The system board is one of the core elements inside every modern electronic device. Whether you use a laptop, desktop PC, tablet, medical device, industrial controller, or even consumer IoT equipment, everything begins with the system board. It is the foundational circuit structure that connects, coordinates, and powers all major hardware components. Without it, a device cannot turn on, cannot transfer data, and cannot function reliably.

Many people know this component by another familiar name: the motherboard. In most contexts, both terms refer to the same thing. However, when you evaluate technical documentation, service manuals, OEM repair guides, or industrial product sheets, you will often encounter the phrase ‚Äúsystem board‚ÄĚ because it reflects a more functional description of the board‚Äôs role. This guide will explain what the system board is, why it matters, what components it contains, and how to differentiate system board vs motherboard.

What Is the System Board?

What Is the System Board? System Board Definition

A system board is the main printed circuit board that hosts and interconnects all major hardware components of an electronic device. It distributes power, manages data communication, holds connectors, supports the CPU and memory, and integrates the firmware that controls boot and hardware configuration.

In a practical sense, the system board is the central nervous system of any computer or smart device. All processing, storage, communication, and peripheral interaction begin with it.

Key characteristics of a system board include:

- It houses the CPU or SoC

- It provides slots and interfaces for memory, storage, and expansion devices

- It manages internal and external I/O

- It contains the chipset or controller hub that coordinates system communication

- It provides power regulation for critical components

- It holds firmware such as BIOS or UEFI

This definition applies across device types, from high-performance servers to compact embedded systems.

Types of System Boards

Because electronic products vary greatly in size, function, and performance demands, system boards come in multiple categories.

1. Desktop System Boards

Common form factors: ATX, Micro-ATX, Mini-ITX. These boards offer replaceable components, expansion slots, GPU support, and thermal flexibility.

2. Laptop System Boards

Compact and heavily optimized. Many components, like RAM or CPU, may be soldered to save space.

3. Server System Boards

Engineered for reliability and scalability. Typical features: multi-CPU sockets, ECC memory support, redundant power design, strong I/O capacity.

