If you‚Äôve ever searched when to use amplifier antenna, you‚Äôre probably already frustrated with weak signal, slow data, or unstable connections. Many users buy an antenna amplifier hoping for an instant fix, only to find that performance doesn‚Äôt improve‚ÄĒor even gets worse.

With 5G, especially 5G UC, things have become even more confusing. Strong signal bars don’t always mean fast speeds, and adding hardware without understanding your signal environment can backfire.

This guide explains exactly when an antenna amplifier helps, when it doesn’t, and how to use it correctly.

What Is an Antenna Amplifier?

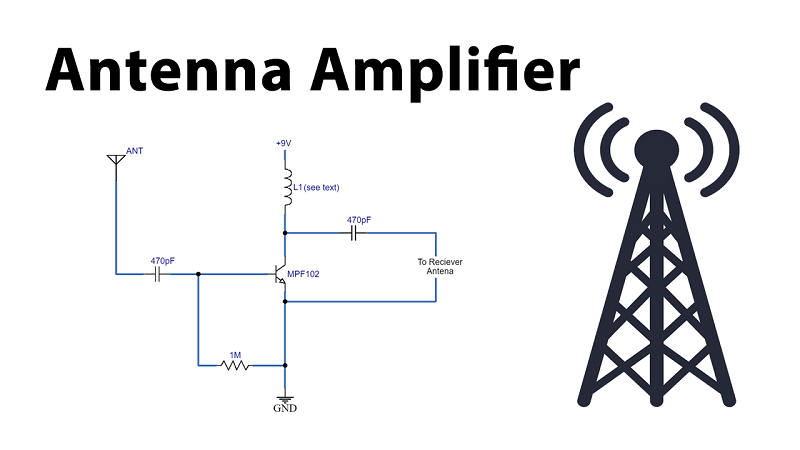

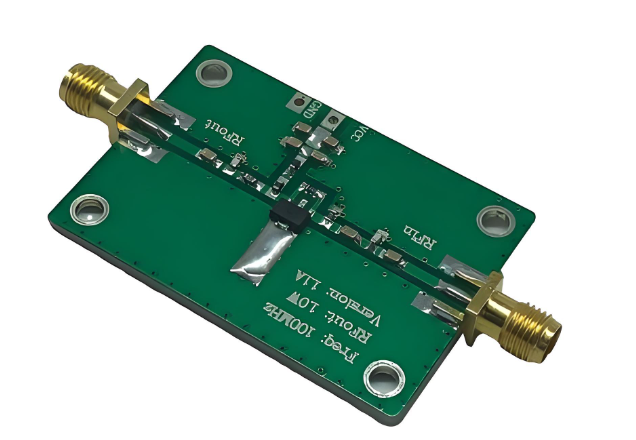

An antenna amplifier is an active electronic device that increases the amplitude of radio-frequency signals received by an antenna before they reach a tuner, receiver, or distribution network. It does not improve antenna sensitivity, change antenna directionality, or recover information that was never received in the first place.

In practical systems, antenna amplifiers are used to compensate for signal losses introduced after reception, such as coaxial cable attenuation, splitter insertion loss, and impedance mismatches. Understanding this limitation is critical because many signal issues originate at the antenna itself, not downstream.

What Is an Antenna Amplifier?

How Does an Antenna Amplifier Work?

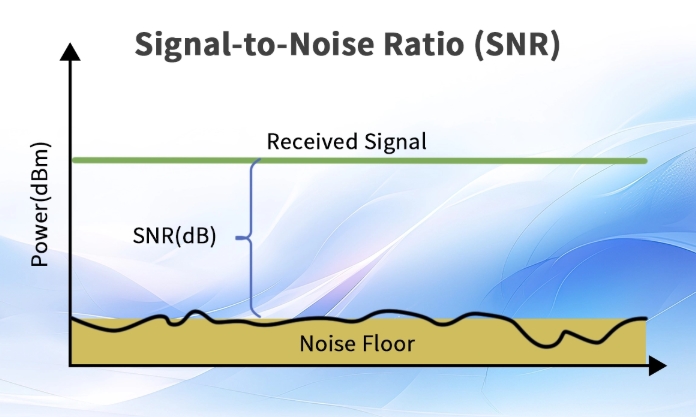

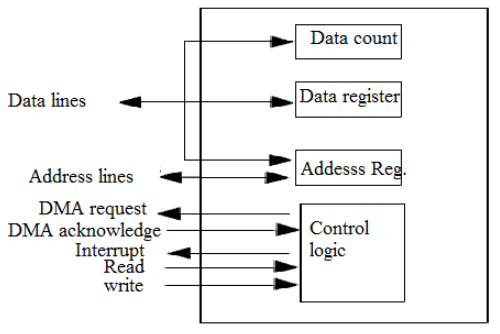

An antenna amplifier operates by taking a weak RF signal and increasing its voltage level across a specified frequency band. Internally, it uses low-noise transistors or integrated RF amplifier stages designed to preserve signal integrity while boosting amplitude.

However, amplification is indiscriminate. The amplifier boosts:

- Desired signals

- Background noise

- Interference from nearby transmitters

This is why amplifiers must be matched carefully to the signal environment. In clean, weak-signal scenarios, amplification improves the signal-to-noise ratio at the receiver input. In noisy or high-signal environments, it often degrades performance by saturating the tuner.

When Do I Need an Antenna Amplifier?

You need an antenna amplifier only when the antenna already receives usable signals, but those signals degrade before reaching the receiver. This distinction matters more than distance alone.

