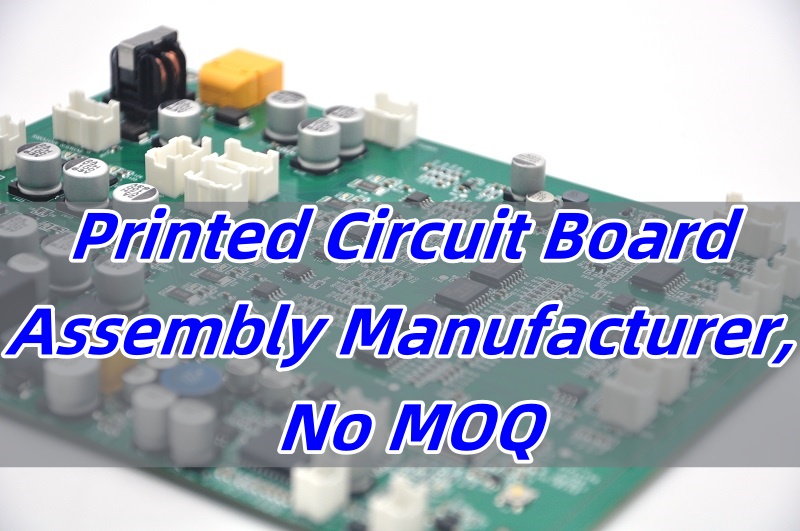

SMT board assembly is one of the key stages in modern electronics manufacturing. It uses automated methods to mount components onto the surface of PCBs. This process brings precision, speed, and scalability to production. At EBest Circuit (Best Technology), we deliver top-tier SMT assembly with no MOQ, letting you stay flexible and competitive.

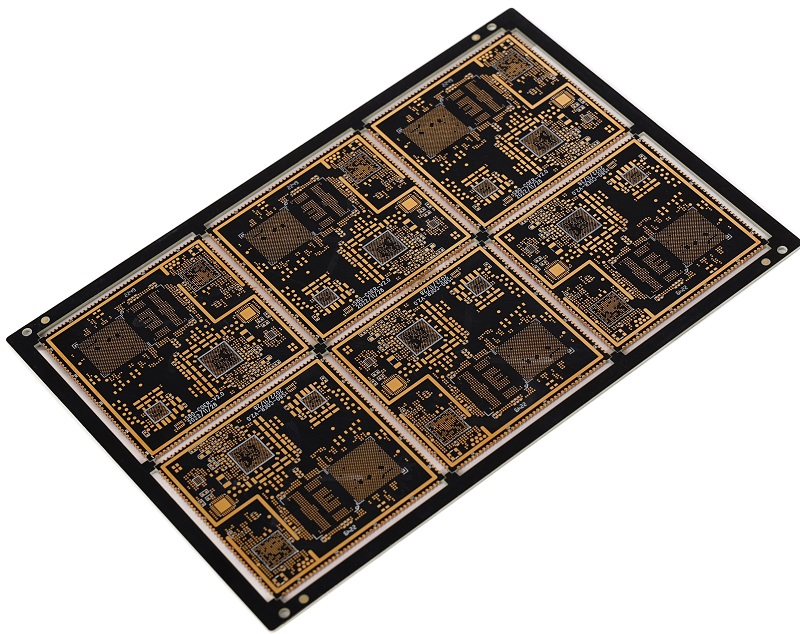

As an established SMT PCB assembly factory, EBest Circuit (Best Technology) is committed to providing no MOQ SMT board assembly service to the global market. Providing Small Batch PCB Assembly, maintaining the consistency of quality, on-time delivery, turnkey PCB assembly, and quick before and after-sales service are our product positioning. We are accountable for the SMT board assembly quality. If you need a one-stop SMT PCBA service, pls free to contact EBest Circuit (Best Technology) at sales@bestpcbs.com.

What Is SMT Board Assembly?

