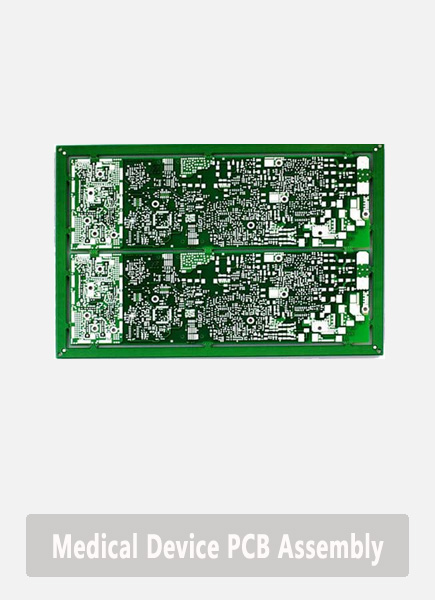

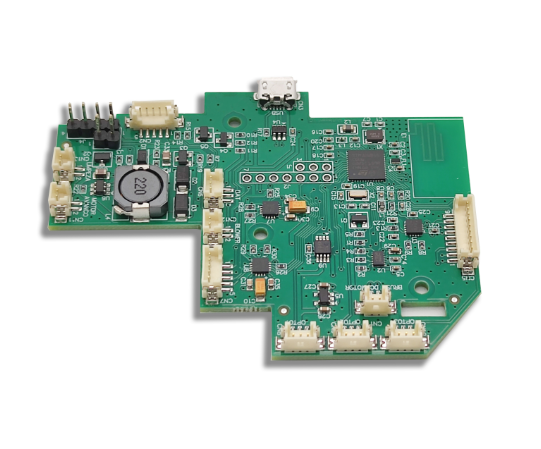

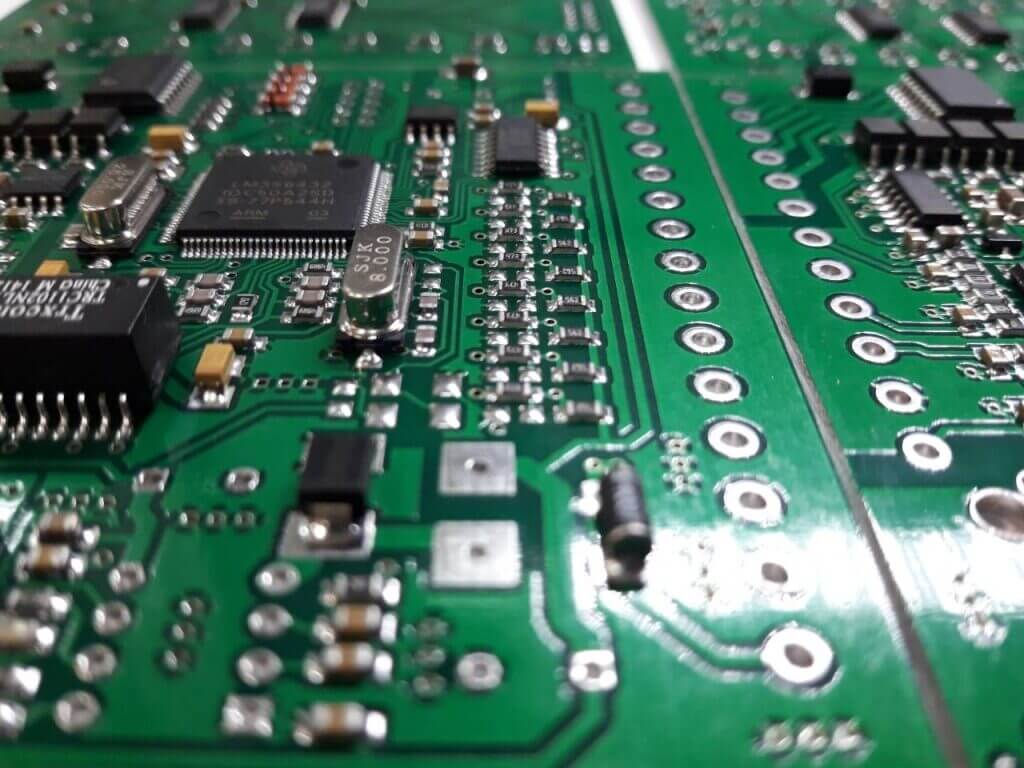

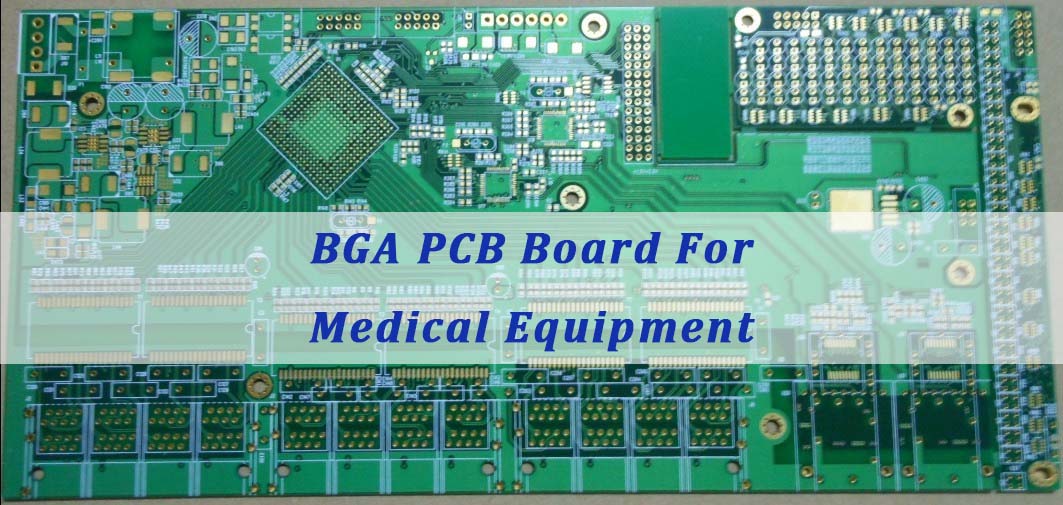

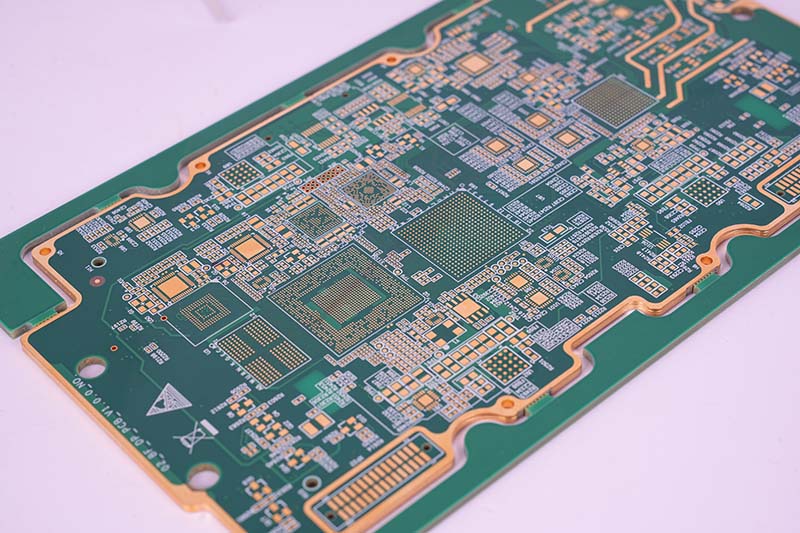

BGA PCB board for medical equipment is not just a high-density interconnect solution ‚ÄĒ it is a reliability-critical architecture used in patient monitoring systems, imaging platforms, portable diagnostics, and surgical electronics.

Medical OEMs commonly face the following pain points:

- Micro-pitch BGA solder joint cracking under thermal cycling

- Signal integrity issues in imaging and data acquisition systems

- Inconsistent traceability across supply chains

- Failure to meet ISO 13485 documentation requirements

- Prototype-to-mass-production reliability gaps

These challenges require engineering-driven solutions:

- Controlled impedance stack-up design and microvia optimization

- X-ray inspection and BGA void ratio monitoring

- Full material traceability and MES tracking

- Medical-grade process validation and PPAP documentation

- NPI engineering validation before mass production

EBest Circuit (Best Technology) is an engineering-led PCB and PCBA manufacturer with extensive experience in medical electronics production. Our facilities support BGA, HDI, rigid-flex, ceramic, and high-layer-count PCB fabrication aligned with ISO 13485 quality systems.

We provide full lifecycle support ‚ÄĒ from DFM review to final functional test ‚ÄĒ ensuring compliance, reliability, and traceability. For medical-grade PCB solutions, contact sales@bestpcbs.com.