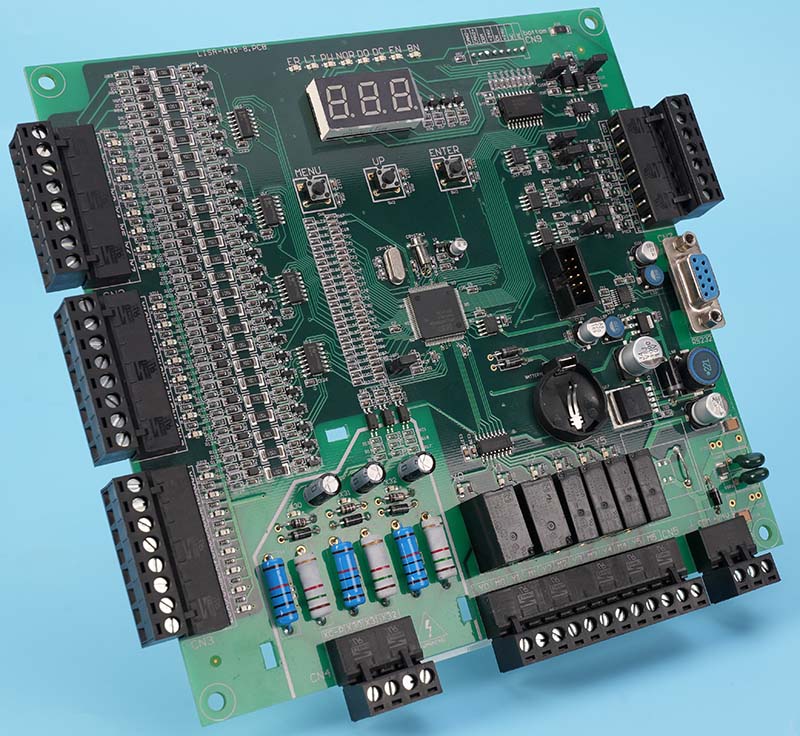

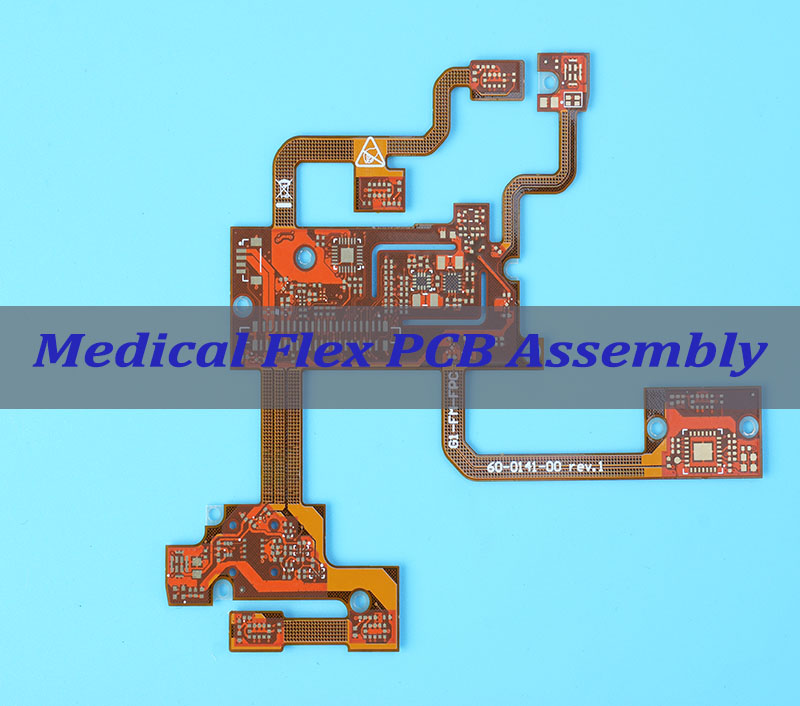

4. Embedded and Industrial System Boards

Used in factories, automation equipment, medical devices, and IoT controllers. Highly customizable layouts and long lifecycle availability.

5. Mobile Device System Boards

Found in smartphones and tablets. Use integrated SoC packages with wireless modules, power regulators, and dense multilayer stack-ups.

Each type has a different design approach, but they all perform the same core role: providing the platform on which the entire system operates.

How Does a System Board Work?

A system board works by acting as the central communication and power distribution platform for all hardware inside a device. Every major component‚ÄĒCPU, memory, storage, graphics, power modules, and external interfaces‚ÄĒrelies on the system board to operate in sync. It functions as both the electrical backbone and the coordination center of the entire system.

A system board works by:

1. Delivering stable power

2. Offering high-speed communication pathways

3. Running firmware to start the device

4. Synchronizing all operations

5. Managing data traffic

6. Physically integrating all components

7. Monitoring system health

It is the one component that must function perfectly for the entire system to operate. At every moment, the system board is directing traffic among dozens of active hardware elements.

