Looking for a reliable PCB manufacturer Greece? This blog will introduce the pain points of PCB manufacturer Greece and how EBest Circuit(Best Technology) solve these problems.

As the Greek electronics industry continues to grow, the demand for high-quality PCB manufacturing services is steadily increasing. For businesses looking for a reliable partner, understanding the top 10 PCB manufacturer Greece is crucial for making informed decisions. This article aims to provide a comprehensive overview of the top 10 PCB manufacturer in Greece, analyze the main pain points in local PCB design and assembly processes, and introduce EBest Circuit(Best TechnologyÔľČ, a professional PCB manufacturing partner serving the Greek market, and how it addresses these challenges with tailored solutions. Whether you are looking for a PCB design Greece, PCB Assembly Greece or Greece PCB manufacturing services, or services, this article will provide you with a practical procurement guide.

Top 10 PCB Manufacturer Greece

| Company Name | Main Business | Core Advantages | Process Capability | Lead Time |

| EBest Circuit Co., Limited (Best Technology Circuit Co., Limited) | PCB manufacturing, PCB assembly, PCB design, DFM analysis | 19 years of experience, multiple international certifications, cost-competitive, 24-hour quick prototyping | HDI PCB, rigid PCB, flexible PCB, rigid-flex PCB, multi-layer PCB (up to 40 layers), full inspection for mass production | 24-hour quick prototyping, 3-7 days for small batches, 7-15 days for mass production, 99.2% on-time delivery rate |

| Elca Electronics S.A. | PCB manufacturing, electronic component assembly, custom electronics manufacturing | Localized service, compliance with EU CE standards, strong quality control for industrial electronics | Rigid PCB (up to 16 layers), through-hole assembly, surface mount technology (SMT) assembly | 5-10 days for prototyping, 10-20 days for mass production |

| Microtech Electronics Greece | PCB design, PCB manufacturing, PCBA testing services | Specialized in high-precision PCB solutions, professional testing support, EU environmental standard compliance | HDI PCB, multi-layer PCB (up to 20 layers), PCB testing (AOI, X-ray) | 7-12 days for prototyping, 12-18 days for mass production |

| Greek Electronic Manufacturing Ltd. | Standard and custom PCB manufacturing, PCB assembly, small-batch production | Flexible order support, quick response to local demands, transparent pricing | Rigid PCB (up to 12 layers), SMT assembly, through-hole assembly | 3-8 days for prototyping, 8-15 days for mass production |

| Eurocircuits Greece Branch | PCB manufacturing, PCB assembly, electronic manufacturing services (EMS) | Global supply chain resources, standardized production processes, compliance with RoHS/REACH | Rigid-flex PCB, multi-layer PCB (up to 24 layers), SMT/through-hole hybrid assembly | 6-10 days for prototyping, 10-18 days for mass production |

Pain Points of PCB Manufacturer Greece

- Insufficient capability in high-precision PCB assembly: Struggles to meet the assembly requirements of high-density, miniaturized electronic components, leading to low yield rates in complex projects.‚Äč

- Long lead times for specialized PCB prototyping: Lack of advanced equipment for quick prototyping, resulting in delayed project progress and missed market opportunities.‚Äč

- Inadequate integration of PCB design and manufacturability: Design schemes often fail to align with production processes, leading to repeated modifications and increased production costs.‚Äč

- High cost of mass production: Limited production scale leads to high unit costs, reducing the competitiveness of end products in the market.‚Äč

- Difficulty in complying with strict EU environmental standards: Challenges in sourcing eco-friendly materials and optimizing production processes to meet REACH and RoHS requirements.‚Äč

- Unstable supply chain for electronic components: Reliance on imported components leads to supply delays and potential quality risks in PCB assembly Greece projects.

