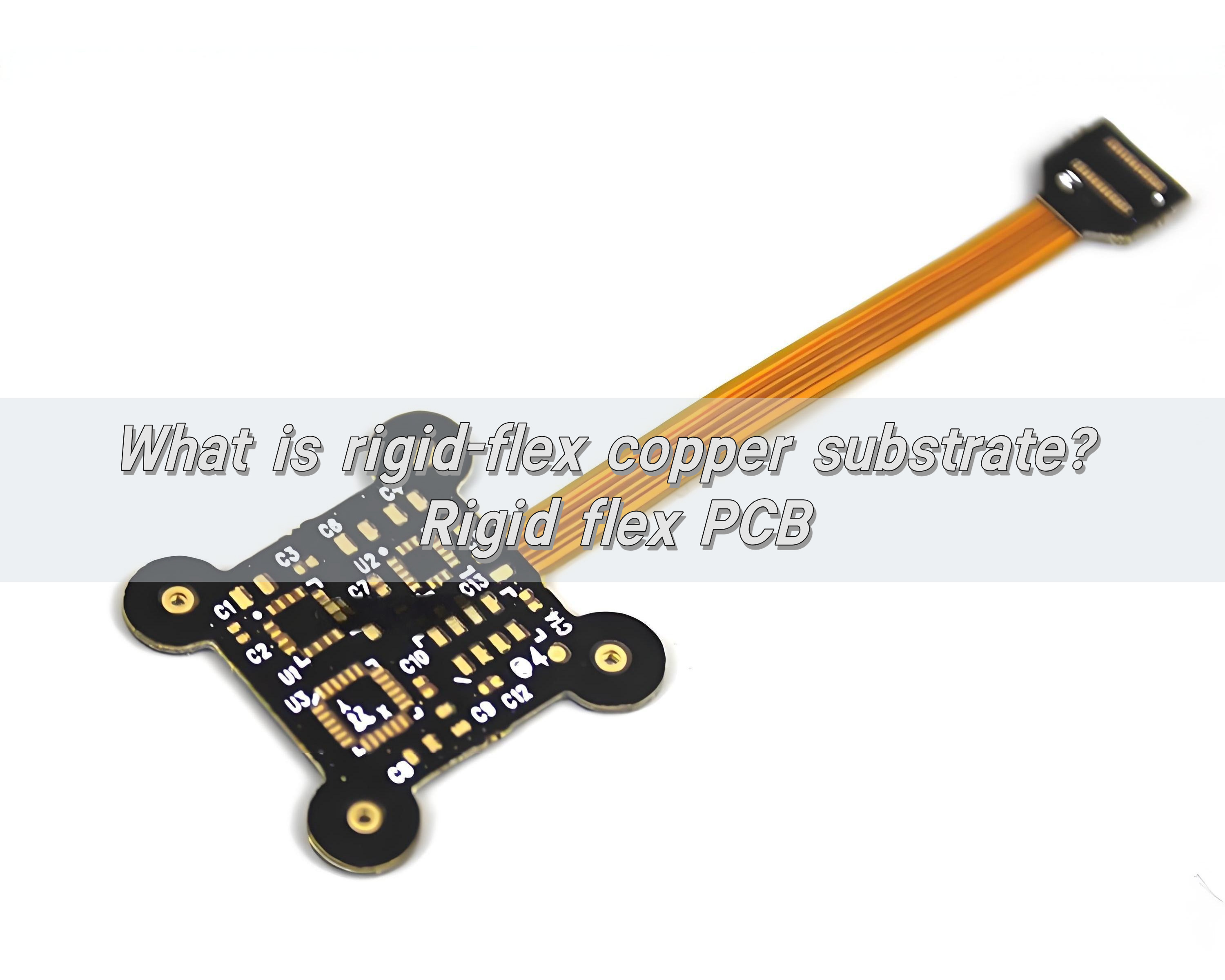

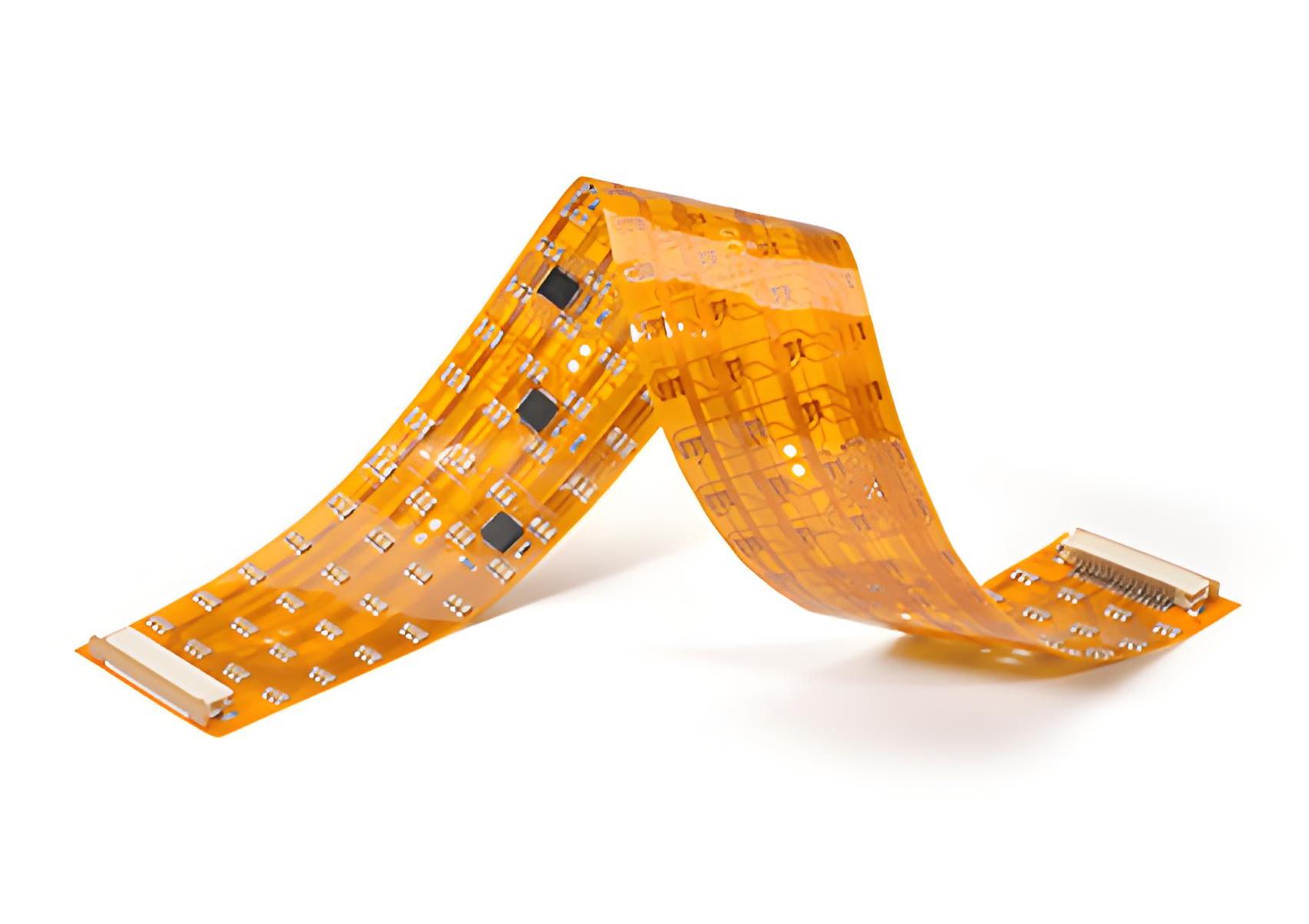

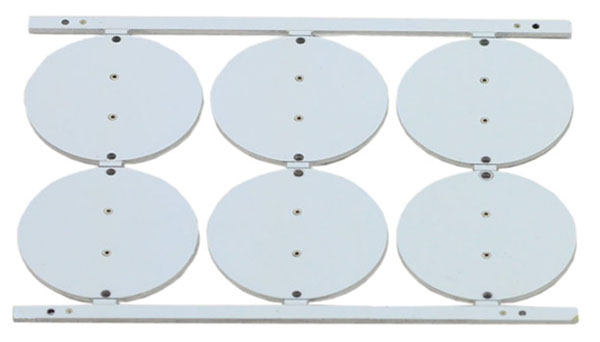

Bendable aluminum substrate is a metal-based copper-clad laminate with folding or bending functions. It is bent and shaped through a special process. It has the advantages of good thermal conductivity, lightweight, and bending resistance. It is mainly used in the bendable structure of LED lamps and lightweight foldable components of electronic devices such as mobile phones.

Are you curious about:

- What are the core advantages of bendable aluminum substrates?

- How many bends can they last?

- What is their heat dissipation performance?

- What applications are they generally suitable for?

BEST Technology can provide you with high-performance bendable aluminum substrates. Our aluminum substrates offer the following properties:

- High heat dissipation from the aluminum substrate combined with flexibility and bendability, ensuring both heat dissipation and surface adaptability.

- Dynamic bending resistance of â„80,000 times (R=1.5mm), ensuring continuous circuitry.

- The aluminum substrate’s thermal conductivity and high adhesive layer provide a thermal resistance of â€1.0°C/W, improving heat dissipation by 25% or more compared to ordinary flexible substrates.