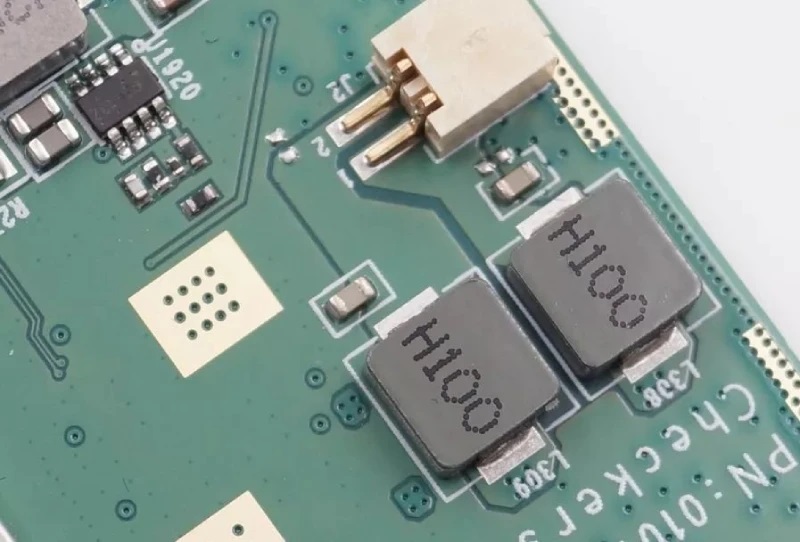

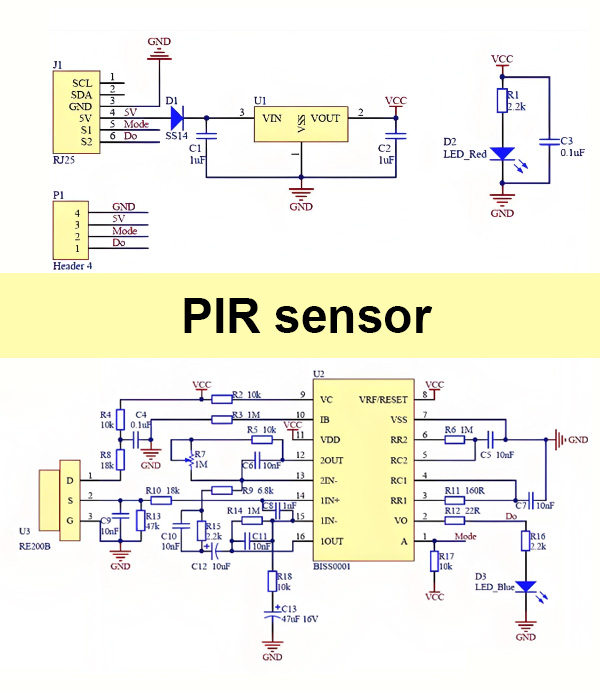

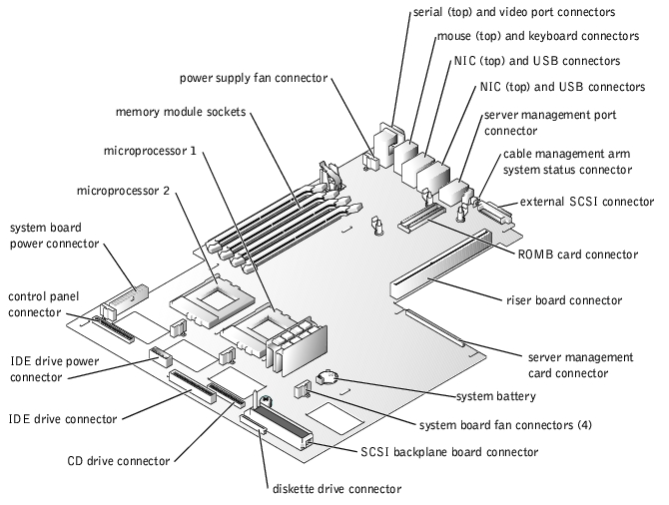

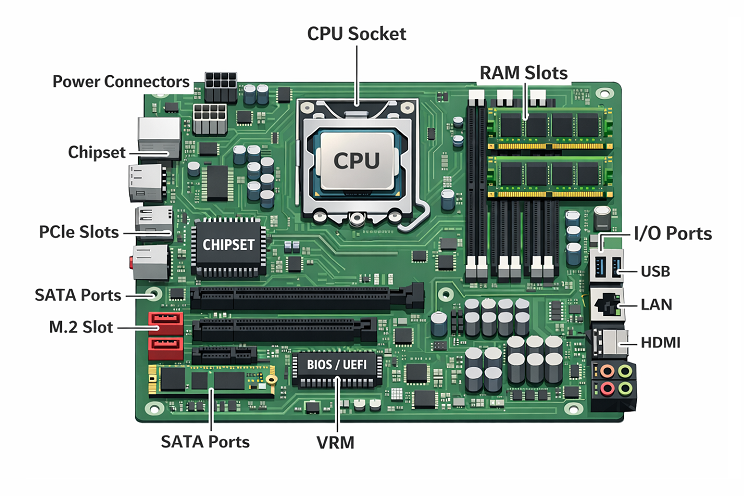

System Board Diagram

Below is a simplified conceptual layout of a typical system board, it includes:

- CPU socket

- Chipset (Northbridge/Southbridge or PCH)

- Memory (DIMM/SODIMM slots)

- PCIe slots

- Storage interfaces (M.2, SATA)

- Power connectors (24-pin, 8-pin CPU)

- I/O interfaces (USB, Ethernet, audio)

- BIOS/UEFI firmware chip

- VRM power modules

- Internal headers (fan, front panel, RGB, etc.)

