A PCB manufacturer in Europe‚Äč stands as a strategic partner for innovators, offering not just circuit boards but a blend of technological excellence, supply chain resilience, and rigorous quality standards crucial for bringing complex designs to life. This article explores the European PCB manufacturing landscape, examining its key strengths, defining characteristics of top-tier suppliers, and how it specifically empowers faster, more reliable prototype development.

Developing a new electronic product is exhilarating, yet the prototyping phase often becomes a bottleneck fraught with unforeseen challenges. Many engineering teams face significant hurdles when sourcing prototype PCBs:

- Prototype Delays:‚Äč Slow turnaround from overseas suppliers delays critical testing, pushing back your entire development timeline.

- Inconsistent Quality:‚Äč Unclear processes and variable quality in early builds lead to failed tests, re-spins, and wasted budget.

- Communication Barriers:‚Äč Language gaps and time zone differences hinder crucial technical discussions, leading to misunderstandings and errors.

- Technical Limitations:‚Äč Inability to source or manufacture with advanced materials (e.g., high-frequency, high-Tg) or complex constructions (HDI, heavy copper) stunts innovation.

- Supply Chain Fragility:‚Äč Geopolitical disruptions and long logistics lines risk your project‚Äôs continuity and intellectual property security.

The solution lies in partnering with a capable and responsive PCB prototype Europe‚Äč specialist. A local expert directly addresses these pain points:

- Rapid Prototype Turnaround:‚Äč Proximity enables dramatically faster quotes, production, and delivery, accelerating your design iterations.

- Stringent Quality Systems:‚Äč Adherence to international certifications (e.g., ISO, IATF, UL) and robust in-process controls ensure first-article reliability.

- Seamless Engineering Collaboration:‚Äč Local teams provide direct, real-time support for Design for Manufacturing (DFM) reviews, ensuring your design is optimized for success.

- Advanced Technical Capabilities:‚Äč In-house expertise in advanced processes and materials allows you to push the limits of your prototype‚Äôs performance.

- Resilient and Secure Supply:‚Äč Short, transparent supply chains within the EU reduce risk, protect IP, and ensure project stability.

At BEST Technology, we embody this solution-oriented approach. As a specialist in advanced PCB prototype and PCB series manufacturing, we combine nearly 2 decades of deep technical expertise with a client-centric model. Our printed circuit board facility is equipped to handle the most demanding prototype challenges, from high-frequency RF boards to complex HDI designs, ensuring your project moves from concept to validation with speed. For your next prototype, pls feel free to contact our team at sales@bestpcbs.com.

Why Global Brands Prefer a PCB Manufacturer in Europe?

Selecting a PCB manufacturer in Europe‚Äč is a strategic decision driven by more than just geography. For global brands, especially in sectors like automotive, aerospace, industrial automation, and medical technology, it aligns with core operational values that mitigate risk and enhance product integrity. The preference stems from a combination of tangible benefits that directly impact the bottom line and innovation speed.

- Unmatched Proximity and Agile Timelines:‚Äč

Physical closeness to R&D centers enables an agile development cycle.

Faster shipping (often 1-2 days within the EU versus weeks from overseas) allows for more prototype iterations in the same timeframe.

This proximity facilitates just-in-time manufacturing and reduces inventory costs for series production.

- Stringent Quality and Traceability Standards:‚Äč

European manufacturers operate within a robust regulatory framework.

Compliance with ISO 9001 (Quality), IATF 16949 (Automotive), ISO 13485 (Medical), and AS9100 (Aerospace) is standard.

This culture of quality ensures rigorous process control, full material traceability, and comprehensive documentation‚ÄĒcritical for audits and in regulated industries.

- Enhanced IP Protection and Data Security:‚Äč

The EU’s strong legal framework for intellectual property (IP) and data protection (GDPR) provides significant security.