Our Solutions to These Pain Points

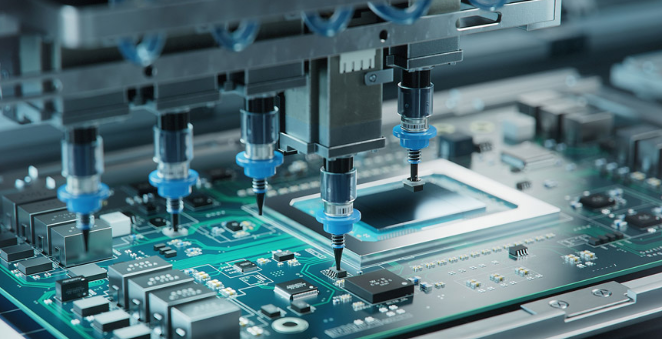

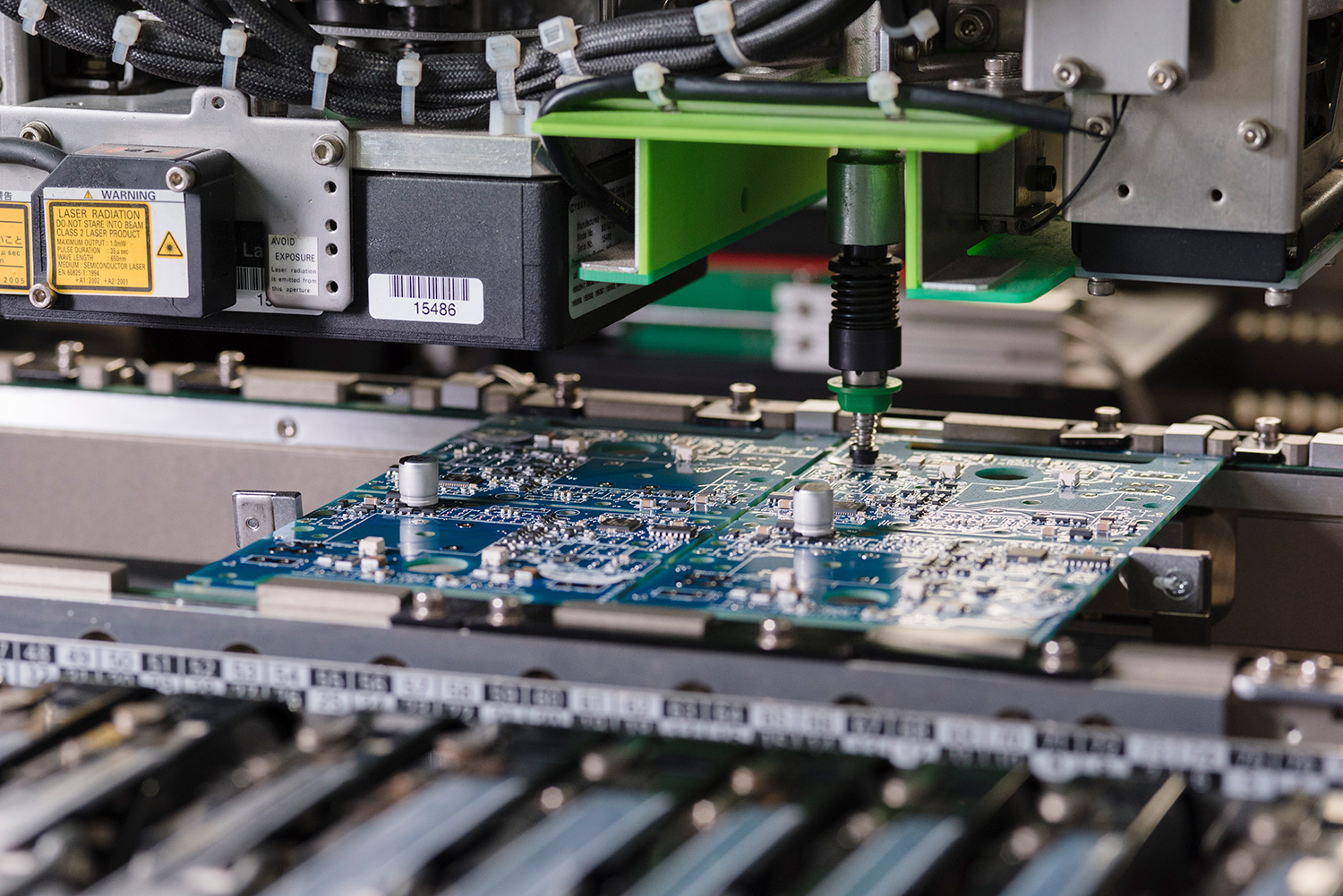

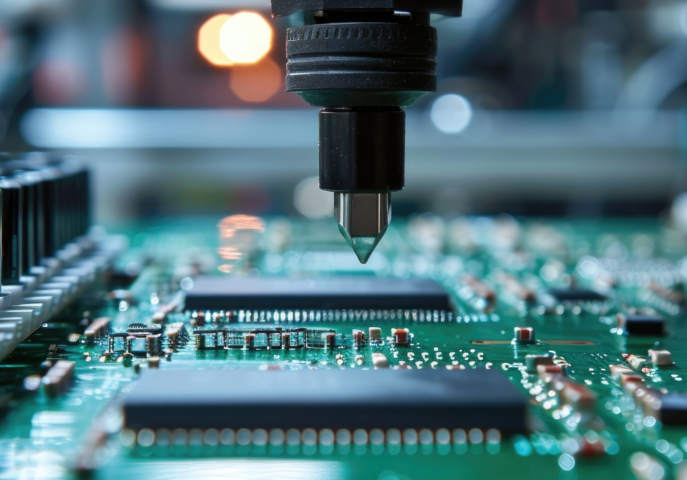

- High-precision assembly support: Equipped with advanced SMT equipment and X-ray inspection tools, capable of handling high-density component assembly with a yield rate of over 99.8%.

