Everyone may know that PCBs are easy to be bended or warped when get through the reflow process. Do you how to avoid this issue? here are some advices your reference.

- Reduce the effect of temperature on PCB board stress

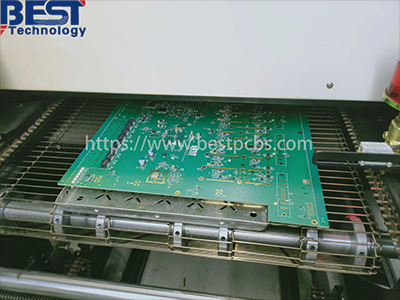

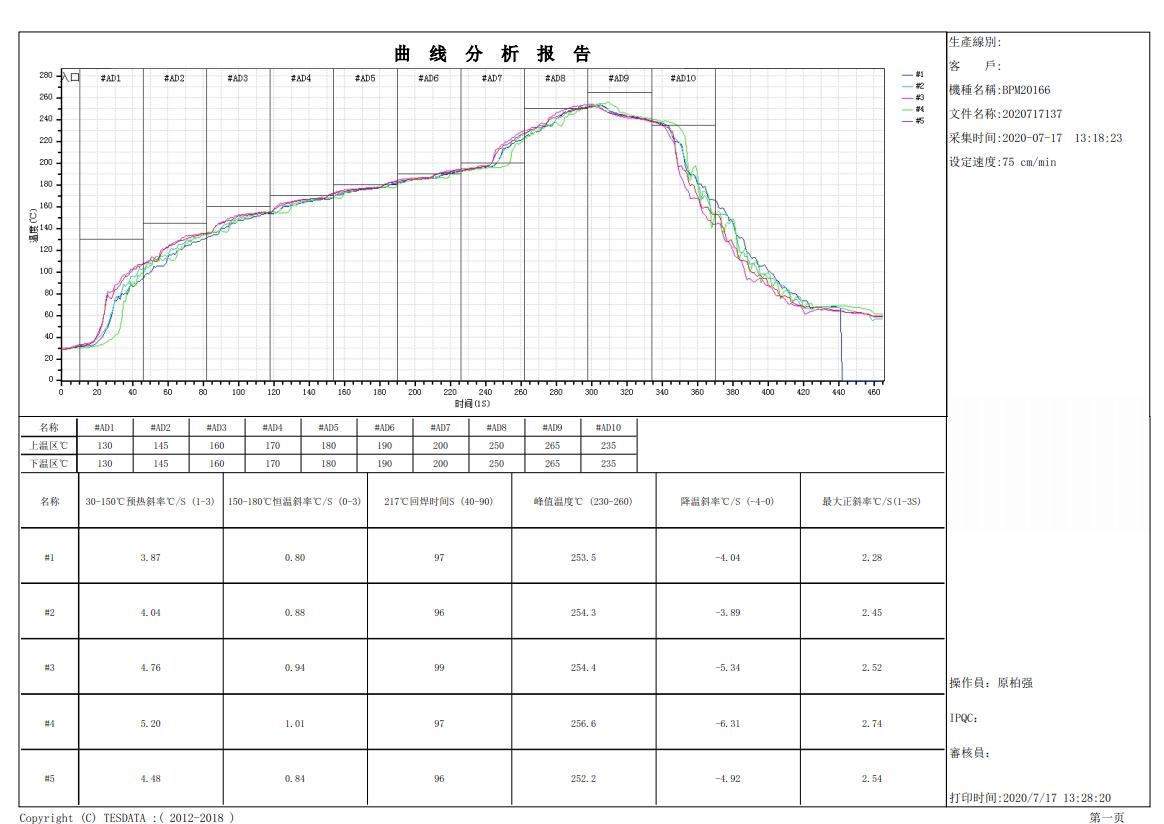

Due to the “temperature” is the main source of stress for board, so as long as the temperature of the reflow oven reduce the temperature or slow the speed of warming up and cooling down in the reflow oven, the board bending and warping issue can be reduced. But it may be occurring other issues, such as short circuit when soldering. See Best Tech make control for the temperature of the reflowing process.

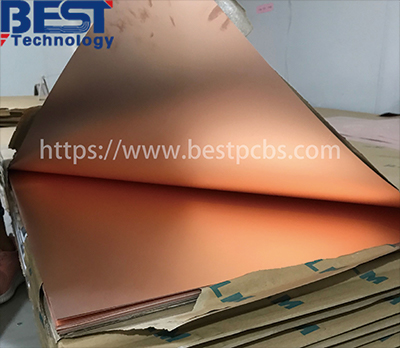

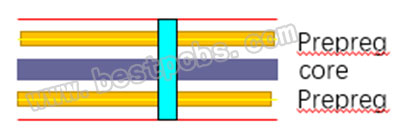

2. Use high Tg plate

Tg is the glass transition temperature. The lower of the Tg value, the faster of board starts to soften after finishing reflowing, and deformed of the board become more serious. if use of higher Tg 170 material can increase the ability to withstand stress deformation, but the price of TG170 material is higher. See the stock of high Tg material from Best Tech.

