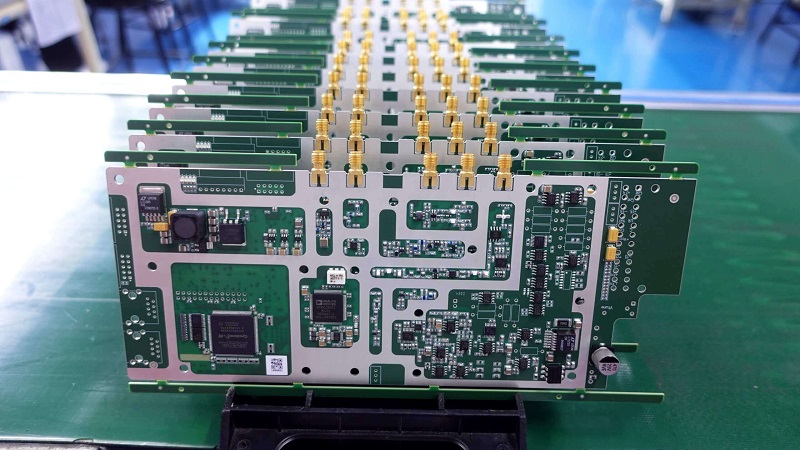

Industrial PCB manufacturing is the backbone of mission-critical electronic systems in aerospace, automotive, industrial automation, and medical devices. Unlike commercial PCBs designed for consumer-grade use, industrial-grade printed circuit boards are engineered to withstand extreme conditions‚ÄĒincluding wide temperature ranges (-40¬įC to 125¬įC), continuous operation for a decade or more, and high mechanical stress from vibration or shock. With 20 years of expertise, our industrial PCB manufacturing services deliver unmatched durability, precision, and reliability, making us the trusted partner for 300+ leading enterprises (including 20 Fortune 500 companies) in high-stakes applications.

Why Choose Our Industrial PCB Manufacturing Services? 5 Core Advantages

Selecting the right industrial PCB manufacturing partner is critical to avoiding costly downtime, quality issues, and project delays. Our 20-year track record speaks for itself with these industry-leading benefits:

- Exceptional Quality: 99.9% defect-free rate (industry average 85%), 10-year trouble-free operation guarantee, and failure rate below 3PPM (parts per million)

- Technical Expertise: 50+ senior engineers specializing in HDI, rigid-flex, high-temperature, high-frequency, and high-power industrial PCB manufacturing, with 10,000+ complex projects completed

- Rapid Response: Dedicated account managers available 24/7, 1-hour consultation response, and DFM (Design for Manufacturability) reports within 4 hours

- Transparent Pricing: Direct supplier pricing with up to 40% bulk discounts, clear pricing for special processes (impedance control, edge plating), and no hidden fees

- On-Time Delivery: 98% of orders shipped on time or early, emergency prototyping in as fast as 24 hours, and zero major delivery incidents in 10 years

Industrial PCB Manufacturing Solutions for 3 Key Industry Pain Points

Our industrial PCB manufacturing services are tailored to solve the most pressing challenges faced by engineers and procurement teams:

– Tight Deadlines? IPC Class 3 certified production with 24-hour prototyping for 1-4 layer boards, 48-hour delivery for multi-layer PCBs, and 7-day accelerated mass production‚ÄĒ3x faster than industry averages

– Quality Concerns? Premium materials including high-Tg FR4 (135¬įC+), ceramic, and polyimide substrates; copper thickness ‚Č•2oz; 10,000-cycle connector durability; and 4-stage testing (AOI, X-ray, thermal cycling, vibration)

– Cost Overruns? Free DFM optimization (reducing production costs by 15% on average), tiered bulk pricing, no minimum order quantity (start with 10 units), and lifetime valid quotes with no price hikes

Whether you need small-batch prototyping, medium-volume pilot runs, or large-scale production, our engineering team provides end-to-end support from design review to delivery, helping clients shorten time-to-market by 30% and reduce overall costs by 20%.

