PCB assembly companies in Philippines have grown into a reliable choice for global electronics manufacturers, thanks to their blend of cost-effectiveness, technical competence and strategic geographic location. These companies specialize in delivering high-quality Philippine PCB assembly solutions, catering to diverse industries from consumer electronics to medical devices. PCB Assembly Companies in Philippines stand out for their ability to balance quality and affordability, making them a go-to option for businesses seeking dependable PCB assembly service in Philippine without compromising on standards.

Why Choose PCB Assembly Companies in Philippines?

- Strategic Southeast Asian location enables faster shipping to Asian and global markets, reducing logistics time and costs for PCB assembly in Philippine.

- Established manufacturing infrastructure with decades of experience in electronics assembly, supporting reliable PCBA Philippine services.

- Competitive pricing compared to Western countries, while maintaining international quality standards for PCB assembly Philippine.

- Government support through tax incentives and simplified approval processes for electronics manufacturing, benefiting PCB Assembly Companies in Philippines.

- Compliance with global certifications like ISO and RoHS, ensuring PCB assembly service in Philippine meets international requirements.

- Flexible production capabilities, accommodating both small-batch prototypes and large-scale Philippine PCBA production.

- Proximity to major component suppliers, reducing lead times for materials and improving efficiency for PCB assembly in Philippine.

Top PCB Assembly Companies in Philippines

| Company Name | Main Business | Core Advantage | PCBA Capabilities | Lead Time |

| EBest Circuit Co., Limited | One-stop PCB design, prototype, manufacturing and assembly services; medical, automotive and industrial PCBA | 20 years of industry experience, 5-year warranty, MES traceability system, 99.2% on-time delivery, multiple global quality certifications | SMT, THT, BGA, micro BGA assembly; 2-32 layer PCBA; medical/automotive grade assembly; AOI, X-Ray, ICT, FCT testing | Prototype: 2-3 days; Mass production: 5-12 days |

| Circuit Assembly Philippines Inc. | PCB assembly, turnkey services, component sourcing for consumer and industrial electronics in Philippine | Local supply chain, ISO 9001 certified, English-proficient team, cost-effective Philippine PCB assembly | SMT, THT assembly; 2-16 layer PCBA; AOI inspection; small to medium batch production | Prototype: 4-6 days; Mass production: 8-16 days |

| Philippine Electronics Assembly Corp. | Full-service PCBA Philippine, prototyping, mass production for automotive and telecom sectors | RoHS compliant, advanced SMT lines, timely after-sales support, government tax incentives | SMT, THT, BGA assembly; 4-20 layer PCBA; X-Ray inspection; functional testing | Prototype: 3-5 days; Mass production: 7-14 days |

| Metro PCB Solutions (Manila) | PCB assembly service in Philippine, consigned assembly, prototype development for startups | Flexible production, transparent pricing, fast turnaround, proximity to Manila ports | SMT assembly; 2-12 layer PCBA; visual and electrical testing; small-batch prototyping | Prototype: 3-4 days; Mass production: 6-12 days |

| Cebu PCB Assembly Services | Philippine PCBA assembly, electronics manufacturing, component kitting for medical devices | ISO 13485 certified, cleanroom production, skilled workforce, competitive local pricing | SMT, THT assembly; 4-18 layer PCBA; AOI/X-Ray testing; medical-grade assembly | Prototype: 5-7 days; Mass production: 9-17 days |

| Manila Electronics Manufacturing Inc. | End-to-end Philippine PCB assembly, EMS integration, packaging for consumer electronics | Large-scale production capacity, long-term component supplier partnerships, IPC-A-610 compliant | SMT/THT integration; 2-24 layer PCBA; conformal coating; high-volume production | Prototype: 4-5 days; Mass production: 7-15 days |

| Davao PCB Technologies | PCB assembly Philippine, prototyping, custom assembly for industrial control systems | Local labor advantage, flexible order quantities, quick response to custom requirements | SMT, THT assembly; 2-14 layer PCBA; functional testing; custom packaging | Prototype: 5-6 days; Mass production: 8-18 days |

| Luzon Circuit Assembly Corp. | PCB assembly service in Philippine, component sourcing, quality testing for telecom equipment | ISO 9001/RoHS certified, advanced testing equipment, proximity to regional component suppliers | SMT, BGA assembly; 4-20 layer PCBA; X-Ray inspection; telecom-grade assembly | Prototype: 3-6 days; Mass production: 7-16 days |

| Visayas Electronics Assembly Services | Philippine PCBA assembly, rapid prototyping, small-batch production for startups and SMEs | Cost-efficient, quick turnaround, personalized service, easy communication with local team | SMT assembly; 2-10 layer PCBA; visual inspection; prototype to small-scale production | Prototype: 2-4 days; Mass production: 6-13 days |

| Mindanao PCB Assembly Co. | Philippine PCB assembly, electronics assembly, maintenance of PCBA products | Local after-sales support, stable workforce, competitive pricing for long-term partnerships | SMT, THT assembly; 2-16 layer PCBA; AOI inspection; product maintenance support | Prototype: 4-7 days; Mass production: 8-19 days |