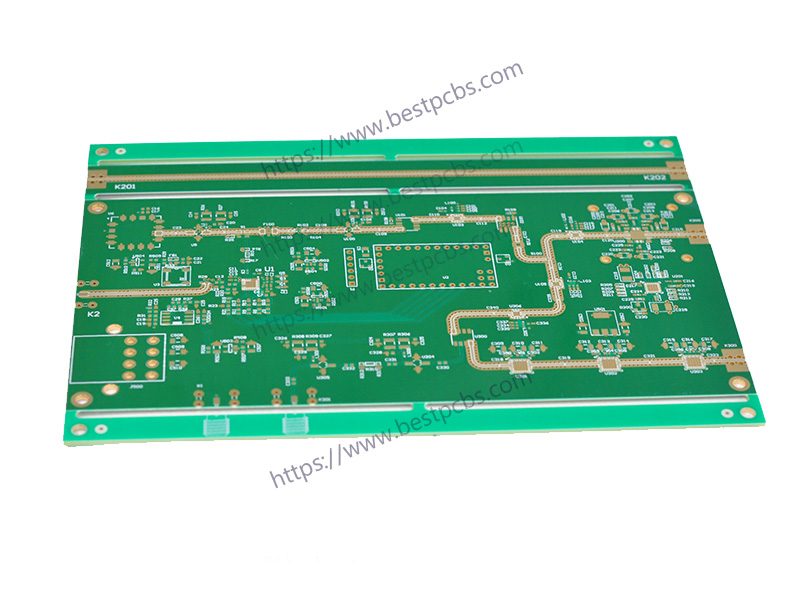

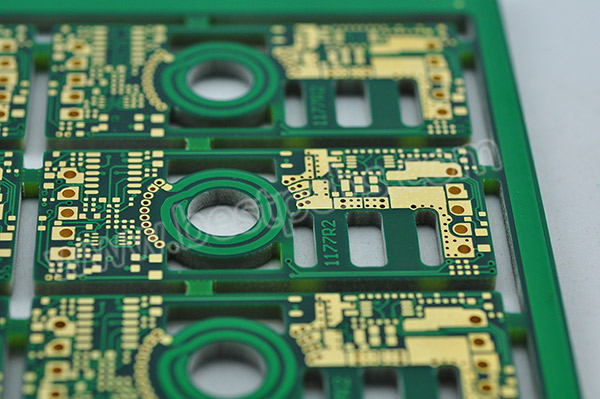

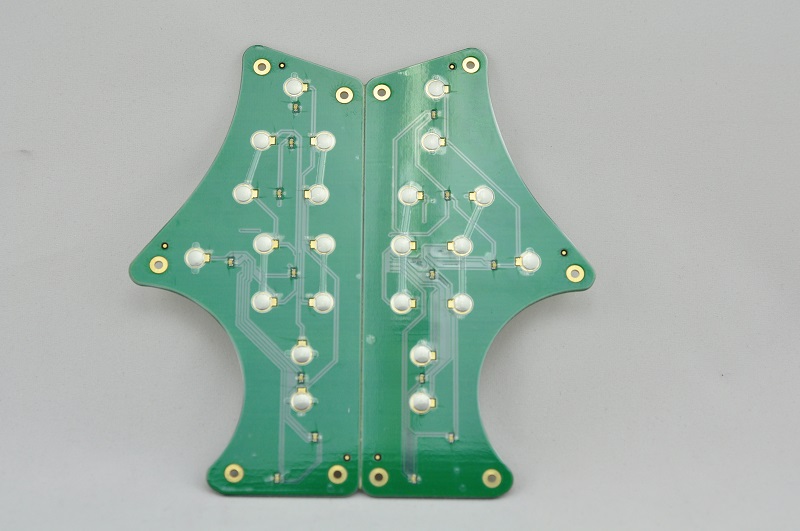

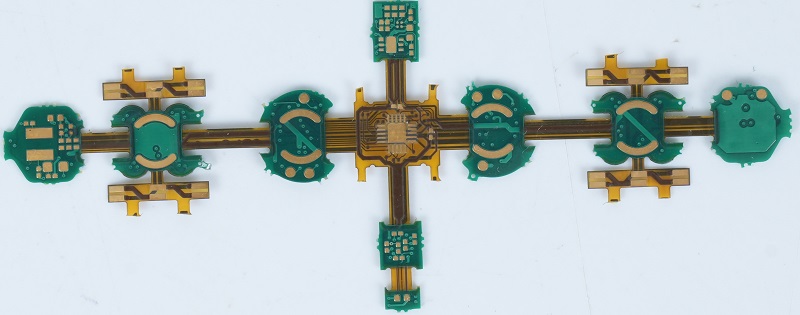

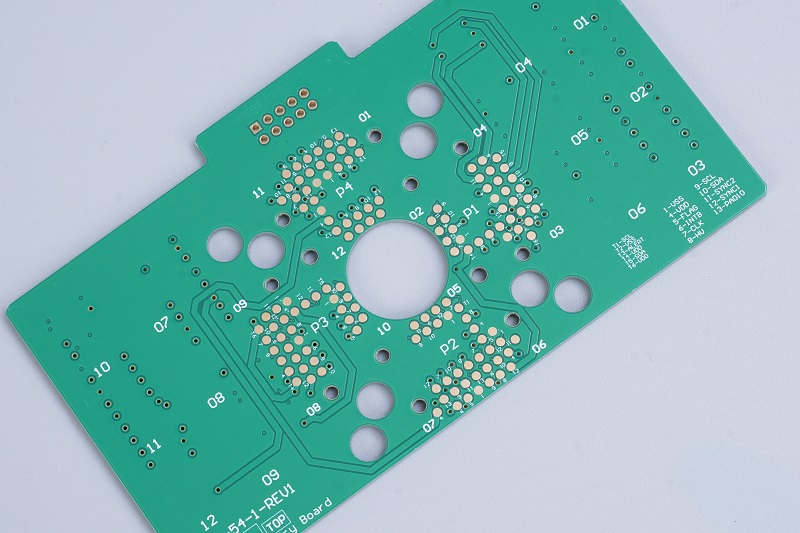

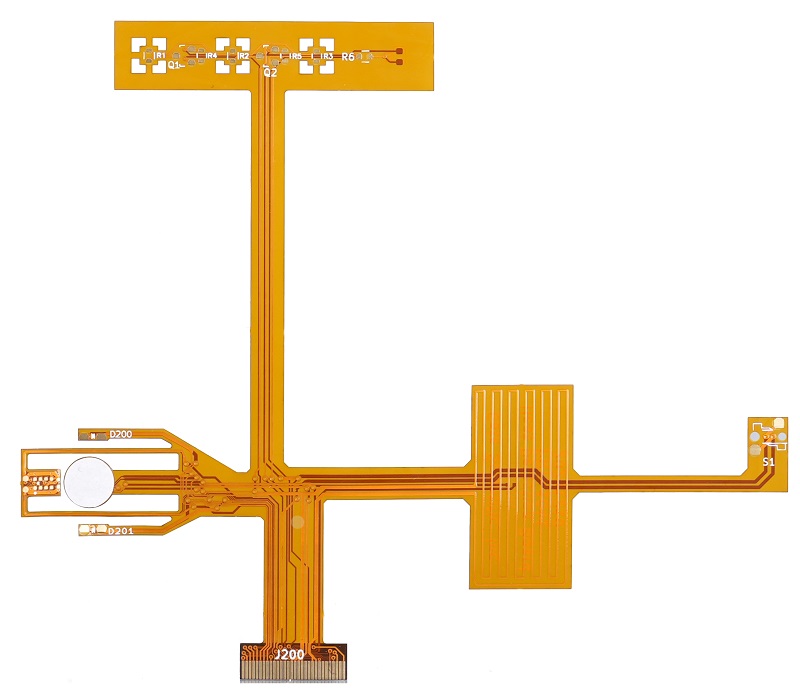

SMT board assembly is the process of placing surface-mounted devices (SMDs) onto a printed circuit board (PCB). Unlike traditional through-hole methods, SMT doesnât require drilled holes. It saves space and improves signal flow. This makes SMT the best choice for modern electronics where small size and high performance are key.

Is SMD the Same as SMT?

Not exactly. SMD refers to the components themselvesâsmall chips that mount on a PCB. SMT is the process that places and solders those SMDs. They are closely connected but not the same. Think of SMDs as the parts, and SMT as the way theyâre installed. When both work smoothly, the final result is reliable.

What Are SMT Components?