Key Requirements for High-Performance Industrial PCB Manufacturing

The difference between commercial and industrial PCB manufacturing lies in reliability under extreme conditions. We understand that a single PCB failure can cause million-dollar losses, production downtime, or safety hazards‚ÄĒso our industrial-grade PCBs meet these strict criteria:

- Wide temperature tolerance: Stable operation from -40¬įC to 125¬įC (covering polar, desert, and high-temperature workshop environments)

- Long service life: 10+ years of continuous use (vs. 2-5 years for consumer-grade PCBs) with <0.1% annual aging rate

- Harsh environment resistance: Waterproof, dustproof, chemical corrosion resistance, and 48-hour salt spray test pass

- Mechanical durability: Vibration resistance (10-2000Hz), shock resistance (50G), and suitability for high-frequency movement in automotive, aerospace, and industrial equipment

These standards are backed by meticulous attention to detail: our specialty substrates cost 60% more than standard materials, copper etching tolerance is controlled to ¬Ī0.1mm (industry average ¬Ī0.3mm), and plating thickness is ‚Č•30őľm‚ÄĒensuring each PCB is a reliable component of critical systems.

4 Core Materials for Industrial PCB Manufacturing

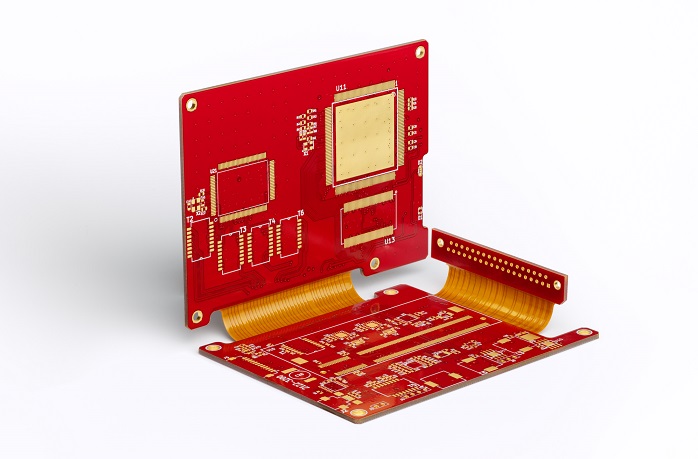

Material selection is critical to industrial PCB manufacturing performance. We partner directly with the world’s top 3 substrate suppliers to ensure consistent quality:

High-Tg FR4 Substrates (60% Application Rate)

- Thermal stability: 135¬įC+

- Ideal for: Industrial control, power electronics, automotive electronics

- Advantages: Best cost-performance ratio, 30% bulk pricing discount, fastest delivery time

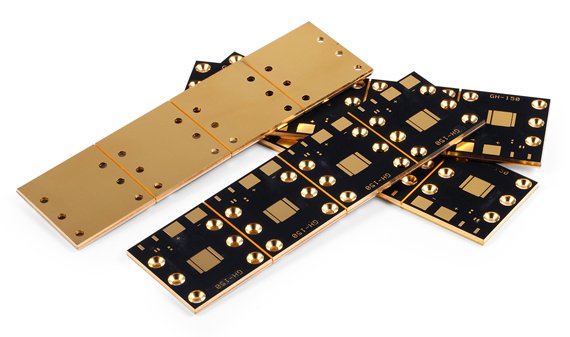

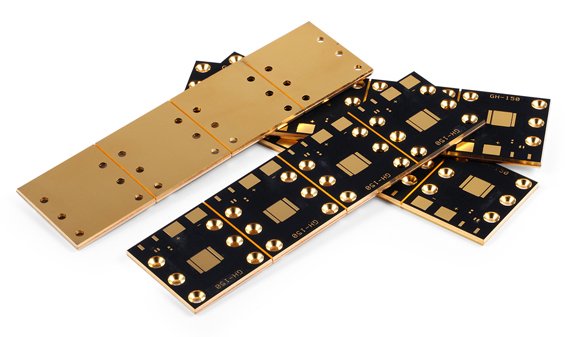

Metal Core PCBs (High-Power Applications)

