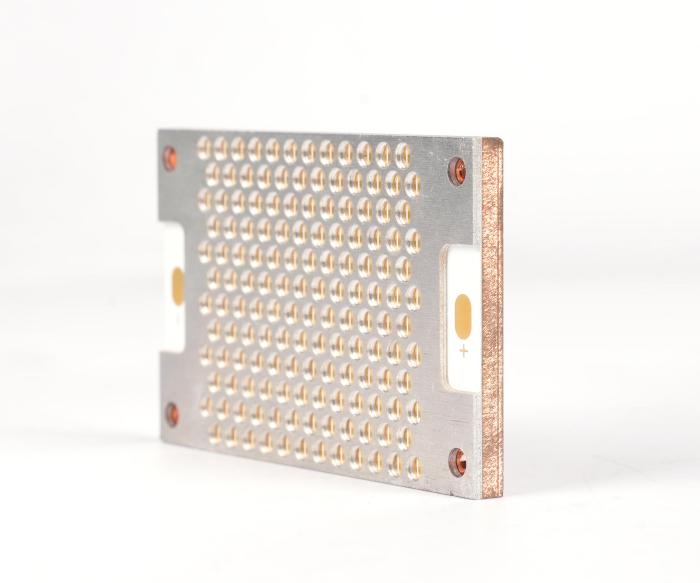

What Is DB Technology Hoot Circuit Board?

The DB Technology Hoot Circuit Board is an advanced control board used in hot tubs to manage and automate various functions, making your spa experience efficient and enjoyable. This circuit board is central to the hot tubâs operation, overseeing everything from heating the water to powering the jets. It communicates with the control panel, relays commands, and adjusts settings based on user inputs. Essentially, the Hoot Circuit Board is the brain of the hot tub, coordinating multiple components to maintain a smooth, safe, and personalized experience for the user. It is known for its durability and reliability, this board can, however, develop faults over time due to age, moisture, or electrical issues, necessitating a replacement.

