Looking for ceramic PCB board solutions? Let’s explore its benefits, application and why choose Best Technology as a ceramic PCB board manufacturer.

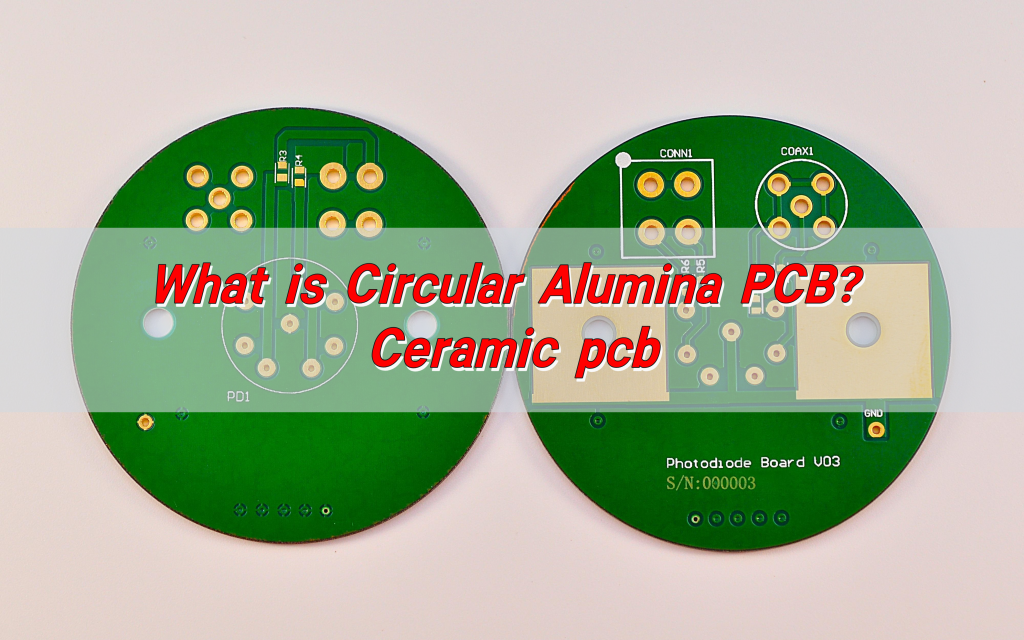

What is a Ceramic PCB Board?

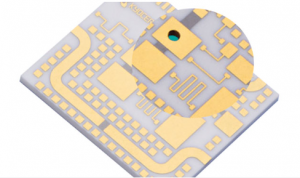

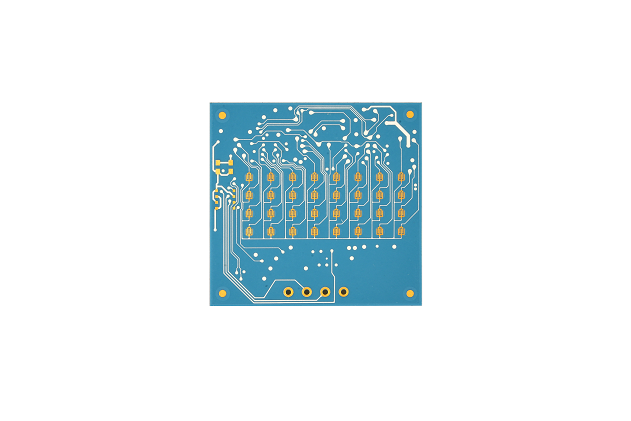

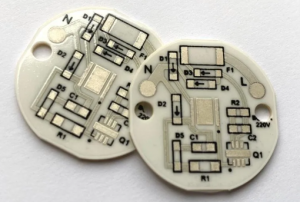

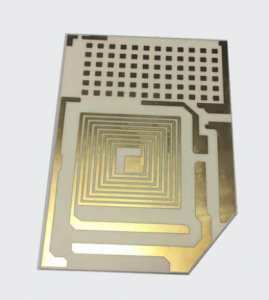

A Ceramic PCB Board is a specialized type of printed circuit board that uses ceramic materials as the substrate instead of traditional FR4. Known for their excellent thermal conductivity, high-temperature resistance, and superior electrical insulation properties, ceramic PCB boards are ideal for applications requiring efficient heat dissipation and reliability under extreme conditions. These boards are widely used in industries such as LED lighting, power electronics, automotive, and aerospace.