Working with a local PCB factory in Europe‚Äč minimizes the risk of IP leakage or unauthorized design replication, giving companies peace of mind, especially for cutting-edge, proprietary technologies.

- Supply Chain Resilience and Sustainability:‚Äč

Local sourcing of key materials and shortened logistics chains reduce exposure to global disruptions. Furthermore, Europe is at the forefront of environmental regulations (e.g., RoHS, REACH, WEEE), meaning PCB manufacturing companies in Europe‚Äč are leaders in sustainable, green manufacturing processes, aligning with corporate ESG (Environmental, Social, and Governance) goals.

- Deep Technical Collaboration:‚Äč

Shared time zones and cultural affinity enable seamless communication.

Engineers can easily discuss complex DFM feedback, material selections, and technical challenges in real-time with their manufacturing partner, turning the supplier into a true extension of the development team.

In summary, choosing a European PCB partner is an investment in reduced risk, protected innovation, accelerated time-to-market, and adherence to the world’s highest standards of quality and sustainability.

Growth Trends Among PCB Manufacturers in Europe

The landscape for PCB manufacturers in Europe‚Äč is dynamic, shaped by technological evolution and strategic regional priorities. Rather than competing on volume alone, the continent‚Äôs industry is pivoting towards high-value, specialized manufacturing that leverages its historical strengths in engineering and precision.

- Specialization in High-Value, Technology-Intensive Segments:‚Äč

European PCB manufacturing in EU‚Äč is increasingly focused on sectors with high barriers to entry. This includes substrates for power electronics (e.g., for EVs and renewable energy), advanced packaging for semiconductors, ultra-reliable boards for aerospace & defense, and sophisticated RF/microwave circuits for telecom and radar.

This shift moves the industry up the value chain.

- Accelerated Adoption of Automation and Industry 4.0:‚Äč

To maintain competitiveness in a high-cost environment, factories are heavily investing in automation, AI-driven process optimization, and digital twins.

This “smart factory” approach enhances yield, consistency, and allows for highly flexible, low-volume/high-mix production‚ÄĒperfect for prototypes and specialized series.

- The “Green Manufacturing” Imperative:‚Äč

Sustainability is a core driver.

Trends include reducing water and energy consumption, implementing closed-loop recycling systems for chemicals and metals, and developing halogen-free and bio-based materials.

This isn’t just regulatory compliance; it’s a key competitive advantage for eco-conscious global brands.

- Onshoring and Supply Chain Regionalization:‚Äč

Geopolitical events have accelerated the trend of bringing critical electronics manufacturing closer to end markets.

This benefits PCB suppliers in Europe, as both European and international companies seek to “friend-shore” production, creating demand for reliable local capacity.

- Focus on Advanced Materials and Processes:‚Äč

Research and development are geared towards mastering new frontiers.

This includes substrates for higher frequency applications (e.g., PTFE, ceramic-filled laminates), improved thermal management materials (metal-clad, insulated metal substrates), and advanced processes like mSAP (modified Semi-Additive Process) for ultra-fine-line HDI.

The trajectory for European PCB manufacturing is clear: it is consolidating its position as a center for innovation, quality, and sustainable production for the world’s most demanding applications.

Overview of PCB Manufacturing Companies in Europe

The ecosystem of PCB manufacturing companies in Europe‚Äč is diverse, catering to a wide spectrum of needs. Understanding this structure helps in identifying the right partner for a specific project, from a simple prototype to a mission-critical automotive component.