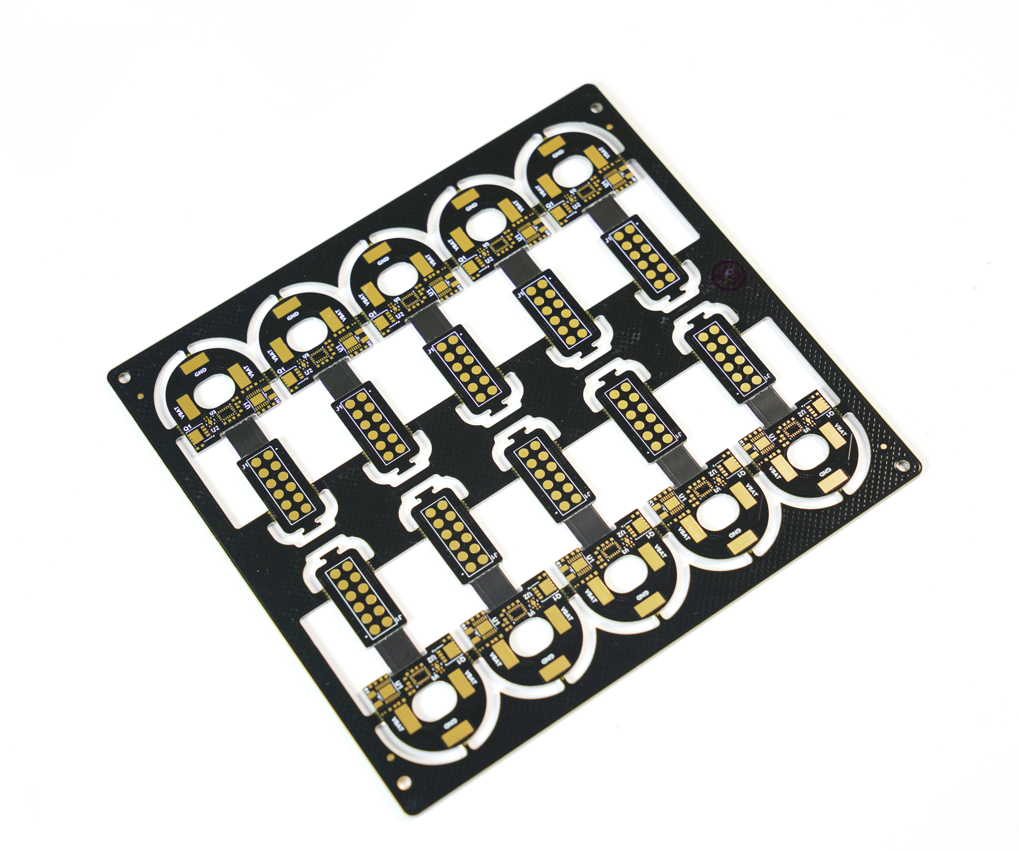

- LED flexible light strips, curved automotive lights, wearable devices, and other applications require both bending and heat dissipation.

What is flexible aluminum substrate?