This diagram helps visualize how tightly integrated the components are and how the board organizes both power and data pathways.

What Is the Purpose of the System Board?

The core purpose of the system board is to:

- Integrate all essential components into a unified platform

- Enable communication between hardware modules

- Provide physical mounting points and electrical pathways

- Supply and regulate power from the power input

- Facilitate system startup and firmware control

- Handle data flow to internal and external devices

Put simply, it is the foundation on which the entire computing system is built.

Key Components Found on a System Board

A modern system board integrates a wide range of functional components:

- CPU socket or SoC package

- RAM slots (DIMM or SODIMM)

- PCH or chipset

- PCIe interfaces

- M.2 slots

- SATA connectors

- VRM power modules

- BIOS/UEFI firmware chip

- Internal headers (USB, fan, RGB, front panel)

- Rear I/O ports (USB, HDMI, LAN, audio)

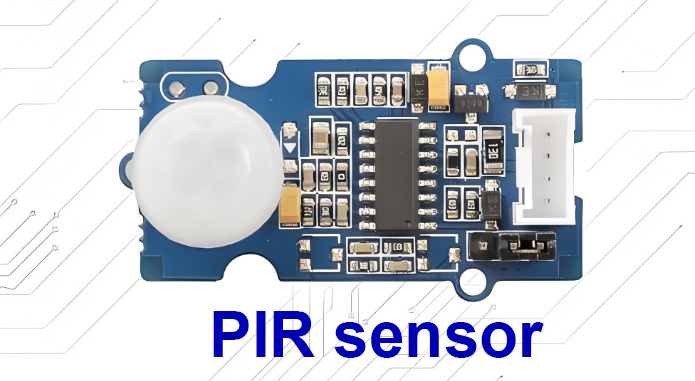

- Embedded controllers (TPM, sensors, management ICs)

Each element contributes to the total functionality and performance capability of the device.

System Board vs Motherboard: What Are the Differences?

Although many people treat these terms as identical, there are subtle distinctions:

System Board

- Used in enterprise service documents

- Emphasizes system-level integration

- Common in servers, industrial controllers, embedded systems

- More neutral, technical terminology

Motherboard

- Popular in consumer PC building

- More common in desktop, gaming, and DIY markets

- Focuses on expandability and performance features

- Broadly recognized by non-technical users

Key takeaway

Both terms describe the same type of hardware, but they differ in usage context.

What Is the System Board Used For?

Anywhere data is processed or controlled, a system board exists. System boards are found in nearly all electronic systems:

- Desktop PCs

- Laptops

- Smartphones

- Servers

- Medical devices

- Automotive electronics

- Industrial automation controllers

- Robotics

- Consumer electronics

- IoT devices

- Network equipment

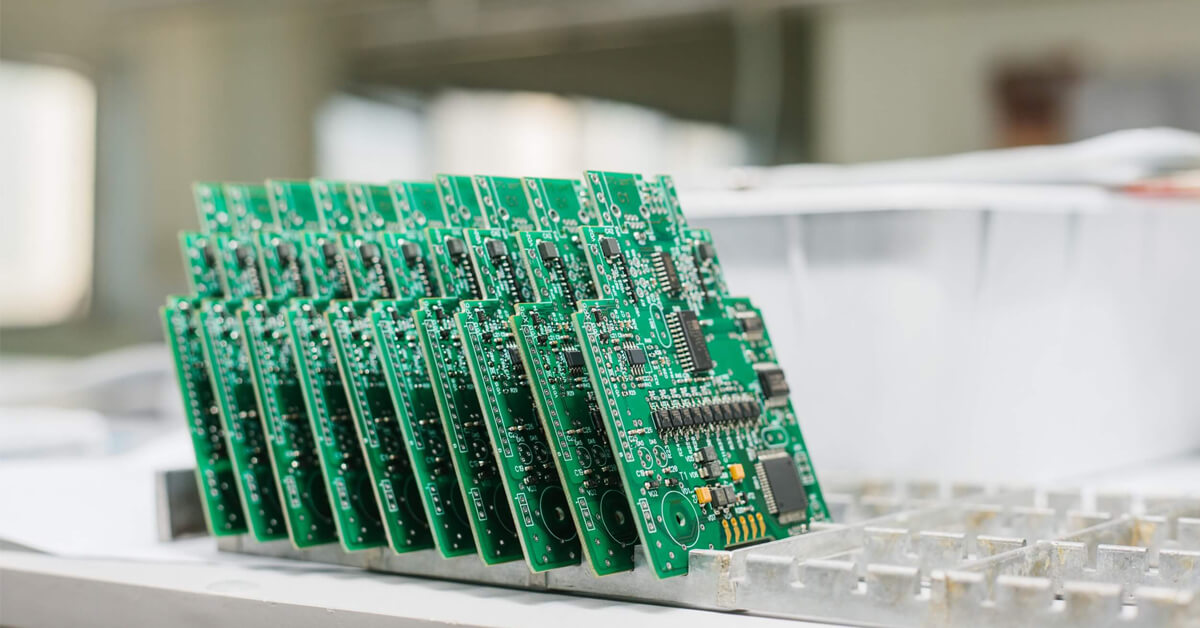

Why System Board Manufacturing Requires Professional PCB & PCBA Capabilities?

