PCB Assembly China is the top choice for global electronics brands. This guide explains why China dominates the market and how EBest Circuit (Best Technology) delivers quality, speed, and cost efficiency for your projects.

Do you face these challenges in your electronics production?

- High costs eating into your profit margins.

- Long lead times delaying product launches.

- Inconsistent quality causing rework and returns.

- Poor communication with overseas suppliers.

- Limited technical support for complex designs.

These pain points are challenging. But they can be solved by reliable China PCB assembly service suppliers‚Äč.

- Competitive pricing without sacrificing quality.

- Reliable lead times with on-time delivery.

- Strict quality control for consistent output.

- English-speaking teams for smooth communication.

- Expert engineering feedback to optimize your design.

At EBest Circuit (Best Technology), we specialize in high-end PCB assembly for global clients. Our advanced facility, certified processes, and customer-first approach make us a trusted partner. Contact us at sales@bestpcbs.com to start your project.

Why Choose PCB Assembly China for Your Electronic Projects?

In the global electronics landscape, choosing where to manufacture your printed circuit board assemblies (PCBA) is a critical decision. While many options exist, China has consistently remained the dominant hub. Why choose PCB assembly China for your electronic projects? The reasons extend far beyond low cost, encompassing a powerful trifecta of ‚Äčadvanced technology, unparalleled supply chain efficiency, and proven manufacturing excellence.‚Äč‚Äč

Here’s a breakdown of the key advantages:

- ‚ÄčUnmatched Cost-Efficiency Without Compromise‚Äč

It’s no secret that competitive pricing is a major draw. However, the real advantage lies in the¬†structure¬†of the cost savings. China’s deeply rooted electronics ecosystem means:- ‚ÄčLocalized Supply Chain:‚Äč‚Äč Key components, raw materials like FR4 substrates, and machinery are often produced domestically. This drastically reduces logistics and import costs that other regions face.

- ‚ÄčEconomies of Scale:‚Äč‚Äč High-volume production capabilities allow manufacturers to optimize operational costs, passing the savings on to you. This makes China ideal for both ‚Äčlow-volume PCB assembly‚Äč runs and mass production.

- ‚ÄčAdvanced Technical Capabilities and Expertise‚Äč

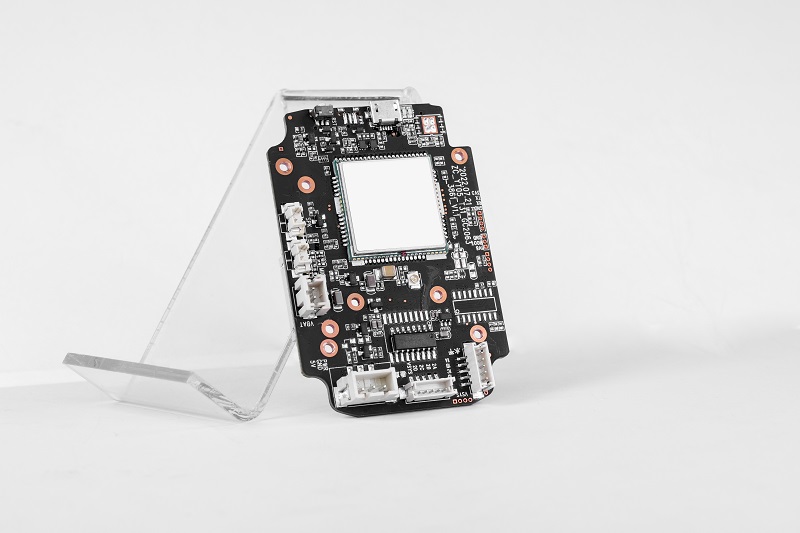

China’s PCB industry has evolved from basic assembly to handling highly complex projects. Leading manufacturers like EBest Circuit (Best Technology) invest heavily in state-of-the-art equipment and skilled engineers. We specialize in:- ‚ÄčHigh-Density Interconnect (HDI) boards‚Äč and complex ‚ÄčBGA PCB assembly.

- Advanced techniques for ‚Äčflexible PCB assembly‚Äč and ‚Äčaluminum PCB assembly‚Äč for LEDs.

- Sophisticated processes like surface mount technology (SMT) and through-hole assembly, supported by automated optical inspection (AOI) and X-Ray testing.