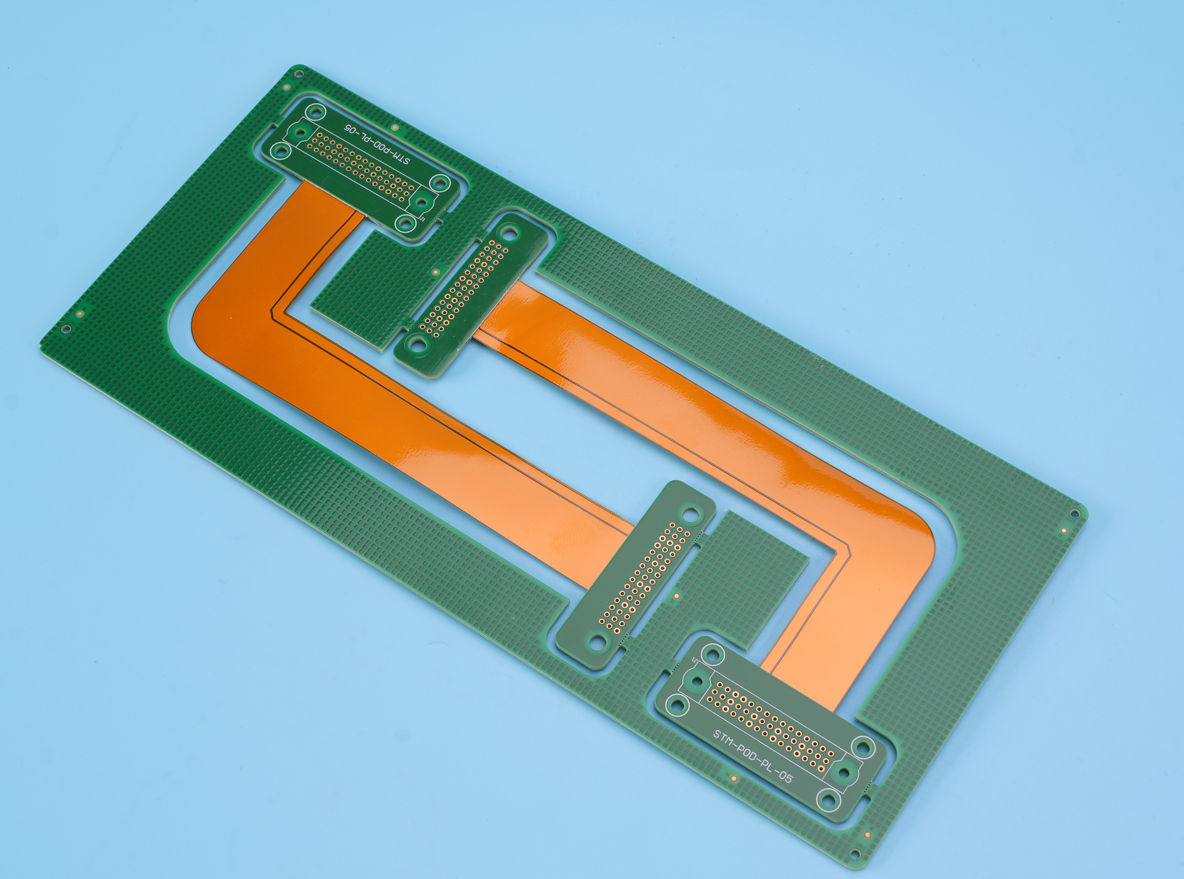

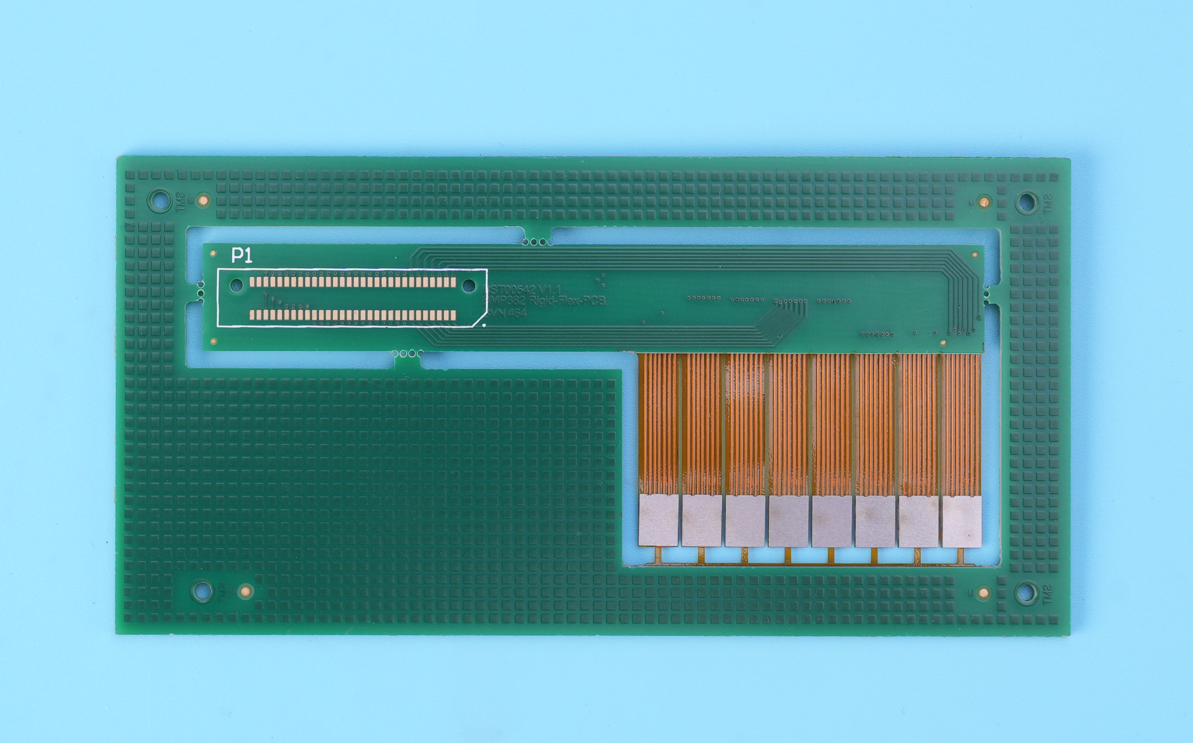

Flexible aluminum substrate is a special type of circuit board base that uses bendable aluminum as its core layer. Unlike traditional rigid aluminum PCBs, these substrates are engineered to withstand controlled bending without cracking or losing structural integrity.

In PCB manufacturing, the substrate acts as the backbone. It supports copper traces, dissipates heat, and maintains mechanical stability. With bendable aluminum, you get all the advantages of aluminumâs high thermal conductivity and durabilityâplus the added ability to shape or curve the board during assembly or installation.

This property is particularly valuable in LED lighting strips, automotive electronics, aerospace control systems, and wearable devices. It allows products to fit into tighter spaces, wrap around surfaces, or follow curved housing designs without sacrificing performance.

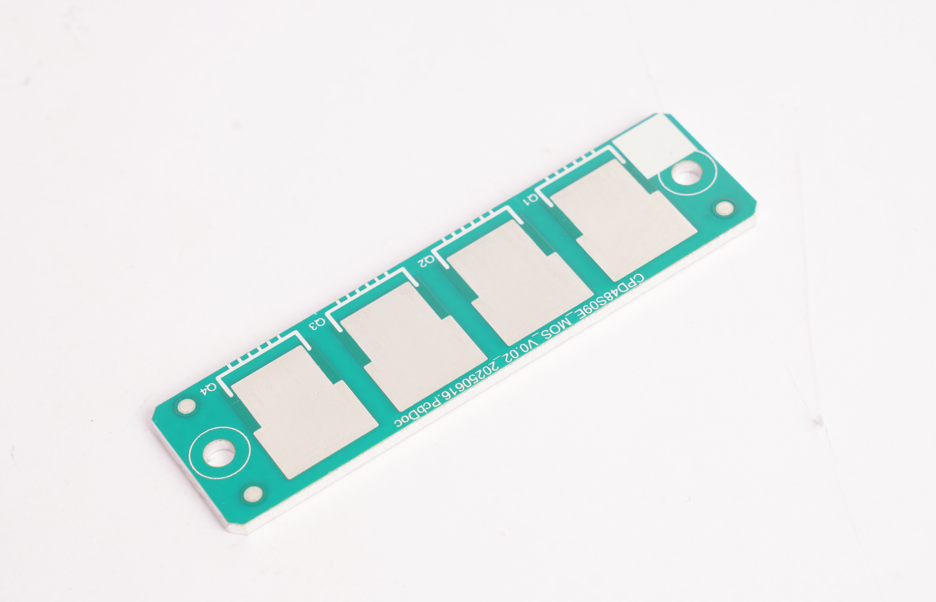

What grades of bendable aluminum sheets are available?

Not all aluminum grades can be bent easily. The alloy composition and temper determine flexibility. Here are common grades relevant to PCB substrates:

1050 and 1100 Series

- High-purity aluminum with excellent corrosion resistance.

- Very good bendability, suitable for tight radius bends.

- Often used for applications needing high ductility.

3003 Aluminum

- Alloyed with manganese for better strength than 1100.

- Maintains good bending properties.

- Common in lighting and decorative PCB applications.

5052 Aluminum

- Stronger than 3003, with excellent corrosion resistance.

- Good formability, works well for medium bend radii.

- Often selected for outdoor electronics or marine-grade designs.

6061 Aluminum

- High strength but less ductile than 5xxx series.

- Bendable in annealed tempers (O-temper) but more difficult in T6.

- Ideal for structural applications where mechanical strength is critical.

6063 Aluminum

- Good surface finish and corrosion resistance.

- Easier to bend than 6061 in certain tempers.

- Often used in heat sink-integrated boards.

Key takeaway: When choosing a grade, balance strength, bend radius, and thermal performance. In PCB manufacturing, 3003, 5052, and 6063 are common for bendable aluminum substrates.

How to test a bendable aluminum sheet?