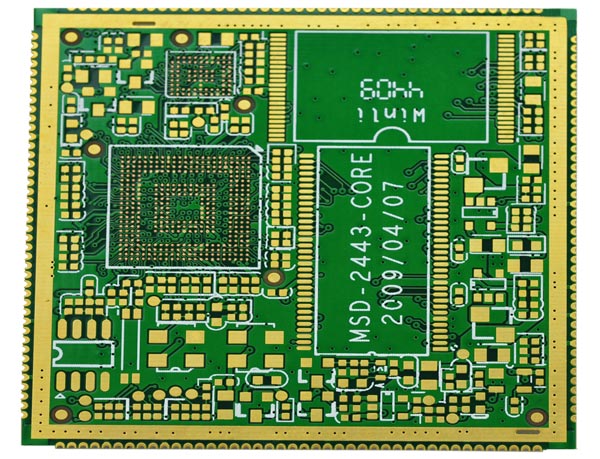

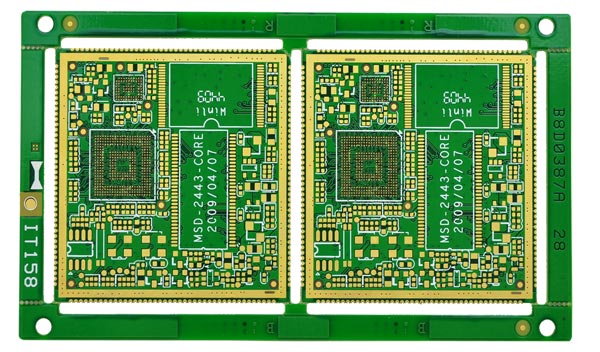

What Makes A BGA PCB Board For Medical Equipment Different From Standard PCB Designs?

A bga pcb board for medical equipment must meet far stricter reliability, traceability, and inspection standards than commercial boards. The margin for failure is effectively zero.

Key differences include:

| Parameter | Commercial PCB | Medical BGA PCB |

|---|---|---|

| IPC Class | Class 2 | Class 3 |

| Inspection | AOI only | AOI + X-ray + Microsection |

| Traceability | Batch level | Component-level |

From an engineering perspective, BGA void control (<25%), controlled reflow profiling, and CAF prevention are mandatory. In summary, design complexity directly impacts manufacturing reliability.

Why Is Medical Equipment PCB Manufacturing Required To Meet ISO 13485 Standards?

Medical equipment pcb production must comply with ISO 13485 because it governs risk management, documentation, and process validation.

Core requirements include:

- Documented work instructions

- Lot traceability

- Corrective action procedures

- Process validation records

Under real manufacturing conditions, regulatory audits require full transparency across materials and processes. To sum up, compliance is non-negotiable.