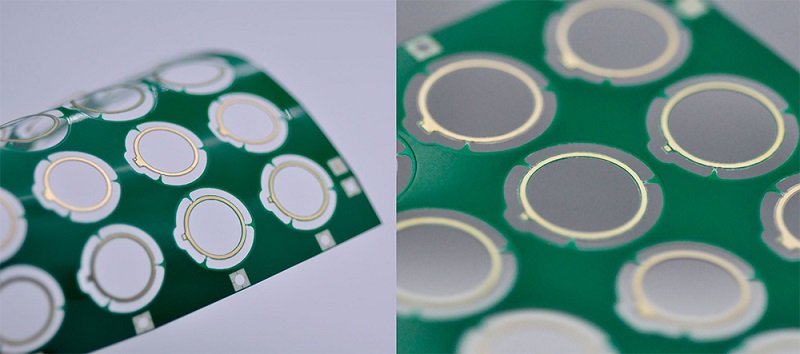

- High-Frequency & RF Specialists:‚Äč

These are niche PCB makers in Europe‚Äč focused on radio frequency, microwave, and millimeter-wave applications.

They excel with low-loss materials like Rogers, Taconic, or PTFE, offering precise impedance control and specialized surface finishes.

They are key partners for telecom, aerospace, and defense projects.

- Rapid Prototype & Quick-Turn Shops:‚Äč

A vital segment for R&D, these suppliers prioritize speed.

Many operate online as PCB manufacturer online‚Äč platforms, offering streamlined quoting and ordering for standard-technology prototypes.

They are ideal for initial design validation and lower-complexity boards where fast turnaround is the primary driver.

- Automotive & Industrial Powerhouses:‚Äč

Often among the largest PCB manufacturers in Europe, these facilities are characterized by massive scale, full automation, and certifications like IATF 16949.

They specialize in high-reliability, high-volume production for automotive control units, power electronics for industrial drives, and other demanding applications.

- Aerospace, Defense, and Medical-Grade Manufacturers:‚Äč

This group represents the pinnacle of reliability and documentation.

Their processes are exhaustive, with absolute traceability for every material and process step.

They commonly hold AS9100 and ISO 13485 certifications and handle complex, multilayer, and often rigid-flex boards for life-critical systems.

- Material and Technology Innovators:‚Äč

Beyond pure board fabrication, Europe is home to leading material science companies that develop the core laminates, prepregs, and coatings.

The synergy between these material innovators and advanced PCB assembly manufacturer in Europe‚Äč partners drives the continent‚Äôs technological edge in areas like thermal management and high-speed digital performance.

This varied landscape means that for every project, from a simple PCB prototype Europe‚Äč order to a complex series production, there is a specialized European manufacturer equipped to deliver.

What Defines the Top PCB Manufacturers in Europe?

Identifying the top PCB manufacturers in Europe‚Äč requires looking beyond basic capabilities. These industry leaders are defined by a holistic set of standards that separate them from competent manufacturers, establishing them as benchmarks for the sector.

- Comprehensive and Depth of Technical Certification:‚Äč

A true top-tier manufacturer possesses more than just ISO 9001.

It is defined by industry-specific certifications: IATF 16949‚Äč for automotive, AS9100‚Äč for aerospace, and ISO 13485‚Äč for medical devices.

These are not just plaques on the wall but represent deeply integrated quality management systems.

- Mastery of an Advanced Material Portfolio:‚Äč

They don’t just work with FR-4.

They offer expert guidance and proven process windows for a wide range of high-performance materials‚ÄĒhigh-frequency laminates (Rogers, Taconic), high-Tg and low-loss halogen-free materials, polyimide for flex, and specialized thermal management substrates.

This material expertise is fundamental.

- Uncompromising Process Control and Traceability:‚Äč

From lot-number tracking of every laminate sheet and chemicals to automated optical inspection (AOI) and electrical test data logging, every step is controlled and documented.

Full traceability is non-negotiable, allowing for root-cause analysis of any anomaly, which is critical for high-reliability sectors.

- Proven Cross-Industry Experience and References:‚Äč

The best PCB manufacturers in Europe‚Äč have a demonstrable track record across multiple demanding verticals.

They have case studies and client references from automotive tier-1 suppliers, aerospace primes, and leading medical device companies.

This experience translates into proactive problem-solving ability.

- Investment in R&D and Future Technologies:‚Äč

They are not passive producers.