- ‚ÄčRobust and Resilient Supply Chain‚Äč

Speed to market is crucial. China’s integrated supply chain is a significant accelerator. From ‚ÄčPCB fabrication and assembly‚Äč to component sourcing and box-build, a true ‚Äčone-stop PCB assembly service‚Äč under one roof minimizes delays. This ‚Äčturnkey‚Äč approach simplifies your logistics, reduces management overhead, and ensures better control over the entire production timeline. - ‚ÄčHigh Quality Standards and Stringent Certifications‚Äč

The outdated notion of variable quality is just that‚ÄĒoutdated. Reputable ‚ÄčPCB assembly companies in China‚Äč adhere to international quality standards. At EBest Circuit (Best Technology), our operations are certified under ISO 9001, IATF 16949 (for automotive), ISO 13485 (for medical devices), and AS9100D (for aerospace). This rigorous framework guarantees that every board, from a ‚ÄčPCB prototype assembly‚Äč to a full production run, meets the highest levels of reliability and performance. - ‚ÄčProven Experience as a Global EMS Partner‚Äč

China has been the world’s workshop for decades. This means its top manufacturers have vast experience serving diverse international clients. This experience translates into:- Better understanding of global market requirements (CE, UL, RoHS compliance).

- Skilled project management teams accustomed to bridging time zones and cultural differences.

- Established logistics networks for reliable worldwide shipping.

EBest Circuit (Best Technology) differentiates ourselves through exceptional engineering support, transparent communication, and a commitment to building long-term partnerships. We transform the inherent strengths of ‚ÄčPCB Assembly China‚Äč into a tailored, low-risk, and high-value solution for your specific electronic projects. Pls feel free to contact our team today at sales@bestpcbs.com for a transparent ‚ÄčPCB assembly China online quote.‚Äč‚Äč

Turnkey PCB Assembly China ‚Äď EBest Circuit (Best Technology)

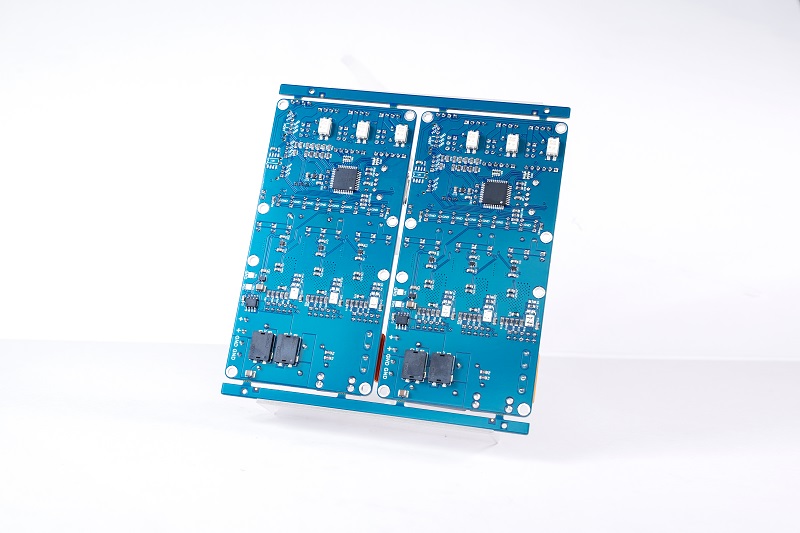

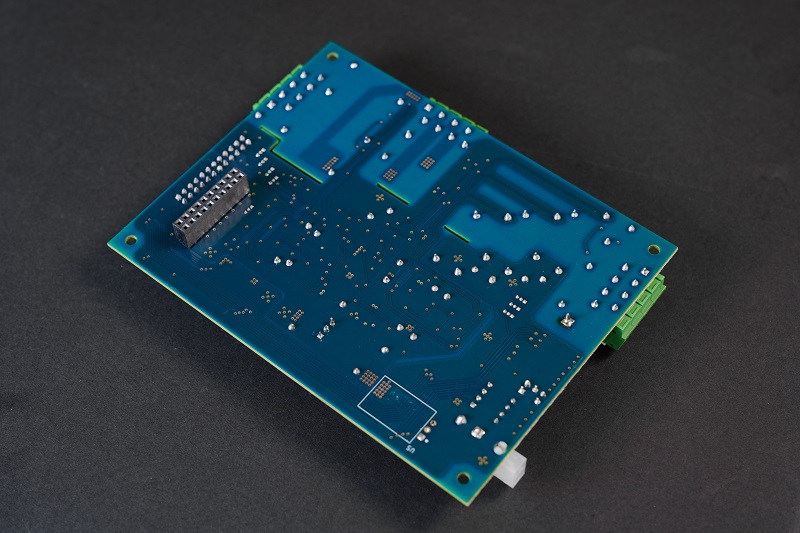

A turnkey solution simplifies everything. EBest Circuit (Best Technology) provides a full-service experience. We manage the entire process for you. This includes PCB fabrication, component sourcing, assembly, and testing. You get a finished product ready for use.