- Rapid prototyping service: 24-hour quick prototyping for urgent orders, ensuring timely verification of design schemes and accelerating project progress.

- Integrated design and manufacturing service: Embed manufacturability analysis into the early stage of cooperation, providing professional suggestions to optimize design schemes and avoid repeated modifications.

- Cost optimization system: Relying on large-scale production capacity and mature supply chain, providing cost-sensitive solutions to reduce unit costs of mass production.

- Strict environmental compliance guarantee: Adopt eco-friendly materials and processes, fully complying with EU REACH, RoHS and other environmental standards, ensuring smooth market access of products.

- Stable component supply chain: Cooperate with global well-known component suppliers, establishing multi-channel supply guarantee system to avoid supply delays.

- Full-process quality control: Implement strict quality inspection at every stage from material incoming to product delivery, including AOI inspection, functional testing and reliability testing.

- Professional after-sales support: Provide timely technical support and problem-solving services after delivery, ensuring smooth progress of customer projects.

Why Choose EBest Circuit (Best Technology) for Greece PCB Manufacturer Partner?

Reasons Why Choose EBest Circuit (Best Technology) for Greece PCB Manufacturer Partner:

- 19 years of industry experience: With nearly two decades of expertise in PCB manufacturing and assembly, we excel at handling complex projects. Our professional team provides targeted solutions to effectively reduce your overall production costs.‚Äč

- Free DFM in-depth analysis: Offer free Design for Manufacturability (DFM) analysis services at the early stage of cooperation, optimizing design schemes to avoid repeated modifications, improve production efficiency and reduce unnecessary rework costs.‚Äč

- 24-hour rapid prototyping: Rapid response to urgent prototyping demands, completing high-quality samples within 24 hours to help you verify design schemes quickly and seize market opportunities in a timely manner.‚Äč

- Ultra-high on-time delivery rate of 99.2%: Rely on mature production management systems and sufficient production capacity to maintain a long-term on-time delivery rate of 99.2%, eliminating project delays caused by supply chain issues.‚Äč

- Strict quality control throughout the entire process: Implement 100% full inspection for mass production, covering incoming material inspection, in-process quality control and final delivery testing. A complete quality management system ensures stable and reliable product performance.‚Äč

- Tailor cost-sensitive solutions: based on actual project needs, balancing superior quality with competitive pricing to enhance the market competitiveness of your end products.‚Äč

- Full stack international authoritative certifications: Hold authoritative certifications including ISO9001:2015, ISO13485:2016, REACH, RoHS and IATF16949, fully complying with EU market access requirements and ensuring smooth product circulation.‚Äč

- Customized exclusive services: Deeply align with diverse application scenarios, tailoring one-stop PCB manufacturing and assembly solutions according to your unique project requirements, achieving precise matching of supply and demand.