Top manufacturers invest a significant percentage of revenue into R&D, collaborating with material suppliers and equipment vendors to pioneer next-generation processes, such as embedding active/passive components, ultra-fine-line patterning, and advanced surface finishes for enhanced reliability.

In essence, a top European PCB manufacturer is a strategic partner whose capabilities, systems, and culture are built to assure success in the world’s most quality-sensitive and technologically advanced applications.

Strengths of a PCB Factory in Europe for High-Precision Builds

When the design calls for extreme precision, the inherent strengths of a modern PCB factory in Europe‚Äč come to the fore. Their advantage lies in a combination of state-of-the-art equipment, deeply ingrained engineering discipline, and a focus on process mastery rather than just throughput.

- Expertise in HDI and mSAP Processes:‚Äč

For boards requiring high-density interconnects (HDI) with microvias and trace/spacing below 75¬Ķm, European factories are leaders.

Many employ the modified Semi-Additive Process (mSAP), which allows for exceptionally fine lines and spaces (down to 15¬Ķm) crucial for advanced packaging and miniaturized devices.

- Precision in Heavy-Copper and Power Electronics:‚Äč

Building reliable boards for high-current applications is a distinct skill.

European facilities excel in manufacturing PCBs with extreme copper weights (up to 20 oz or more), managing the associated lamination challenges, and ensuring uniform plating in deep vias for effective thermal management and current carrying.

- Superior High-Frequency/High-Speed Performance Control:‚Äč

The ability to consistently achieve target impedance and minimize signal loss is paramount.

This requires not just the right materials but exceptional process control in etching, lamination, and plating to maintain consistent dielectric thickness and conductor profile‚ÄĒa standard strength in European precision manufacturing.

- Advanced Direct Imaging and Automated Optical Inspection:‚Äč

The use of laser direct imaging (LDI) provides superior alignment accuracy and finer feature resolution compared to traditional phototooling.

This is coupled with high-resolution AOI systems that can detect minute defects, ensuring that even the most complex, high-layer-count boards are built to specification.

- Integrated Engineering Support for DFM:‚Äč

The strength is not just in the machines but in the people.

Experienced process engineers work directly with client designs, providing detailed PCB order Europe‚Äč DFM feedback.

They analyze aspects like copper balancing, via structures, and material selection to prevent manufacturing issues and optimize the design for yield and performance before it goes to production.

For high-precision builds, the European PCB factory acts as a precision engineering partner, where every micron is accounted for and every process parameter is optimized for repeatability and quality.

How PCB Prototype Europe Services Support Faster Development?

PCB prototype Europe‚Äč services are the catalyst for accelerated product development. By leveraging local manufacturing, engineering teams can compress their design cycles and de-risk projects more effectively than with distant suppliers.

- Dramatically Reduced Logistics Time:‚Äč

The most obvious advantage is physical proximity.

Shipping a prototype from within Europe often takes 24-48 hours, compared to 5-15 days from Asia. This speed enables a true “build-test-iterate” agile cycle, allowing multiple design revisions within a single month.

- Iterative Development with Real-Time Feedback:‚Äč

Fast turnaround enables an iterative approach.

Engineers can test a design, identify flaws, modify the layout, and receive a new version in days.

This rapid learning loop leads to a more optimized and robust final design much faster than with long lead times.

- Collaborative DFM from Day One:‚Äč

Local PCB suppliers in Europe‚Äč for prototyping often provide more accessible and collaborative DFM analysis.

Engineers can have quick calls or even face-to-face meetings to discuss constraints, material choices, and cost drivers, preventing errors before the first board is made and avoiding costly re-spins.

- Access to Specialized Materials for Niche Testing:‚Äč

For advanced applications, the prototype phase is the time to test specialized materials (high-frequency, high-Tg, flexible).

European prototype services typically offer a wider, more accessible portfolio of these materials locally, allowing for realistic performance testing early in the R&D phase.

