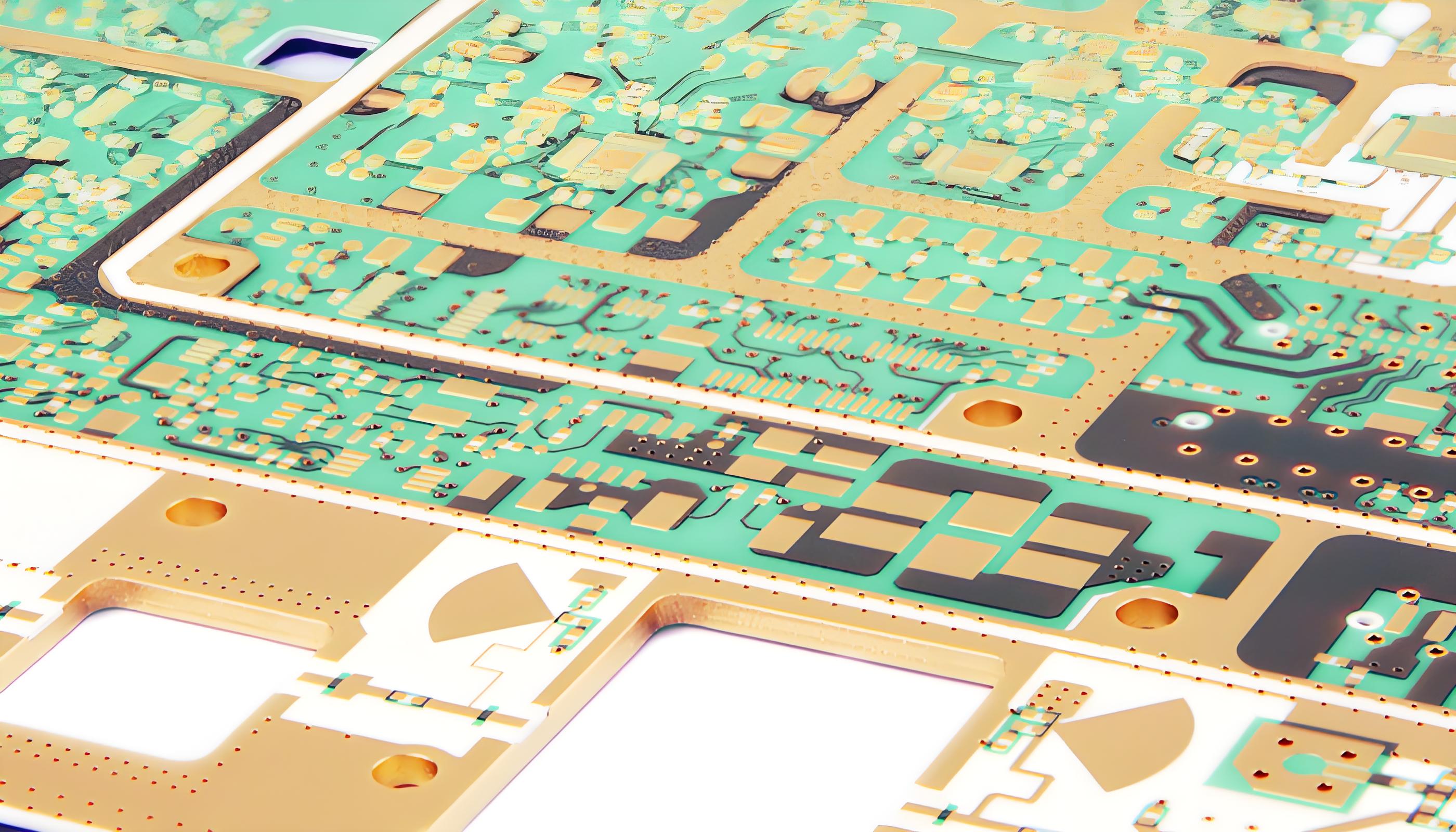

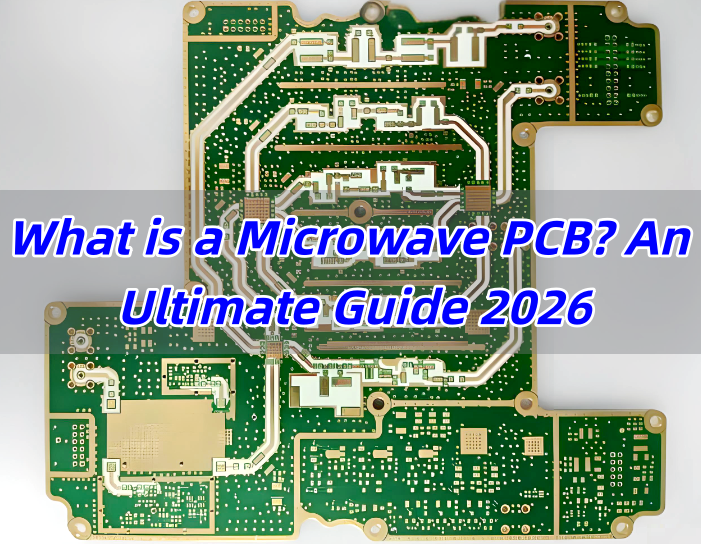

A microwave PCB handles signals that run at very high frequencies, and these boards support systems that need clean, stable performance. You will find a microwave PCB in equipment such as radar modules, satellite links, high-speed wireless platforms, and precision test devices. As industries push toward higher data rates and smaller RF systems, the need for dependable microwave boards grows quickly.

Today, many engineers search for rf microwave PCB options that keep loss low and impedance steady. Others look for complete rf & microwave PCB solutions that simplify material choice, stack-up planning, and manufacturing. If you’re evaluating RF microwave PCB materials or sourcing RF & microwave PCB solutions, this article will give you a complete understanding.

What Is a Microwave PCB?

A microwave PCB is a printed circuit board designed to operate at extremely high frequencies, typically:

- Microwave band: 300 MHz – 30 GHz

- Millimeter-wave (mmWave): 30 – 100+ GHz

At these frequencies, PCB traces behave like transmission lines, and even tiny layout variations can impact signal loss, phase accuracy, antenna performance, and overall system reliability.