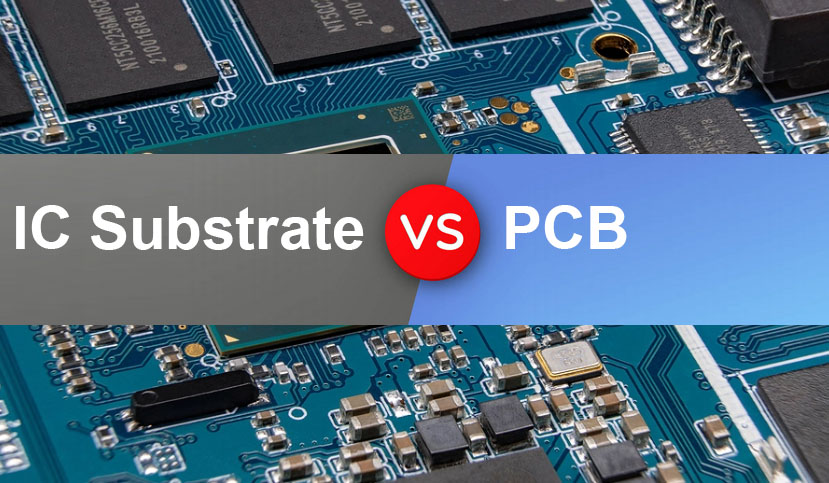

Components and Functions of the Hoot Circuit Board

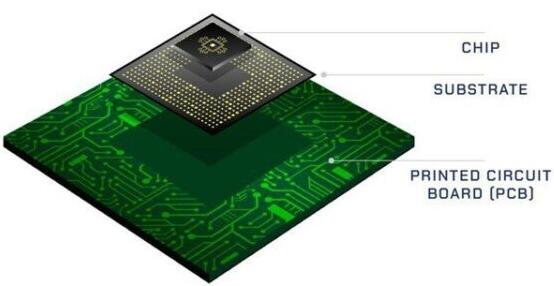

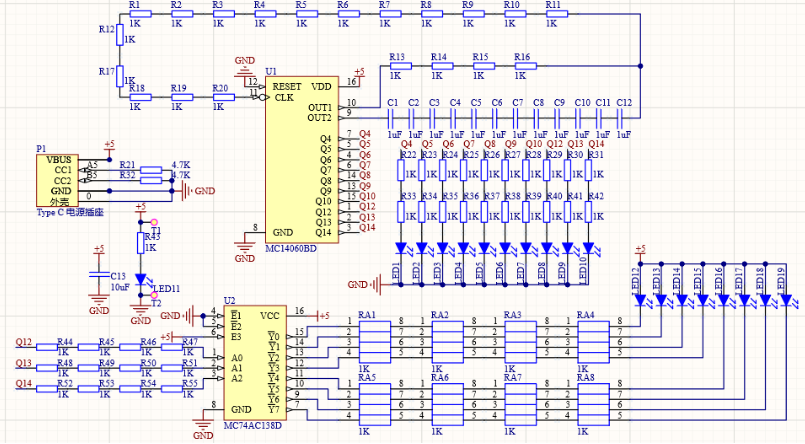

The DB Technology Hoot Circuit Board consists of several key components, each serving an essential role in the functioning of your hot tub:

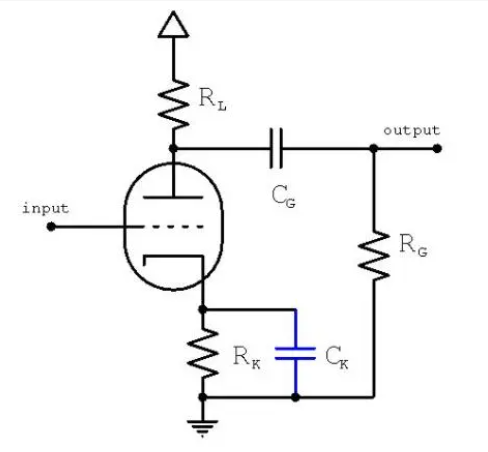

- Microcontroller Unit (MCU): The MCU is the core of the circuit board, processing commands from the control panel. It manages tasks like temperature adjustments, pump speed, and safety protocols.

- Relay Switches: These switches control the power flow to various parts of the hot tub, such as heaters and pumps. They act as the gatekeepers, opening and closing circuits based on commands from the MCU.

- Sensors and Thermistors: These components monitor temperature and water flow. They ensure the hot tub operates within safe limits, preventing overheating and other potential hazards.

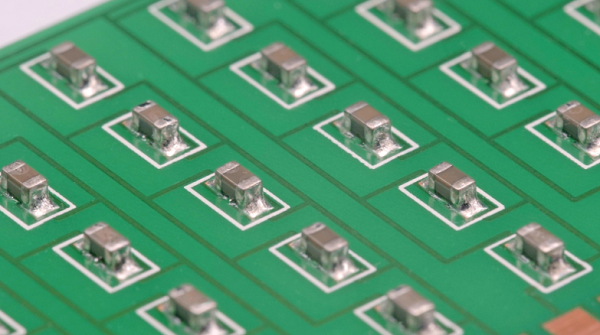

- Power Supply Components: The power components, including capacitors and resistors, regulate voltage and current, ensuring stable power delivery to the entire system.

- Communication Ports: These ports allow the circuit board to communicate with the control panel and other connected devices, facilitating real-time adjustments and error reporting.

Each part of the Hoot Circuit Board works together to provide a safe and enjoyable hot tub experience. However, when one component fails, it can affect the entire system.

How Much Does It Cost to Replace a Circuit Board on a Hot Tub?

Replacing a circuit board on a hot tub can vary in cost, depending on the model and brand. For a DB Technology Hoot Circuit Board, replacement prices typically range between $200 and $600. Factors influencing the cost include the availability of the board, whether itâs purchased directly from the manufacturer or a third-party supplier, and any additional installation fees.

If you opt to replace the board yourself, you may only need to pay for the board and any tools required. However, this approach demands basic knowledge of electronics and safety precautions.

Or you can hirea professional can add to the cost, with service fees ranging from $100 to $200. Though more expensive, a professional installation ensures the board is installed correctly, minimizing risks of further issues.