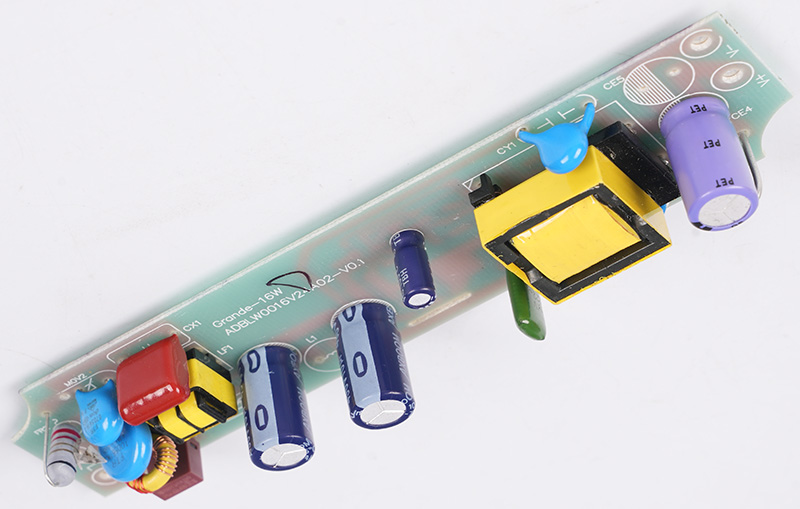

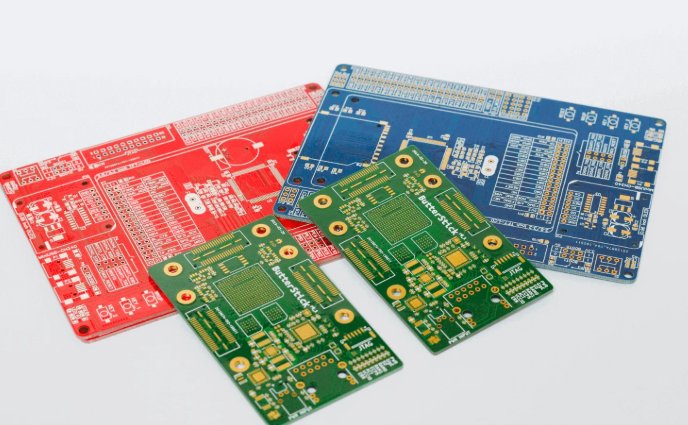

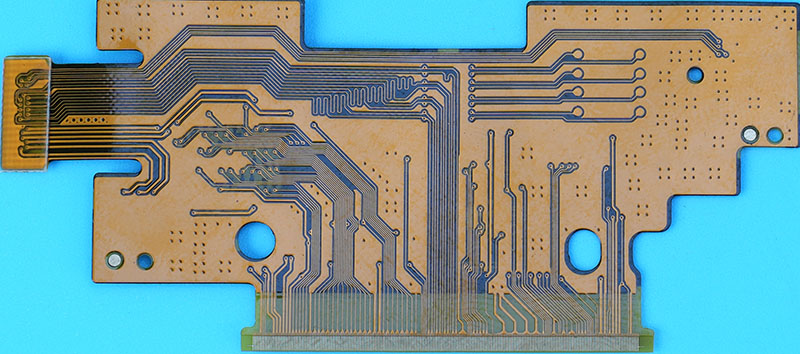

Although readers usually think of the system board as a finished computer component, its reliability begins much earlier in the PCB manufacturing and assembly stages. A system board is a complex, multilayer PCB with dense routing, high-speed interfaces, strict impedance control, and tight thermal requirements. This makes the quality of its PCB and PCBA processes critical.

Modern system boards typically include:

- Multilayer stack-ups (8L, 10L, 12L and above)

- High-speed differential pairs for PCIe, USB, HDMI, LVDS

- Controlled impedance traces for stable signal integrity

- BGA and LGA CPU packages

- Fine-pitch connectors and ultra-dense component layouts

- High-current VRM power stages

- M.2, SATA, and PCIe slot soldering

- Embedded controllers, BIOS/UEFI ICs, and power management circuits

Manufacturing and assembling such boards requires precision, stability, engineering support, and strict testing procedures.

This is exactly where EBest Circuit (Best Technology) helps global customers gain reliable performance.

How EBest Circuit (Best Technology) Supports System Board Production?

EBest Circuit (Best Technology) has long served customers who require complex mainboards, server logic boards, laptop controller boards, industrial control boards, and embedded system boards. Our fabrication and assembly services are engineered to meet the stringent requirements of system-level products.