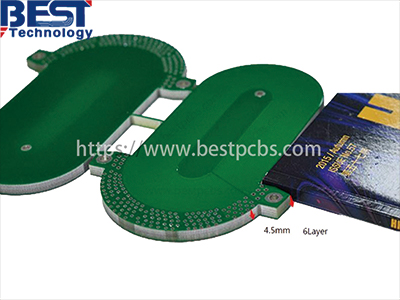

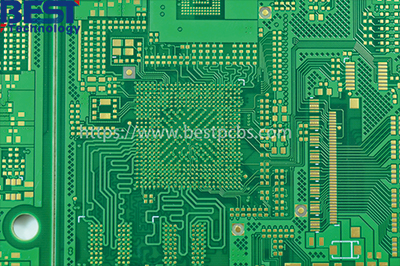

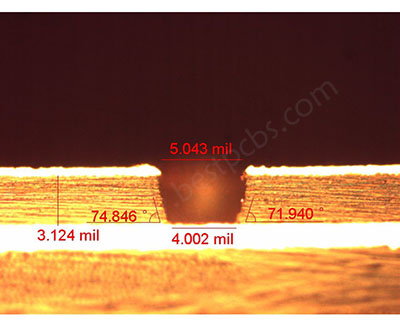

3. Increase the board thickness

If final application allowed, we recommend 1.6mm thickness to prevent the risk of board bending. Best Tech can provide PCB board thickness to 4.5~8.0mm.

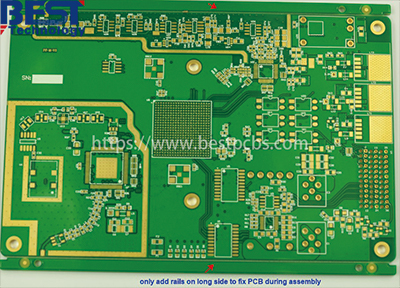

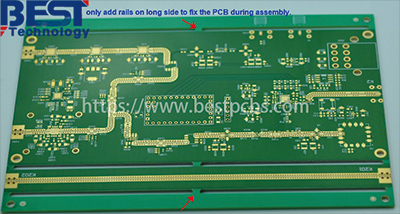

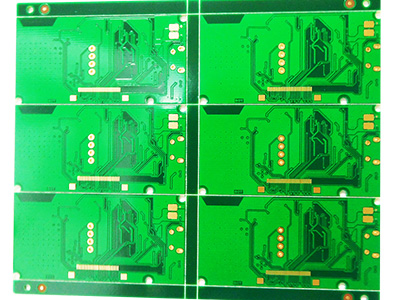

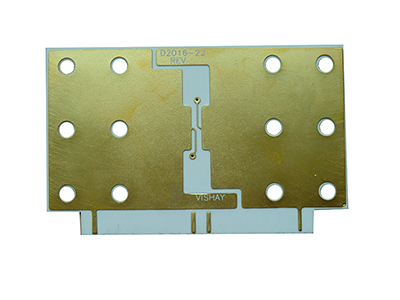

- Try to reduce the size of the board and the number of panels during design

Since most reflow oven use chains to driving the board forward, if larger size of the FR4 PCB, the own weight will be deformed in the reflow oven, so during design try to design the long side of the PCB as a board edge, it can reduce the deformed. And