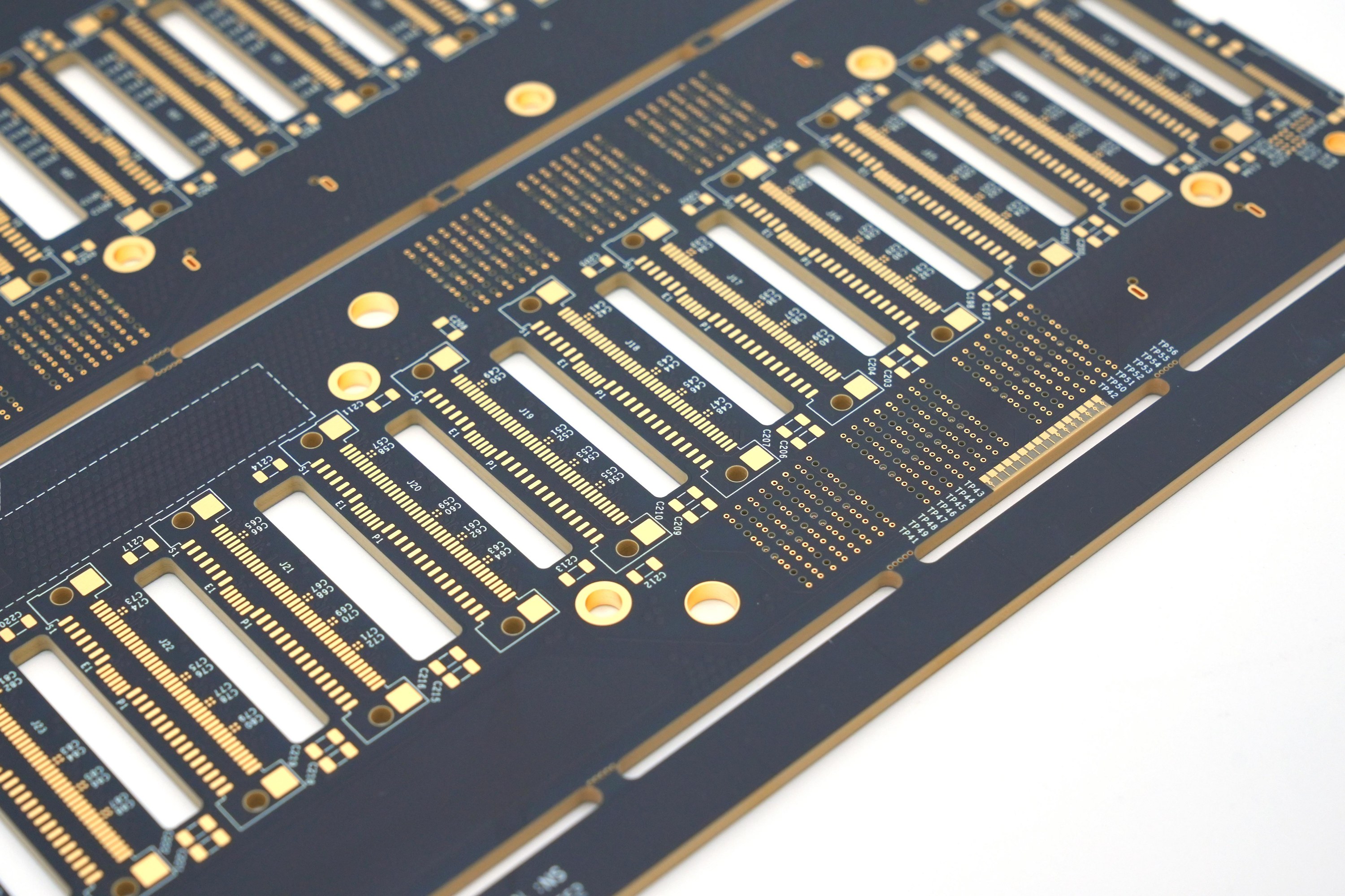

Microwave PCBs are commonly used in radar systems, satellite communication, aerospace navigation, and 5G mmWave modules. Compared with standard RF boards, microwave PCBs demand more precise materials, controlled impedance, and stricter fabrication tolerances.

What Materials Are Used for Microwave PCBs?

Material choice is one of the most important decisions in microwave design. Standard FR-4 cannot support microwave frequencies due to high loss and unstable dielectric properties. Instead, microwave PCBs use advanced materials engineered for low loss and tight dielectric tolerances.

Here are the materials most commonly used:

| Material Type | Examples | Features | Best Use Case |

| PTFE (Teflon) | RT/duroid 5880, Taconic TLY | Extremely low loss, stable Dk, best for high GHz | Radar, mmWave, satellites |

| Hydrocarbon Ceramics | Rogers RO4350B, RO4003C | Low loss, easy to manufacture, cost-effective | 1–20 GHz microwave circuits |

| Ceramic-Filled PTFE | Rogers RO3006/3010 | Ultra-stable Dk, low thermal expansion | High-power microwave and phased arrays |

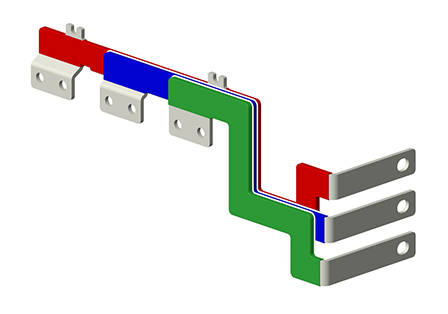

| Hybrid Stackups | FR4 + Rogers | Performance + lower cost | Mixed-signal RF/microwave designs |

The best material depends on target frequency, environmental exposure, and mechanical requirements. Each laminate affects loss, phase stability, and long-term reliability.