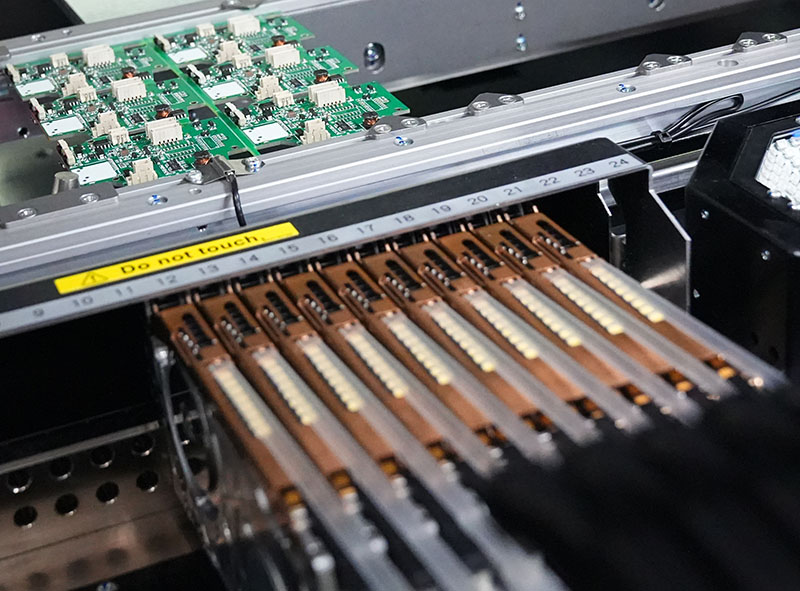

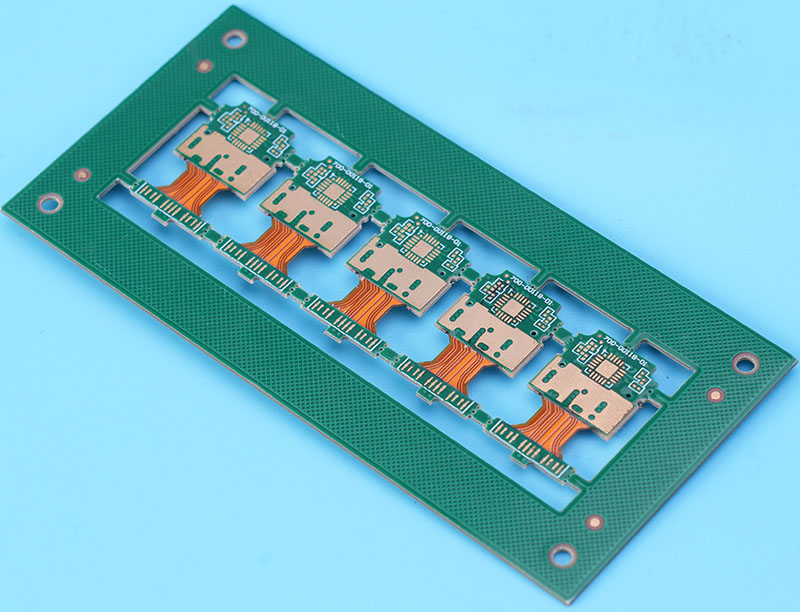

1. Advanced PCB Manufacturing Capabilities

Our factories support:

- Up to 40-layer PCB stack-ups

- HDI structures (laser microvias, blind/buried vias, via-in-pad)

- High-speed materials (Megtron, Isola, Rogers hybrid builds)

- Tight impedance control ¬Ī8% or better

- Thick copper options for power stages

- High-temperature laminates for reliability

- ENIG, ENEPIG, Immersion Tin, Hard Gold and other finishes

These capabilities allow us to fabricate system boards that support stable high-speed signaling and long-term operational reliability.

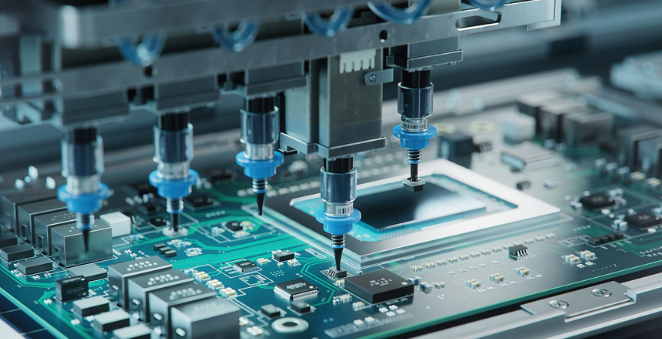

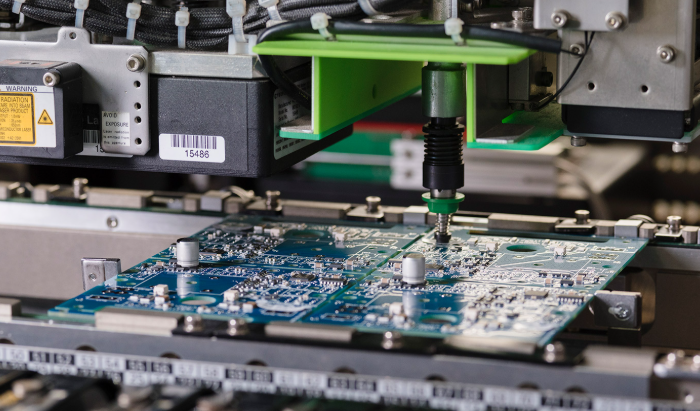

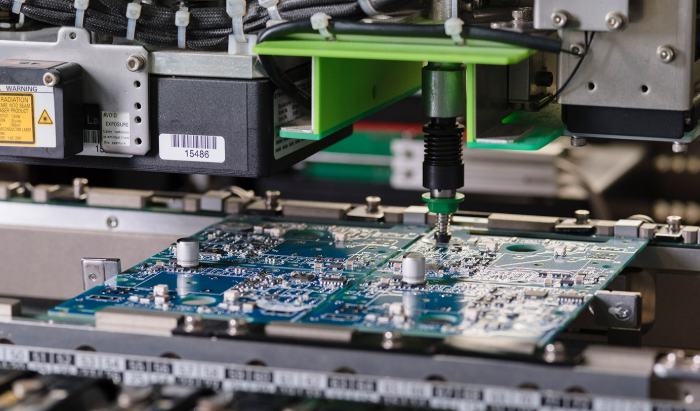

2. Professional SMT & PCBA Assembly

With SMT factories in China and Vietnam, we support flexible production, fast lead times, and global supply chain advantages.