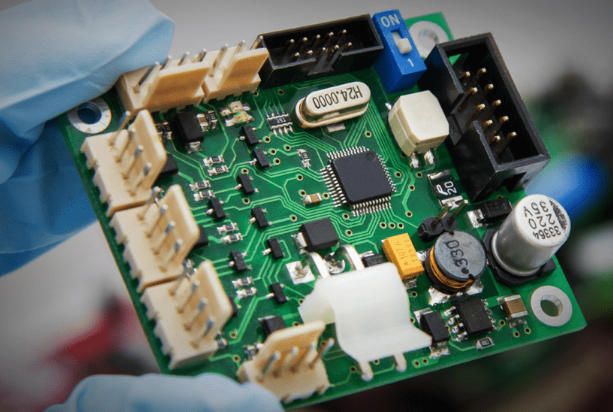

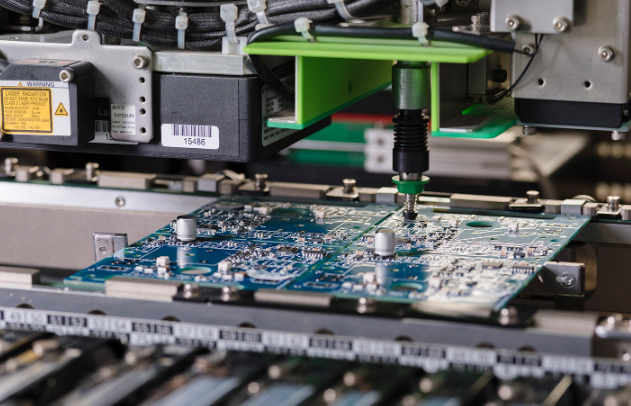

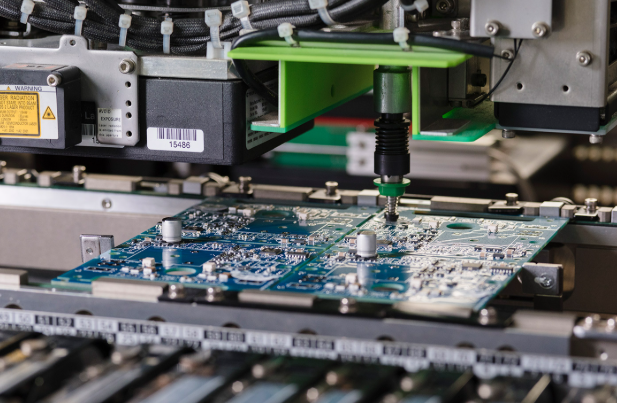

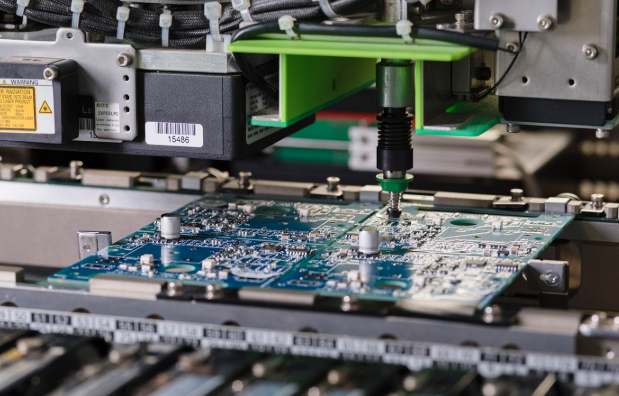

How Does A China Medical Equipment PCB Manufacturer Ensure High BGA Reliability?

A china medical equipment pcb manufacturer ensures reliability through process control and advanced inspection.

Critical controls:

- Nitrogen reflow (O‚āā < 1000 ppm)

- SPI solder paste volume verification

- X-ray void ratio analysis

- Thermal profiling for SAC305

Evidence shows controlled nitrogen environments reduce oxidation and improve joint integrity. As a result, BGA fatigue resistance improves significantly.

What Should You Evaluate When Choosing A Medical Equipment PCB Manufacturer In China?

You should evaluate certification level, engineering capability, and BGA inspection equipment.

Checklist:

- ISO 13485 certification

- IPC Class 3 capability

- In-house X-ray & AOI

- DFM review support

More importantly, request process capability reports (CpK data). In contrast to general EMS providers, medical-focused manufacturers emphasize validation.

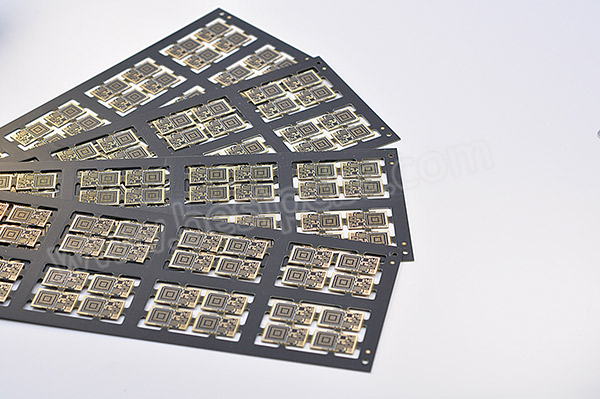

How Does A Medical Equipment PCB Supplier In China Control Traceability And Risk?

A medical equipment pcb supplier in china must implement digital MES traceability.

Key systems include:

- Barcode-level PCB tracking

- Component reel traceability

- Reflow oven profile logging

- Defect database monitoring

The bottom line is, without digital traceability, regulatory compliance fails.

