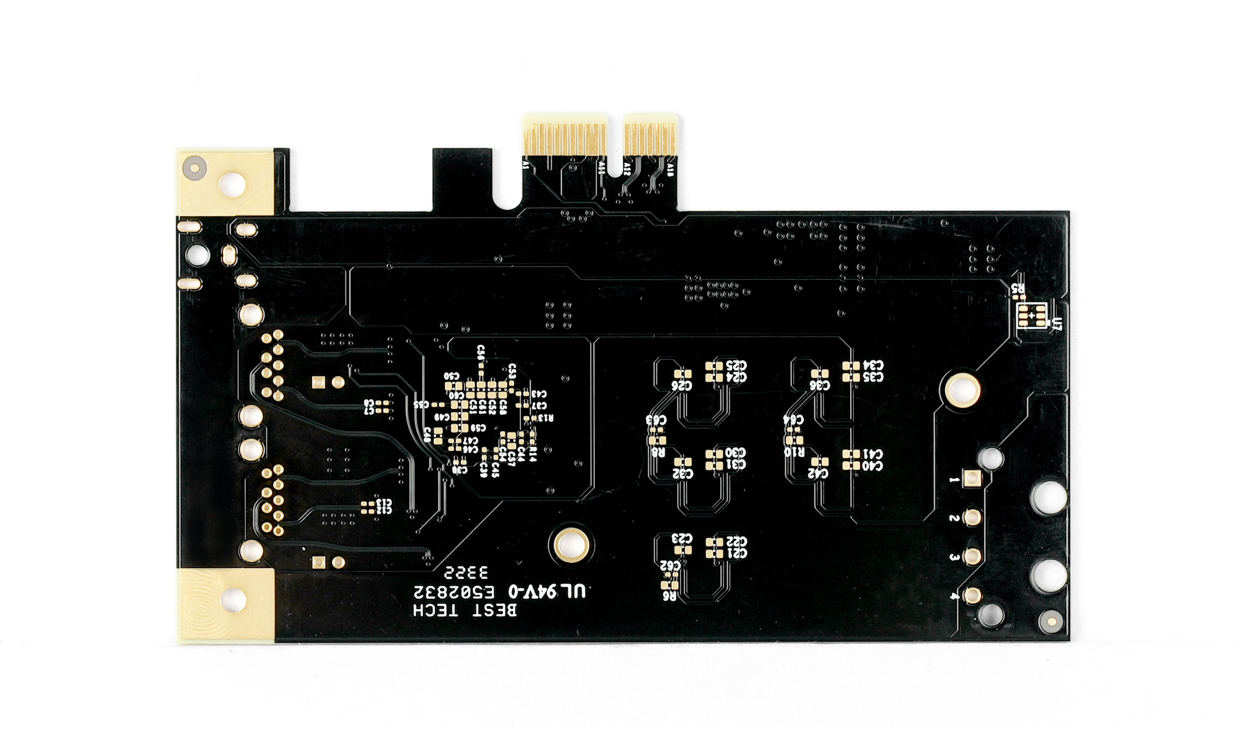

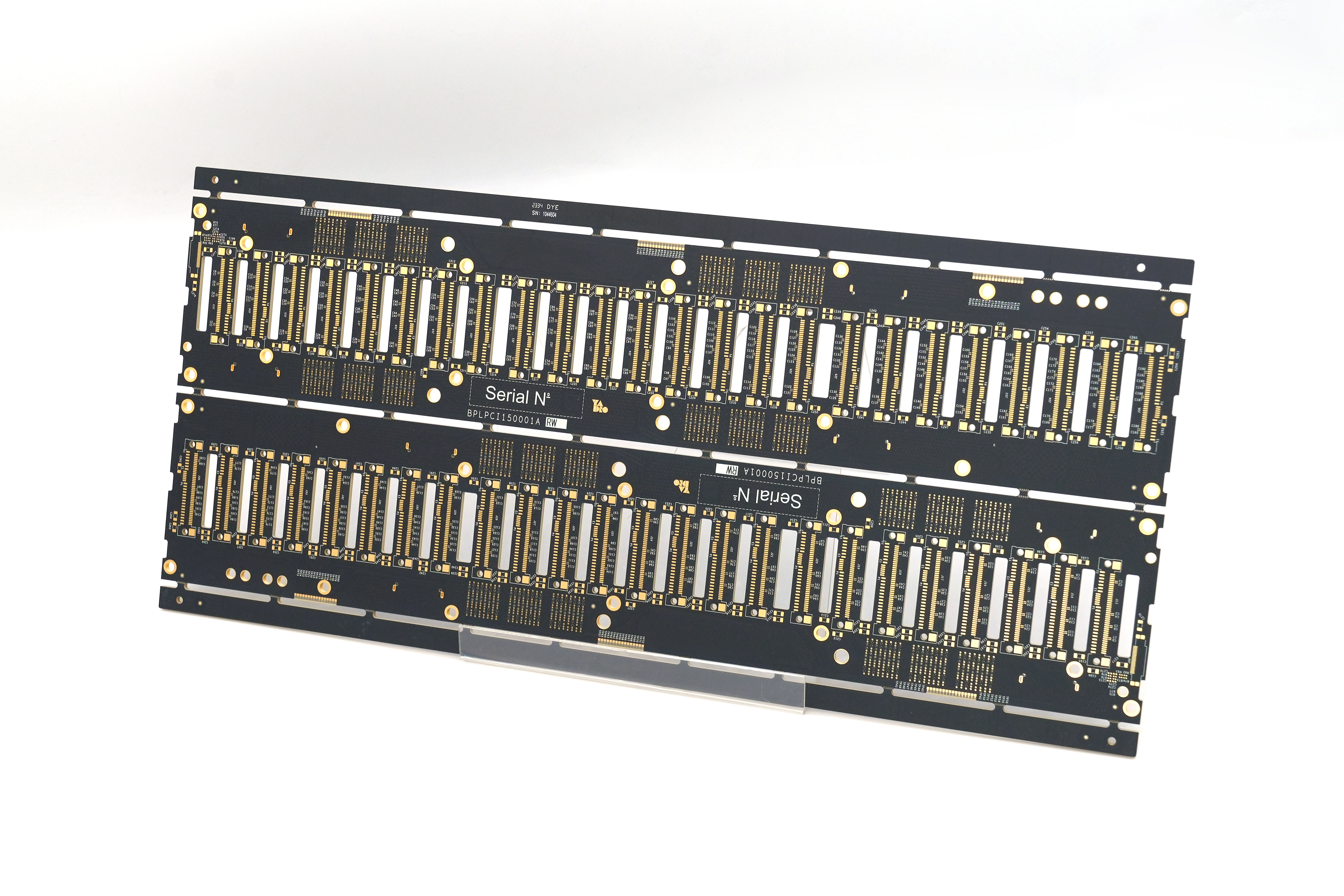

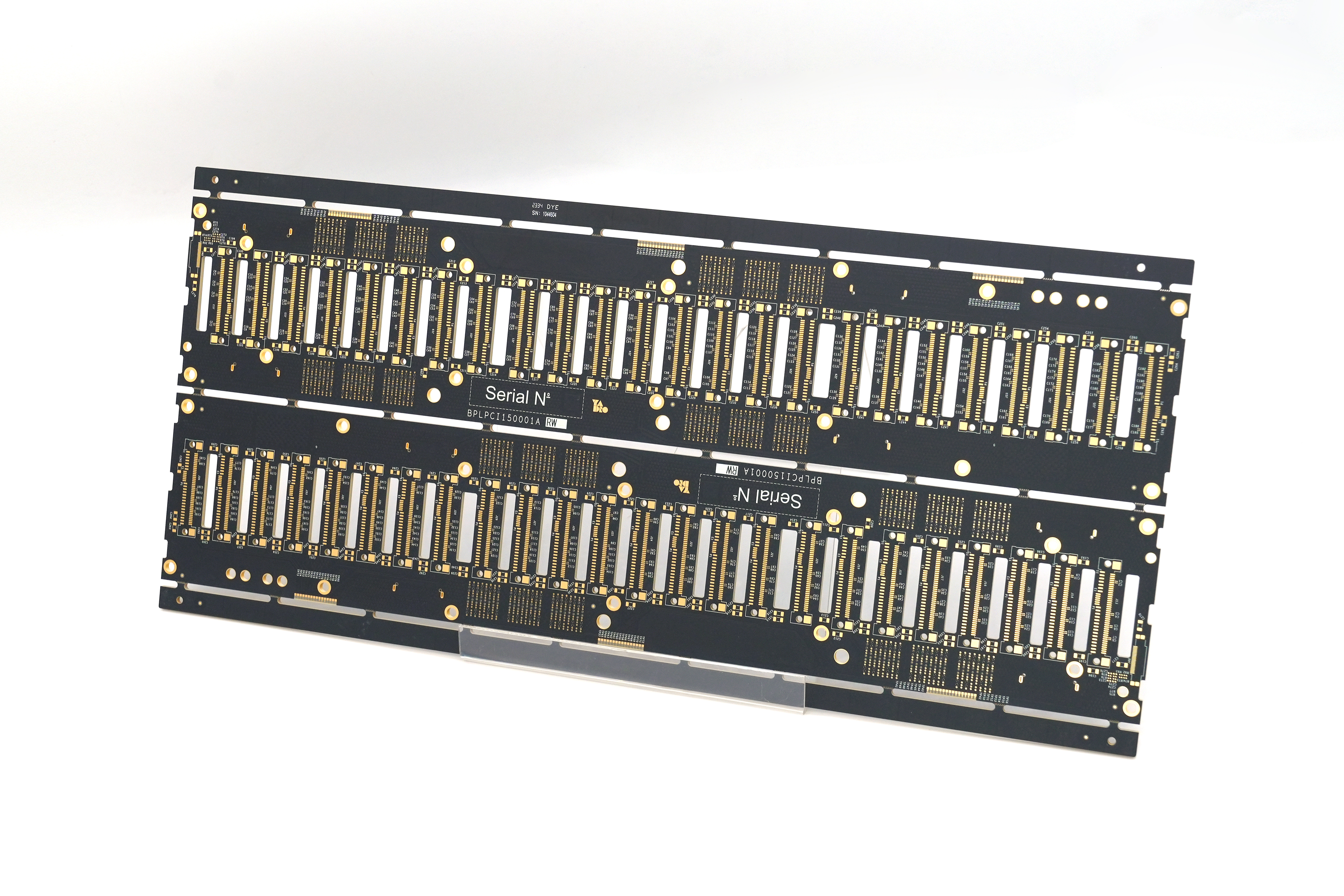

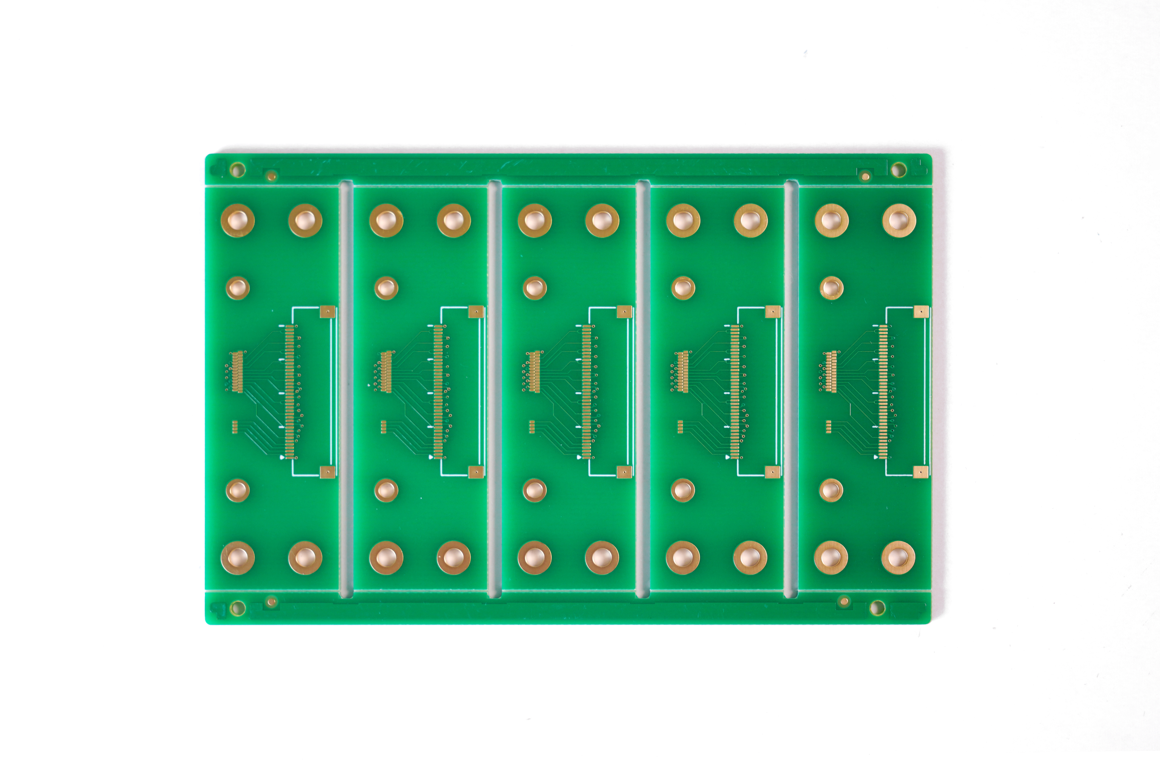

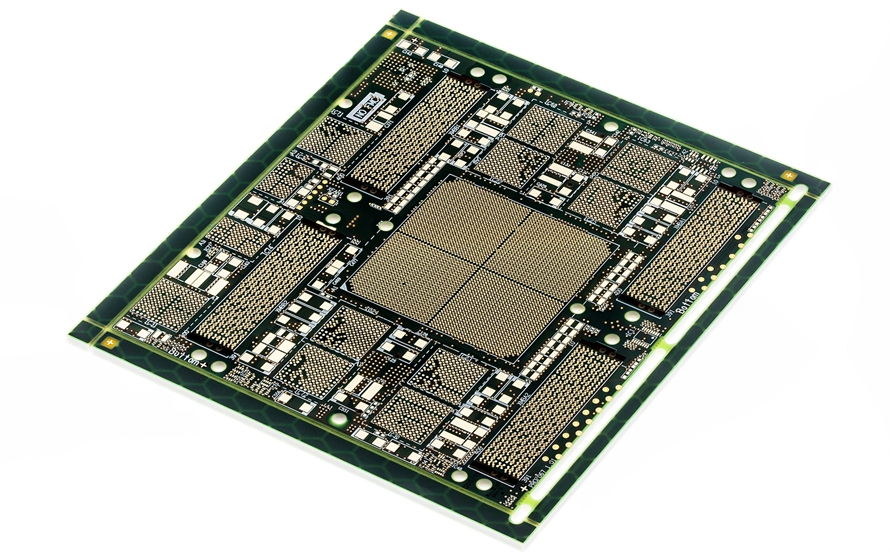

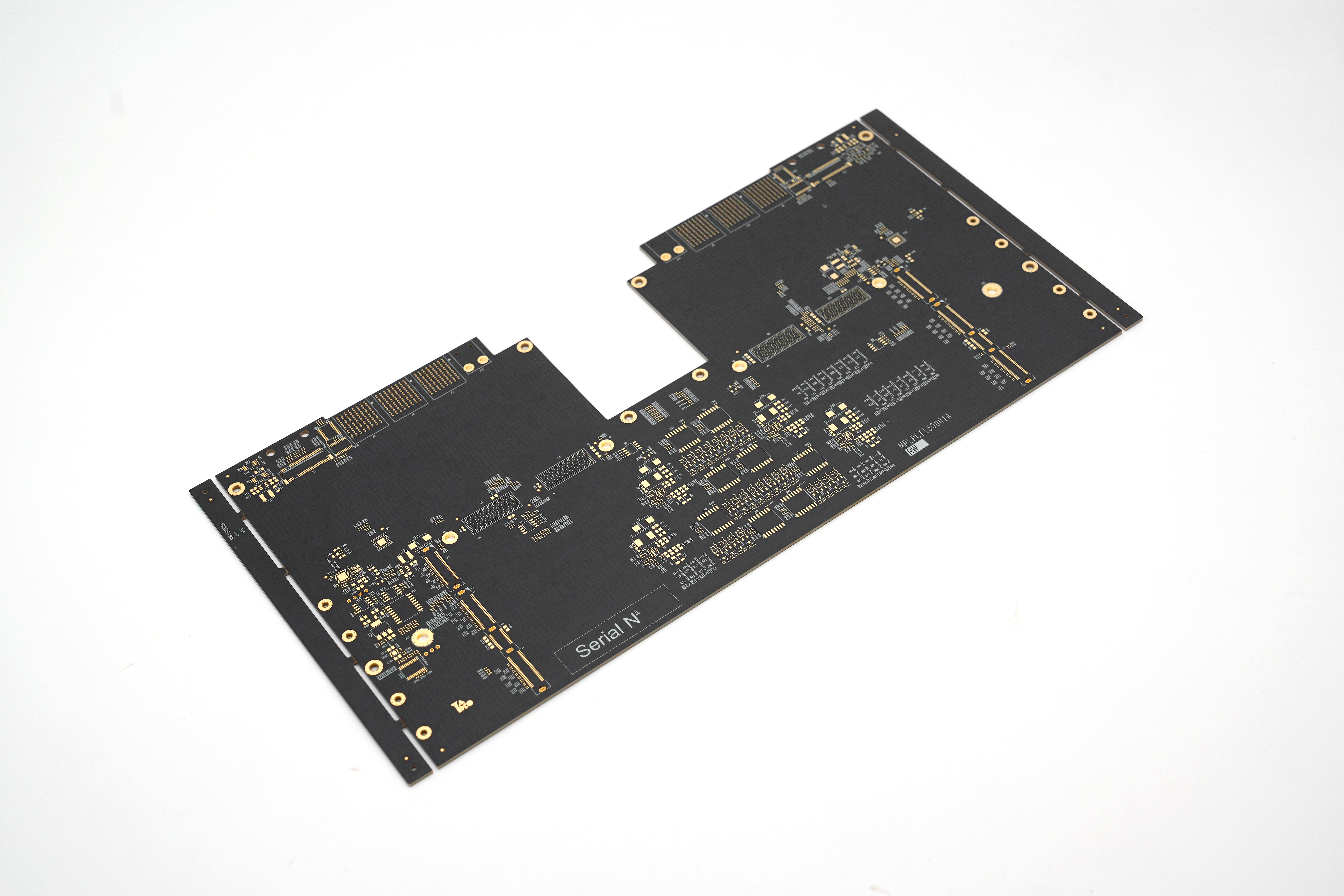