Our assembly strengths include:

- 0201, 0402, 0603 to high-power components

- BGA, LGA, QFN, WLP, CSP, and high-density IC packages

- Fine-pitch 0.3 mm and VFQFN layouts

- Automated SPI, AOI, X-ray BGA inspection

- Lead-free & RoHS-compliant processes

- Fast prototype to mass-production capability

For system boards, precise soldering of BGA CPU sockets, M.2 connectors, PCIe slots, and high-speed controllers is essential‚ÄĒand our inspection workflow ensures stable solder quality.

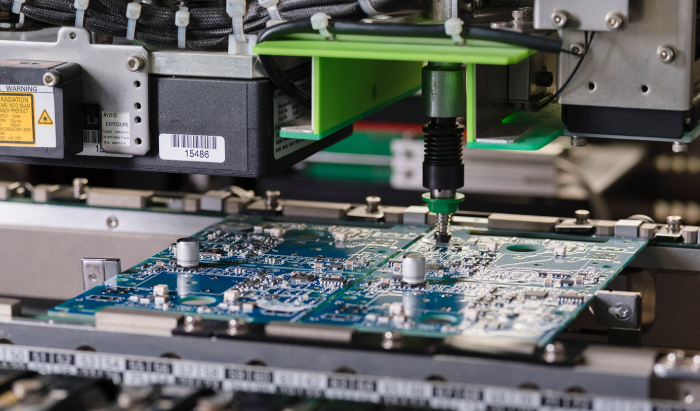

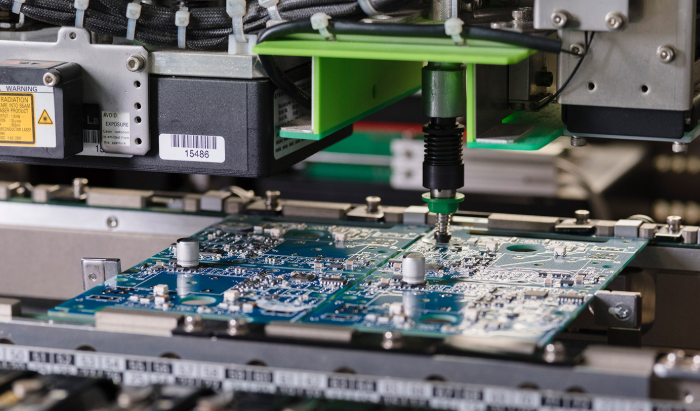

3. Complete Electrical Testing & Functional Verification

System boards must pass strict testing because they are the ‚Äúbrain‚ÄĚ of the entire device.

We use:

- Flying-probe testing

- Automated in-circuit testing (ICT)

- Functional testing based on customer firmware

- Boundary scan (JTAG) for high-density digital boards

- Burn-in testing upon request

High-layer count PCBs often hide defects deep inside the stackup, so our process ensures that every board delivered meets performance expectations.

4. Full Engineering Support

- Stack-up design assistance

- DFM / DFA review

- Impedance simulation

- Material recommendation for high-speed designs

- Prototype revision feedback

- One-stop BOM sourcing

Our engineering team collaborates directly with OEMs, industrial designers, and hardware architects to optimize manufacturability before production begins.

Why Many Global Brands Choose EBest Circuit (Best Technology) for System Board Projects?

Companies choose EBest Circuit (Best Technology) because we provide:

- One-stop PCB + PCBA integration

- Factories in China and Vietnam for flexible cost and lead time

- High-layer, high-speed, HDI capability for complex logic boards

- Professional SMT assembly with strict inspection

- On-time delivery and stable quality

- UL, ISO 9001, ISO 13485, AS9100D and IATF 16949 quality certifications

Over a decade of experience serving electronics, industrial, automotive, medical, and computing customers

If you are developing a system board, embedded controller, logic board, medical equipment mainboard, or industrial computer board, EBest Circuit (Best Technology) can support you from prototype to mass production.

To get a fast quotation or technical consultation:

Email: sales@bestpcbs.com

Website: www.bestpcbs.com

We will evaluate your Gerber files, BOM, and assembly requirements, then provide optimized PCB stack-ups, material choices, and lead-time proposals based on your project needs.