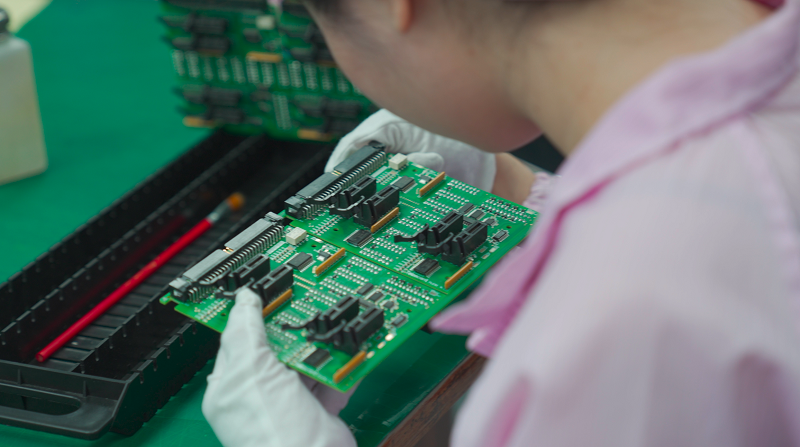

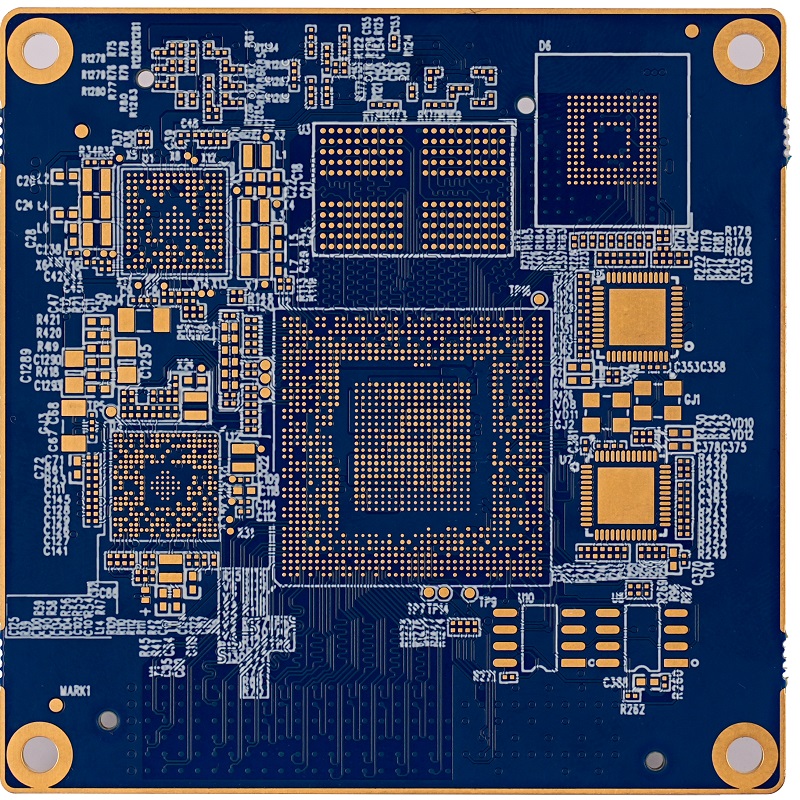

SMT components include resistors, capacitors, ICs, LEDs, and transistors. These parts come in tiny packages that fit directly onto PCB pads. Because they are compact, they need accurate placement. Even slight misalignment can lead to defects. At EBest Circuit (Best Technology), we use high-precision machines to ensure perfect positioning.

What Temperature Should SMT Solder Paste Be?

Solder paste temperature must be carefully controlled. The reflow oven follows a heat profile, usually peaking between 230°C and 250°C. For lead-free solder, control is even more important. If the paste overheats, it may spatter. If too cold, cold solder joints may occur. EBest Circuit (Best Technology) uses advanced ovens with stable profiles. This ensures every joint is smooth and strong.

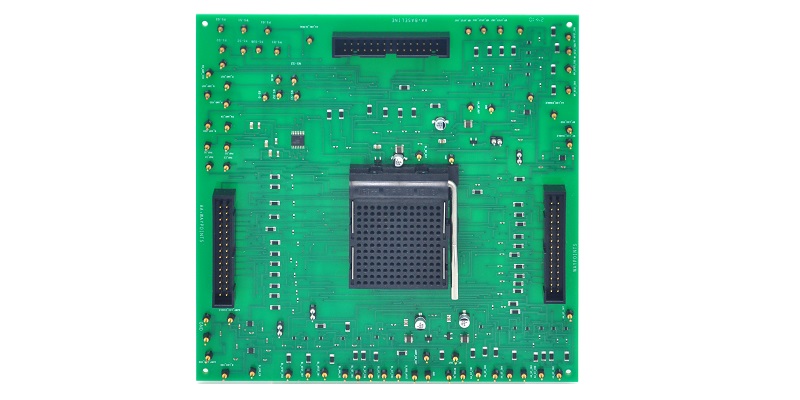

How Does SMT Board Assembly Work on a CPU?