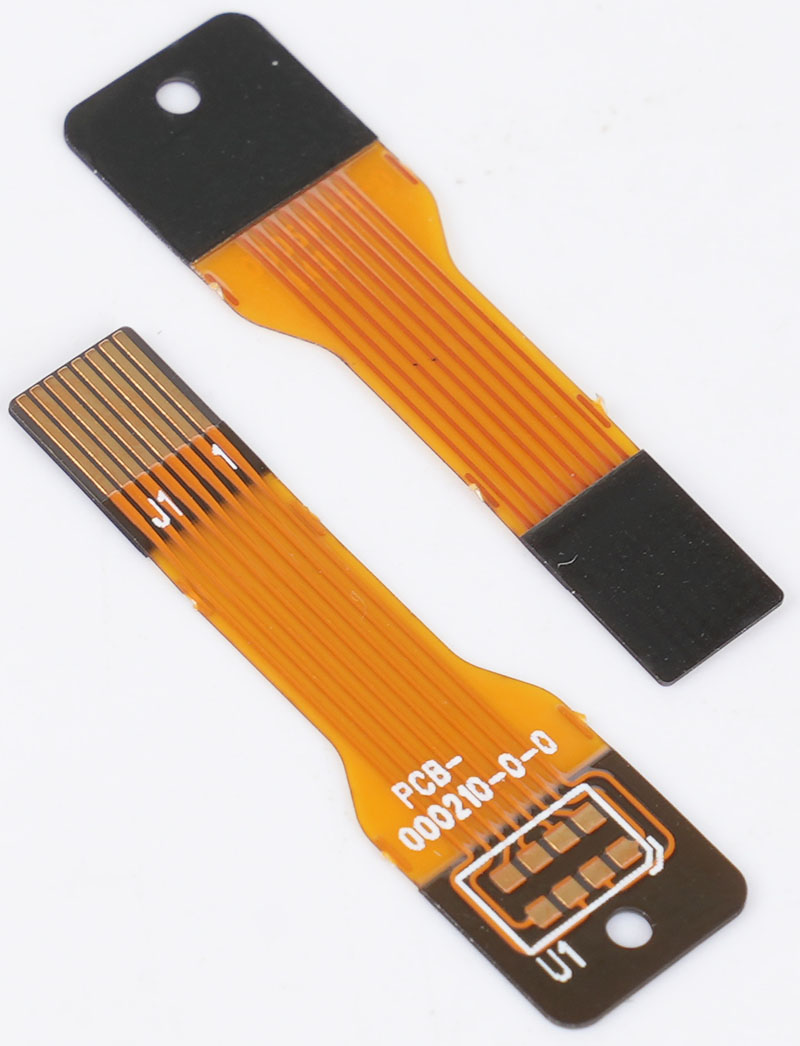

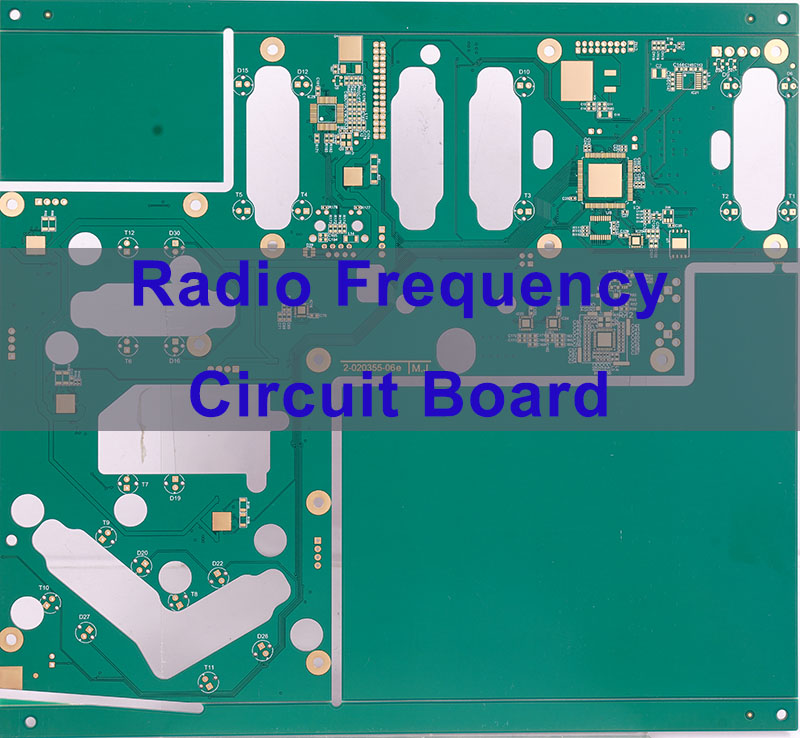

Types of Greece PCB Assembly We Can Provide

Here Are Three Types of Greece PCB Assembly Service We Can Provide You:

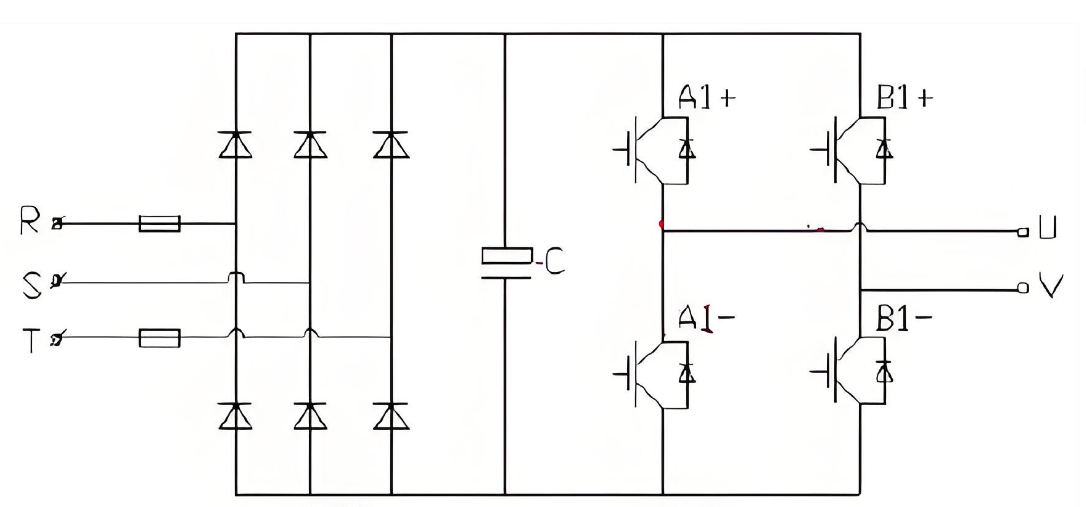

- Surface Mount Technology (SMT) Assembly: Suitable for miniaturized, high-density electronic components, ensuring high assembly precision and efficiency.

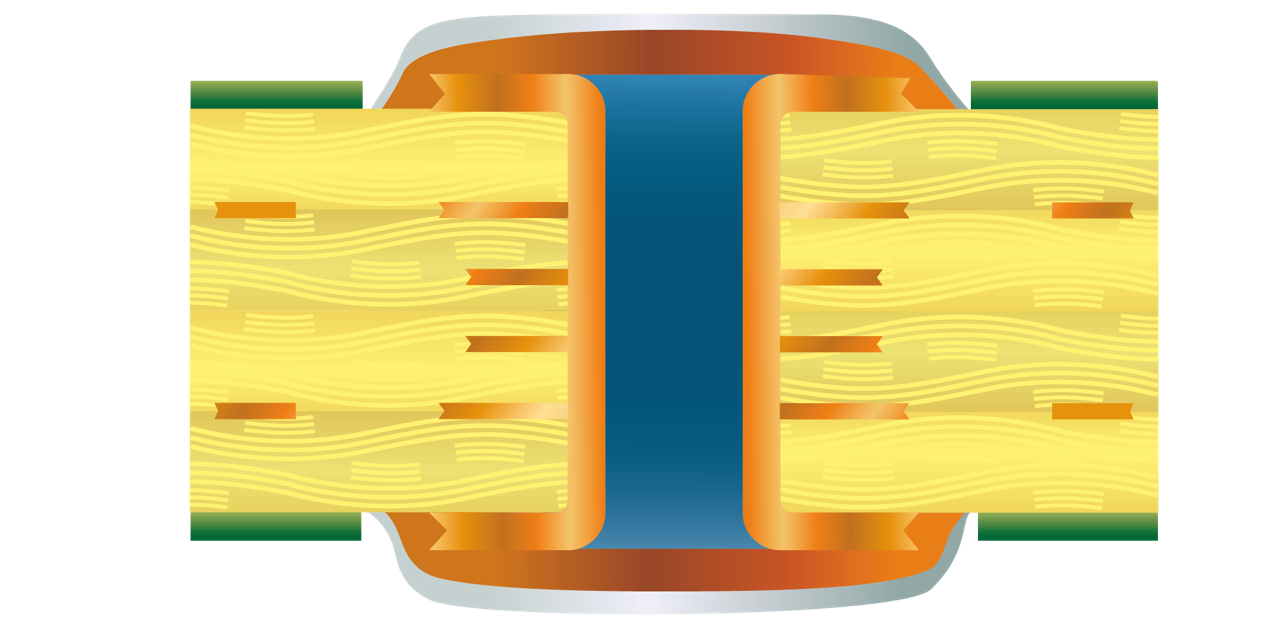

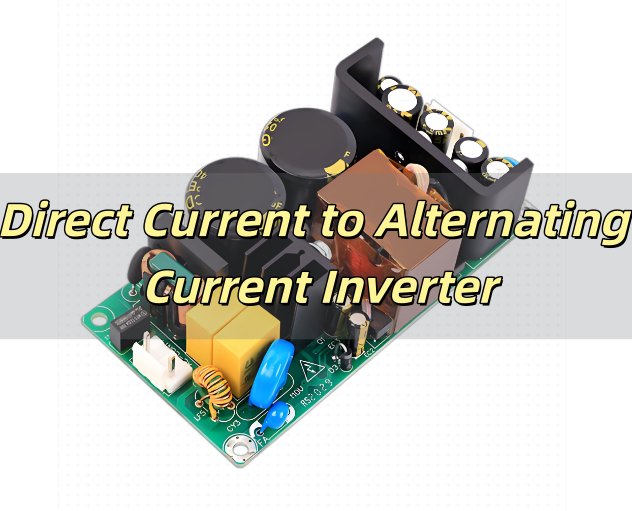

- Through-Hole Assembly: Applicable to components that require high mechanical strength, such as connectors and power components.