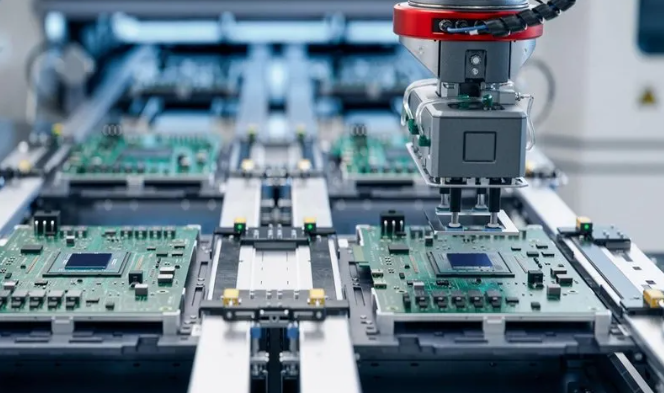

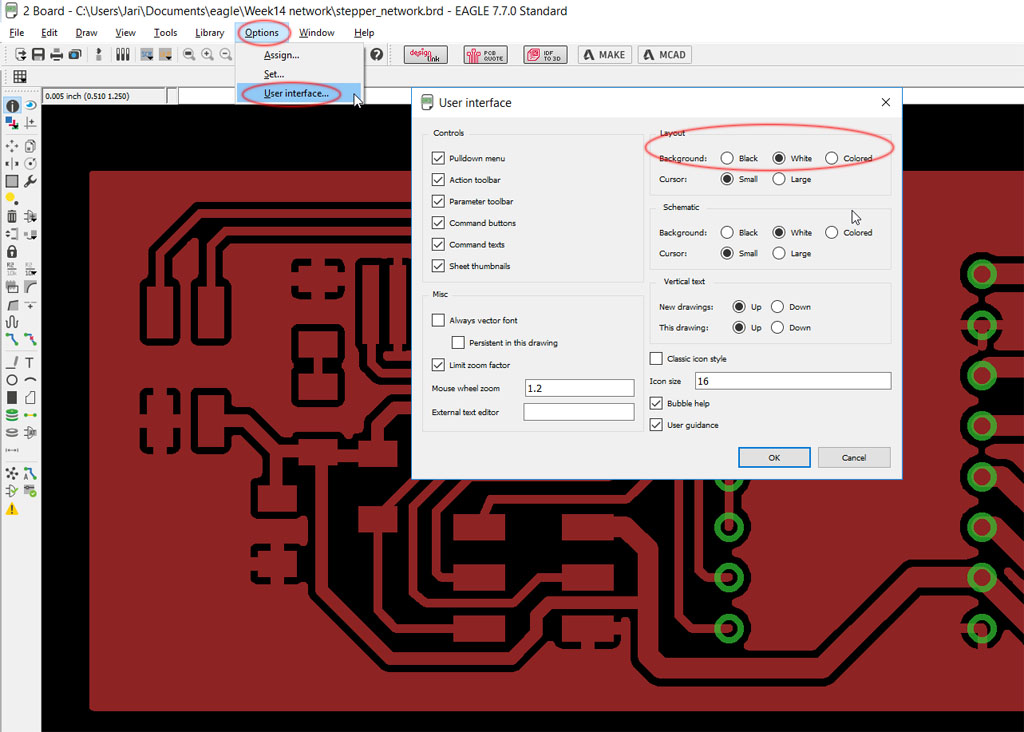

When Should OEM Medical Equipment PCB Factories Be Involved Early In BGA Design?

OEM medical equipment pcb factories should be involved during schematic and stack-up planning.

Benefits include:

- Via-in-pad feasibility review

- Impedance modeling

- Thermal simulation

- Pad size optimization

With this in mind, early DFM engagement prevents redesign delays.