While the initial cost may seem high, replacing a faulty circuit board can extend the life of your hot tub and improve its performance, making it a worthwhile investment.

How Long Do Hot Tub Circuit Boards Last?

The life of the circuit board of the hot tub is affected by many factors, and a fixed number of years cannot be given. â

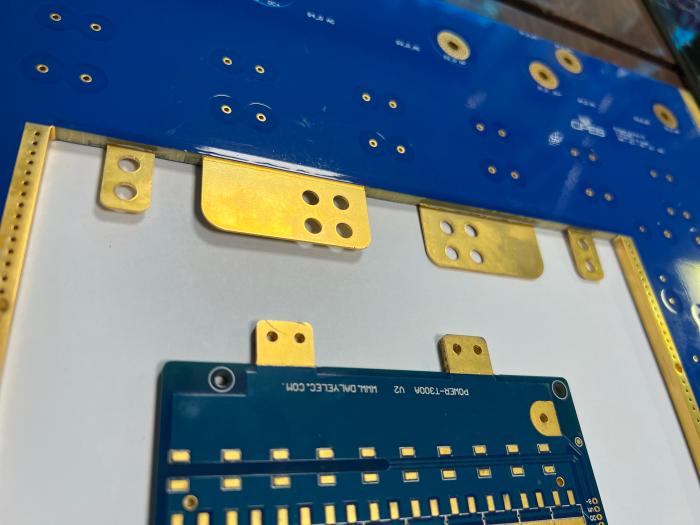

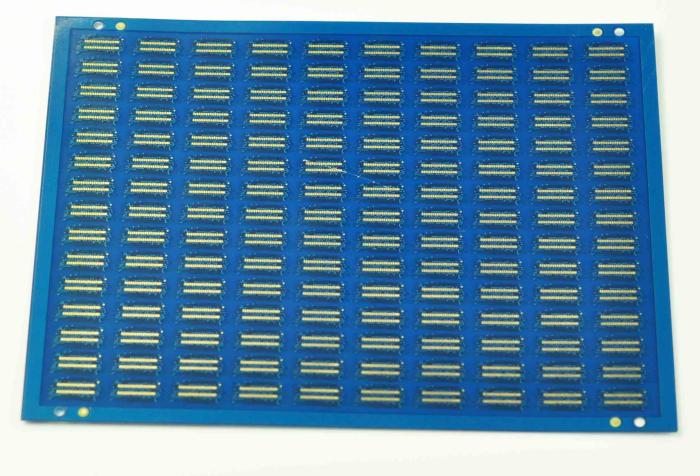

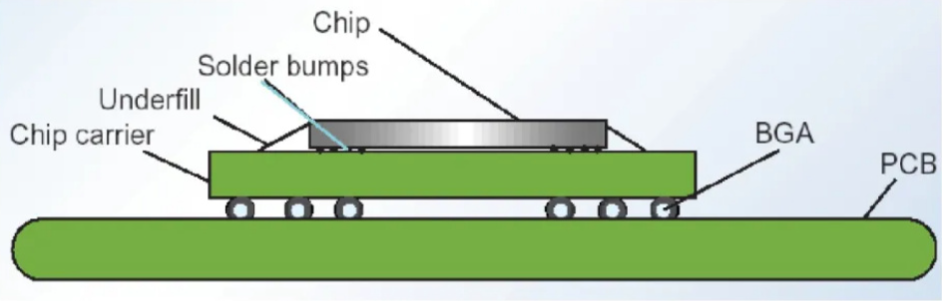

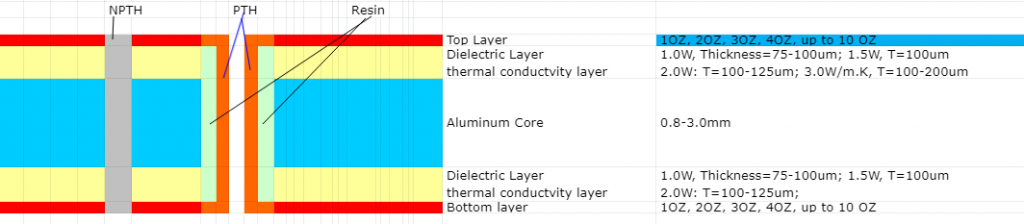

The life of hot tub circuit board is affected by many factors such as raw material quality, production process, environmental factors and so on. High-quality substrates and copper foils effectively reduce the risk of aging and failure, while high-precision production processes and strict quality control reduce defects and improve long-term stability. In addition, environmental factors such as humidity, temperature, and the presence of contaminants can also cause the board to age. Therefore, maintaining appropriate environmental conditions, such as controlling humidity and temperature, is an effective measure to extend the shelf life of the circuit board.