- Thermal conductivity: 10x higher than standard FR4

- Ideal for: LED modules, motor controllers, inverters

- Advantages: 40% lower heat dissipation costs, 2x longer service life

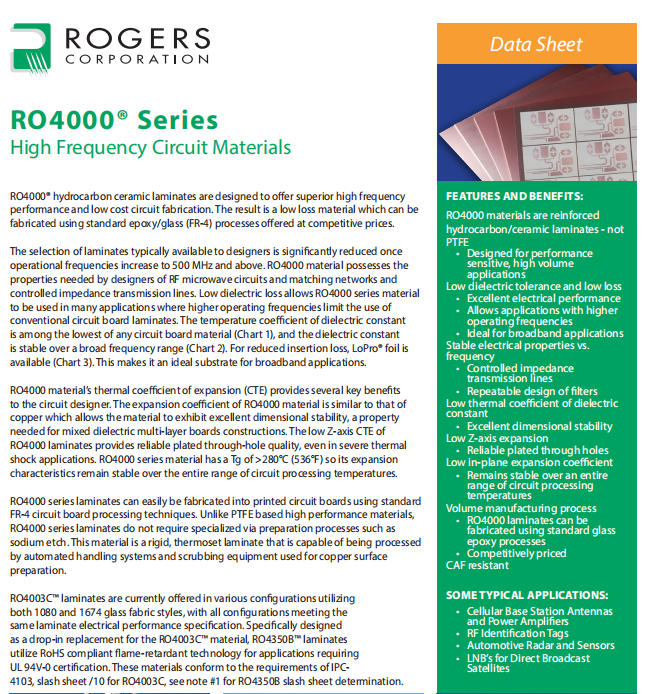

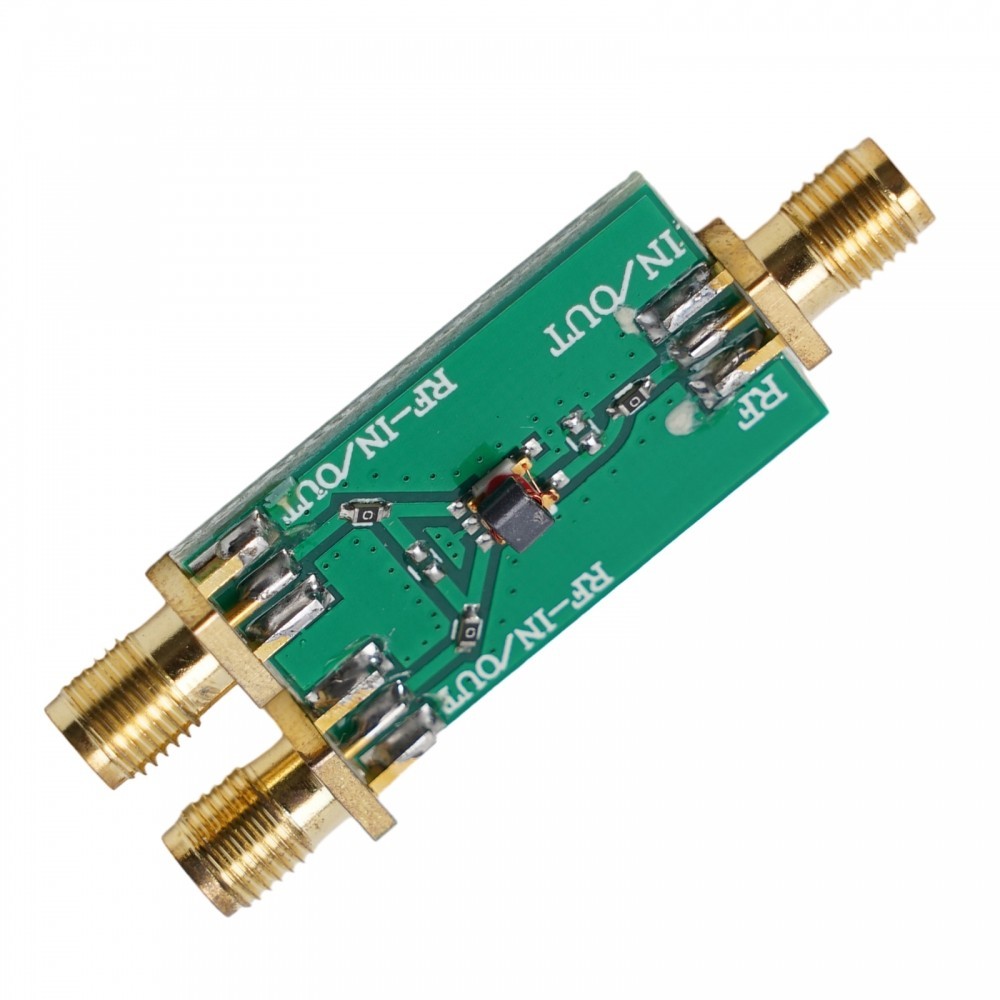

Ceramic Substrates (High-Frequency/High-Temperature)

- Materials: Aluminum nitride (AlN), aluminum oxide (Al2O3)

- Ideal for: Aerospace, RF communication, laser equipment

- Advantages: 200¬įC maximum operating temperature, <5% signal transmission loss

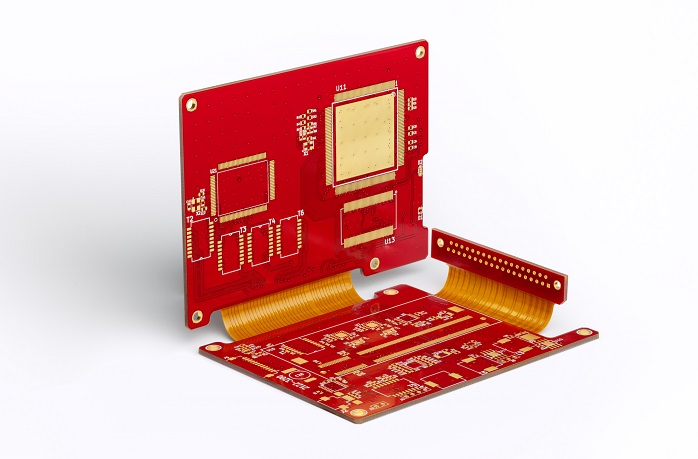

Polyimide Substrates (Extreme Environments)

- Temperature range: -269¬įC to 280¬įC

- Ideal for: Downhole drilling, military, medical implants

- Advantages: <0.05% annual aging rate, military-grade reliability certification

6 Critical Processes in Our Industrial PCB Manufacturing

We’ve developed an internal quality control system exceeding IPC standards, with 6 rigorous processes for every industrial PCB manufacturing project:

- DFM Intelligent Review: AI + manual double-check to identify design flaws (e.g., insufficient line width, hole misalignment), with optimization plans within 4 hours‚ÄĒreducing prototyping failure rate by 90%

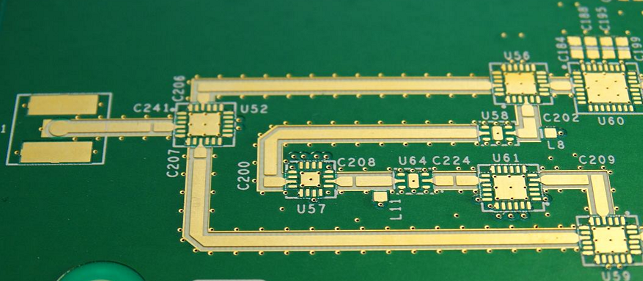

- High-Precision Lamination: Imported pressing equipment with ¬Ī0.1mm copper etching tolerance and ¬Ī0.05mm layer alignment accuracy to avoid signal interference