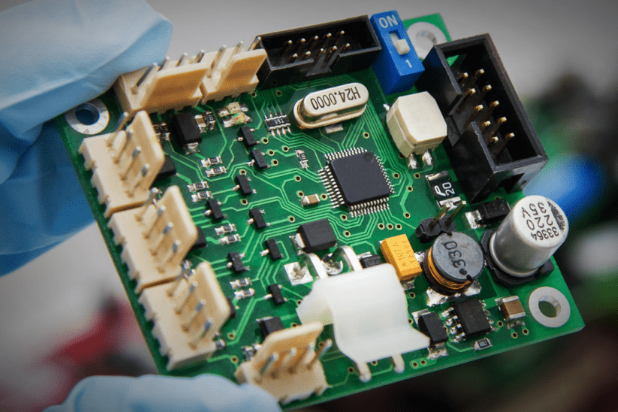

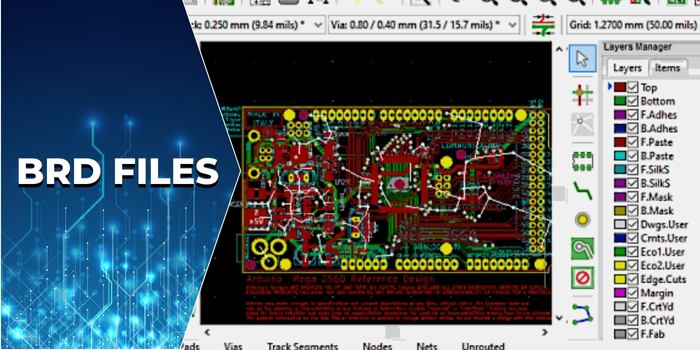

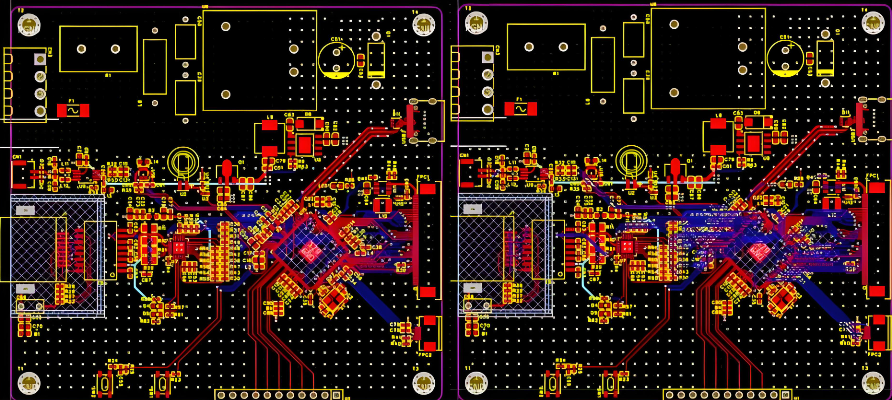

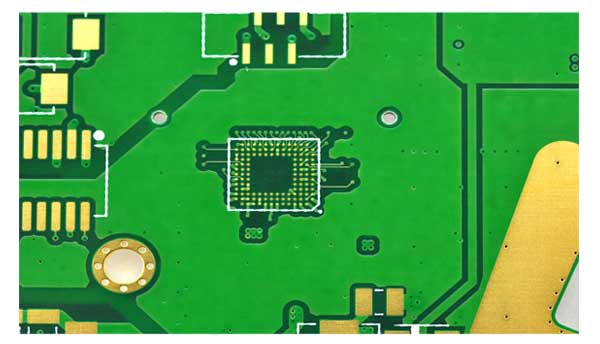

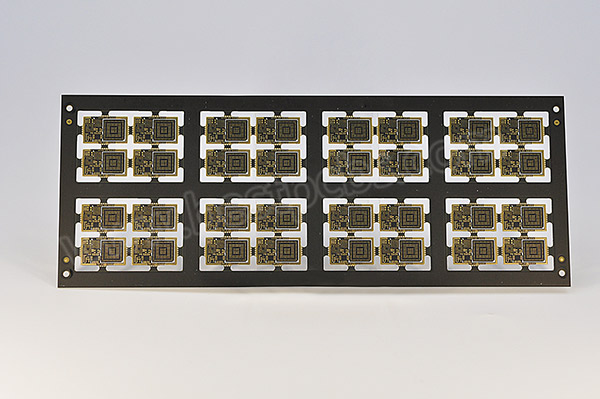

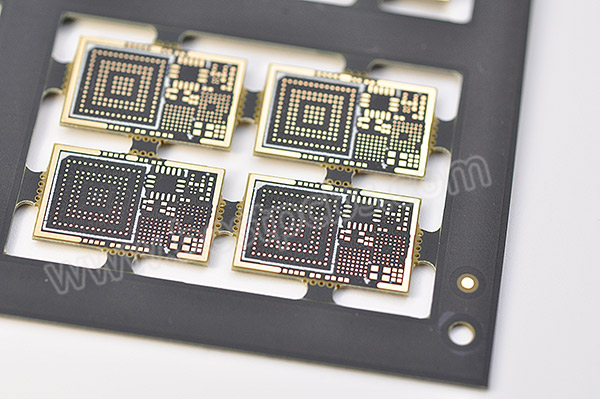

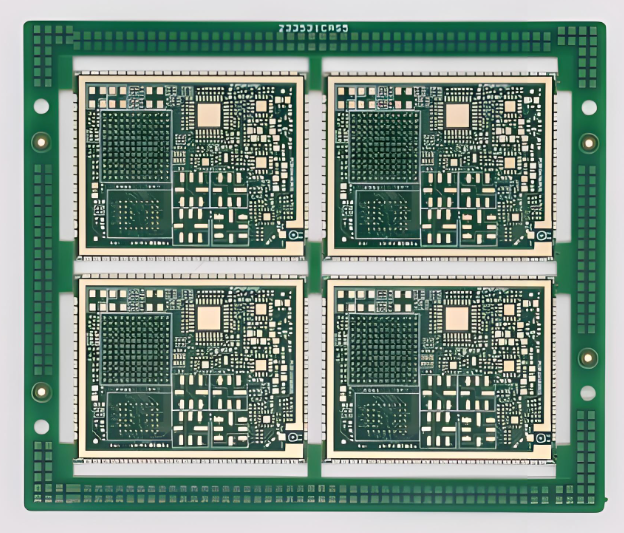

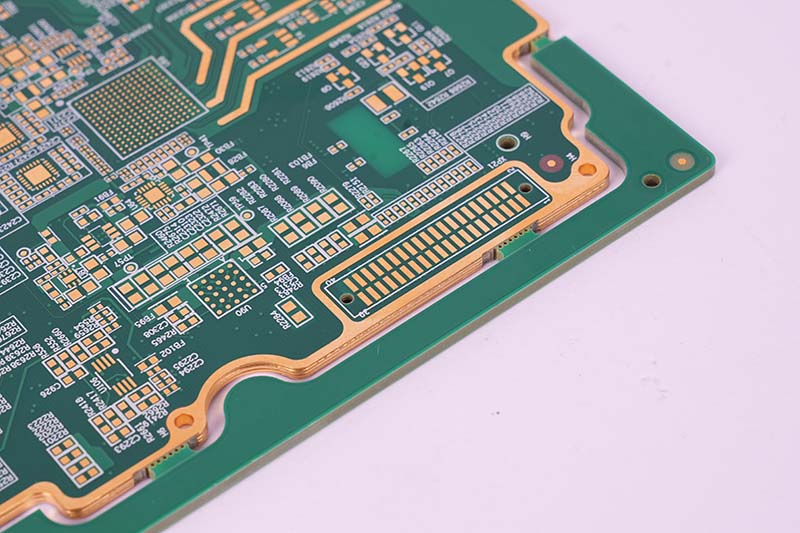

What Design Rules Apply To PCB For Medical Equipment Using Fine-Pitch BGA?

PCB for medical equipment using fine-pitch BGA must follow HDI rules.

Typical constraints:

- Microvia diameter ‚ȧ 0.1 mm

- Laser-drilled stacked vias

- ENIG or ENEPIG finish

- 50ő© / 100ő© impedance control

Ultimately, controlled stack-up reduces signal loss in imaging systems.