For electric water heaters, their service life is between 5-15 years, which indicates that the life of the circuit board will also be affected by the overall use of the electric water heater. Therefore, the life of the hot tub circuit board not only depends on the quality and maintenance of the circuit board itself, but also is affected by the frequency of use of the water heater, maintenance and other factors. In order to ensure the safety and effectiveness of use, it is recommended to regularly inspect and maintain the hot tub and its circuit board, follow the manufacturer’s recommendations for maintenance and replacement to ensure the best performance and safety.

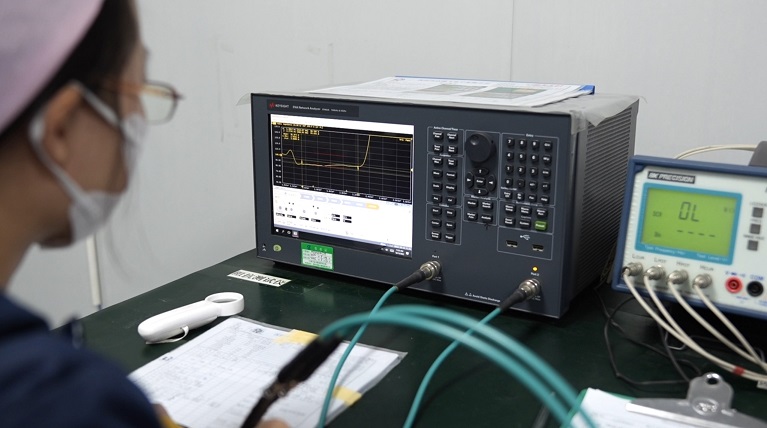

How Do I Know If My Circuit Board Is Bad?

Recognizing the signs of a failing circuit board early can help prevent further damage and costly repairs. Here are common indicators to be done if your DB Technology Hoot Circuit Board might be malfunctioning:

1. Visual inspection

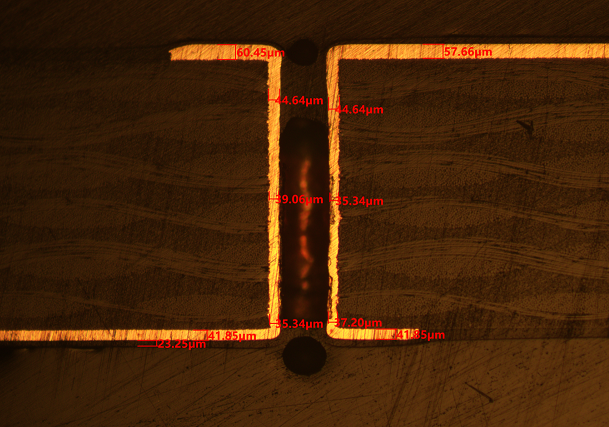

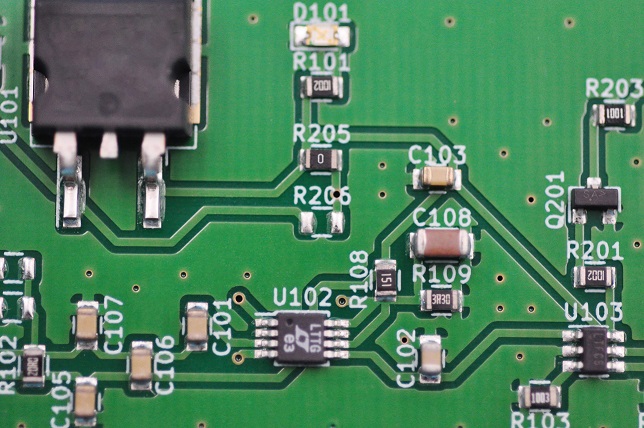

Carefully observe whether the surface of the circuit board has obvious physical damage, such as burning, cracking, corrosion, etc. If an anomaly is found, it is likely a sign of damage to the circuit board.