Common indicators include:

- Signal strength drops significantly after adding long coaxial runs

- Channels disappear when splitters are introduced

- Reception improves when equipment is moved closer to the antenna

If the antenna itself cannot capture stable signals, amplification will not fix the issue. In those cases, antenna type, height, orientation, or location must be addressed first.

Common Application Where an Antenna Amplifier Helps?

Antenna amplifiers are most effective in predictable, loss-dominated systems.

Large homes often require long cable runs that introduce attenuation, especially at higher frequencies. Multi-room installations suffer splitter losses that accumulate quickly. Outdoor antennas feeding indoor distribution networks frequently lose signal strength before reaching the tuner.

In these cases, amplification restores signal margin that would otherwise be consumed by passive components. The amplifier does not improve reception quality at the antenna, but it preserves what the antenna already captures.

Antenna Amplifier vs Preamplifier

Although often confused, antenna amplifiers and preamplifiers serve different functions.

A preamplifier installs close to the antenna and boosts signals before cable loss occurs. It is designed for weak-signal environments and typically features lower noise figures.

A standard antenna amplifier installs further downstream, usually indoors, and compensates for losses already introduced. It is better suited for distribution systems rather than fringe reception areas.

Choosing the wrong type leads to common failures, especially when amplifiers are installed far from the antenna in weak-signal conditions.

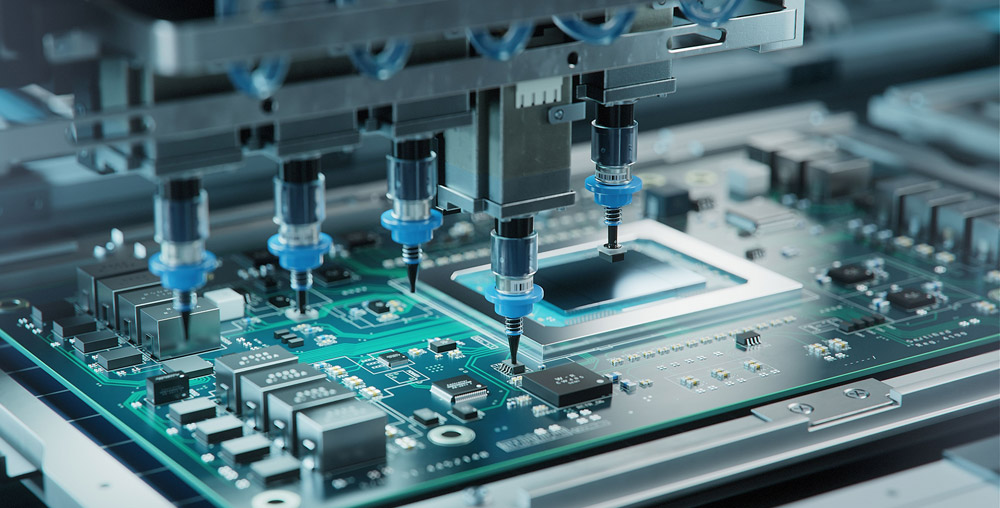

Where Do You Put an Antenna Amplifier?

Placement determines effectiveness. An amplifier must be positioned before the dominant loss point in the signal chain.

If cable loss is the issue, the amplifier should be installed before long coaxial runs. If splitter loss is the problem, it should be placed ahead of the splitter. Installing an amplifier after losses have already occurred limits its benefit and often increases noise.

Incorrect placement is one of the most frequent reasons users believe amplifiers ‚Äúdo not work.‚ÄĚ

Indoor vs Outdoor Antenna Amplifier Placement

Indoor placement offers convenience and protection from weather but limits performance recovery. Outdoor or mast-mounted placement allows amplification closer to the signal source, preserving signal quality earlier in the chain.

Outdoor installations require weather-rated enclosures, grounding, and surge protection. While installation complexity increases, performance consistency improves significantly in weak-signal environments.

When an Antenna Amplifier Can Hurt Signal Quality?

Amplifiers often cause problems in high-signal environments. Strong nearby transmitters can overload the amplifier or receiver, creating distortion that blocks weaker channels.

Symptoms include:

- Pixelation after amplification

- Loss of channels that were previously stable

- Intermittent reception despite strong signal readings

In these cases, removing the amplifier often restores performance. Amplification should never be the first troubleshooting step.

How to Choose the Right Antenna Amplifier?

Choosing an amplifier requires balancing gain, noise figure, and frequency coverage. Excessive gain introduces distortion. Poor noise performance reduces clarity. Incompatible frequency ranges waste amplification where it is not needed.

Adjustable-gain models provide flexibility, especially in mixed signal environments. Lower gain with better noise performance often outperforms high-gain designs in real installations.

Installation Tips to Avoid Signal Overload

Install only one amplifier per signal path. Avoid stacking amplifiers. Use amplification only where loss is measurable. Test reception before and after installation using real channel stability rather than signal bars.

Small improvements in placement often outperform amplification entirely. Amplifiers should refine systems, not compensate for poor antenna selection.

FAQs

1. Does an antenna amplifier improve signal strength or quality?

It improves strength, not quality. Quality improves only when amplification prevents loss-induced degradation.

2. Can I use an antenna amplifier with indoor antennas?

Yes, but results depend on signal availability at the antenna location.

3. Is more gain always better?

No. Excessive gain often causes overload and distortion.

4. Do antenna amplifiers work for cellular or Wi-Fi signals?

No. They are frequency-specific and designed for RF broadcast ranges.

5. Should I use an amplifier if I live close to broadcast towers?

Usually not. Strong local signals often perform better without amplification.