- Hybrid Assembly: Combine SMT and through-hole assembly technologies to meet the needs of complex electronic products with diverse components.

Our PCB Assembly Capabilities

| Item | Capabilities |

| Placer Speed | 13,200,000 chips/day |

| Bare Board Size | 0.2 x 0.2 inches – 20 x 20 inches / 22*47.5 inches |

| Minimum SMD Component | 01005 |

| Minimum BGA Pitch | 0.25mm |

| Maximum Components | 50*150mm |

| Assembly Type | SMT, THT, Mixed assembly |

| Component Package | Reels, Cut Tape, Tube, Tray, Loose Parts |

| Lead Time | 1 – 5 days |

Case Studies of Our PCB Greece Manufacturing

Project Overview

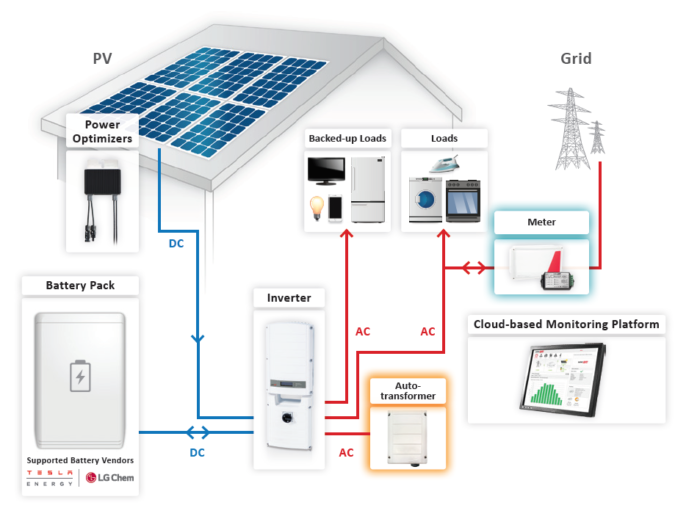

A Greek hydrogen energy equipment manufacturer required a reliable Greece PCB assembly partner for its 50MW electrolyzer control system, they demanded EU CE certification and 10+ years of reliability in harsh industrial environments (high humidity/temperature).

Core Requirements

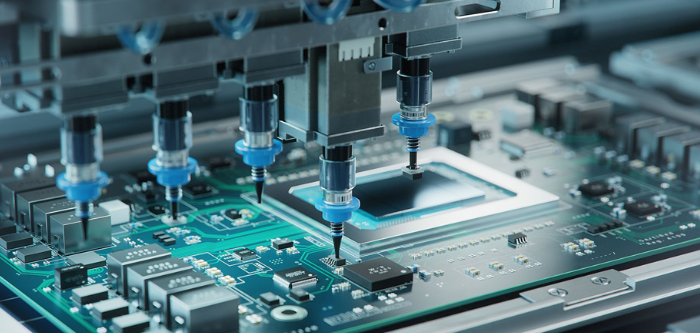

- HDI PCB assembly with micro-precision (<0.25mm BGA pitch, 01005 components).

- Strict compliance with RoHS/REACH environmental standards.

- Prototyping ‚ȧ3 days; mass production delivery ‚ȧ10 days.

- 10-year service life in extreme conditions.