Testing ensures the sheet meets your mechanical and thermal requirements before it becomes part of a PCB. Here are standard methods:

- Bend Test: The sheet is bent to a specified radius and checked for cracks or surface deformation. For PCBs, smaller radii require more ductile alloys.

- Elongation Test: Measures how much the aluminum can stretch before breaking. Higher elongation values mean better bendability.

- Hardness Test: Indicates resistance to deformation. Softer aluminum generally bends more easily.

- Thermal Cycling Test: Exposes the material to repeated heating and cooling to simulate operating conditions.

- Surface Adhesion Test: Checks how well dielectric and copper layers adhere after bending.

These tests help engineers confirm that flexibility does not compromise thermal conductivity or copper adhesion.

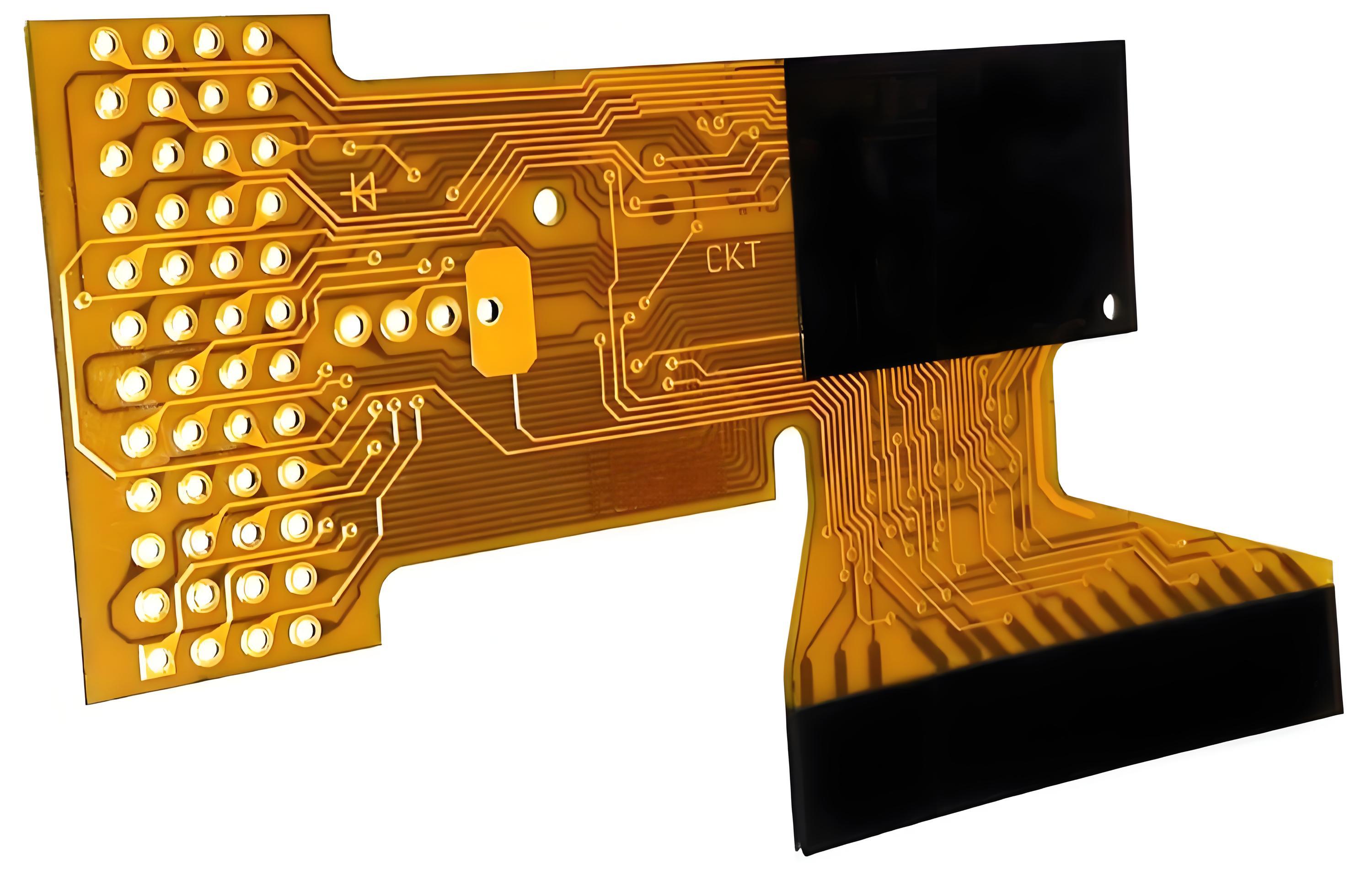

How to make bendable aluminum substrate?

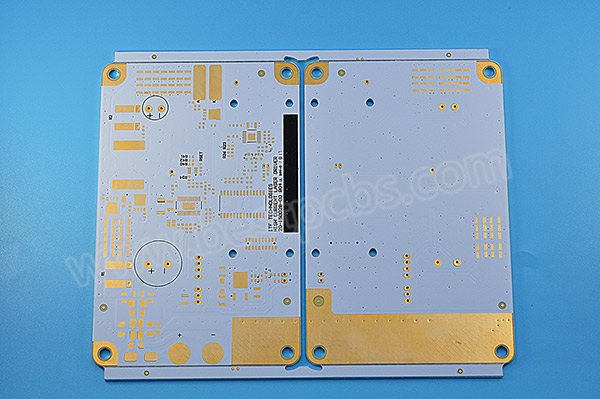

The process combines materials science and precision PCB manufacturing.

- Select the Aluminum Core: Choose the alloy and thickness based on bending needs. Thinner cores bend more easily but handle less load.