CPU boards need extreme accuracy. Their BGA components sit under the chip body, making inspection harder. SMT board assembly for CPUs includes paste printing, placement, reflow, and X-ray checking. Each step must be flawless. We use 3D paste inspection, AOI, and X-ray to detect any hidden issues. Thatâs how we keep our CPU boards reliable.

What Is the SMT Board Assembly Process?

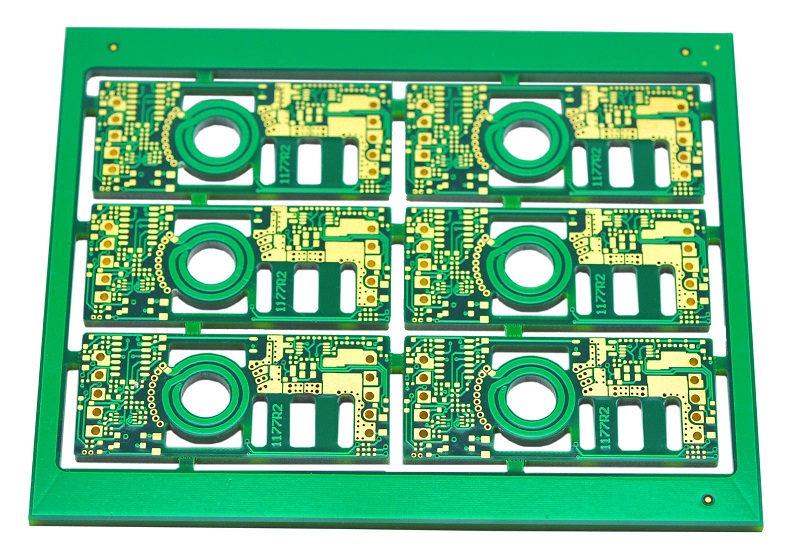

Hereâs a step-by-step look at how SMT board assembly works:

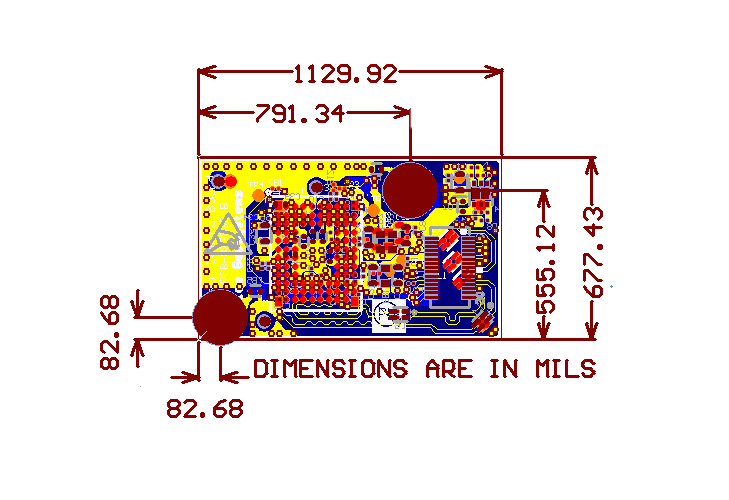

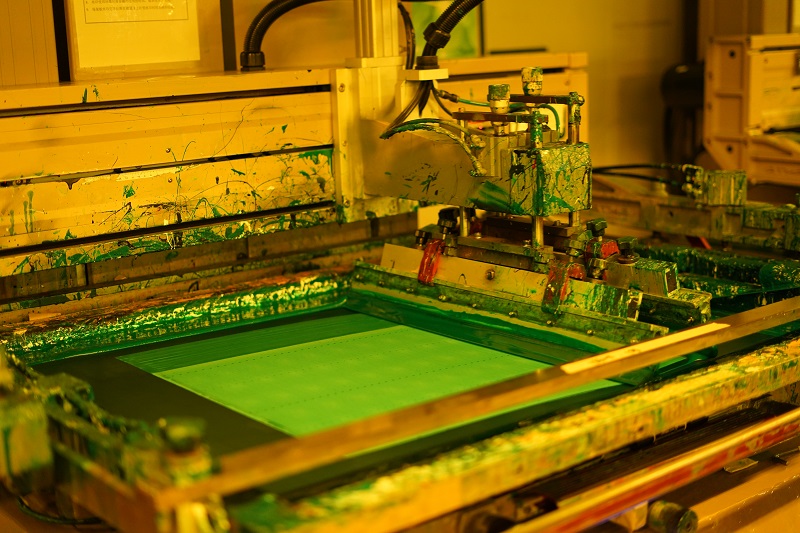

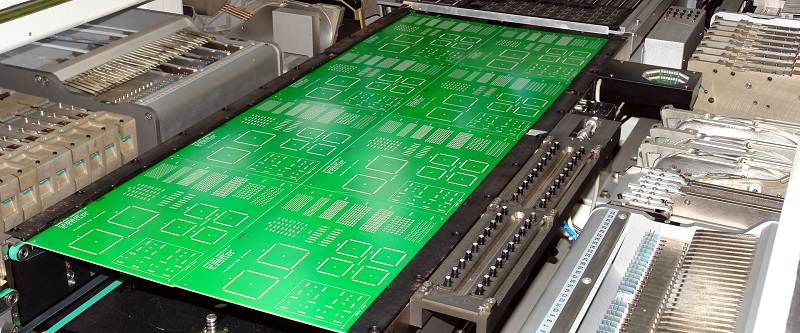

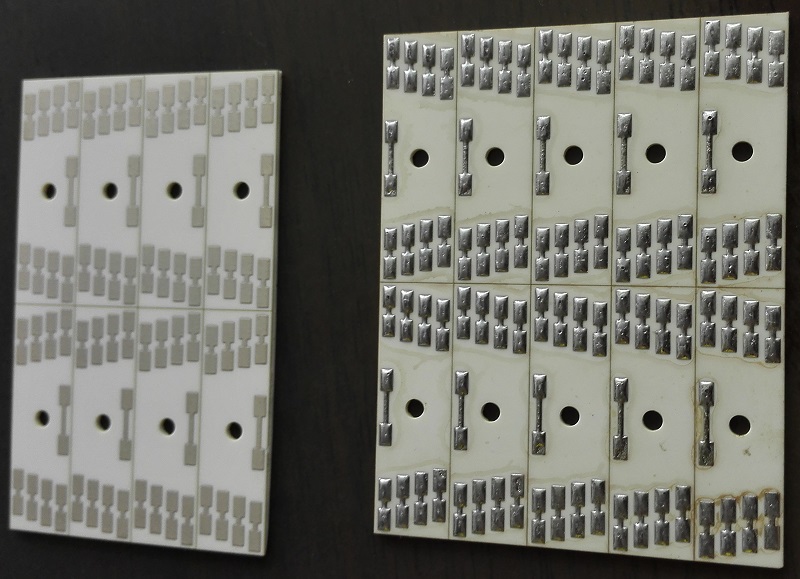

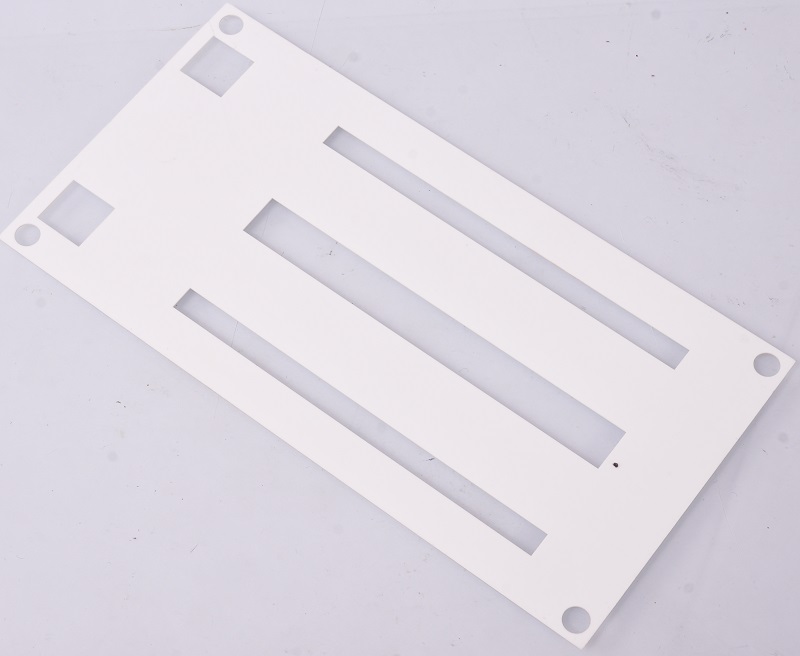

- Solder Paste Printing:Â Paste is applied on PCB pads with a stencil. We check for even coverage and correct alignment.