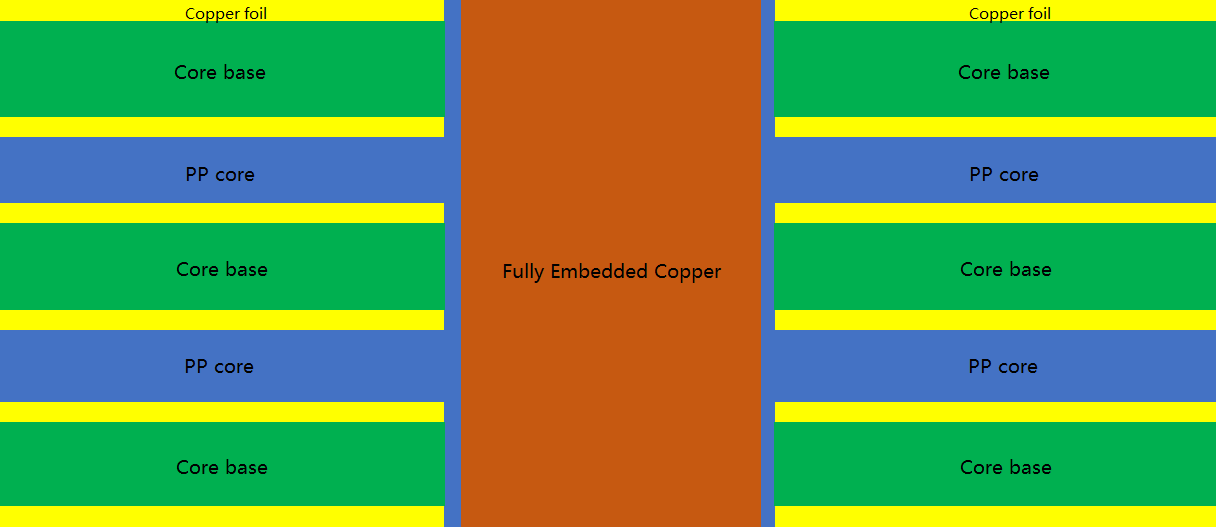

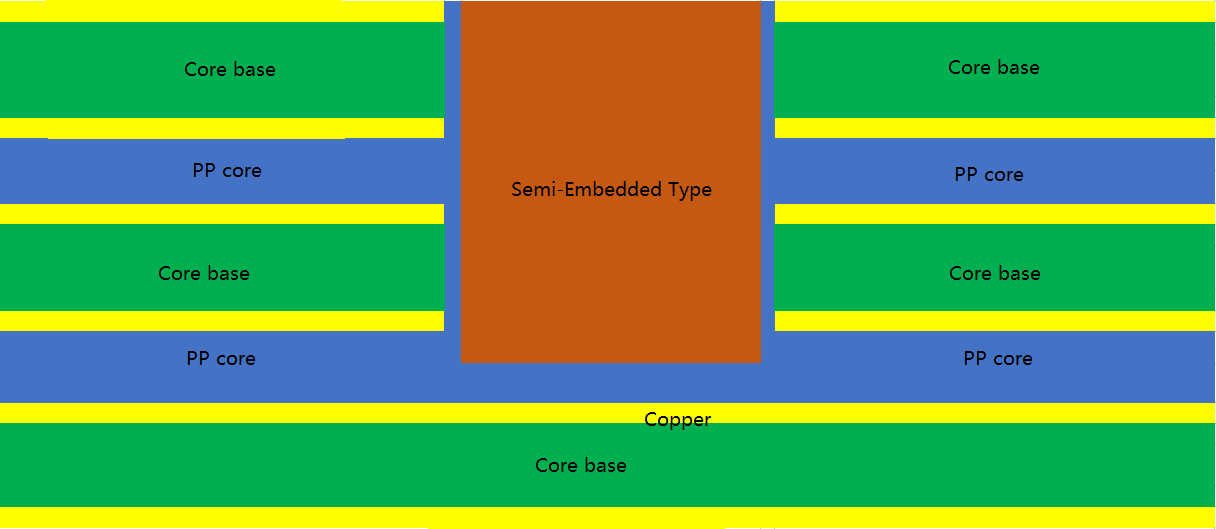

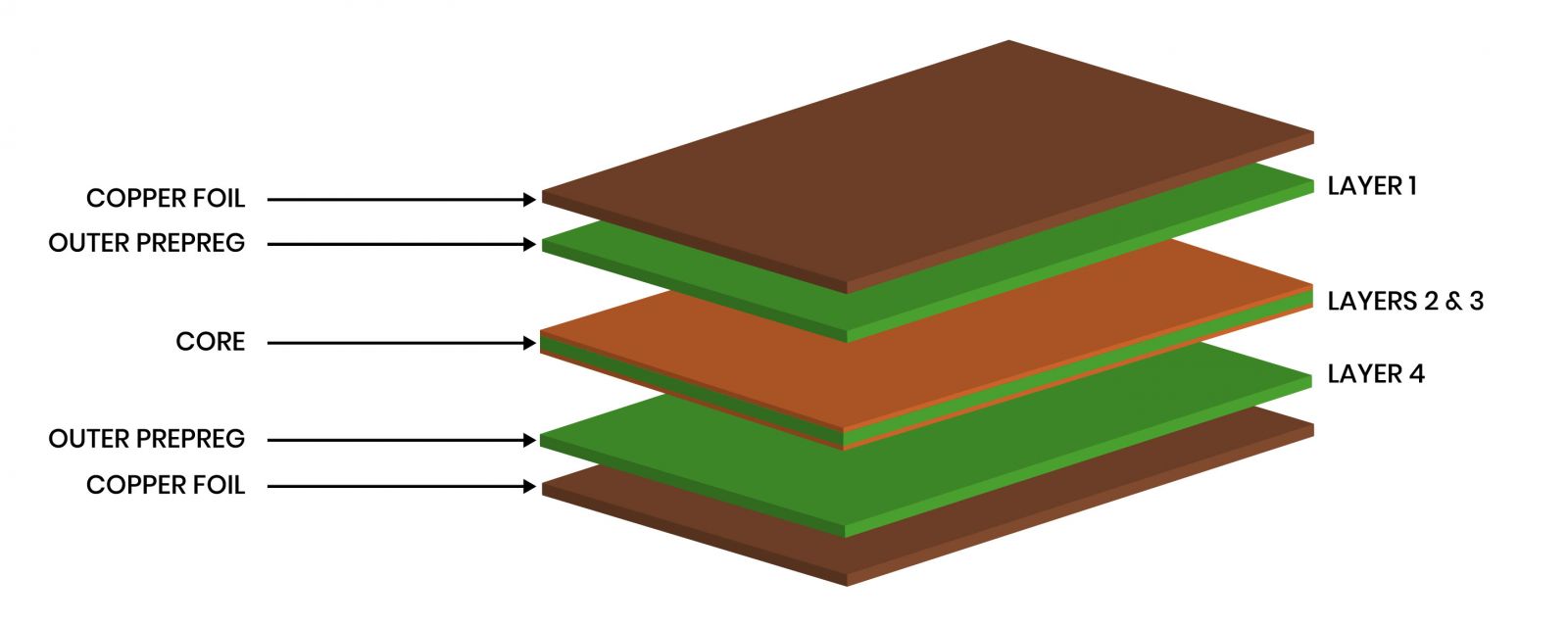

Key Design Rules and Layout for Microwave PCB Design

Designing a microwave PCB is very different from routing a standard digital or low-frequency board. At microwave frequencies, each copper trace behaves like a transmission line. Small changes in width, dielectric height, copper roughness, or via structure can shift impedance and alter the entire RF chain. Because of that, layout and stack-up design must follow strict engineering rules to keep signal quality stable.

Below are the core principles used by RF engineers when building reliable microwave layouts.

1. Maintain Tight Impedance Control

Stable impedance is the foundation of microwave design. Even small dimensional changes can introduce reflections or distort the waveform.

Key requirements:

- Define target impedance early (commonly 50Ω or 75Ω).

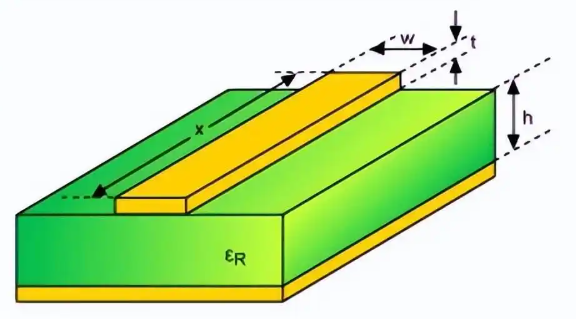

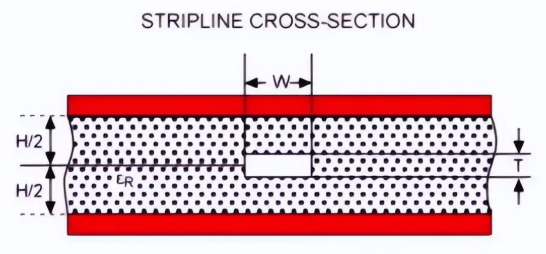

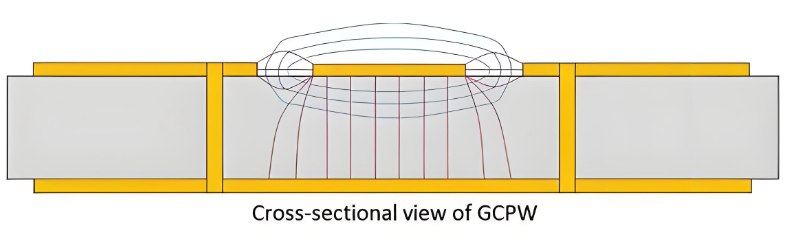

- Choose the correct structure: microstrip, stripline, or grounded coplanar waveguide (GCPW).