- Apply the Dielectric Layer: High thermal conductivity insulation is laminated onto the aluminum. Materials like polyimide or flexible epoxy composites are used.

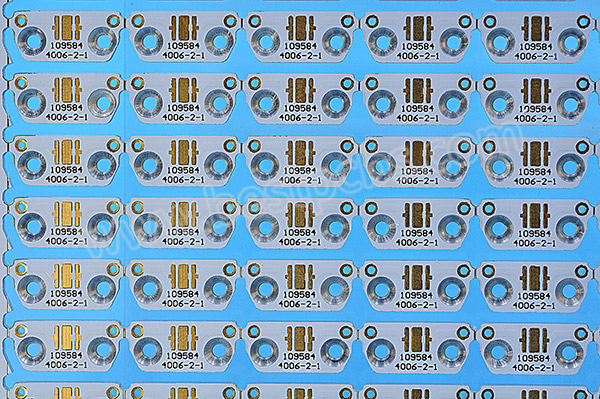

- Add Copper Foil: The copper layer is laminated and patterned through photolithography and etching.

- Protect with Solder Mask: Flexible solder mask layer shields the copper and dielectric.

- Final Forming: Boards may be partially formed before delivery, or bent during final assembly.

Special care is needed in temperature control, lamination pressure, and adhesive selection. Poor processing can cause delamination when bending, so experienced BEST Technology use advanced bonding techniques.

What are the benefits of bendable aluminum substrate?

The benefits go beyond just flexibility:

- Superior Heat Dissipation: Aluminumâs high thermal conductivity allows efficient heat transfer away from heat-generating components.

- Lightweight Strength: Maintains structural integrity even at reduced thickness.

- Design Freedom: Enables curved or irregular shapes without multiple rigid sections.

- Long Service Life: Resistant to corrosion, vibration, and impact.

- Reduced Assembly Costs: A single bendable board can replace multiple interconnected rigid boards.

For manufacturers, this means better performance and simpler mechanical integration. For buyers, it means lower total cost and fewer failure points.