- De-risking Ramp to Series Production:‚Äč

Using a local prototype vendor that also has series production capabilities (or partners closely with a volume house) ensures a seamless transition.

The processes, materials, and knowledge are transferred, eliminating the “re-qualification” shock that often occurs when moving a prototype design to a different, high-volume PCB manufacturer in USA‚Äč or Asia.

In short, European prototype services turn the PCB from a project bottleneck into a development accelerator.

How to Choose Reliable PCB Suppliers in Europe for Complex Projects?

Selecting the right partner from the many PCB suppliers in Europe‚Äč for a complex project‚ÄĒinvolving HDI, advanced materials, or high-reliability requirements‚ÄĒrequires a diligent, criteria-driven evaluation.

- Technical Capability Audit:‚Äč

Don’t just review a capability matrix; request evidence.

Ask for samples of similar technology (e.g., a 20-layer HDI board, a heavy-copper power board). Inquire about their standard process controls for impedance, their experience with your specific target material, and their yield rates for comparable designs.

- Quality and Certification Verification:‚Äč

Ensure their certifications (IATF, AS, ISO) are current and scope-appropriate.

Ask about their internal audit schedule, how they handle non-conformances, and request a summary of their quality manual.

For critical projects, an on-site audit is highly recommended.

- Engineering Engagement and Communication:‚Äč

Assess the responsiveness and depth of their engineering team during the quoting/DFM stage.

A reliable partner will ask detailed questions and may suggest alternatives to improve manufacturability or performance.

Gauge their willingness to engage in technical dialogue.

- Supply Chain Transparency and Security:‚Äč

Inquire about their key material suppliers and secondary sources.

Understand their business continuity plans.

For IP-sensitive projects, confirm they have robust IT security (ISO 27001) and clear NDAs/IP agreements in place.

- Scalability and Partnership Approach:‚Äč

Discuss not just the prototype, but the path to medium or high-volume production.

Do they have the capacity, or a trusted partnership model?

Choose a supplier that acts as a long-term partner invested in your product’s success, not just a one-time vendor.

Choosing reliably means looking beyond price and lead time to the underlying systems, expertise, and cultural fit that will ensure project success.

Why Many Teams Work With a PCB Assembly Manufacturer in Europe?

Integrating with a PCB assembly manufacturer in Europe‚Äč for a turnkey or consignment assembly service adds another layer of efficiency and quality assurance to the electronics manufacturing process, especially for prototypes and complex builds.

- Single Point of Accountability:‚Äč

Managing a PCB fab, a component sourcing agent, and an assembler separately creates logistical complexity and finger-pointing risk.

A European-based assembly partner that manages the entire process‚ÄĒfrom procuring the bare board (often from a trusted local fab) to sourcing components and performing assembly‚ÄĒprovides one responsible entity for the final assembled PCB (PCBA).

- Accelerated Time-to-Finished Prototype:‚Äč

Local assembly drastically reduces the time between receiving bare boards and having a functional prototype.

It eliminates international shipping of bare boards and components, allows for faster programming and testing setup, and enables quick engineering changes if rework is needed.

- Superior Quality in Fine-Pitch and Advanced Packaging:‚Äč

European assembly houses are typically equipped for high-mix, complex builds.

They have the expertise and equipment (e.g., advanced SMT lines, X-ray inspection, 3D AOI) to reliably assemble fine-pitch BGA, QFN, and 01005 components, as well as handle underfill and conformal coating processes to a high standard.

- Simplified Logistics and Reduced Overhead:‚Äč

Consolidating the supply chain within one geographic region (or even one facility) minimizes customs paperwork, shipping costs, and transit damage risk.

It simplifies inventory management and can improve cash flow.

- Enhanced Design for Assembly (DFA) Feedback:‚Äč

A local assembly partner can provide early and ongoing DFA feedback, just as the fab provides DFM. This collaboration can optimize component placement, stencil design, and test point accessibility, improving first-pass yield and long-term reliability.