- Keep trace width consistent along the entire path.

- Maintain stable dielectric thickness and copper thickness.

- Use field-solver tools (ADS, HFSS, CST, Polar SI, or Altium impedance calculator).

- Keep differential pairs phase-matched if used in RF mixers or high-frequency paths.

GCPW is widely used for microwave PCB design because it offers strong field confinement and supports compact layouts.

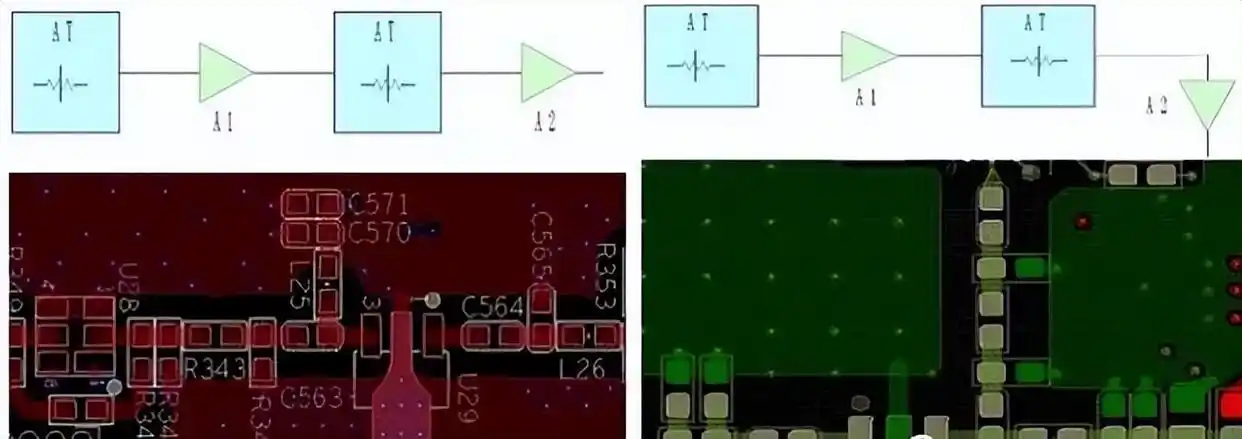

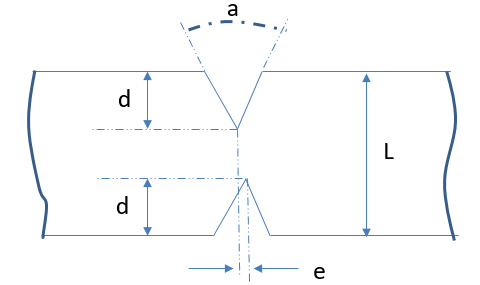

2. Use Smooth Routing Instead of Sharp Corners

High-frequency energy does not like sudden changes. Sharp corners cause impedance shifts and increase local reflections.

Preferred routing practices:

- Avoid 90° turns.

- Use gradual curves (arc routing) for cleaner field transitions.

- Use mitered 45° bends if space is limited.

- Keep sensitive paths straight and short whenever possible.

Smooth routing helps preserve phase stability and reduces insertion loss.

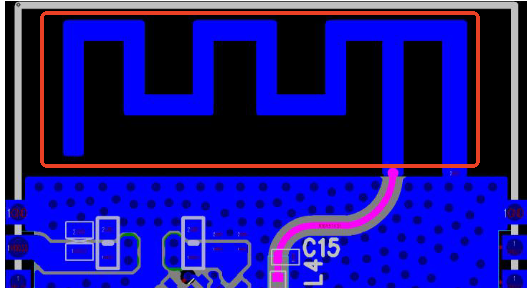

3. Keep the Ground Plane Continuous

A microwave signal needs a clean, uninterrupted return path. Gaps in the ground plane cause radiation, coupling, and impedance drift.

Ground plane guidelines:

- Maintain a solid ground layer directly under RF traces.

- Avoid splits, voids, or cutouts beneath the signal path.

- Do not place digital return paths through RF areas.

- Add stitching vias around RF traces to create a “via fence” barrier.

A well-designed ground structure stabilizes the electromagnetic field and reduces unwanted emissions.

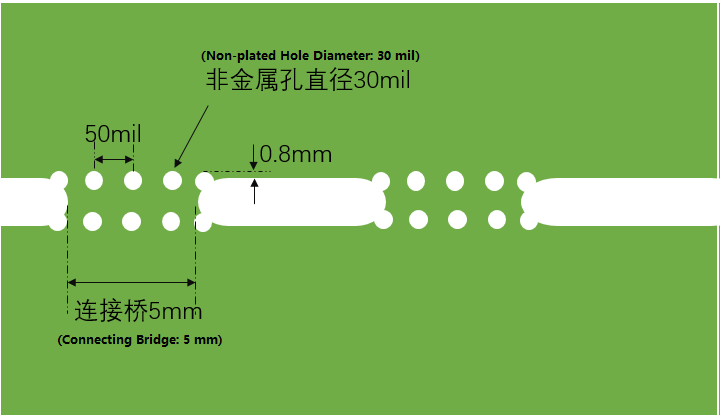

4. Manage Vias Carefully

A via is not just a hole at microwave frequencies—it’s a small inductor. Too much via inductance can degrade signal quality.

Best practices for vias:

- Avoid unnecessary layer jumps.

- Use multiple parallel vias to lower effective inductance.

- Keep via barrels short when possible.

- Add grounding vias around pads and connectors to improve shielding.

- Avoid routing RF traces directly over via fields or ground voids.

Good via strategy can significantly improve stability in PA, LNA, and filter sections.