2. Test voltage

Use a digital multimeter or multifunction tester to measure the voltage between each key point on the circuit board. If there is an abnormal voltage value (such as short circuit, open circuit, or abnormal high and low), it indicates that there may be a problem with the board.

3. Tracking signals

When some functions on the circuit board do not work properly, devices such as oscilloscopes or logic analyzers can be used to track the signal path and determine whether there is interruption or interference.

4. Component testing

If there are removable components on the circuit board, such as integrated circuit chips, electrolytic capacitors or diodes, you can use test instruments to test these components to confirm whether their performance is normal.

5. Thermal imaging

Use an infrared thermal imaging camera to scan the surface of the circuit board to detect whether there are hot spots or abnormal temperature areas. This can help detect possible faults or overload conditions in the board.

Please note that if you do not have the relevant expertise and skills, it may be risky to determine whether the board is damaged. It is recommended to consult a professional or seek the help of professional repair services like EBest Circuit (Best Technology) when it is necessary to judge or repair the circuit board.

Alternatives to the Hoot Circuit Board

If a replacement Hoot Circuit Board is not readily available or doesnât fit your budget, consider alternative options that offer comparable performance:

- Generic Replacement Boards

Some manufacturers produce universal circuit boards compatible with multiple hot tub brands. These boards can serve as a suitable alternative but may require additional wiring adjustments.

- Upgraded Boards

You can upgrade your circuit boards with enhanced features, like advanced control settings or energy efficiency improvements, are available. Though slightly more expensive, these boards can enhance your hot tub experience.

- Used or Refurbished Boards

Pre-owned or refurbished circuit boards can be a cost-effective solution. Ensure that these boards are tested and come with a warranty to avoid future issues.

Choosing the right alternative depends on your hot tubâs compatibility and your specific needs. Always verify compatibility before purchasing a replacement.

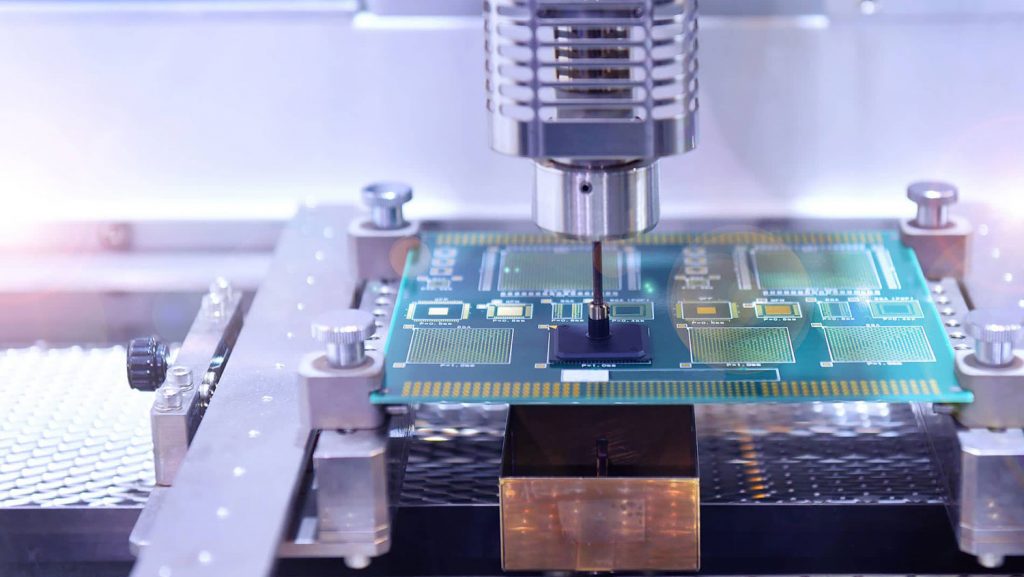

Step-by-Step Guide to Replacing Your Hoot Circuit Board

Replacing your DB Technology Hoot Circuit Board can be a manageable task with the right tools and guidance. Hereâs a simple step-by-step guide:

1. Before starting, turn off the power supply to your hot tub at the breaker box to avoid electrical shock.

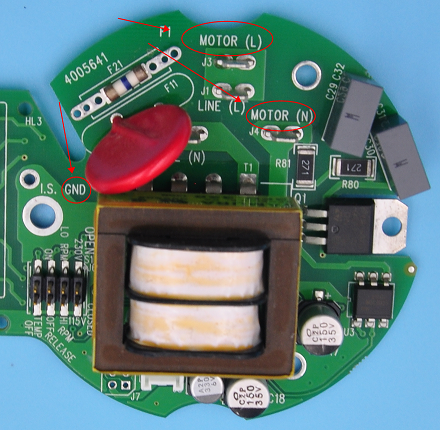

2. Locate the control box that houses the circuit board. Remove the cover using a screwdriver.

3. Before disconnecting anything, take detailed photos of the circuit board and wiring connections. This will help you reconnect everything correctly.

4. Carefully remove the connectors and wiring attached to the circuit board. Unscrew any mounting screws holding the board in place.

5. Position the new Hoot Circuit Board in place and secure it with screws. Reconnect all wires and connectors as per your reference photos.

6. Turn the power back on and test all functions of the hot tub to ensure the new board is working correctly. Check for any error messages or irregular operation.

7. Once everything is functioning as expected, replace the control box cover securely.

Replacing a circuit board can be a straightforward process, but if youâre unsure, consulting EBest Circuit (Best Technology) is always a good idea to ensure safety and proper installation.