For teams looking to streamline their build process and ensure the highest quality in the final assembled product, partnering with a European PCBA manufacturer is a logical and effective strategy.

Top 10 PCB Manufacturers in Europe

Europe’s PCB Market

China Dependency

- Over 65% of Europe’s PCB raw materials and standard boards come from China.

Automotive Focus

- Automotive electronics‚ÄĒespecially EV systems‚ÄĒremain a critical driver of European PCB demand.

Market Concentration

- The European PCB industry is fragmented, with many mid-sized specialist firms rather than a few global giants.

Europe excels where speed, reliability, and engineering collaboration outweigh sheer output volume.

| Rank | Company | Headquarters | Core Specialization |

|---|---|---|---|

| 1 | Eurocircuits | Belgium | Rapid Prototyping |

| 2 | NCAB Group | Sweden | Contract Manufacturing & Assembly |

| 3 | W√ľrth Elektronik | Germany | PCB + Passive Components |

| 4 | Elvia PCB Group | Austria | High-Reliability PCBs |

| 5 | Beta LAYOUT | Germany | Design-to-Manufacturing |

| 6 | Aspocomp | Finland | High-Frequency & High-Speed |

| 7 | Lab Circuits | Netherlands | Custom PCB Engineering |

| 8 | ICAPE Group | France | Aerospace & Defense |

| 9 | eXception PCB | Germany | Flexible & Rigid-Flex PCBs |

| 10 | Trackwise | UK | Rapid Small-Batch Production |

Strategic Comparison: Two Dominant Models

Prototyping Specialists (Eurocircuits, Trackwise)

‚ÄĘ Focus on speed and flexibility

‚ÄĘ Target: Startups, IoT developers, R&D labs

‚ÄĘ Standard process includes online ordering and short turnaround (1‚Äď3 days)

‚ÄĘ Higher cost per unit due to focus on agility

Engineering Giants (NCAB Group, W√ľrth Elektronik)

‚ÄĘ Focus on long-term supply, engineering support, and integration

‚ÄĘ Target: Automotive OEMs, aerospace, and large global brands

‚ÄĘ Emphasis on DFM optimization and scalable production

‚ÄĘ Lower unit costs for medium to large volumes

Selection Criteria Checklist

Consider the following factors when choosing a European PCB manufacturer:

- Project Phase

Prototypes suit Eurocircuits or Trackwise.

Mass production aligns with NCAB or W√ľrth. - Technical Specifications

High-frequency requirements? Choose Aspocomp.

Need passive component integration? W√ľrth stands out. - Geographic Support

Some manufacturers, like NCAB Group, have teams across Europe for local communication and service. - Certifications

Look for:

‚ÄĘ IATF 16949 (Automotive)

‚ÄĘ AS9100 (Aerospace)

‚ÄĘ ISO 9001

‚ÄĘ IPC Class 3 capability for high-reliability builds

Europe’s PCB market thrives on engineering depth, reliability, and rapid innovation cycles rather than mass production. While global giants in Asia dominate volumes, European firms excel in delivering specialized, high-value solutions.

For engineers and procurement teams, the choice depends on project goals:

‚ÄĘ Rapid prototyping for early-stage innovation

‚ÄĘ High-reliability or large-scale production for mature products

Both categories play a vital role in Europe’s evolving electronics ecosystem.