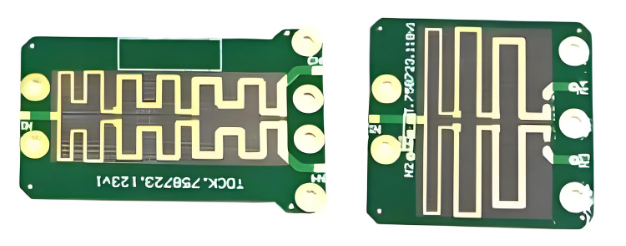

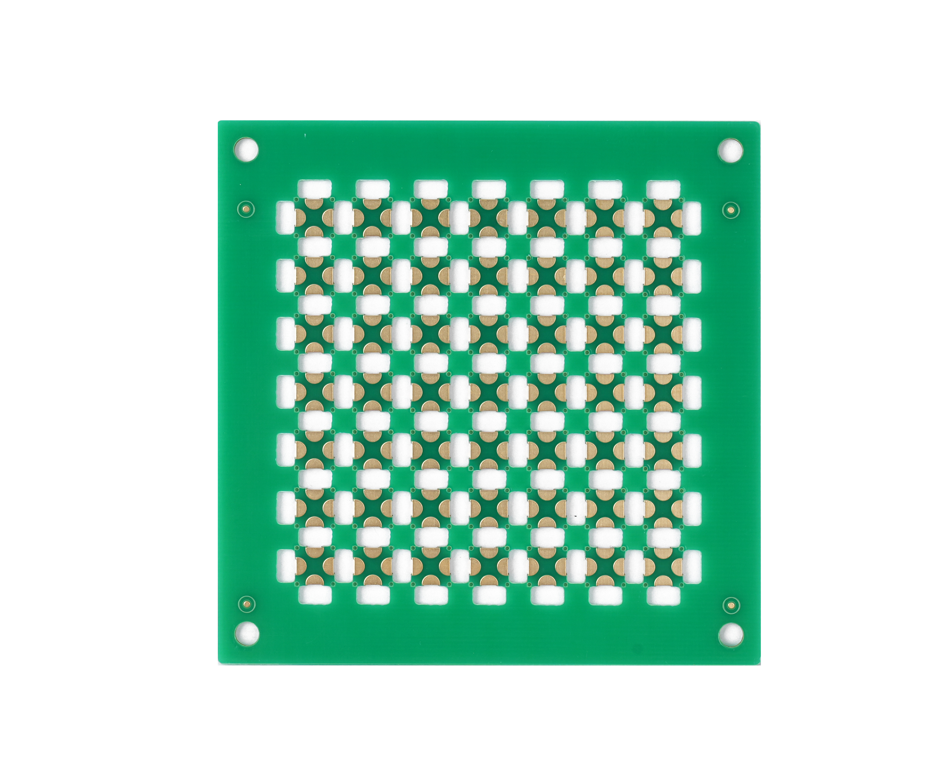

5. Select the Right Transmission Line Structure

Different RF paths require different structures depending on frequency, isolation, and mechanical constraints.

Common options:

- Microstrip – simple, ideal for top-layer routing.

- Stripline – fully shielded, good for noise-sensitive circuits.

- Grounded coplanar waveguide (GCPW) – excellent isolation, compact layout, and easy impedance tuning.

- Wide microstrip – lower conductor loss, suitable for power amplifiers.

GCPW has become the most popular for microwave work due to its predictable behavior and high routing density.

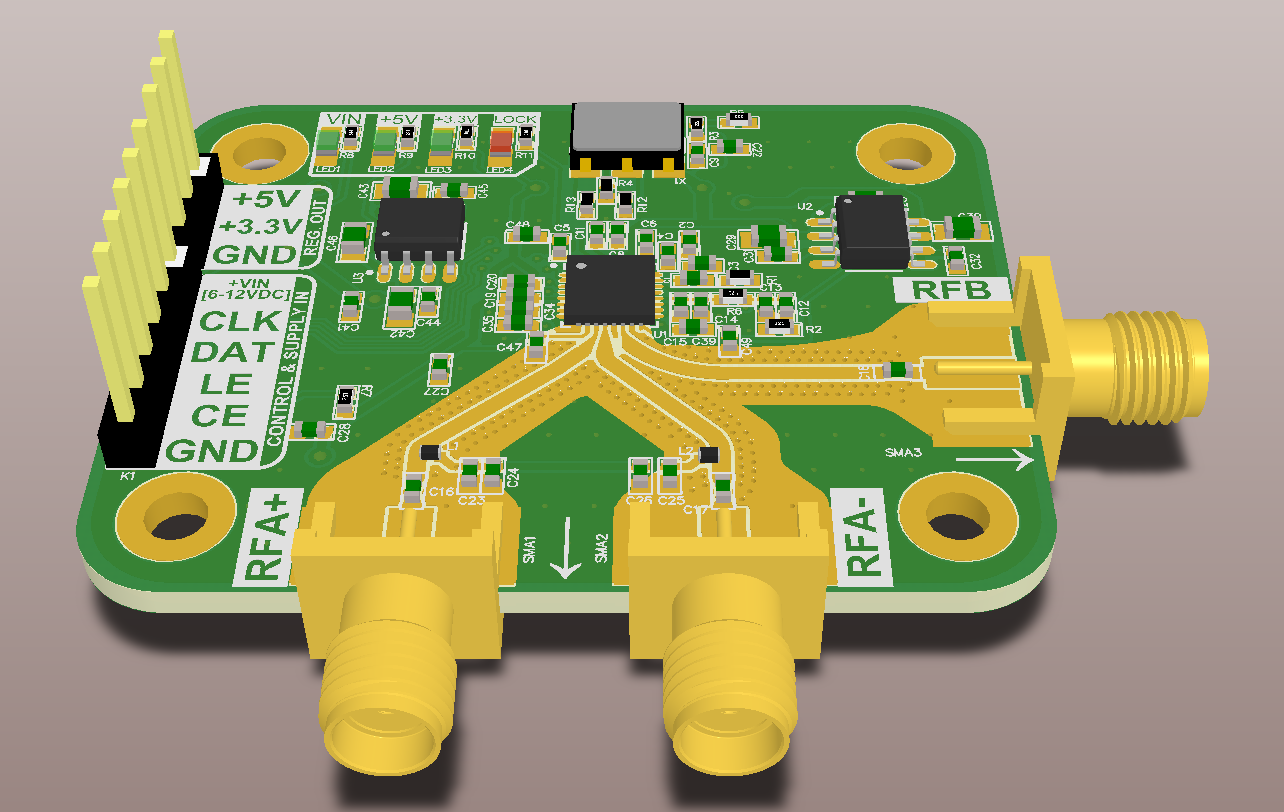

6. Align Components with the Signal Flow

Component orientation affects load matching and return loss.

Component placement guidelines:

- Place RF blocks (filter, LNA, PA, mixer) in the order of the signal chain.

- Keep matching networks close to device pins.

- Avoid unnecessary gaps between RF parts.

- Place RF connectors, such as SMA or SMP, near the board edge for clean transitions.