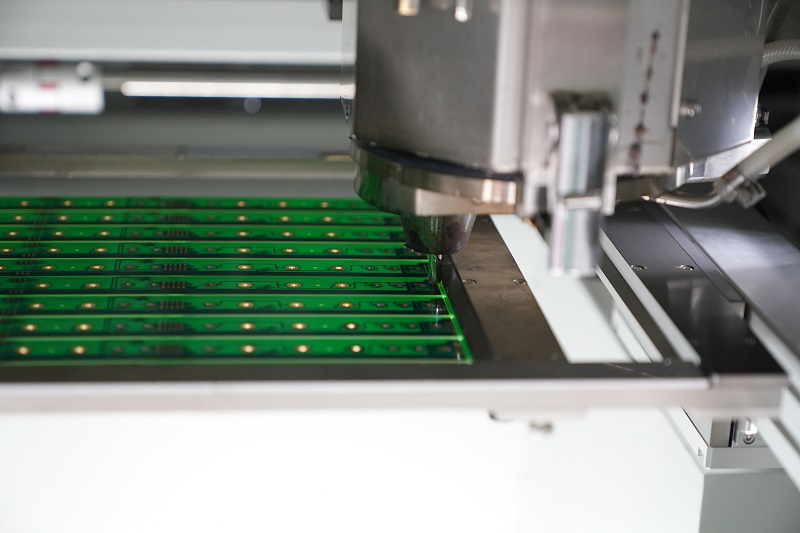

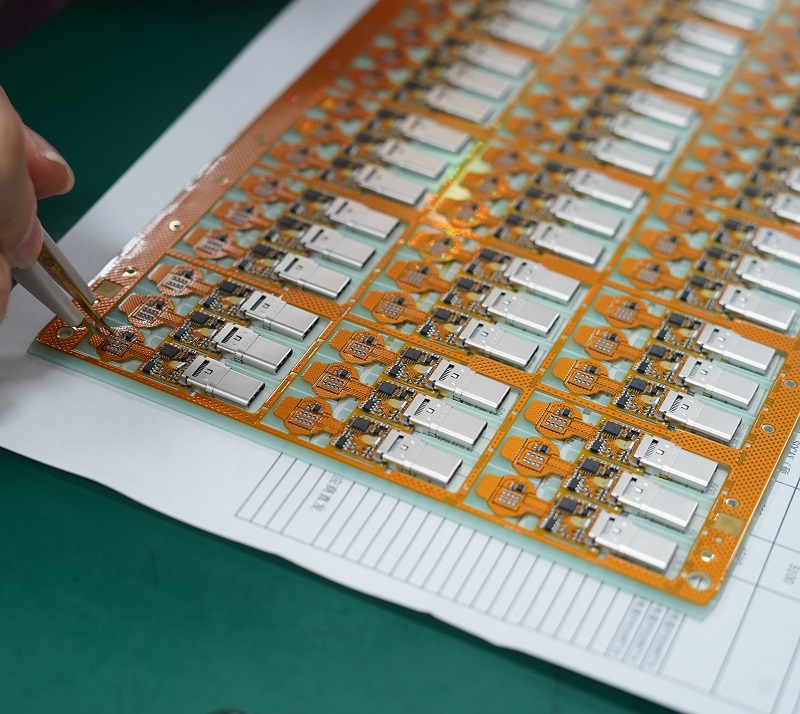

- Component Placement:Â Machines pick and place SMDs based on coordinates. EBest Circuit (Best Technology) uses precise vision systems to avoid misalignment.

- Reflow Soldering:Â The PCB passes through ovens to melt the paste. This bonds components to pads. We control heat curves to avoid cold joints or bridging.