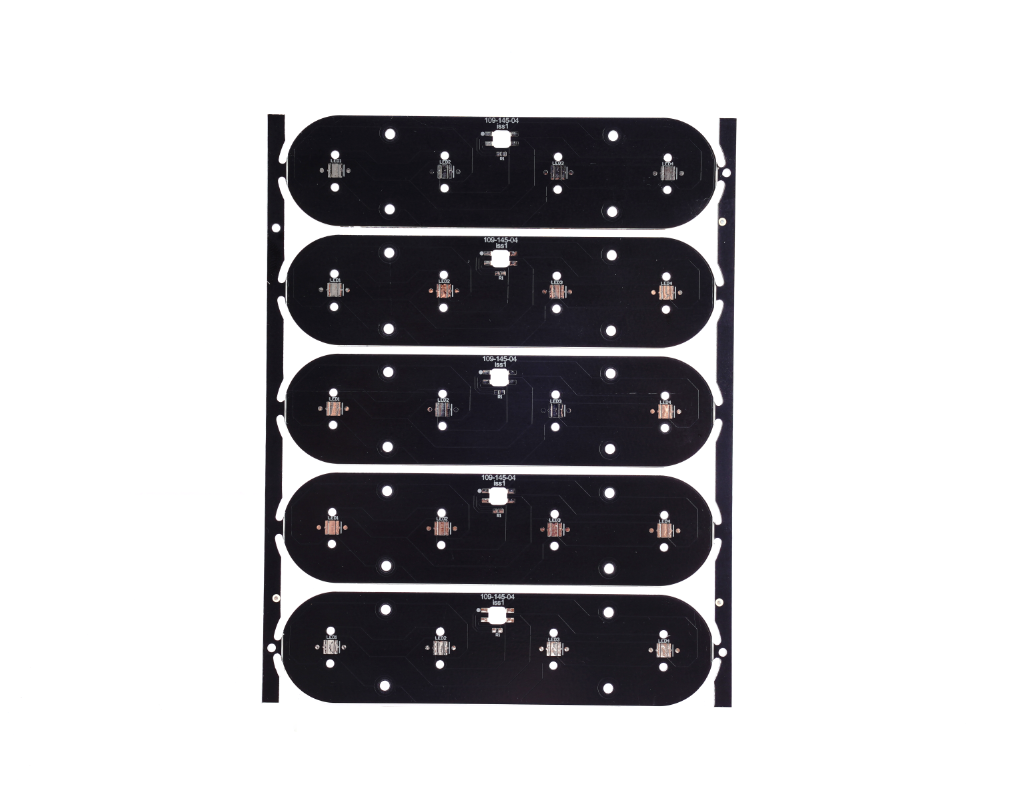

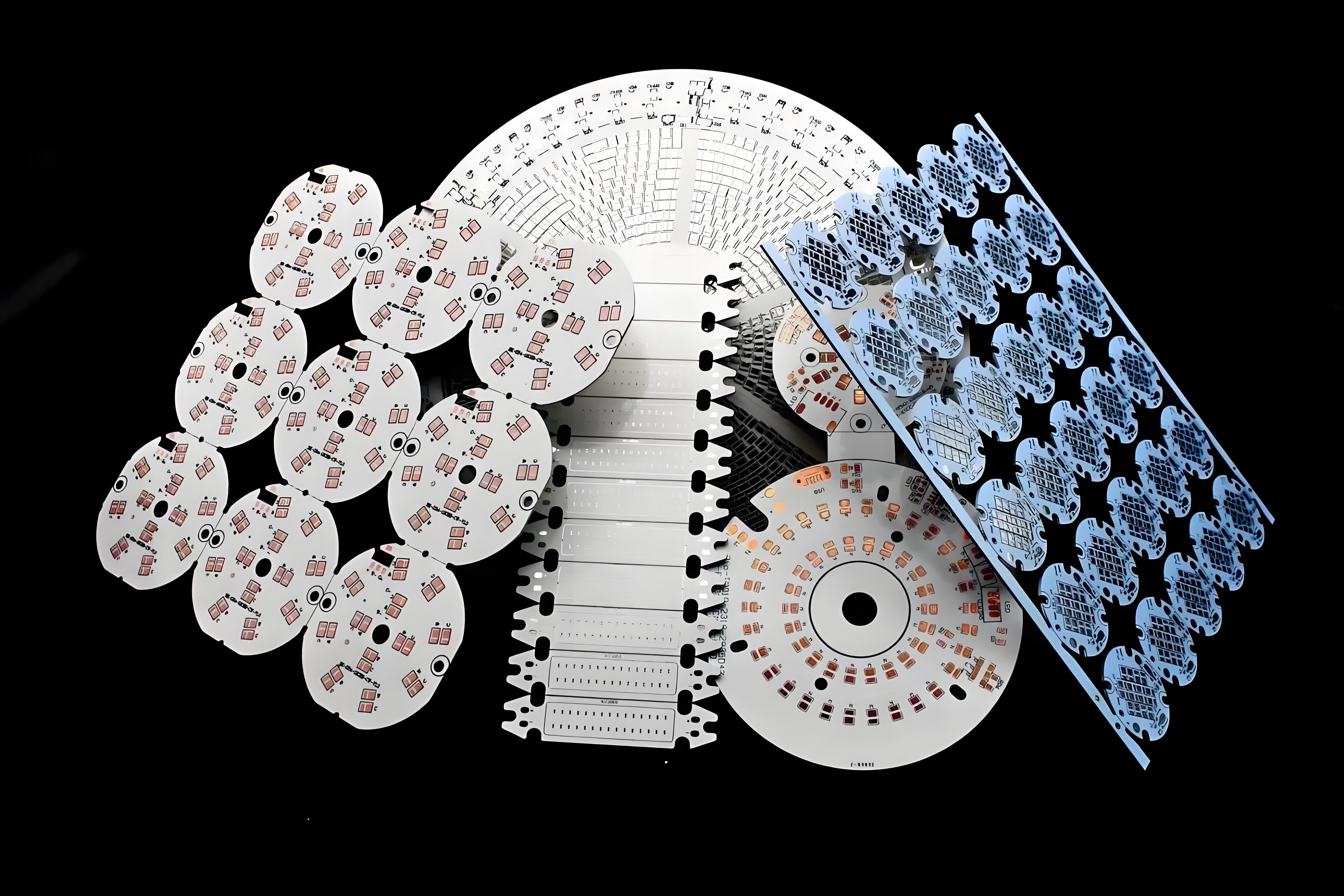

What are the applications of bendable aluminum substrate?

Applications span high-reliability and thermally demanding fields:

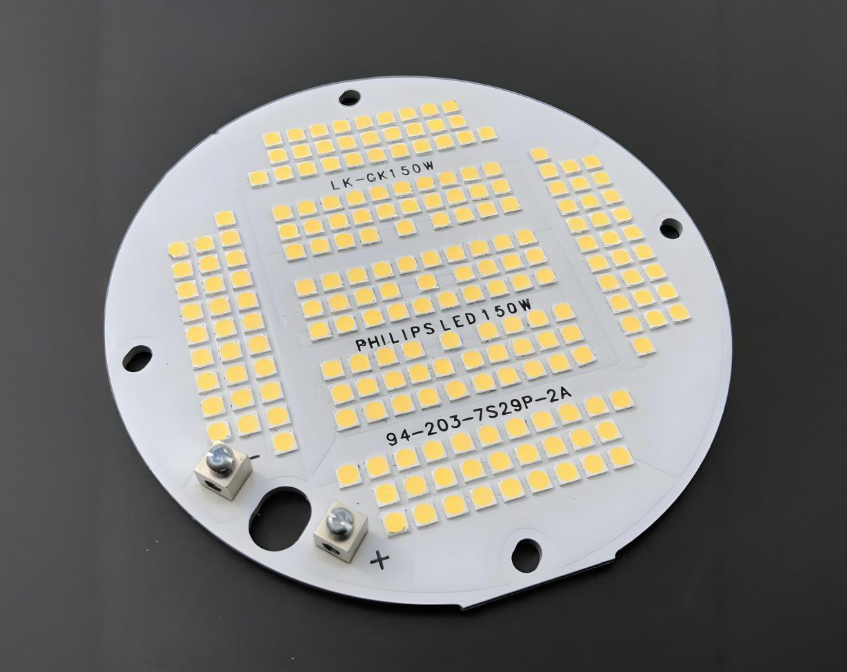

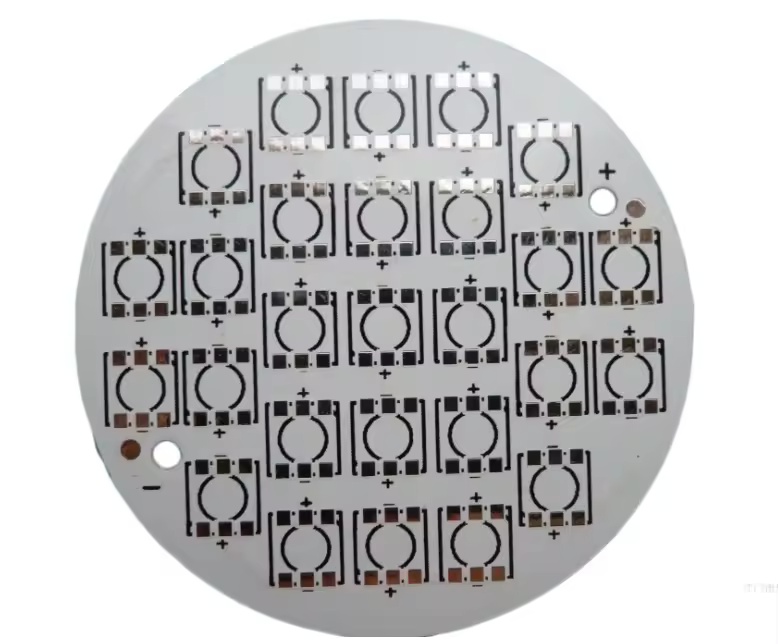

- LED Lighting: Flexible mounting in architectural, automotive, and display lighting.