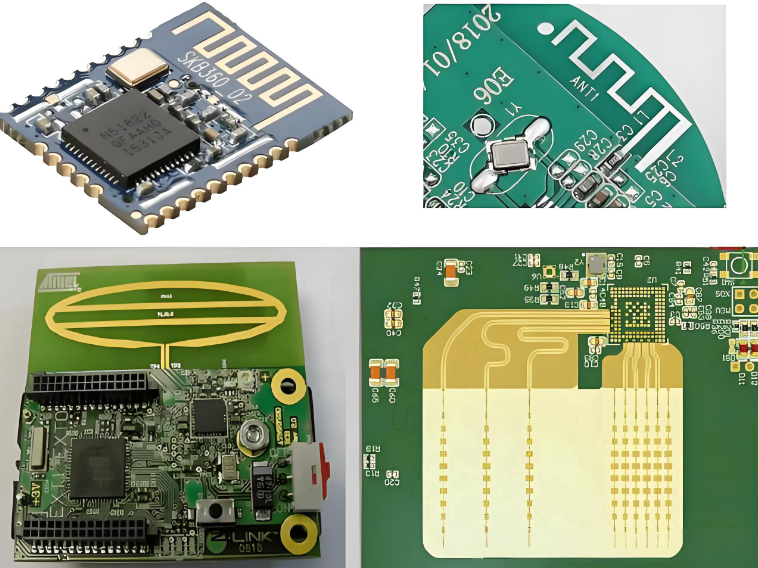

When Should You Choose Microwave PCB vs. RF PCB?

Many engineers compare microwave PCBs with standard RF boards because both handle high-frequency signals. But the decision depends on frequency, performance targets, and loss tolerance.

| Technology | Frequency Range | Best For |

| RF PCB | Up to ~6 GHz | Bluetooth, Wi-Fi, sub-6 GHz communication |

| Microwave PCB | 6–100+ GHz | 5G mmWave, radar, satellite, high-precision sensing |

Choose an RF PCB when:

- Frequencies are below 6 GHz

- Cost is a major concern

- FR-4 or mixed-material stackups are acceptable

Choose a Microwave PCB when:

- You operate above 6 GHz

- You require ultra-low loss

- Your system needs stable phase and predictable impedance

- Applications involve radar, mmWave, or satellite links

In short, microwave PCBs suit high-precision projects where even small layout or material changes can affect real performance. They are the preferred choice for radar, satellite links, and advanced communications.

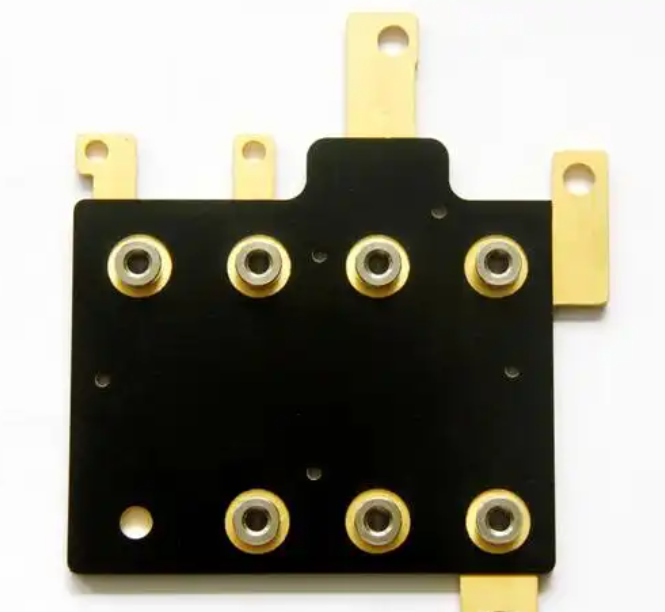

Microwave PCBs Applications & Industries

Microwave PCBs appear in many sectors because they support stable, low-loss transmission for sensitive circuits. You’ll often see them in systems that require fast data, long-range signal paths, or precise sensing.

Common applications include:

- 5G and 6G wireless infrastructure

- Satellite communication systems (SATCOM)

- Automotive radar (24 GHz, 77 GHz)

- Military and commercial radar platforms

- Microwave filters, couplers, and antennas

- High-frequency power amplifiers

- Navigation and guidance systems

- Medical imaging devices such as MRI coils

- Instrumentation and RF test equipment

- Industrial microwave heating and sensing

These industries rely on microwave boards because small performance shifts can affect overall system behavior. Stable materials and predictable routing keep these systems accurate and responsive.

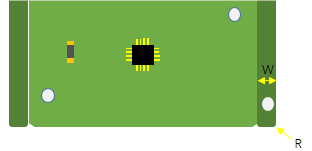

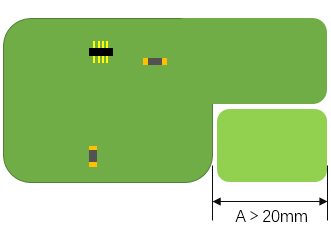

Does Size of a Microwave PCB Affect Its Application?

Yes, board size can influence performance because microwave signals respond to physical dimensions. At these frequencies, even a few millimeters can change how energy travels.

Board size affects:

- Impedance stability:Longer traces add more loss and potential phase distortion.

- Resonance behavior:Larger boards can introduce unwanted resonances.

- Shielding structure:Compact layouts may need tighter via fences.

- Thermal changes:Bigger boards may expand more under heat, shifting dielectric spacing.

- Antenna performance:Antenna length and board shape affect radiation patterns.

Small boards require sharper tolerance control. Large boards demand stronger handling of expansion and material stability. The ideal size depends on whether the circuit is an antenna, filter, amplifier, or sensor.

How to Tell If a Microwave Control Board Is Bad?

Many users ask this because microwave ovens and industrial microwave systems depend on small control boards. Failures are often easy to spot once you know what to check. Common signs of a bad microwave control board include:

- No power, no response, or blank display

- Buttons that fail to react

- Burning smell or visible damage

- Unusual noises or sparking

- Microwave stops heating while lights and fan still work

- Random behavior such as auto-starting or shutting off

- Relays that click repeatedly without function

If above signs occur, you can perform below visual checks safely:

- Scorch marks or dark spots

- Swollen capacitors

- Cracked solder joints

- Damaged connectors

- Loose ribbon cables

These symptoms point to circuitry or relay failure. For home microwaves, technicians often replace the entire board rather than repair individual components.

How Much Does It Cost to Repair a Microwave Circuit Board?

Repair cost depends on equipment type, part availability, and labor requirements.

Typical consumer microwave repair ranges:

- Basic repair: USD 80–120

- Control board replacement: USD 120–250

- High-end or built-in models: USD 180–350

Industrial microwave equipment repair ranges:

- Board-level component repair: USD 250–600

- Full board replacement: USD 400–1,200+ depending on complexity

Factors that influence cost include:

- Part scarcity

- Board size and layer count

- Number of relays, sensors, or high-voltage circuits

- Whether the board is conformal-coated

- Testing and calibration requirements

Consumer microwaves are often cheaper to replace than repair, but industrial microwave systems usually justify board-level repair. EBest Circuit (Best Technology) can repair the microwave circuit board for free if your PCB are ordered from our company.