What are the Advantages of Ceramic PCB Boards?

- High Thermal Conductivity: Efficient heat dissipation for high-power applications.

- Temperature Resistance: Stable performance in extreme temperatures.

- Electrical Insulation: Superior insulation properties for high-frequency applications.

- Durability: Resistant to wear, corrosion, and mechanical stress.

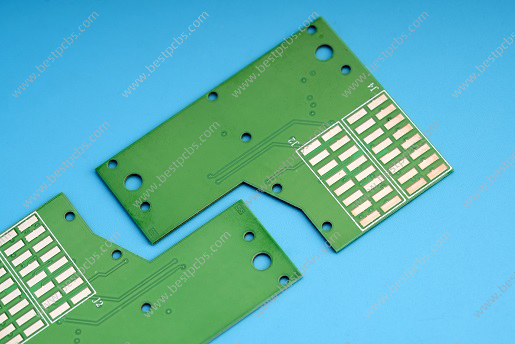

- Miniaturization: Enables compact designs for advanced electronics.

What Problems Can Ceramic PCB Boards Solve?

Ceramic PCB boards address several challenges in advanced electronics, including:

- Heat Dissipation: Efficient thermal management for high-power devices.

- High-Temperature Environments: Reliable performance in extreme conditions.

- Signal Integrity: Superior insulation for high-frequency applications.

- Space Constraints: Compact designs for miniaturized electronics.

Applications of Ceramic PCB Boards

Ceramic PCB boards are used in a wide range of industries and applications, such as:

- LED Lighting: Efficient heat dissipation for high-power LEDs.

- Power Electronics: Reliable performance in inverters and converters.

- Automotive: High-temperature applications in engine control units and sensors.

- Aerospace: Durable and reliable electronics for harsh environments.

- Medical Devices: Compact and reliable solutions for diagnostic and therapeutic equipment.

Our Ceramic PCB Board Services

At Best Technology, we offer comprehensive services for ceramic PCB boards, including:

- Custom Design: Tailored solutions to meet your specific requirements.

- Material Selection: High-performance ceramic substrates for optimal performance.

- Precision Manufacturing: Advanced processes for accurate and reliable production.

- Thermal Management: Designs that ensure efficient heat dissipation.

- Quality Assurance: Rigorous testing to ensure reliability and performance.

Why Choose Us for Ceramic PCB Boards?

- 18+ Years of Experience: Proven expertise in ceramic PCB manufacturing.

- Advanced Technology: State-of-the-art equipment for precise and reliable production.

- Competitive Pricing: Cost-effective solutions without compromising quality.

- ISO-Certified Quality: Adherence to IPC standards for durable and reliable products.

Ceramic PCB Board Capabilities

| Parameter | Capability |

|---|---|

| Materials | Alumina (Al2O3), Aluminum Nitride (AlN), etc. |

| Layer Count | Single-layer, Double-layer, Multilayer |

| Thermal Conductivity | Up to 170 W/mK (AlN) |

| Testing Methods | Function/ICT, X-RAY, AOI |

| Quality Standards | IPC Class 2, Class 3, Class 3A |

How are Ceramic PCB Boards Different from Conventional PCBs?

- Material: Ceramic substrates instead of traditional FR4.

- Thermal Conductivity: Significantly higher for efficient heat dissipation.

- Temperature Resistance: Stable performance in extreme conditions.

- Application Focus: Designed for high-power and high-frequency applications.

Contact Us Today

If you have any questions about ceramic PCB boards or would like to request a quote, feel free to contact us. We are committed to providing the best quality, pricing, and services to meet your ceramic PCB needs.