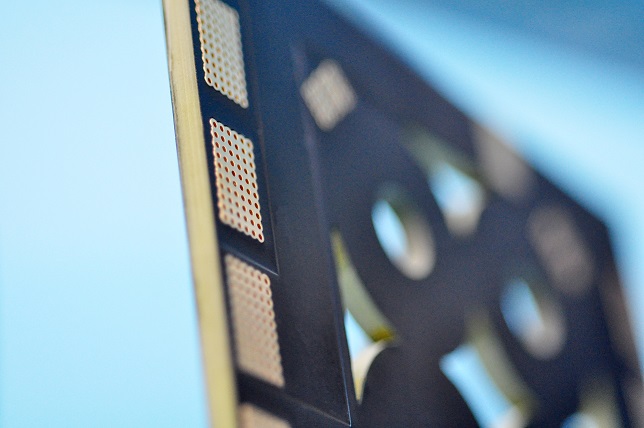

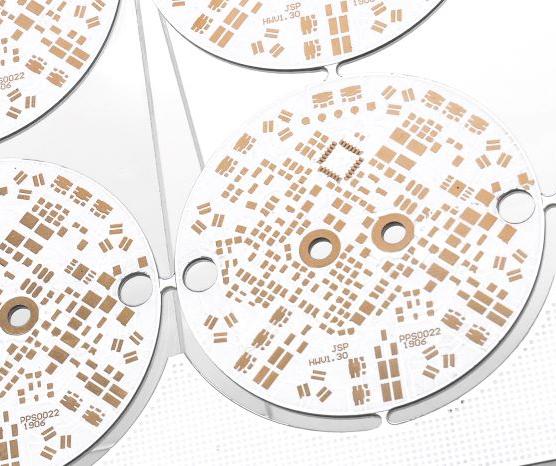

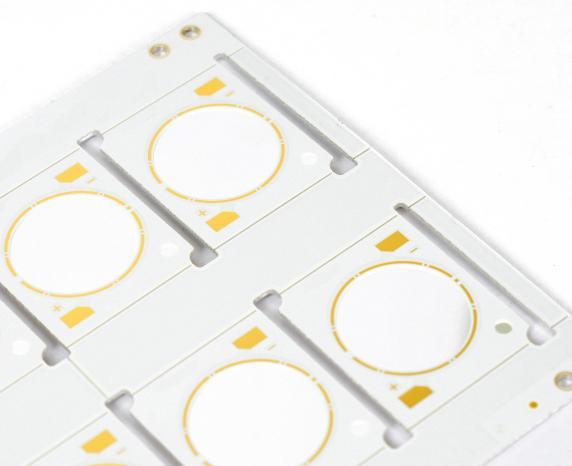

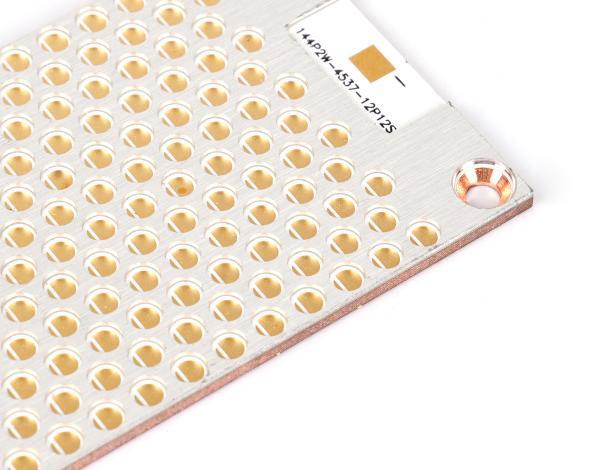

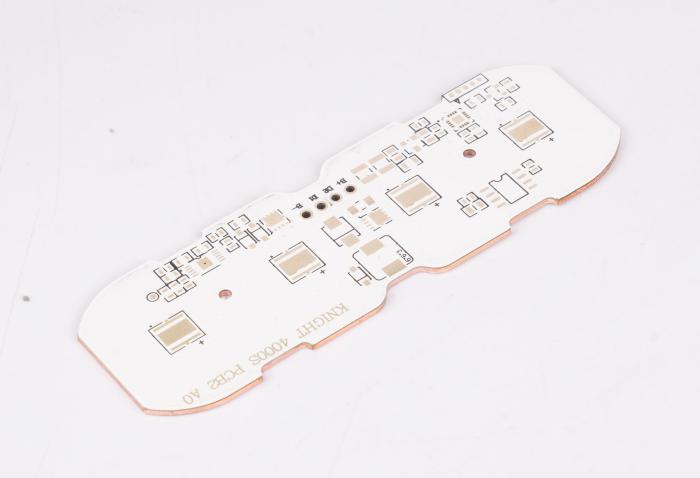

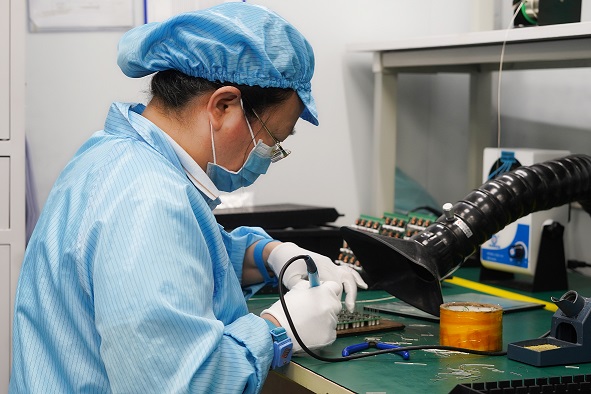

Why Choose EBest Circuit (Best Technology) for Hoot Circuit Board?

Selecting the right supplier for your DB Technology Hoot Circuit Board replacement or upgrade can greatly impact the performance and longevity of your hot tub. Choosing EBest Circuit (Best Technology) as your go-to provider for Hoot Circuit Boards because:

- No stencil, setup fee

- Free capacitors and resistors for prototype customers

- Rapid prototyping: 24-hour delivery, 8-hour rush service

- Dust-free workshop for PCB and PCBA assembly

- Over 2000+ customers all around the world

- Dedicated one-on-one service with WIP production updates

- ISO9001, ISO13485, IATF16949 certificated

- Factory in Vietnam, US, China

You are welcome to contact us any time for PCB projects!!