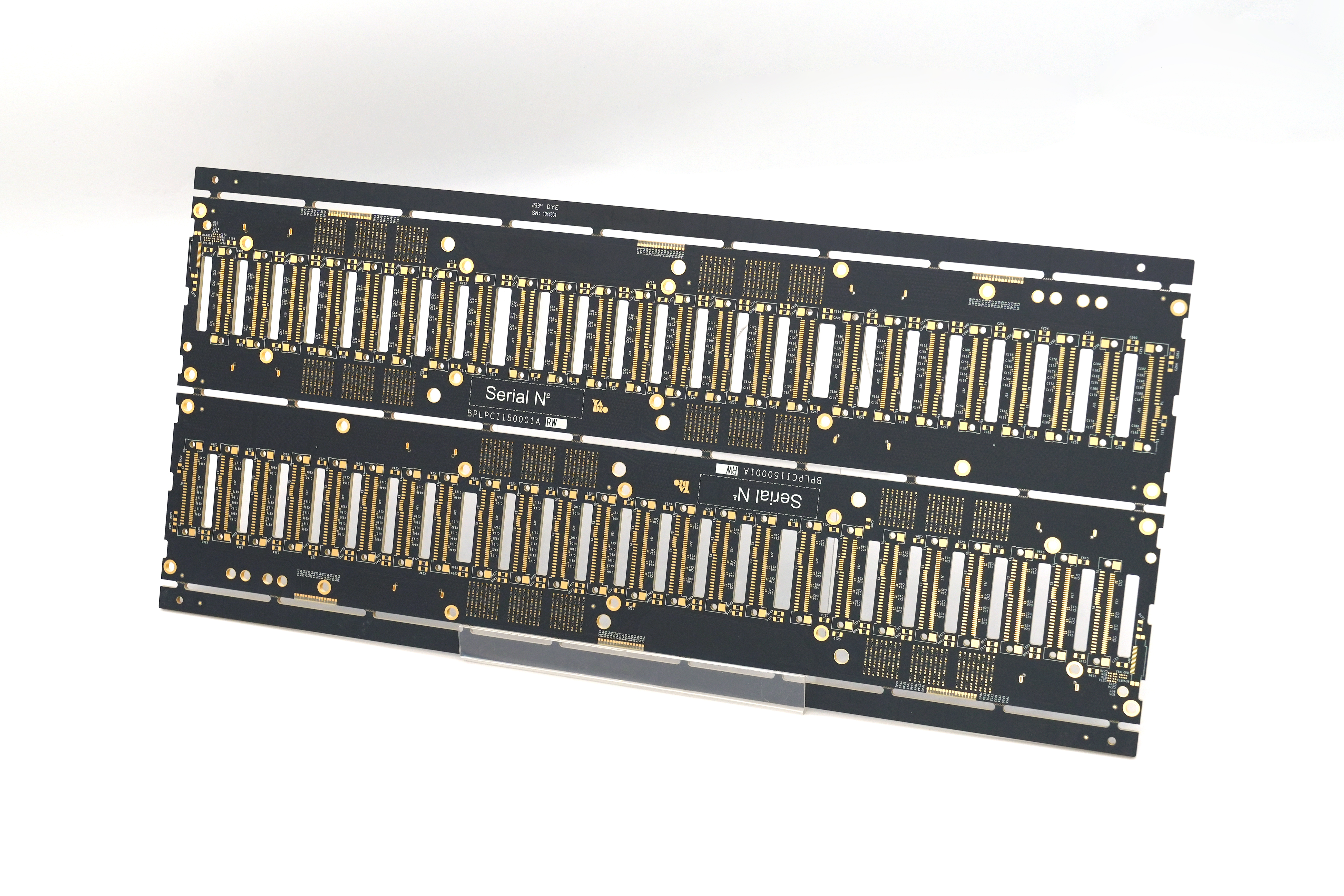

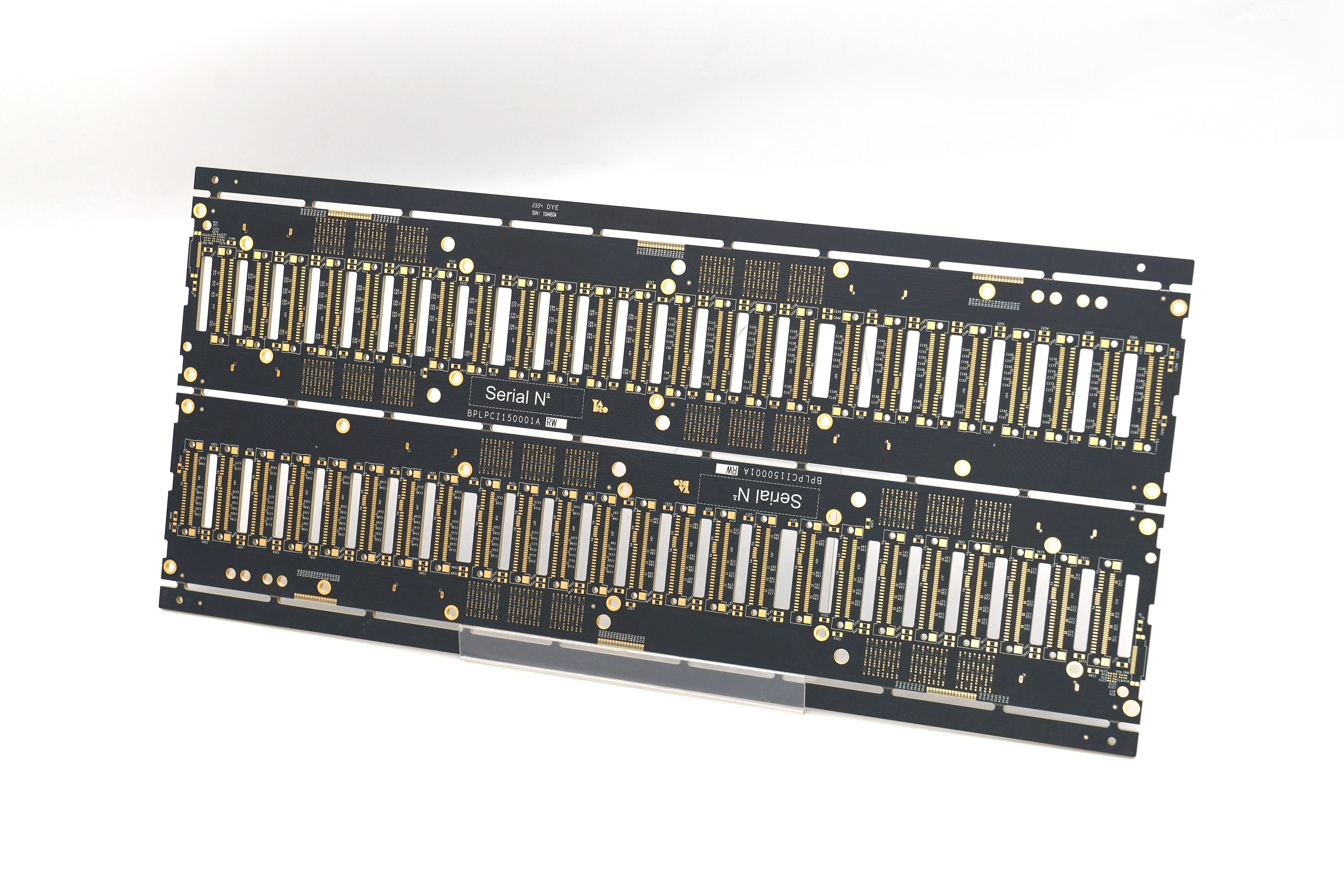

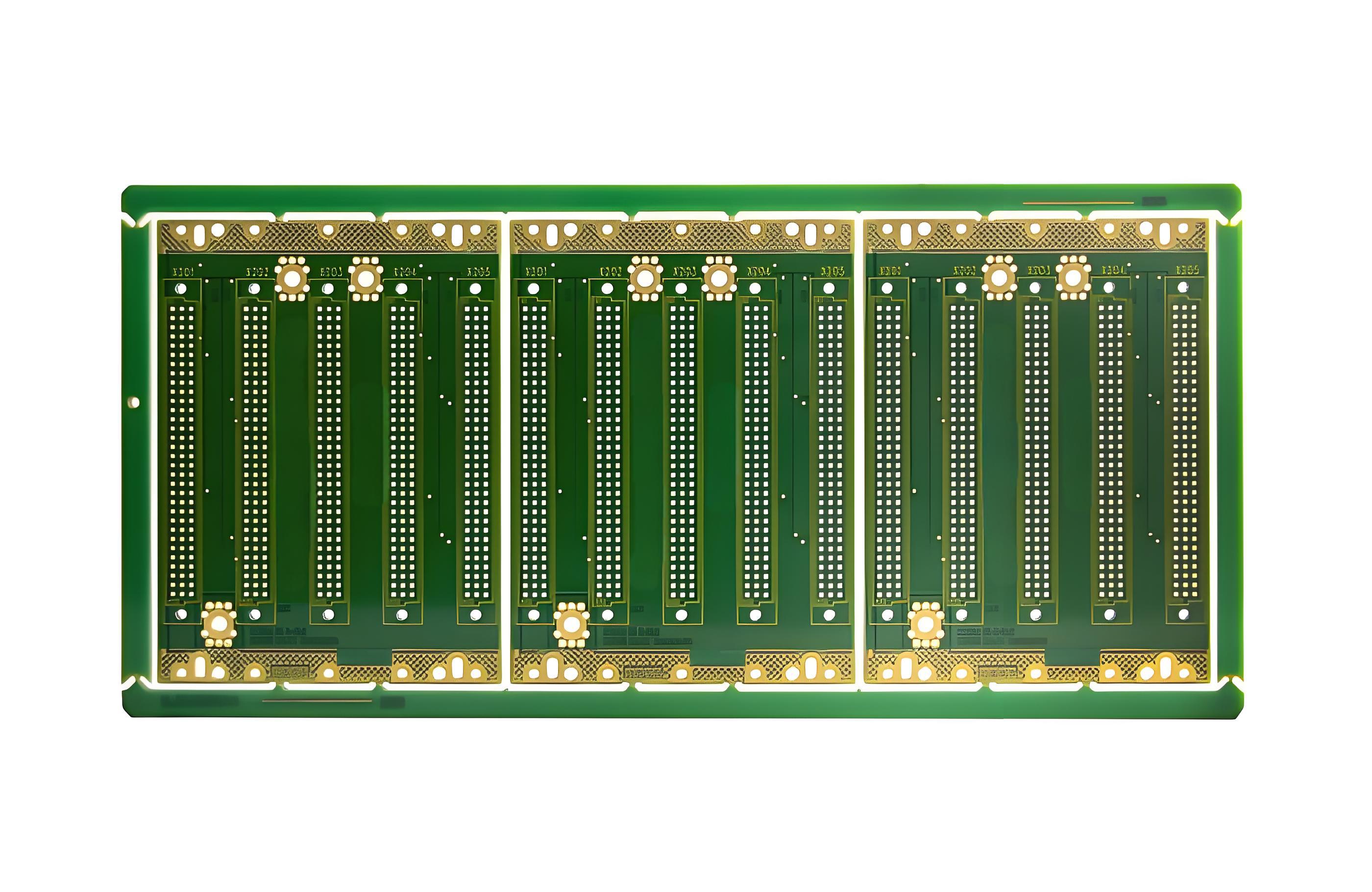

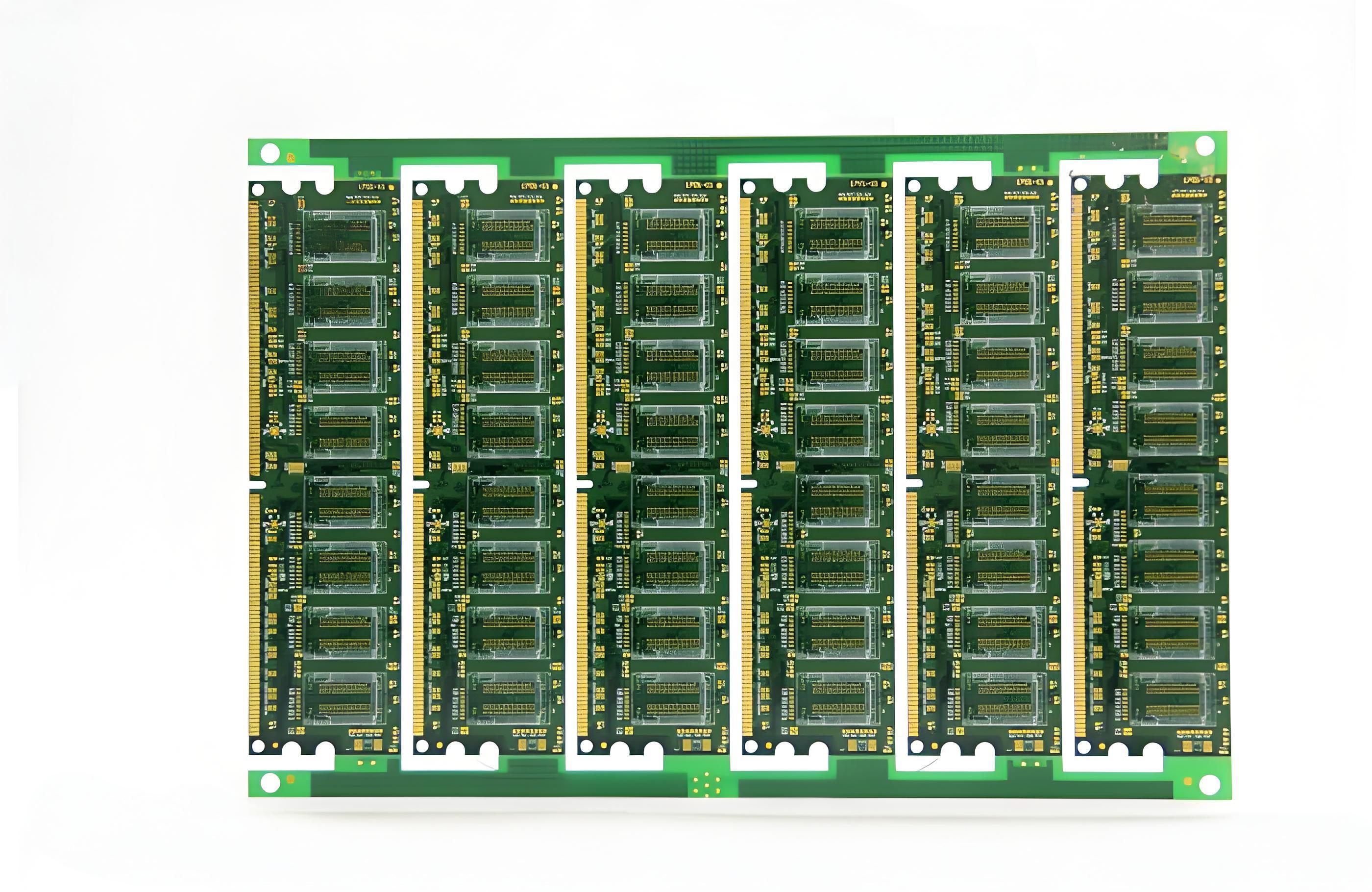

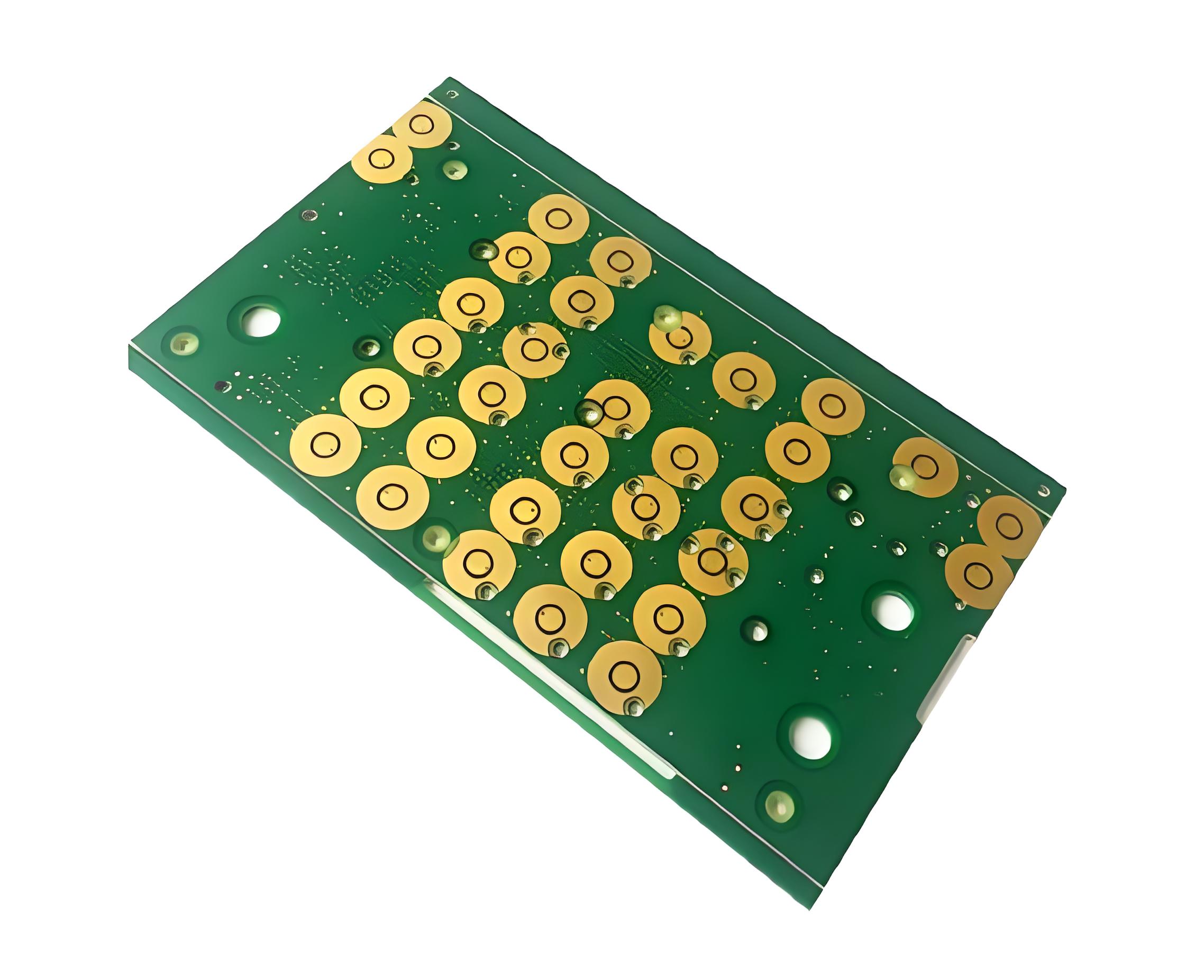

Below is a photo of HDI printed circuit board we did before:

Our HDI Printed Circuit Boards Capabilities

| Parameter | Capabilites |

| PCB Layers: | 1-32L |

| Copper Thickness: | Outer Layer:1oz~30oz; Inner Layer:0.5oz~30oz |

| Min Line Width/Line Space: | Normal: 4/4mil; HDI: 3/3mil |

| Min Hole Diameter: | Normal: 8mil; HDI: 4mil |

| PTH/NPTH Dia Tolerance: | PTH: ± 3mil; NPTH: ±2 mil |

| Surface Treatment: | ENIG(Au 4uââ),ENEPIG (Au 5uââ) Gold finger/Hard Gold Plating(Au 50uââ), HASL /LF HASL, OSP, Immersion Tin, Immersion Silver |

How to Get a Quote for Your HDI PCB Project?

The list of materials required for HDI PCB quotation is as follows:

- Layer count and stack-up configuration.