- Bubble-Free Pressing: Precise temperature (¬Ī1¬įC) and pressure (¬Ī0.1MPa) control, with layer peel strength ‚Č•1.5N/mm to prevent delamination

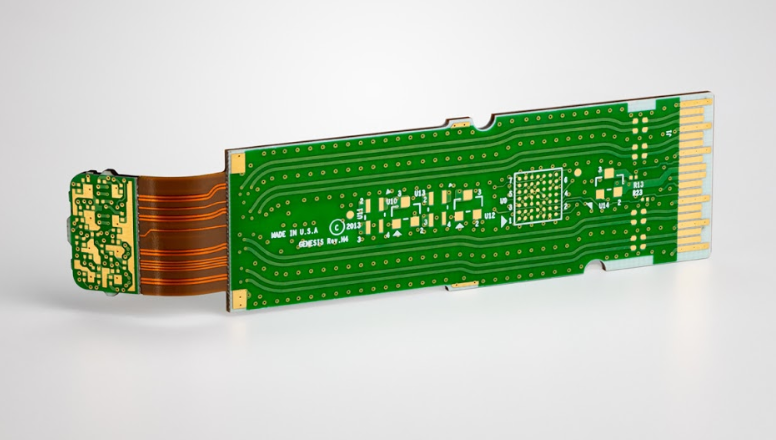

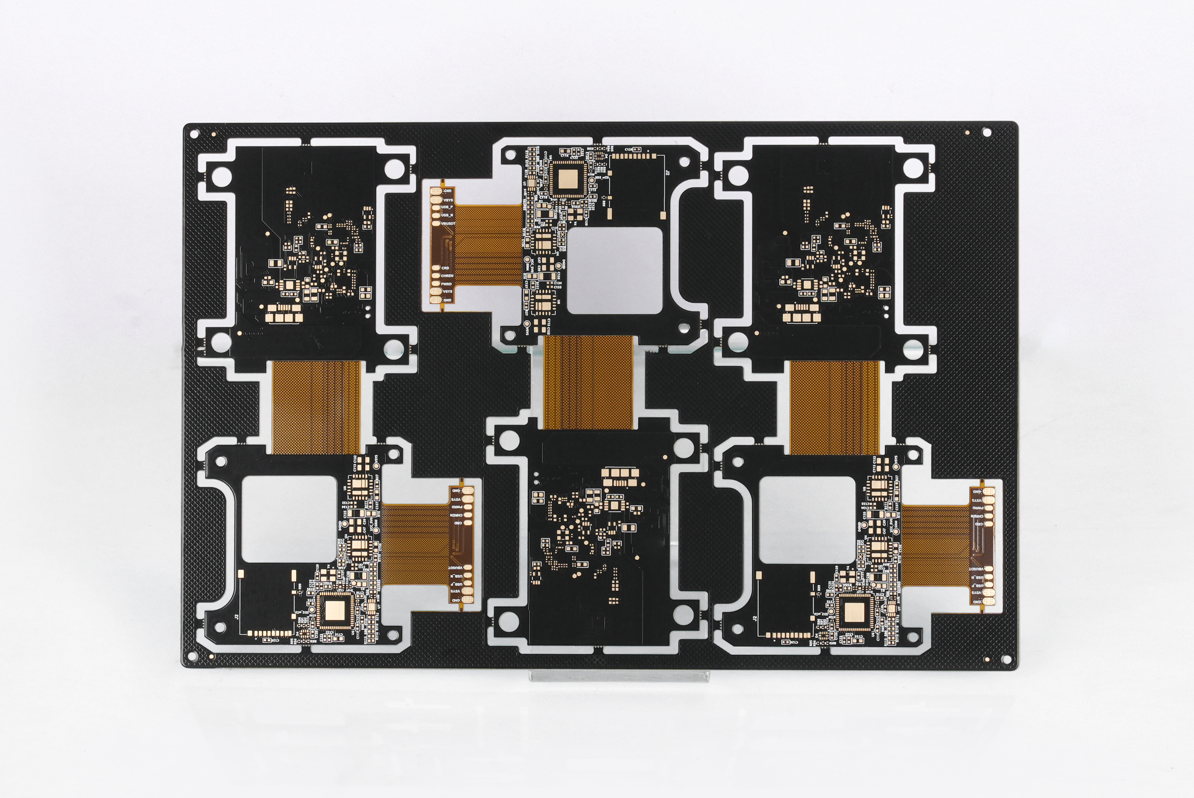

- Laser Micro-Drilling: Minimum hole size 0.1mm, 99.8% yield for blind/buried holes, suitable for HDI (High-Density Interconnect) designs

- Eco-Friendly Plating: ENIG (Electroless Nickel Immersion Gold) or immersion tin processes with uniform plating thickness (¬Ī2őľm) for corrosion resistance and easy soldering

- Comprehensive Testing: AOI optical inspection ‚Üí X-ray internal structure testing ‚Üí electrical continuity testing ‚Üí thermal cycling (-40¬įC~125¬įC, 50 cycles) ‚Üí vibration testing ‚Üí sampling aging testing

Industrial PCB Manufacturing vs. Commercial PCB Production: Key Differences

| Comparison Factor | Our Industrial PCB Manufacturing | Commercial PCB Production |

|---|---|---|

| Quality Standard | IPC Class 3 (Highest Level) + Internal Military-Grade Standards | IPC Class 1-2 (Consumer-Grade) |

| Service Life | 10+ Years (Including Warranty) | 2-5 Years (No Long-Term Warranty) |

| Temperature Range | -40¬įC ~ 125¬įC (Wide Temperature Adaptation) | 0¬įC ~ 70¬įC (Room Temperature Only) |

| Material Quality | High-Tg FR4/Ceramic/Polyimide (Imported Substrates) | Standard FR4 (Low-Cost Domestic Substrates) |