Our turnkey PCB assembly China service covers:

- ‚ÄčDesign Review:‚Äč‚Äč Our engineers check your files for manufacturability. They suggest improvements to boost reliability and cut cost.

- ‚ÄčMaterial Procurement:‚Äč‚Äč We source components from trusted suppliers worldwide. Our buying power gets you the best prices.

- ‚ÄčPCB Fabrication:‚Äč‚Äč We make the boards in-house. This controls quality and speeds up the process.

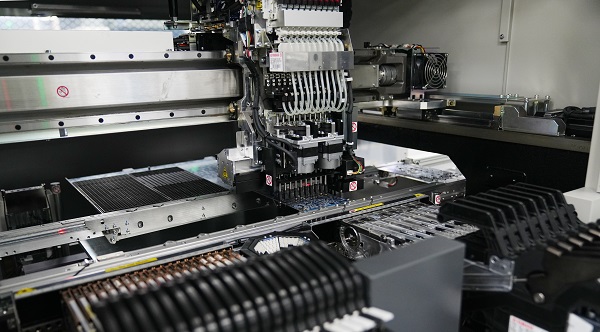

- ‚ÄčAssembly (SMT & Through-Hole):‚Äč‚Äč We use automated lines for precise placement and soldering.

- ‚ÄčTesting and Inspection:‚Äč‚Äč Every board undergoes strict checks. We use AOI, X-Ray, and functional testing.

This approach saves you time and reduces risk. You have one point of contact. You get full traceability. Projects move faster and with fewer errors. For ‚ÄčPCB prototype China‚Äč projects, the same care applies. We build prototypes with production-level quality. This ensures a smooth transition to volume orders.

What Makes EBest Circuit (Best Technology) Stand Out Among Top 10 PCB Manufacturers in China?

The list of top 10 PCB manufacturers in China includes many big names. EBest Circuit (Best Technology) earns its place through technical excellence and customer service. We invest in the latest equipment. We maintain strict quality certifications. Our team solves complex manufacturing challenges daily.

Here’s what sets us apart:

- ‚ÄčAdvanced Engineering Support:‚Äč‚Äč We help optimize designs for cost and performance.

- ‚ÄčHigh-Level Automation:‚Äč‚Äč Our SMT lines ensure accuracy and repeatability.

- ‚ÄčWide Material Experience:‚Äč‚Äč We work with FR-4, aluminum, flex, and high-frequency boards.

- ‚ÄčRigorous Quality Systems:‚Äč‚Äč We follow ISO 9001, IATF 16949, ISO 13485, and AS9100D standards.

We serve many industries. These include medical, automotive, and aerospace. Each sector has unique requirements. Our team understands these needs. We deliver PCBs that meet strict reliability standards.

Technical Capability for PCB Assembly Manufacturer China

EBest Circuit (Best Technology) handles a broad range of projects. Our capabilities include:

- ‚ÄčHigh-Density Interconnect (HDI) PCBs‚Äč

- ‚ÄčBGA and Fine-Pitch Component Assembly‚Äč

- ‚ÄčFlexible and Rigid-Flex PCB Assembly‚Äč

- ‚ÄčLead-Free and RoHS-Compliant Processes‚Äč

- ‚ÄčBox Build and Electro-Mechanical Assembly‚Äč

We work with prototypes and high-volume orders. Our equipment includes high-speed SMT lines, automated optical inspection (AOI), and X-Ray systems. These tools ensure every board is built correctly.

For specialized needs like ‚ÄčChina LED PCB assembly‚Äč or ‚ÄčChina medical PCB assembly, we have specific experience. We understand the thermal management needs of LED boards. We follow strict traceability for medical devices. ‚ÄčFor our clients, this means one less thing to worry about in a complex development cycle.‚Äč

High-Quality Standards in PCB Manufacturing and Assembly China

Quality is non-negotiable in electronics. EBest Circuit (Best Technology) has built a robust quality system. It covers every step from incoming materials to final shipment.

Our quality process includes:

- ‚ÄčIncoming Component Verification:‚Äč‚Äč We check all parts for authenticity and condition.

- ‚ÄčIn-Process Checks:‚Äč‚Äč Operators and machines inspect boards at each stage.

- ‚ÄčFinal Functional Test:‚Äč‚Äč We validate that the assembled PCB works as intended.

We use advanced equipment like SPI (Solder Paste Inspection) and ICT (In-Circuit Test). This data-driven approach minimizes defects. It ensures that every product we ship meets your specifications.