- Board dimensions and thickness.

- BGA region microvia specifications (0.1mm laser-drilled).

- Material grade selection (low Dk/Df PTFE or high-Tg FR-4).

- Copper weight and surface finish.

- Wiring density and signal integrity requirements.

- Thermal management specifications.

- Power integrity targets (PDN impedance â€0.5Ω@100MHz).

- Manufacturing process control (mSAP/MSAP, ±0.05mm accuracy).

- Testing protocols (AOI/X-ray 100% coverage).

- Volume requirements and delivery timeline.

Welcome to contact us if you have any inquiry for HDI circuit board: sales@bestpcbs.com.

HDI Multilayer PCB Design & Manufacturer, Rapid Prototyping

September 19th, 2025What is a HDI multilayer PCB? Let’s discover its stackup, applications, technical parameter, design guide and manufacturing process through this blog.

Are you troubled with these problems?

- Struggling with sub-0.1mm microvia fabrication in traditional PCB processes?

- Facing high costs from signal loss in high-speed products?

- Delayed by slow 8+ layer HDI prototyping impacting launches?

As a HDI multilayer PCB manufacturer, EBest Circuit (Best Technology) can provide you service and solutions:

- Microvia Precision: 0.05mm laser-drilled vias with plasma treatment for compact designs.

- Signal Stability: End-to-end SI/PI support for 10Gbps+ stable transmission.

- Rapid Prototyping: 7-day standard lead time for 8-layer HDI, 5 days for urgent orders.

Welcome to contact us if you have any request for HDI multilayer PCB: sales@bestpcbs.com.

What Is a HDI Multilayer PCB?

HDI Multilayer PCB (High-Density Interconnect Multilayer Printed Circuit Board) is an advanced circuit board that employs precision microvias (aperture â€0.15mm), blind/buried via technology, and ultra-fine lines (line width/spacing â€3mil). Through laser drilling and layer-by-layer stacking processes, it achieves high-density routing across 8 or more layers within compact spaces. This design enhances signal transmission speed, reduces interference, and is specifically engineered for miniaturized, high-performance applications such as 5G devices and wearable electronics.

8 Layers HDI PCB Stackup

| Layer | Layer Type | Main Function | Connection Method |

| L1 | Signal Layer | High-frequency signal transmission / Critical component routing | Surface Blind Via (Connecting to L2) |

| L2 | Power/Ground Plane | Power distribution / Ground network | Buried Via (Connecting to L3-L6), Blind Via (Connecting to L1/L3) |

| L3 | Signal Layer | Inner-layer high-speed signal routing | Buried Via (Connecting to L2/L4) |

| L4 | Signal Layer | Inner-layer control signal routing | Buried Via (Connecting to L3/L5) |

| L5 | Signal Layer | Inner-layer low-speed signal routing | Buried Via (Connecting to L4/L6) |

| L6 | Power/Ground Plane | Power distribution / Ground network | Buried Via (Connecting to L5/L7), Blind Via (Connecting to L7) |

| L7 | Signal Layer | Inner-layer auxiliary signal routing | Blind Via (Connecting to L6/L8) |

| L8 | Signal Layer | High-frequency signal transmission / Critical component routing | Surface Blind Via (Connecting to L7) |

What Are Applications of HDI Multilayer PCB?

Applications of HDI multilayer PCB:

- Smartphones & Mobile Devices: Mobile phone motherboard, Camera module, Sensor module, Antenna system, Automotive Electronics.

- Engine Control Unit (ECU): In-vehicle navigation system, Airbag control module, Advanced Driver Assistance System (ADAS), In-vehicle entertainment system.

- Medical Equipment: MRI imaging equipment, Cardiac pacemaker, Implantable medical devices, Precision diagnostic instruments, Communication Equipment.

- 5G base station: Router/switch, Fiber optic communication module, Satellite communication equipment.

- Industrial Control: Industrial robot control board, PLC control system, Automated sensor network.

- Servers & Data Centers: High-performance server motherboard, Cloud computing hardware, Data storage devices.

HDI Multilayer Circuit Board Technical Parameter

| Parameters | Specifications |

| Layer Range | 8-24 Layers |

| Minimum Line Width/Spacing | 40/40ÎŒm |

| Laser Drill Hole Diameter | 0.1mm |

| Mechanical Drill Hole Diameter | 0.15mm |

| Blind/Buried Via Diameter | 75-150ÎŒm |

| Aspect Ratio | <0.8:1 |

| Blind Via Stack Spacing | â„0.3mm |

| Substrate Type | Rogers/Panasonic MEGTRON/FR-4 |

| Surface Treatment | ENIG/Immersive Silver/OSP |

| Tolerance Range | ±7% |

| Pressing Method | Vacuum Lamination |

| Dielectric Thickness Uniformity | â€Â±10% |

| Plating Process – Copper Thickness Uniformity | â€Â±5ÎŒm |

| Thermal Resistance | -55°C to +125°C |

| Thermal Shock Test Cycles | â„1000 Cycles |

| Routing Density | >20 pads/cmÂČ |

| Insulation Resistance | â„10MΩ |

| Reliability Testing | â„500MΩ |

How to Design a Multilayer HDI PCB?

Below is Multilayer HDI PCB design guide:

1. Modular Schematic Design with Precision

- Divide schematics into functional modules (power, signal processing, interfaces) using hierarchical design.

- Annotate exact component parameters (e.g., 0.4mm pitch BGA CPU) and solder pad dimensions to ensure logical correctness and manufacturability.

2. Advanced Stack-up Structure Planning

- Implement “signal-power-ground” alternating stack-up (e.g., 3-layer signal/3-layer power/3-layer ground).

- Place high-speed signals on outer layers (trace width/space â€4mil) with microvias (60-150ÎŒm laser-drilled) for layer-to-layer connections.

- Use buried vias for interlayer routing (e.g., 1-2 layer blind via + 3-4 layer buried via) and select materials like Rogers 5880 (Dk=2.2) for high-frequency scenarios or FR4-Tg180 for thermal stability.

3. Intelligent Component Placement with Thermal Optimization

- Center critical components (e.g., BGA-packaged CPU/FPGA) and position heat-generating devices near thermal via arrays.

- Use “escape routing” from BGA centers to minimize trace length. Implement grid-pattern thermal vias (â„150 vias/inchÂČ, 0.3mm diameter, 1.0mm spacing) and thermal interface materials (TIMs) with â„5W/m·K conductivity for efficient heat dissipation.

4. High-Speed Signal Routing with Strict Rules

- Enforce differential pair length matching (â€2mil difference) using serpentine routing for via delay compensation (bend radius â„3Ă trace width).

- Avoid crossing power splits to reduce crosstalk. Use stacked microvia structures (e.g., VIA1-2 + VIA2-3) for higher routing density and impedance continuity at connectors via “cross-connection + ground shield” (3Ă trace width spacing) with GND via pairs â€3mm apart.

5. Optimized Power/Ground Plane Design

- Segment multi-layer planes with decoupling capacitor networks (0201 package 10nF+100nF parallel) to achieve PDN impedance â€1Ω.

- Maintain continuous ground planes for low-impedance return paths (â€0.5mΩ) and use grid-pattern power planes to minimize eddy current losses.

6. Detailed Impedance & Signal Integrity Control

- Calculate trace width/spacing for target impedances (e.g., 6mil/7mil for 50Ω single-ended lines). At connector pads, implement “cross-connection + ground shield” with 3Ă trace width spacing.

- Add GND via pairs (â€3mm spacing) for transmission delay compensation and ensure via aspect ratios <0.8 to prevent stress fractures.

7. EMC & Reliability Enhancement with Fine Details

- Deploy 3-stage EMI filtering (source common-mode choke + board-level filter + cable ferrite) and 360° beryllium copper grounding springs at connectors (contact resistance <0.5mΩ).