| Testing Process | 6-Stage Comprehensive Testing (Including Aging/Vibration) | Visual Inspection Only |

| Defect Rate | ‚ȧ3PPM | 15,000PPM (1.5%) |

| Warranty Service | 10-Year Trouble-Free Warranty + Lifetime Technical Support | 1-Year Warranty + Limited Support |

Core Industries for Our Industrial PCB Manufacturing Services

Our industrial PCB manufacturing expertise spans diverse high-demand sectors, with proven success in:

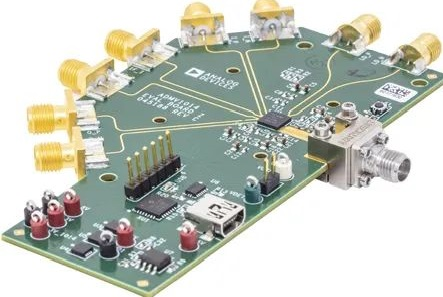

- Automotive: EV powertrains (supplier to BYD/NIO), ADAS (Advanced Driver Assistance Systems), and automotive extreme environment adaptation

- Aerospace: Satellite communication equipment, avionics (supporting COMAC), radiation resistance, and high-voltage testing compliance

- Industrial Automation: PLCs (Programmable Logic Controllers), sensor modules (partner with Siemens/Schneider), and high-frequency start-stop support

- Medical Devices: Diagnostic equipment, implantable devices (ISO 13485 certified), and biocompatibility + reliability compliance

- Energy: Solar inverters, wind turbine control systems (partner with Huawei/Sungrow), and outdoor harsh environment adaptation

FAQ About Industrial PCB Manufacturing

Can You Handle Small-Batch Orders (10-100 Units)? What’s the Lead Time?