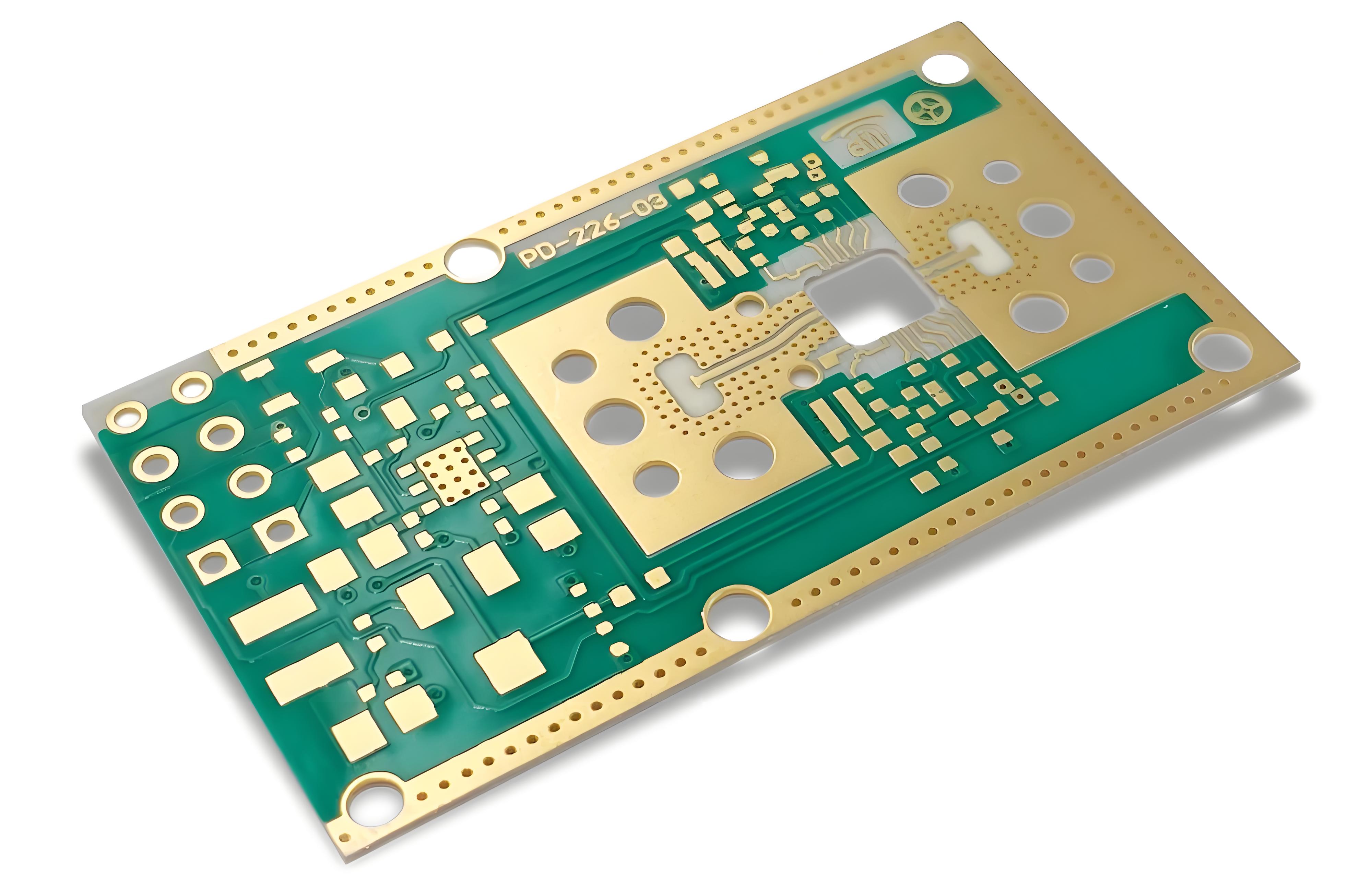

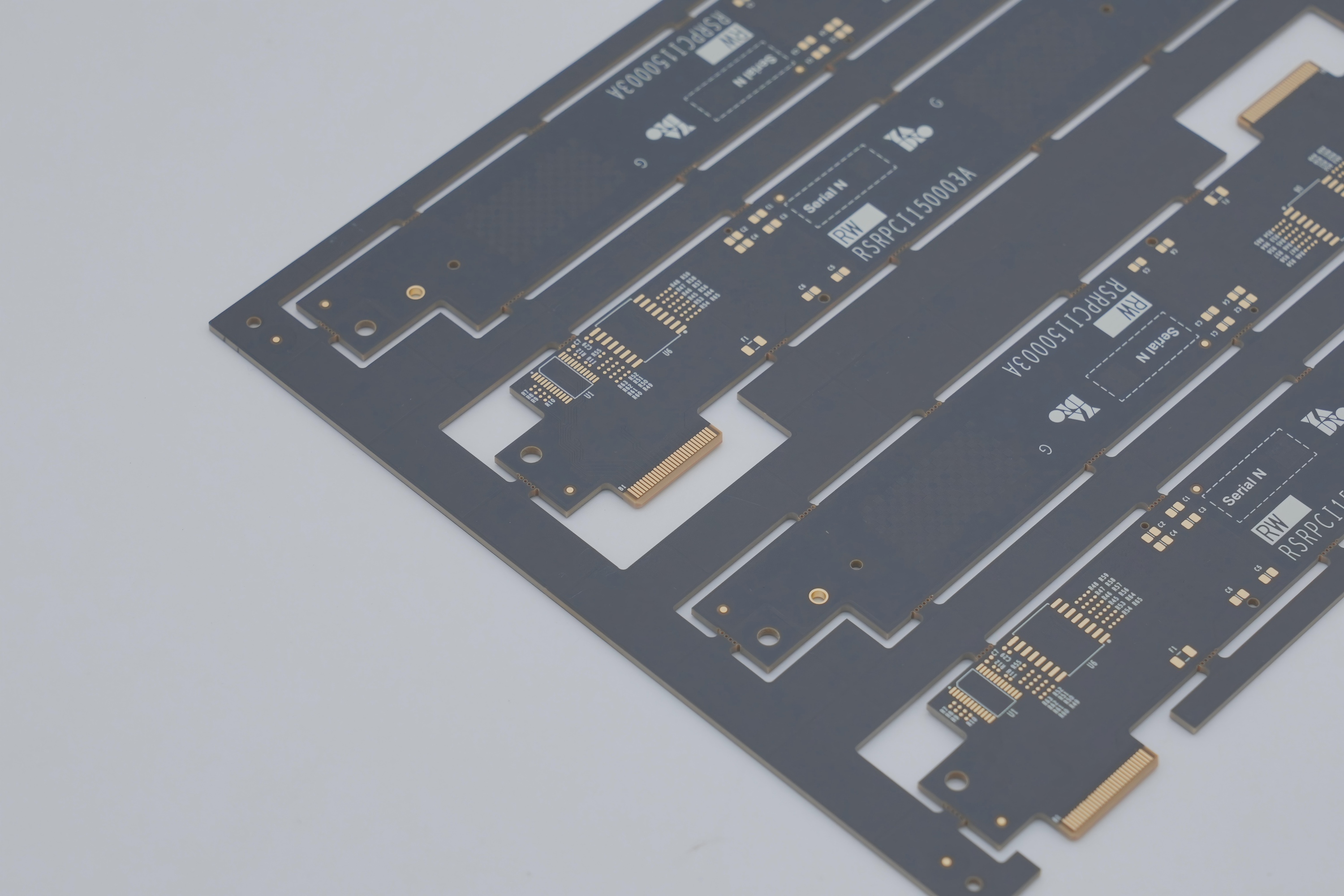

Where to Get RF Microwave PCB Boards with UL/CE Certification?