- Apply ENIG/ENEPIG surface finish (â„3ÎŒm thickness) to prevent oxidation and use X-ray inspection for solder joint voids <10%.

8. Comprehensive Design Rule Verification

- Execute DRC checks (line width/space, via dimensions, impedance compliance) per IPC-6012 Class 3 standards.

- Collaborate with PCB manufacturers( like EBest Circuit (Best Technology)) for DFM analysis: confirm minimum trace/space 3mil, laser drilling accuracy ±10Όm, and process margins (etching tolerance ±0.5mil).

9. Standardized Manufacturing File Generation

- Output Gerber (RS-274X), drill (Excellon), solder mask, and BOM files with precise version control. Include assembly-specific annotations (e.g., polarity marks, fiducial placement) to streamline manufacturing.

10. Prototype Testing & Iterative Optimization

- Conduct electrical tests (flying probe for impedance continuity), thermal tests (infrared thermography for hotspot mapping), and mechanical tests (vibration/shock for reliability).

- Refine designs based on test results (e.g., topology adjustments, additional decoupling capacitors) and prepare for mass production with cost-optimized processes (resin-plugged vias) and quality control measures (AOI/X-ray inspection).

How Are Multilayer HDI PCBs Made?

Manufacturing processes for multilayer HDI PCBs:

1. Inner Layer Substrate Cutting & Pretreatment: Cut high-speed substrates (e.g., FR4, Rogers RO4350B) to design dimensions. Perform chemical cleaning to remove surface oxidation and contaminants, enhancing adhesion between copper layers and prepreg.

2. Inner Layer Pattern Transfer & Etching: Apply dry film, transfer circuit patterns via UV exposure and development. Etch unprotected copper using alkaline solution, followed by AOI (Automated Optical Inspection) to verify circuit integrity.

3. Brown Oxidation & Stack Alignment: Treat inner copper surfaces with brown oxidation to create nano-scale roughness. Stack inner layers, prepreg sheets, and copper foils in sequence, secured with rivets to prevent layer misalignment.

4. Vacuum Hot Pressing: Execute three-stage pressing (heating â main pressure â cooling). Gradually raise temperature at 2-3â/min to Tg point under 20-35kg/cmÂČ pressure, ensuring resin fills voids without cavities.

5. Laser Microvia Drilling: Use UV/COâ lasers to drill blind/buried vias with diameter â€0.15mm and depth tolerance ±0.05mm. Clean hole walls via plasma desmear to remove drilling debris.

6. Via Plating & Filling: Deposit copper electrolessly on via walls, then electroplate to 8-12ÎŒm thickness. Implement via-filling plating (e.g., copper paste) to eliminate voids in blind/buried vias, ensuring reliable electrical conduction.

7. Outer Layer Patterning & Etching: Repeat inner layer processes, apply dry film, expose, develop, and etch to form high-precision lines (width/spacing â€3mil). Strip tin to retain circuit traces and via walls.

8. Solder Mask Printing & Curing: Print UV-curable solder mask ink to protect non-soldering areas. Expose and develop to reveal pads and test points, ensuring soldering reliability.

9. Surface Finish Selection: Apply ENIG (electroless nickel immersion gold), OSP (organic solderability preservative), or ENEPIG (electroless nickel electroless palladium immersion gold) based on application requirements, enhancing corrosion resistance and high-frequency signal integrity.

10. Reliability Testing: Conduct thermal shock (-55â~125â cycles), humidity resistance (85â/85%RH), vibration (â„5G random), and electrical tests (flying probe/4-wire Kelvin testing) to meet IPC-6012 standards and client specifications.

11. CNC Profiling & V-Scoring: Shape boards via CNC routing, implement V-groove scoring for easy separation, ensuring edge dimensional accuracy â€Â±0.1mm without burrs or delamination.

12. Final Inspection & Packaging: Perform FQC (Final Quality Control) to check for defects, dimensional tolerances, and electrical performance. Vacuum-pack products to prevent moisture/oxidation during transport and storage.

Why Choose EBest Circuit (Best Technology) as HDI Multilayer PCB Manufacturer?

Reasons why choose us as HDI multilayer PCB manufacturer:

- Cost-Sensitive Design Solutions: Offer tiered pricing systems and material substitution options, optimizing trace width/spacing and substrate selection (e.g., FR-4/high-frequency material ratios) to reduce per-board costs by 10%-15% while ensuring performance, ideal for price-sensitive products like consumer electronics and IoT devices.

- 24-Hour Rapid Prototyping: Establish dedicated green channels for end-to-end tracking from design file receipt to sample delivery, supporting real-time online progress queries. For urgent needs like prototype validation or exhibition samples, achieve “same-day order placement, next-day shipment” to shorten iteration cycles to 1/3 of traditional timelines.

- 99.2% On-Time Delivery Rate: Leverage intelligent production scheduling systems and localized supply chain layouts, combined with dynamic inventory alerts, to ensure 10-15 day delivery for regular orders and 5-7 day delivery for urgent orders. Historical data confirms over 99.2% of orders meet agreed timelines, supporting clients’ production plans and market windows.

- Full-Batch Quality Inspection: Employ dual AOI+X-ray inspection systems to verify 20+ critical parameters including trace width/spacing, hole precision, and impedance matching, alongside electrical testing and thermal shock trials. All batches meet IPC-6012 standards with defect rates below 0.08%.

- International Authoritative Certification System: Hold ISO 9001, IATF 16949 (automotive), ISO 13485 (medical), and RoHS certifications, enabling global market compliance and reducing re-certification costs for clients targeting EU, North America, and Japan.

- 19 Years of HDI Technical Expertise: Accumulate over 5,000 HDI process case databases across 19 years, covering mobile, server, and medical sectors. The production error database proactively mitigates 90%+ potential issues, minimizing client trial costs.

- Free DFM Design Optimization: Provide end-to-end manufacturability analysis from schematics to Gerber files, including package compatibility checks, routing topology refinement, and impedance matching suggestions, to identify design flaws early, shorten manufacturing cycles, and lower redesign expenses.

- Multi-Tier Material Supply Chain: Strategic partnerships with suppliers like Rogers, Panasonic, and Shengyi ensure stable supply of high-frequency/high-speed materials and eco-friendly substrates, while centralized procurement reduces material costs for clients.

Our HDI PCB Capabilities

| Parameter | Capabilites |

| PCB Layers: | 1-32L |

| Copper Thickness: | Outer Layer:1oz~30oz; Inner Layer:0.5oz~30oz |

| Min Line Width/Line Space: | Normal: 4/4mil; HDI: 3/3mil |

| Min Hole Diameter: | Normal: 8mil; HDI: 4mil |

| PTH/NPTH Dia Tolerance: | PTH: ± 3mil; NPTH: ±2 mil |

| Surface Treatment: | ENIG(Au 4uââ),ENEPIG (Au 5uââ) Gold finger/Hard Gold Plating(Au 50uââ), HASL /LF HASL, OSP, Immersion Tin, Immersion Silver |

How to Get a Quote for HDI Multilayer PCB Project?

All files needs to be submitted to get a quote for HDI multilayer PCB:

- Gerber Files: Include circuit design data for all layers (e.g., signal layers, power layers, silkscreen layers), with annotations for stack-up sequence, impedance-controlled traces, blind/buried via positions, and special process requirements (e.g., via-in-pad, resin plugging).

- BOM (Bill of Materials): Detail component models, package dimensions (e.g., 0201/0402/QFN), supplier information, tolerance grades (e.g., ±1% resistors), and material codes, ensuring alignment with component positions in Gerber files.

- Technical Specifications: Specify layer count range (e.g., 8-24 layers), trace width/spacing (e.g., 40/40Όm), hole diameter precision (e.g., 0.1mm laser drilling), surface finish (e.g., ENIG/immersion silver), impedance control (e.g., 50±7Ω differential pairs), and substrate selection (e.g., FR-4/Rogers RO4350B).