Yes! We have no minimum order quantity‚ÄĒstart with 10 units. 1-4 layer PCBs are delivered in 24 hours, multi-layer PCBs in 48 hours, 3x faster than industry standards. Small-batch quality matches large-scale production.

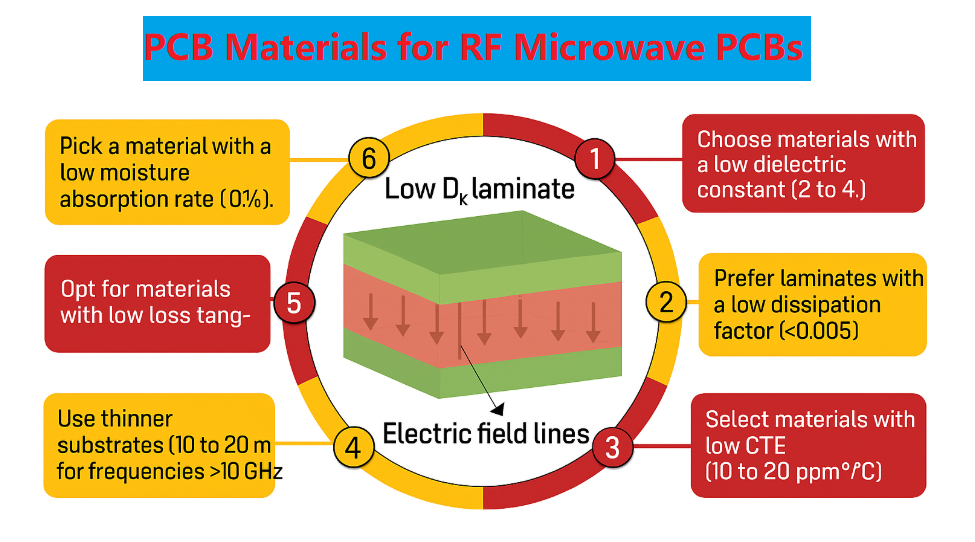

Which Material Is Best for High-Temperature/High-Frequency/High-Power Applications?

– High-temperature (105¬įC+): Polyimide or ceramic substrates

– High-frequency (2GHz+): PTFE substrates

– High-power (‚Č•50W): Metal core PCBs

We offer free material selection consulting for your specific application.

Can You Support Unprofessional Design Schemes?

Absolutely! Our free DFM design review service provides optimization reports within 4 hours of receiving Gerber files‚ÄĒincluding manufacturability improvements, cost reduction suggestions, and reliability enhancements. Perfect for both new and experienced engineers.

What If There’s a Quality Issue?

We stand behind our industrial PCB manufacturing with a 10-year trouble-free warranty. For non-human quality issues, we ship replacement products within 48 hours. For critical projects, we provide backup inventory to ensure zero production downtime.

What Industry Certifications Do You Hold?

All products are certified to IPC-A-600 Class 3, ISO 9001, ISO 14001, and UL 796. Automotive products meet IPC-6012/TS 16949; medical products meet ISO 13485; and aerospace products meet AS9100. Certification reports are available upon request.

Start Your Industrial PCB Manufacturing Project Today

Our production capacity and technical resources are prioritized for high-demand industrial PCB manufacturing clients. Take action now to:

- Get a free copy of the “Industrial PCB Manufacturing Selection Guide” + custom DFM review

- Access our 24-hour emergency delivery channel‚ÄĒcontact your account manager to lock in capacity

Submit your design files and project requirements, and we‚Äôll provide: ‚φ Accurate quotation ‚Ď° DFM optimization report ‚ĎĘ Production timeline ‚Ď£ Warranty plan‚ÄĒall within 24 hours. With 20 years of focus, we make industrial PCB manufacturing risk-free, efficient, and cost-effective‚ÄĒhelping you launch projects faster and gain market advantage.