What Certifications Should a Reliable China PCB Board Assembly Factory Have?

Certifications prove a factory’s commitment to quality. When choosing a partner, look for these key certifications:

- ‚ÄčISO 9001:‚Äč‚Äč Quality Management System standard.

- ‚ÄčIATF 16949:‚Äč‚Äč Required for automotive manufacturing.

- ‚ÄčISO 13485:‚Äč‚Äč Essential for medical device production.

- ‚ÄčAS9100D:‚Äč‚Äč The benchmark for aerospace quality.

EBest Circuit (Best Technology) holds all these certifications. They are not just certificates on the wall. They are part of our daily culture. Our team follows documented procedures. We undergo regular audits to maintain compliance.

How to Select Reliable PCB Assembly Companies in China?

Choosing the right partner is critical. Here is a simple checklist to guide your selection:

- ‚ÄčTechnical Match:‚Äč‚Äč Can they build your specific type of board? Ask about similar projects.

- ‚ÄčQuality Certifications:‚Äč‚Äč Do they have relevant, up-to-date certifications?

- ‚ÄčCommunication Skills:‚Äč‚Äč Is their team responsive and easy to understand?

- ‚ÄčTransparent Pricing:‚Äč‚Äč Do they provide clear, detailed quotes?

- ‚ÄčSupply Chain Stability:‚Äč‚Äč Do they have strong supplier relationships to avoid part shortages?

EBest Circuit (Best Technology) meets all these criteria. We encourage clients to audit our facility. We provide detailed quotes and design feedback. Our project managers speak fluent English. We make overseas collaboration simple and effective.

Case of China EMS PCB Assembly at EBest Circuit (Best Technology)

We serve a diverse client base. Here are two simplified examples:

‚ÄčConsumer Device Example:‚Äč‚Äč

A client needed a compact, high-density board for a smart home device. We used micro-vias and fine-pitch BGAs. Our design team suggested changes to improve solderability. The result was a high-yield, reliable product launched on time.

‚ÄčIndustrial Control Example:‚Äč‚Äč

Another customer required a robust board for a factory controller. It needed wide temperature tolerance and high-voltage isolation. We selected appropriate materials and a conformal coating. The boards have performed perfectly in the field.

‚ÄčOur General Capabilities Snapshot:‚Äč‚Äč

- SMT Placement: 01005 components to large BGAs.

- Through-Hole: Selective soldering for complex boards.

- Testing: In-circuit, functional, and boundary scan.

- Lead Time: As fast as 5 days for quick-turn PCBA.

In conclusion‚Äč, PCB Assembly China offers a powerful value proposition for global businesses. This article has outlined the key benefits and selection criteria. EBest Circuit (Best Technology) combines cost efficiency with high quality. We make the process simple and reliable. Our team is ready to support your next project. For a quick ‚ÄčPCB assembly China online quote, please contact us at sales@bestpcbs.com.

FAQs

1. Which materials and boards require baking before assembly?‚Äč‚Äč

To prevent moisture-related defects, the following items must be baked prior to assembly:

- All Flexible Printed Circuit (FPC) boards.

- Moisture-sensitive Integrated Circuits (ICs).

- LED components.

‚Äč2. What are the standard baking time and temperature parameters?‚Äč‚Äč

Our standard baking profiles are as follows:

- ‚ÄčConventional ICs:‚Äč‚Äč 120¬įC for 12 hours.

- ‚ÄčLEDs and Tape-and-Reel Components:‚Äč‚Äč 60¬įC for 12 hours.

- ‚ÄčFPCs and FR-4 Fiberglass Boards:‚Äč‚Äč 120¬įC for 1.5 hours.

‚Äč3. What solder paste brands and alloys do you commonly use?‚Äč‚Äč

We use high-quality solder pastes to ensure reliable connections:

- ‚ÄčFor International Clients:‚Äč‚Äč Senju (Japan) – Alloy: Sn96.5%/Ag3.0%/Cu0.5% (SAC305).

- ‚ÄčFor Domestic Clients:‚Äč‚Äč Yifenghua (China) – Alloy: Sn99.0%/Ag0.3%/Cu0.7% (SAC0307).

‚Äč4. What are the handling rules for solder paste?‚Äč‚Äč

Proper solder paste management is critical for print quality:

- ‚ÄčWarm-up Time:‚Äč‚Äč 4 hours at room temperature before use.

- ‚ÄčMixing Time:‚Äč‚Äč 3 minutes in a mixer to achieve a homogeneous consistency.

- ‚ÄčRefrigeration Temperature:‚Äč‚Äč Stored at 2-10¬įC.