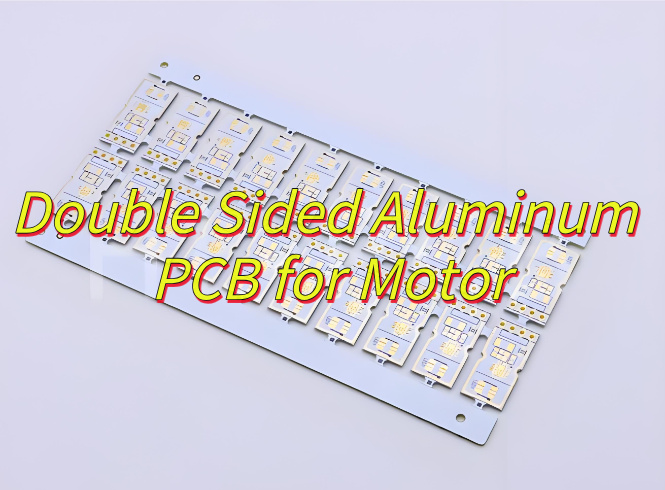

- Automotive Electronics: Curved dashboard PCBs, lighting assemblies, and under-hood electronics.

- Aerospace Systems: Weight-saving designs that fit tight spaces.

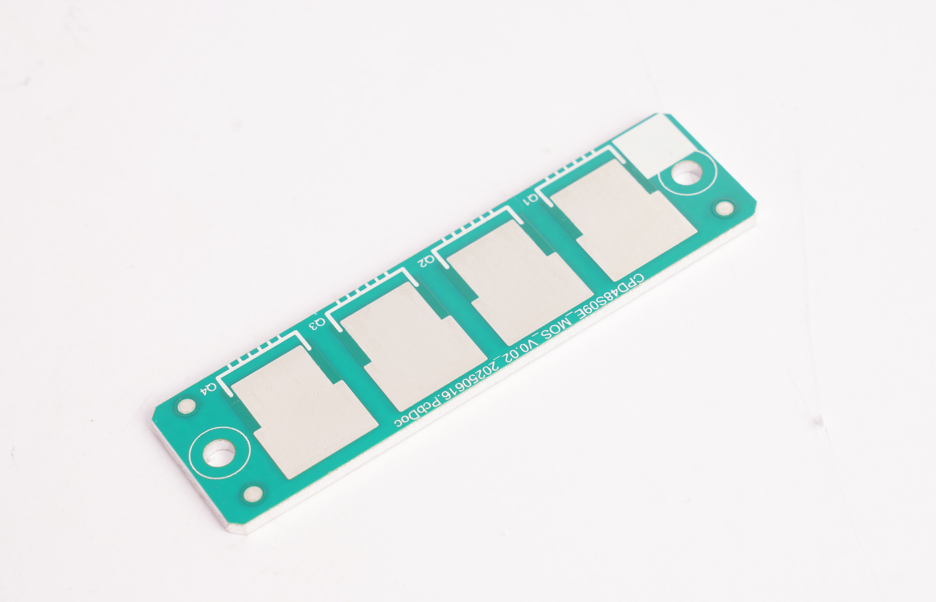

- Wearable Medical Devices: Flexible yet robust circuits for monitoring and control.

- Industrial Controls: Machines that require boards to wrap around mechanical housings.

In each case, the bendable aluminum substrate provides both mechanical adaptability and reliable heat management.

Does bending reduce the strength of aluminum substrate?

Yes, but the effect depends on alloy, temper, and bend radius. When aluminum is bent, it undergoes work hardening, which increases strength in the bend area but can also reduce ductility.

If bending exceeds the materialâs formability limit, micro-cracks can form, reducing fatigue life. Thatâs why BEST Technology design for the proper bend radius based on alloy properties and thickness.

In practice, when using recommended bend parameters and high-quality processing, the strength loss is minimal for most PCB applications.

Why choose BEST Technology to make bendable aluminum substrates?

BEST Technology Co., Ltd. has been a trusted PCB and substrate manufacturer since 2006. We understand that buyers need more than just a supplierâthey need a partner who delivers consistent quality.

Our advantages:

- Material Expertise: We work with multiple aluminum grades, ensuring the right balance of flexibility and performance.

- Precision Manufacturing: Our process maintains ±0.05mm dimensional accuracy, even in bendable designs.

- Thermal and Mechanical Reliability: Each substrate undergoes strict bend, adhesion, and thermal tests.

- Fast Turnaround: Average delivery in 7 days, faster than the industry standard.

- Global Experience: Serving industries in Asia, Europe, and North America with OEM and ODM capabilities.

When you choose BEST Technology, you get a bendable aluminum substrate designed to lastâand a team committed to your projectâs success.

Do you need BEST Technology to make a bendable aluminum PCB for you? We are waiting for your information, please contact us: sales@bestpcbs.com