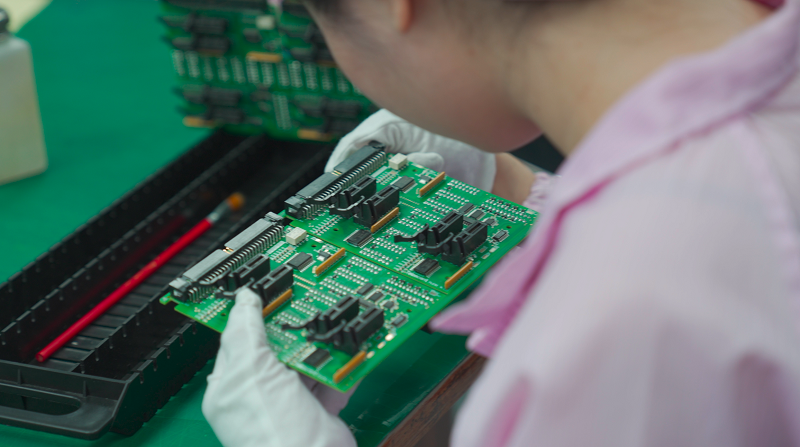

- Inspection:Â AOI checks solder and component positions. For BGAs, we use X-ray inspection to ensure thereâs no tombstoning or voids.

- Testing:Â We run electrical tests and sometimes functional checks to verify the board works before delivery.

This SMT PCB assembly process reduces human error and increases repeatability. It’s efficient and scalable.

Why Should You Choose EBest Circuit (Best Technology) as Your SMT Board Assembly Partner?

Choosing EBest Circuit (Best Technology) involves more than just high-quality SMT Board Assembly; we also provide SMT board assembly solutions.

- Defect Control:Â Our AOI, X-ray, and 3D inspection systems detect short circuits, tombstones, or cold joints early.

- Precise Placement:Â With high-speed pick-and-place machines and updated software, we minimize errors and ensure tight alignment.

- Physical Protection:Â We follow strict handling rules to prevent cracks and board warping during the process.

- Design Feedback:Â If we spot layout problems or missing BOM items, we notify you at once. No delays.

- No MOQ:Â Our flexible model fits startups and R&D teams. Try a prototype today, scale up tomorrow.

- Lead-Free Expertise:Â We manage higher temps and solder behavior with tight control. That means fewer issues and better outcomes.

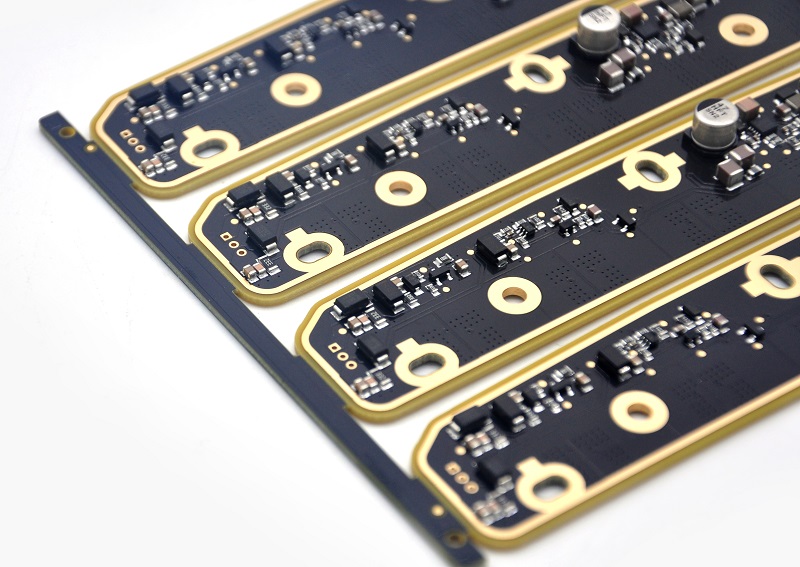

- High-Density Success:Â Tiny components or large BGAs? Weâve done them all. Our cleanroom setup handles complex builds smoothly.

- Quick Turn:Â Need fast delivery? Our 10+ SMT board assembly lines reduces wait time.

Also, EBest Circuit (Best Technology) offers transparent assembly pricing along with strict quality control measures. You wonât just get SMT circuit board assemblyâyouâll get the solutions of the PCB series.

In a nutshell, SMT board assembly is the core of todayâs electronics. But speed and scale aren’t enough. You need reliability, flexibility, and a partner who solves issues before they hurt. Thatâs why EBest Circuit (Best Technology) leads in SMT PCB assemblyâespecially in high-density designs, CPU-grade boards, and small runs with no MOQ. We control paste print, solder quality, and final tests better than most competitors. More importantly, we communicate clearly when BOMs or designs need improvement. Thatâs how we build trust and better PCBs. Feel free to reach out to us by emailing sales@bestpcbs.com. EBest Circuit (Best Technology) is always ready and glad to help!