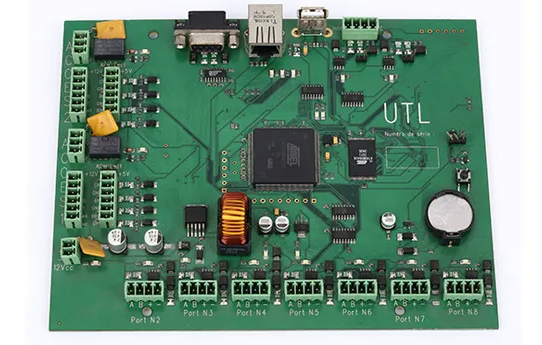

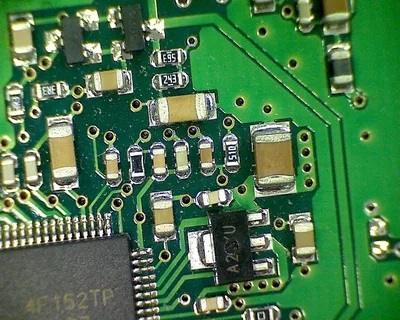

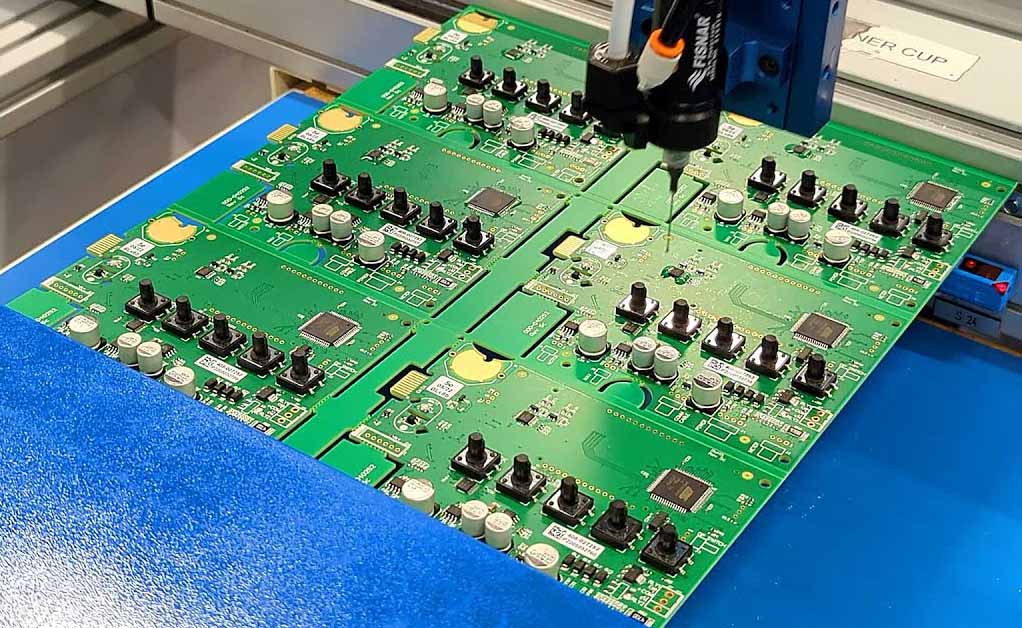

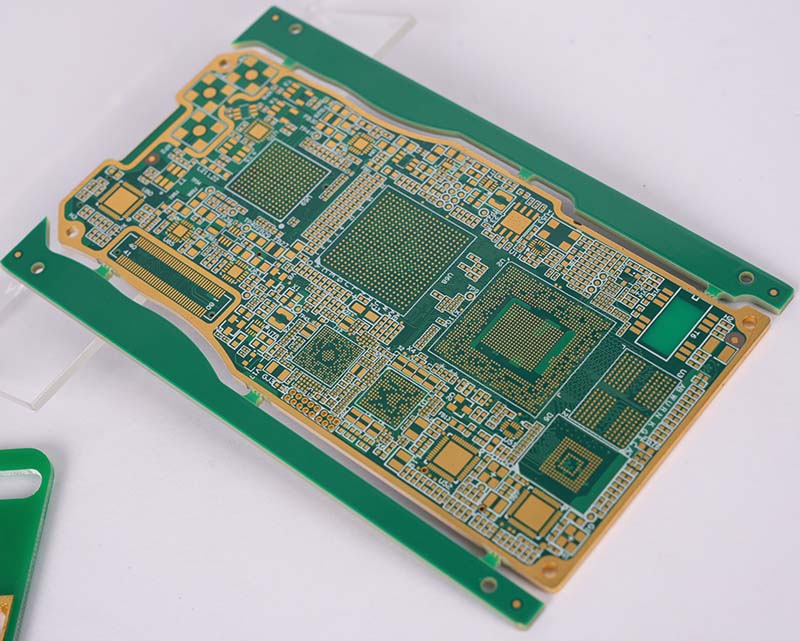

How Does SMD PCB Medical Equipment Assembly Affect Thermal And Signal Integrity?

SMD pcb medical equipment assembly directly influences heat dissipation and EMI stability.

Engineering controls:

- Thermal vias under BGA

- Copper thickness optimization

- Ground plane symmetry

- Controlled reflow ramps

Essentially, assembly quality determines long-term reliability.

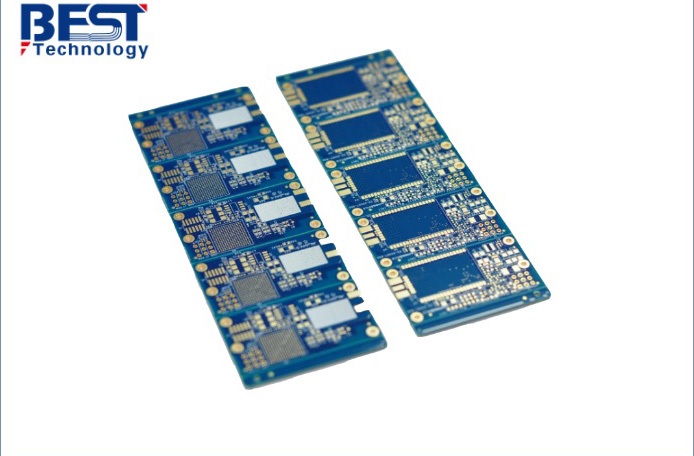

Why Choose EBest Circuit For PCB Customized Immersion Gold Bare PCBA Board For Medical Equipment?

EBest Circuit provides pcb customized immersion gold bare pcba board for medical equipment with full ISO 13485 compliance.

Advantages:

- In-house PCB + PCBA factory

- X-ray BGA inspection

- Class 3 manufacturing

- No MOQ requirement

- Dedicated project coordinator

In closing, engineering support and compliance alignment define long-term partnership value.

All in all, BGA PCB board for medical equipment requires precision engineering, Class 3 manufacturing, and full traceability control. Medical OEMs must prioritize compliance, BGA reliability, and process validation. Selecting an ISO 13485-certified partner reduces regulatory and product risk. For medical-grade PCB manufacturing support, contact sales@bestpcbs.com.

FAQs About BGA PCB Board For Medical Equipment

1. What Void Percentage Is Acceptable For Medical BGA Solder Joints?

Generally below 25% per IPC-7095 guidelines.

2. Is ENIG Required For Medical BGA Boards?

ENIG or ENEPIG is preferred for planarity and corrosion resistance.

3. Can Medical PCB Assemblies Be Reworked Safely?

Yes, under controlled rework stations with thermal profiling.

4. What Documentation Is Required For Medical PCB Procurement?

Material certificates, process validation reports, and traceability logs.