- Special Process Requirements: Indicate needs for via-in-pad, back-drilling, stacked blind/buried vias, high-frequency material applications, thermal management solutions (e.g., thermal via arrays), or EMC protection measures (e.g., three-stage filtering).

- Quantity & Lead Time Requirements: Provide batch order quantities (e.g., 500 pieces/batch), urgent order needs (e.g., 24-hour prototyping), standard lead time expectations (e.g., 10-15 days), and packaging specifications (e.g., vacuum packaging + anti-static bags).

- Quality Certification & Testing Needs: List applicable international standards (e.g., IPC-6012, ISO 9001), specific test items (e.g., flying probe impedance testing, â„1000 thermal shock cycles), and acceptable defect rate thresholds (e.g., â€0.08%).

- Design File Version & Revision History: Include the latest design file version number, revision history, and design change notes to ensure manufacturing accuracy and timeline.

Welcome to contact us if you have any request for HDI multilayer PCB board: sales@bestpcbs.com.

PCB Circuit Board Manufacturers, PCB Factory, No MOQ

September 18th, 2025As a PCB Circuit Board Manufacturers, EBest Circuit (Best Technology) is committed to becoming your partner for high-precision PCBs, providing various types of circuit boards.

Are you looking for reliable PCB circuit board manufacturers? Do you have the following questions?

- What industry certifications does your factory have?

- How many layers of circuit boards can you produce?

- What types of PCBs do you specialize in?

- How do you ensure PCB quality?

EBest Circuit (Best Technology) is your best choice and can solve your concerns~

- We are ISO 9001, IATF 16949, and UL certified. We strictly adhere to IPC standards for production and inspection, ensuring our quality system meets international standards.

- We can consistently produce multi-layer boards with 1-32 layers, with a minimum line/space accuracy of 2/2 mil (50ÎŒm) in mass production, meeting most high-precision design requirements.

- We specialize in high-reliability PCB manufacturing, with extensive experience and technical advantages in high-frequency, high-speed boards, HDI boards, rigid-flex boards, and metal substrates (heat-dissipating aluminum substrates).

- We utilize comprehensive inspection equipment such as AOI (Automated Optical Inspection), flying probe testing, and X-ray inspection, combined with strict process control (IPQC/IQC) to ensure the quality and reliability of every PCB.

If you have any PCB needs, please contact us: sales@bestpcbs.com

How to design a PCB circuit board?

BEST Technology engineers first define the board’s functionality, power requirements, and size. A simple prototype or schematic follows. Good planning avoids costly rework later.

Next, designers use electronic design automation software such as Altium or KiCad. These tools map every trace, pad, and via. Each copper path must handle the right current while avoiding interference. Shorter paths mean less signal loss.

High-speed signals should travel straight and short. Sensitive parts like sensors stay away from noisy circuits.

After layout, we create Gerber files. Gerber files show each layer, drill hole, and mask. A quick design review catches errors before fabrication.

Collaboration with experienced circuit board manufacturing companies helps here. BEST Technology engineers will provide more optimal cabling or stacking solutions. This feedback can save time and reduce risks.

How to make PCB circuit board?

Once design files pass review, production begins. First comes imaging. The factory prints the circuit pattern onto copper-clad laminate using a photoresist film. Light hardens the image, and unwanted copper is etched away. The result is a clean network of copper traces.

Drilling follows. Precision machines create micro-holes for vias and through-hole parts. Laser drilling handles very small features common in todayâs compact devices.

Plating adds a thin copper layer inside holes, creating reliable connections between layers. For multi-layer boards, technicians press and heat inner cores together, bonding them with resin.

Next is solder mask. This green (or sometimes blue, red, or black) coating protects copper and keeps solder only where needed. Silk-screening then prints component labels and logos.

Electrical testing is critical. Automated probes check continuity and isolation. Any shorts or open circuits trigger rework.

Finally, the panel is cut into individual boards. Each product is cleaned, packaged, and ready to be shipped to the assembly line or directly to you.

Which PCB manufacturing steps matter most?

Every step counts, but three stand out.

- Imaging and Etching: Accurate imaging ensures the circuit matches design specs.

- Drilling and Plating: Proper plating guarantees strong inter-layer connections.

- Testing: Rigorous electrical tests catch defects before assembly.

BEST Technology uses advanced equipment and strict quality controls during these critical stages. Automated optical inspection, clean rooms, and real-time monitoring protect consistency.

What is in a circuit board components list?

A circuit board components list, often called a bill of materials (BOM), details everything needed for assembly. It includes:

- Integrated Circuits (ICs): Microcontrollers, processors, memory chips.

- Passive Components: Resistors, capacitors, and inductors that manage current and voltage.

- Connectors: USB, HDMI, headers, and terminals to link with the outside world.

- Discrete Semiconductors: Diodes, transistors, MOSFETs.

- Special Parts: Sensors, antennas, or displays unique to your design.

Each item specifies part numbers, tolerances, and approved suppliers. A clean BOM speeds sourcing and lowers cost.

BEST Technology, as an experienced printed circuit board PCB manufacturers, usually helps to complete the list and recommend parts with a stable supply and better prices.

Which materials do PCB factories use?

The foundation of a PCB is the laminate. FR-4, a fiberglass-epoxy composite, remains the industry standard. It balances strength, thermal resistance, and cost.

For high-frequency or high-speed boards, BEST Technology’s factories will use materials such as Rogers or polyimide. These offer lower dielectric loss and better heat performance.

Copper foil forms the conductive layers. Thickness ranges from 0.5 oz to 3 oz per square foot depending on current needs.

Solder mask is usually epoxy-based for durability. Surface finishes like ENIG (Electroless Nickel Immersion Gold), HASL (Hot Air Solder Leveling), or OSP (Organic Solderability Preservative) protect pads from oxidation and improve soldering.

What drives PCB manufacturing cost and speed?

Several factors influence cost and lead time.

- Layer Count: More layers mean more drilling, lamination, and testing.

- Board Size and Quantity: Larger or thicker boards use more material and require longer machine time.

- Trace Width and Spacing: Fine pitch designs demand tighter process control and raise cost.

- Surface Finish: Gold plating and advanced coatings cost more than simple HASL.

- Testing Level: Flying-probe or functional tests add time but ensure reliability.

To speed up production, BEST Technology, a top PCB manufacturer, uses automated production lines and intelligent scheduling. We also offer a no-minimum-order option, allowing for rapid prototyping without waiting for volume orders.

What certifications should circuit board manufacturing companies hold?

Quality certifications prove a factory follows global standards.

- ISO 9001: Shows strong quality management across the entire process.

- UL Certification: Ensures boards meet safety standards for flammability.

- RoHS and REACH Compliance: Confirms materials are free of restricted hazardous substances.

- IATF 16949: Important for automotive electronics.

- ISO 13485: Required for medical device PCBs.

Working with certified circuit board manufacturers protects your product and brand reputation. We hold relevant quality certifications that validated our commitment to provide high quality products. These certificationsact as a guarantee of product excellence, ensuring customers and partners a good quality assurance practices.

How to pick the best PCB circuit board manufacturer?

Selecting the right partner means balancing technology, service, and flexibility.

Start with capability. Does the factory handle your board size, layer count, and finish? Do they support rigid-flex or HDI if you need them?

- BEST Technology begin to As a printed circuit board (PCB) vendor in Asia, we are dedicated to be your best partner of advance, high-precision printed circuit boards, such as heavy copper boards, mixed layers, high TG, HDI, high frequency (Rogers, Taconic), impedance controlled board, Metal Core PCB (MCPCB) such as Aluminum PCB, Copper PCB, and so on.

Established PCB manufacturer teams know how to solve complex issues and scale from prototype to mass production.