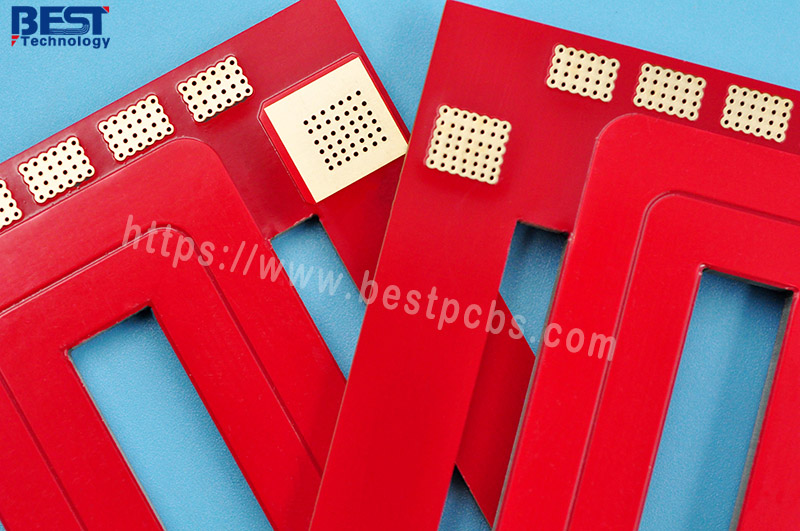

Case Studies of PCB Order Europe Projects Supported by EBest Circuit (Best Technology)

At BEST Technology, we pride ourselves on being a strategic partner for European innovators, turning complex specifications into reliable, high-performance PCBs that power advancements across industries. Each PCB order Europe‚Äč we receive is a unique challenge, met with precision engineering and rigorous quality control. Below are two distinct case studies showcasing how our manufacturing expertise supports diverse technological applications.

Case Study 1: High-Speed Data Acquisition Module for Automotive Radar Testing

Application Scenario:

An automotive R&D lab in Sweden required a robust and reliable data acquisition module for their advanced driver-assistance systems (ADAS) testing platform. This module acts as the interface between high-frequency automotive radar sensors and the data processing unit. The PCB’s primary function was to preserve signal integrity for high-speed digital data streams while withstanding the mechanical vibrations and temperature variations typical in a vehicular test environment. Precise impedance control was non-negotiable to ensure accurate signal capture without distortion or crosstalk.

Board Parameters:

- Type:‚Äč 4-Layer FR4 PCB

- Board Thickness:‚Äč 1.723mm ¬Ī10%

- Tg:‚Äč 170¬įC

- Copper Weight:‚Äč 53őľm (Inner & Outer Layers, ~1.5 oz)

- Surface Finish:‚Äč ENIG (Au 1őľ”)

- Hole Copper:‚Äč 20őľm

- Solder Mask / Silkscreen:‚Äč Green LPI / White

- Critical Requirement:‚Äč Controlled 90ő© impedance (¬Ī10%) for differential pairs

- Quality Assurance:‚Äč 100% Electrical Testing. Impedance test coupon (with trace/copper thickness data) and full test report (including impedance results) required for shipment.

- Tolerances:‚Äč NPTH: +2/-1 mils; Via: +0/-Finished Hole Size; Other PTH: ¬Ī3 mils.

Case Study 2: High-Current Motor Drive Controller for Industrial Automation

Application Scenario:

A German manufacturer of precision industrial robots was designing a next-generation motor drive controller. This PCB needed to manage high inrush and continuous currents for powerful servo motors. The key challenges were efficient heat dissipation to prevent thermal throttling and ensuring absolute reliability under continuous operational stress. The design demanded heavy copper layers to carry current, along with certifications to meet stringent international safety and quality standards for industrial equipment.

Board Parameters:

- Type:‚Äč 6-Layer FR4 PCB

- Board Thickness:‚Äč 2.06mm ¬Ī10%

- Tg:‚Äč 170¬įC

- Copper Weight:‚Äč 3 oz (Inner & Outer Layers, ~105őľm)

- Surface Finish:‚Äč ENIG (Au 1őľ”)

- Solder Mask / Silkscreen:‚Äč Green LPI / White

- Standards & Certifications:‚Äč Compliant with UL, RoHS, and IPC-6012 Class 2 standards.

- Quality Assurance:‚Äč 100% Continuity testing prior to shipment. Complete documentation package including Certificate of Conformance (CoC), Microsection Report, Electrical Test Report, Solderability Test Report, and Copper Thickness Report.