Many companies need microwave PCBs that meet safety and compliance standards, especially when the final product enters global markets. UL and CE certifications help confirm material reliability and safety. When sourcing certified microwave boards, a good supplier should provide:

- UL-certified laminates (Rogers, Taconic, Arlon, Panasonic)

- CE-compliant production and testing

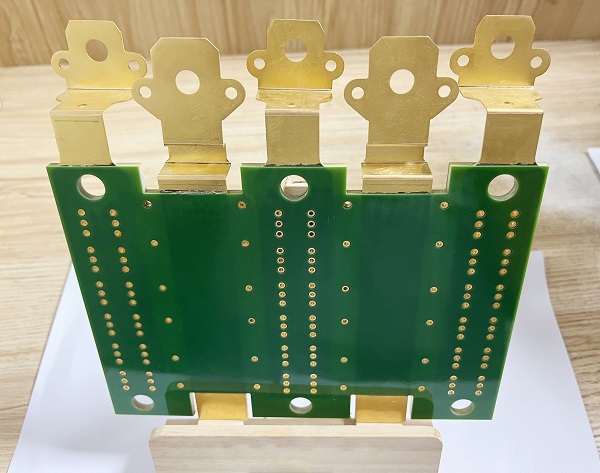

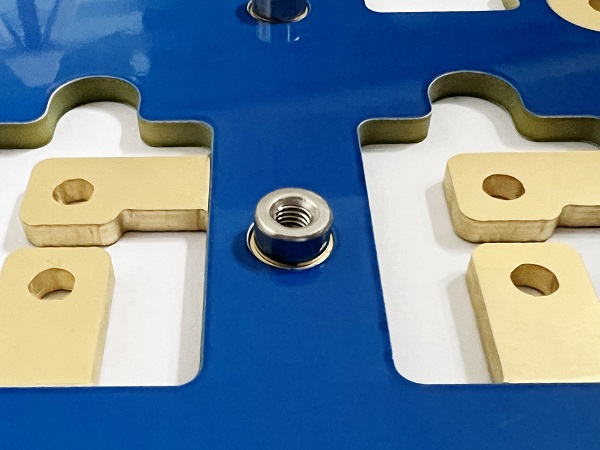

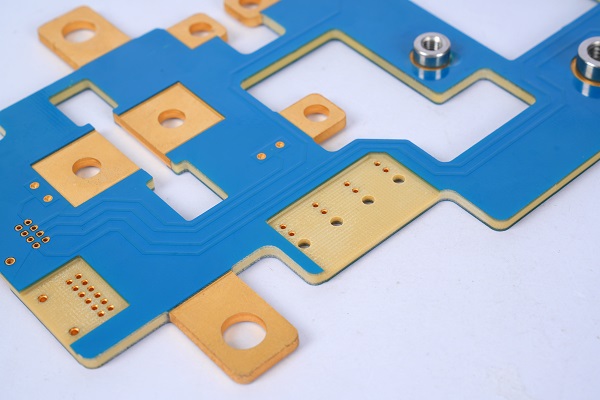

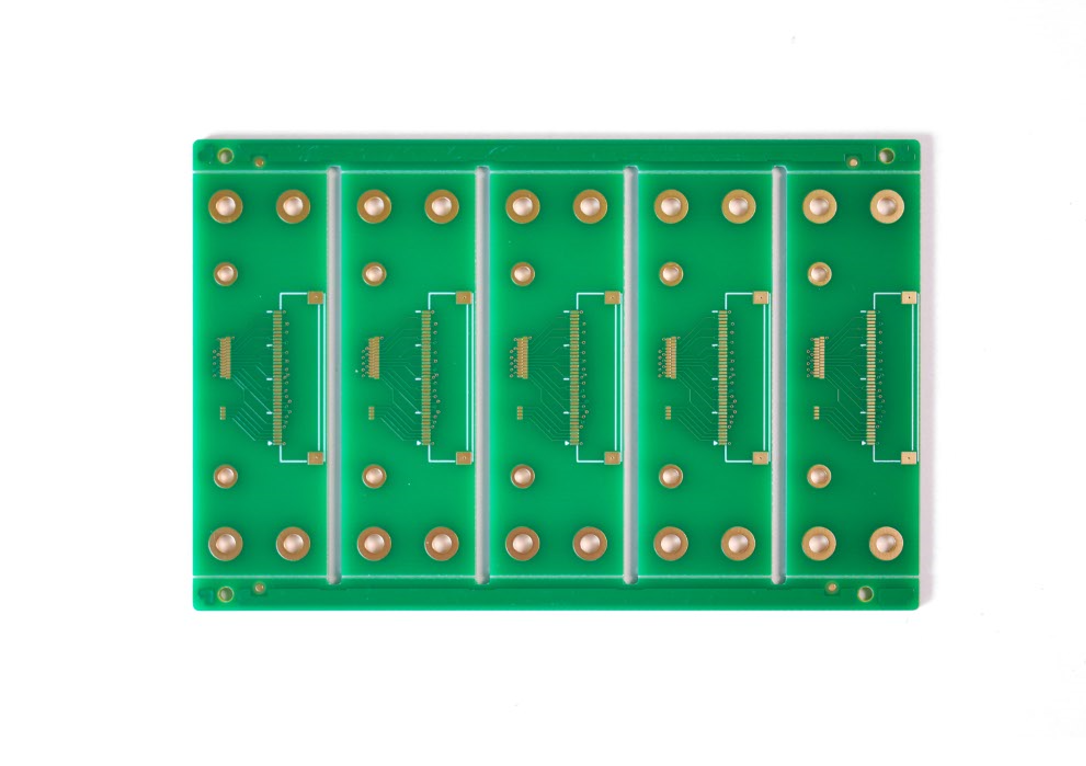

- Rogers/PTFE/ceramic microwave PCB fabrication

- Controlled impedance testing reports

- Hybrid laminations and multi-layer microwave stackups

- RF & microwave PCB solutions for 1–100 GHz

EBest Circuit (Best Technology) is a strong option for RF and microwave PCB production because the company offers:

- UL-approved material systems

- Stable performance with PTFE, Rogers, and ceramic-filled substrates

- Tight impedance control for microwave designs

- Complete CE-related documentation support

- Strong engineering assistance during stack-up and DFM review

- Consistent production with IPC standards

- Fast global delivery for prototypes and batches

If you are preparing a new microwave PCB or RF hardware program, welcome to contact us at sales@bestpcbs.com, our team is 24/7 hours online for you!