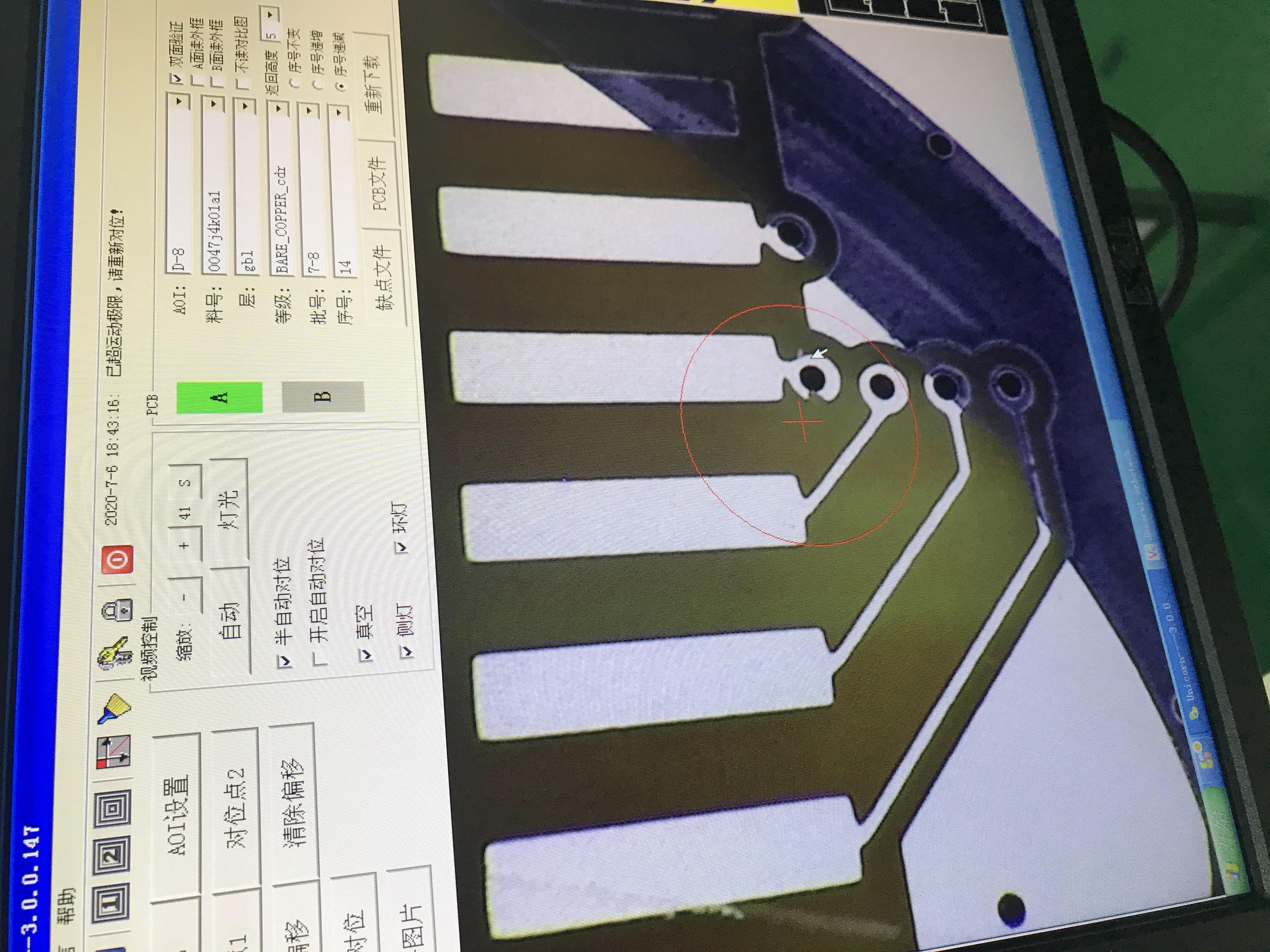

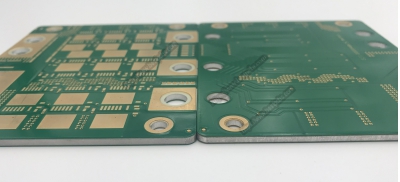

Same reason, if there are many PCBs in a big panel, PCB will be bigger and heavier, when get through the oven, the speed in the oven will be slowly and it will influence the deformed of the PCB. See following PCB board, we only panel 1 single piece into a panel to keep the size of FR4 PCB panel not bigger.

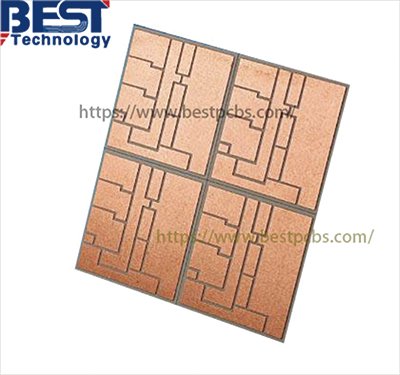

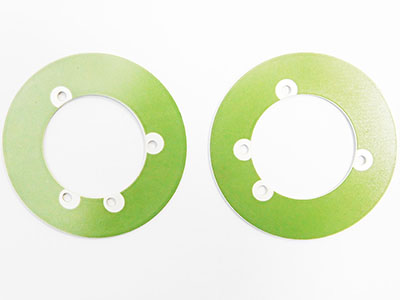

5. Use the reflow carrier/tray

If above methods cannot get a good result for deforming, you maybe can use a reflow carrier/tray to reduce the deformation. The reason reflow tray can fix the circuit board, after the temperature of the printed circuit board is lower than the Tg value, it can maintain the original size.

6. Use Router instead of V-Cut

Since V-Cut will destroy the structural strength of the panels, try to use Router PCB board or just reduce the depth of the V-Cut will helps the deform issue.

If you want to know more about how we control the bended and warped for PCB, you are welcome to contact us.