Key Challenges

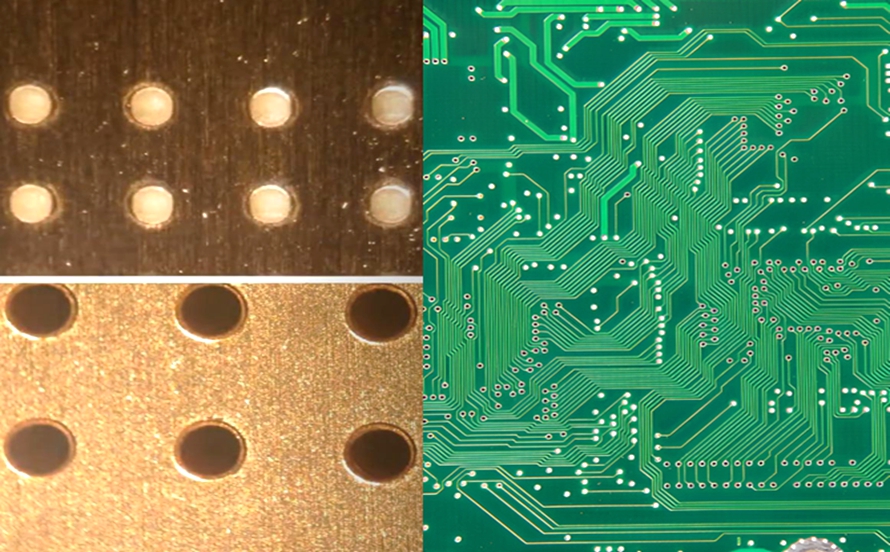

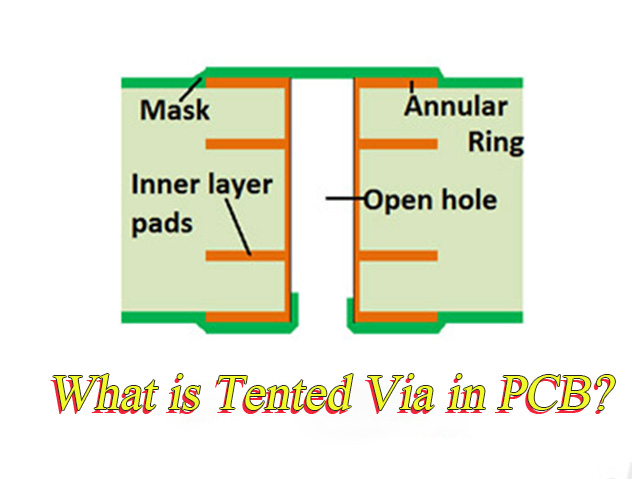

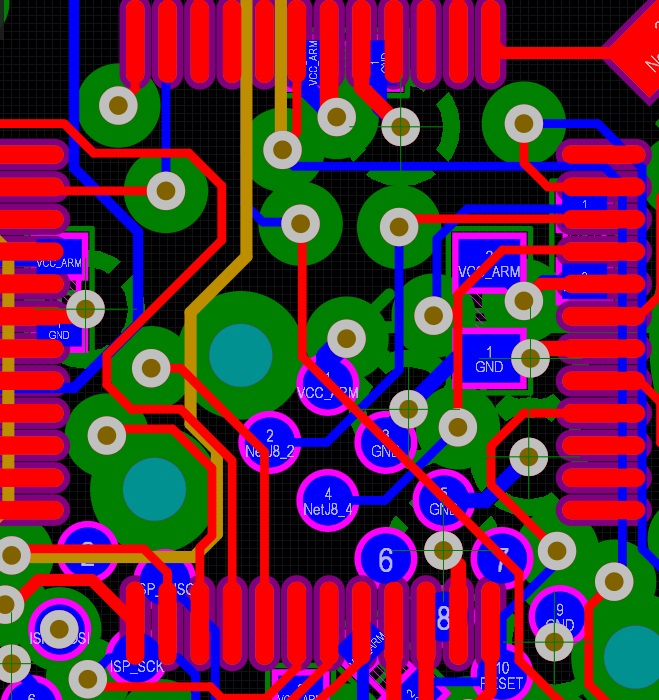

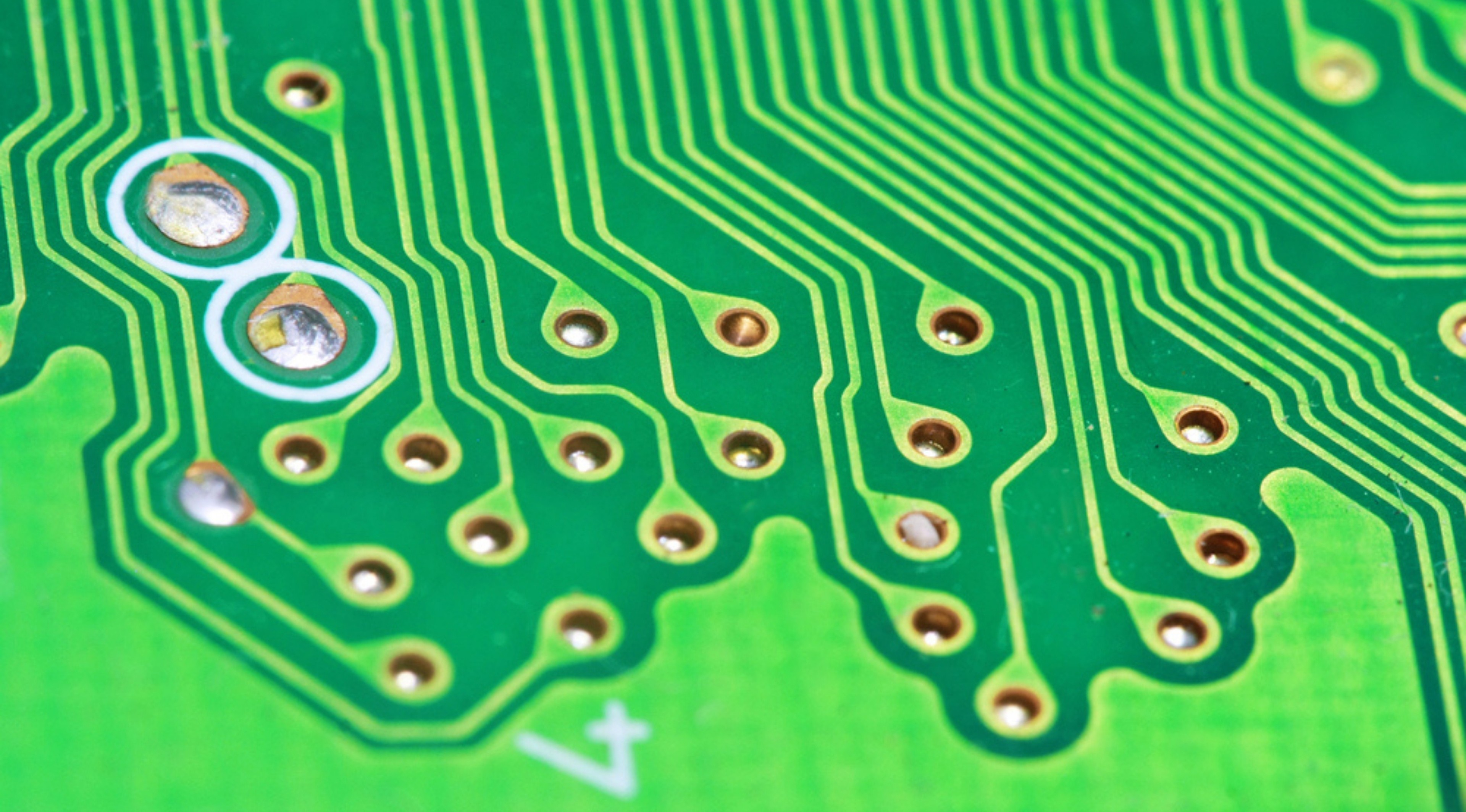

- High-density PCB design (fine lines, small vias) requiring sub-millimeter assembly accuracy.

- Hybrid assembly (SMT + through-hole) for diverse control system components.

- Stringent environmental reliability testing (thermal/humidity cycling, vibration).

- Tight production timeline balancing precision and efficiency.

Optimized Solution

- DFM Analysis: Free design optimization to enhance manufacturability (component layout refinement).

- Advanced Equipment: High-speed SMT machines (13.2M chips/day) + X-ray inspection for micro-assembly accuracy.

- Certified Supply Chain: Compliant components from vetted suppliers.

- Agile Production: Dedicated team & process optimization to compress cycles (2-day prototyping, 10-day mass production).

- Reliability Validation: Accelerated life testing (85¬įC/85% RH, vibration) ensuring CE compliance.

Outcome

- Prototyping: Completed in 2 days (1 day ahead of schedule).

- Mass Production: 500 units delivered on time within 10 days.

- Quality: 99.9% first-pass yield; 100% CE certification success.

- Field Performance: Zero failures in 6 months of operation under extreme conditions.

- Long-term Partnership: Earned designation as the customer’s exclusive Greece PCB assembly provider.

How to Get A Quote for Your PCB Assembly Project?

Step Guide to Obtaining a Custom PCBA Quote from EBest Circuit (Best Technology-Your Greece PCB Manufacturer Partner)

1. Submit Project Details

- Email essential files and specifications to sales@bestpcbs.com.

- PCB design files: Gerber files + BOM (Bill of Materials).

- Project specifications: Quantity, delivery timeline, application environment (e.g., industrial/medical), and compliance requirements (e.g., CE, RoHS, REACH).

2. Complimentary Rapid Evaluation

- Receive a free DFM (Design for Manufacturing) analysis report within 2 hours of submission.

- Get an initial transparent quote with no hidden fees or obligations.

- The evaluation includes manufacturability checks, material compatibility verification, and process optimization suggestions.

3. Confirm and Launch Production

- Review the quote and DFM report.

- Sign the formal quote document or reply to the email to authorize project start.

- Formal quotes are valid for 30 days, allowing flexible decision-making.

Welcome to contact us if you have any request for PCB design, prototyping, mass production and assembly: sales@bestpcbs.com.