These case studies demonstrate BEST Technology’s capability to deliver on critical PCB prototype Europe‚Äč projects, from high-speed, impedance-sensitive applications to high-power, reliability-driven industrial systems. Our commitment to meeting exact specifications and providing comprehensive documentation ensures your project moves forward smoothly. For your specialized requirements, pls feel free to contact our team at sales@bestpcbs.com.

Why Choose EBest Circuit (Best Technology) for Supporting PCB Prototype Europe Projects?

- Extensive Experience and Specialization‚Äč

- 19+ years of expertise in PCB manufacturing and assembly.

- Specialized in advanced PCB types: Metal Core (MCPCB), Ceramic, FR4, Heavy Copper (up to 20 oz), HDI, High-Frequency (Rogers/Taconic), and Rigid-Flex boards.

- Proven capability to handle complex prototypes (e.g., 50+ layers, 0.15mm thin boards) and stringent European standards.

- Comprehensive Prototyping Capabilities‚Äč

- Rapid prototyping services: 24-hour turnaround‚Äč for urgent FR4/MCPCB prototypes.

- Wide technical specifications:

- Layer count: 1‚Äď50 layers (up to 100L with review).

- Board thickness: 0.4‚Äď6mm (standard), 0.15‚Äď10mm (limit).

- Fine line width/spacing: Down to 2.5/2.5 mil (limit).

- Diverse materials: FR4, high-TG, high-frequency, halogen-free, and custom options.

- Support for advanced processes: Laser drilling (0.07mm), impedance control (¬Ī5ő©), and mixed-surface finishes (ENIG, ENEPIG, OSP, etc.).

- Quality Assurance and Certifications‚Äč

- ISO 9001:2015, ISO 13485:2016, IATF 16949, RoHS, and REACH‚Äč compliance.

- Rigorous quality control: Automated optical inspection (AOI), X-ray testing, flying probe testing, and micro-section analysis.

- Adherence to IPC standards for reliability in automotive, medical, and industrial applications.

- Turnkey Solutions and Supply Chain Efficiency‚Äč

- End-to-end services: PCB design, fabrication, component sourcing, assembly, and box-build.

- Partnerships with global component distributors (Digikey, Mouser, Avnet) to avoid counterfeit parts.

- One-stop workflow reduces communication barriers and accelerates time-to-market for European clients.

- Transparent Pricing and On-Time Delivery‚Äč

- Quick prototyping without MOQ requirements.

- 97% on-time delivery rate‚Äč with real-time production tracking (WIP updates).

- Optimized logistics for European markets, including expedited shipping options.

- Dedicated Customer Support‚Äč

- Engineering sales teams provide 24/7 technical support‚Äč and DFM feedback.

- Multilingual communication (English, etc.) and tailored solutions for European regulatory needs.

With strong engineering support, advanced manufacturing tools, complete quality certifications, and seamless communication, EBest Circuit (Best Technology) helps customers shorten development time, reduce redesign risks, and transition smoothly from prototype to production. For your next PCB prototype requirement in Europe, our team is ready to support you with speed, precision, and professional service. Pls feel free to contact us anytime at sales@bestpcbs.com.

In closing, a PCB manufacturer in Europe‚Äč represents a strategic nexus of technological prowess, quality adherence, and collaborative partnership, essential for navigating the complexities of modern electronics development. This article has explored the compelling reasons to choose European manufacturing, the trends shaping its future, and the standards that define its leaders.

For teams seeking a reliable partner to transform innovative designs into tangible, high-quality prototypes with speed and precision, the European ecosystem offers distinct advantages. At BEST Technology, we embody these advantages, combining full technical expertise with a client-focused approach to support your most challenging Europe PCB projects from prototype through production. Pls feel free to reach out to start a conversation via sales@bestpcbs.com.