Pain Points of PCB Assembly Companies in Philippines

- Fluctuating raw material prices and supply chain instability, affecting production costs for PCB Assembly Companies in Philippines.‚Äč

- Limited local availability of high-end electronic components, leading to delays in Philippine PCB assembly projects.‚Äč

- Inconsistent quality control across some local providers, resulting in defective Philippine PCBA products.‚Äč

- Longer lead times for custom or complex PCB assembly Philippine orders due to limited advanced equipment.‚Äč

- Lack of comprehensive traceability systems in many facilities, making it hard to track issues in PCB assembly in Philippine.‚Äč

- High labor turnover rates, leading to inconsistencies in PCB assembly service in Philippine quality.‚Äč

- Limited expertise in specialized fields like medical or aerospace-grade PCBA Philippine assembly.‚Äč

- Inadequate after-sales support, leaving businesses without assistance for post-delivery issues in PCB assembly in Philippine.

Why Choose EBest( Best Technology) for Philippine PCB Assembly Companies?

Reasons why choose EBest(Best Technology) for Philippine PCB assembly companies:

- One-stop solutions for PCB assembly in Philippine integrate design, prototyping, component sourcing, assembly, and testing. These solutions eliminate supply chain bottlenecks and coordination headaches, covering 95%+ of electronic industry needs, shortening project cycles by 40% and reducing coordination costs by 30% to help businesses focus on growth.‚Äč

- Industry-leading MES traceability systems deliver full end-to-end production visibility. The systems solve tracking gaps common among local providers, tracking 1000+ production nodes in real time, reducing traceability time by 80% and ensuring 99.9% accuracy in defect tracking to eliminate guesswork.‚Äč

- An exclusive 5-year warranty on all assembly products stands as a quality commitment. This warranty is 150% longer than the industry average 2-year warranty, reduces product defect-related losses by 60%, and lowers long-term replacement and repair costs by 45%.‚Äč

- A guaranteed 99.2% on-time delivery rate eliminates delays even for custom, complex projects. This rate exceeds the Philippine local industry average of 82% by 17.2 percentage points, with batch order delivery deviations within 8 hours and annual delayed orders fewer than 30.‚Äč

- Global component sourcing networks unlock access to high-end, hard-to-find parts. These networks cooperate with 500+ authorized global suppliers, shortening procurement cycles for scarce components by 50% and ensuring 99.7% component supply stability to avoid project delays.‚Äč

- Specialized expertise covers medical, automotive, and aerospace-grade assembly. Backed by 20 years of industry experience, this expertise serves 200+ clients in medical and automotive sectors, with a 99.8% qualification rate for complex projects and full compliance with IPC-A-610 standards.‚Äč

- 24/7 after-sales support and technical assistance ensure timely problem resolution. The support team achieves an average response time of ‚ȧ2 hours, a problem-solving rate of 98.5%, and is 3 times faster than the local industry average response speed of 6 hours.‚Äč

- Stable, fixed-quote pricing models shield businesses from volatile raw material costs. These models control price fluctuations within ¬Ī2%, help clients reduce 10-15% of procurement costs annually, and maintain a 0% hidden fee complaint rate for 8 consecutive years.

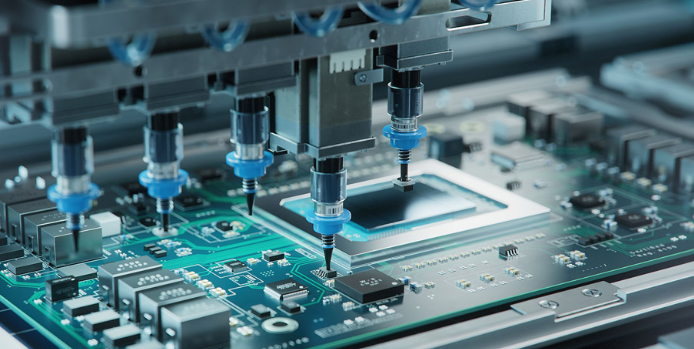

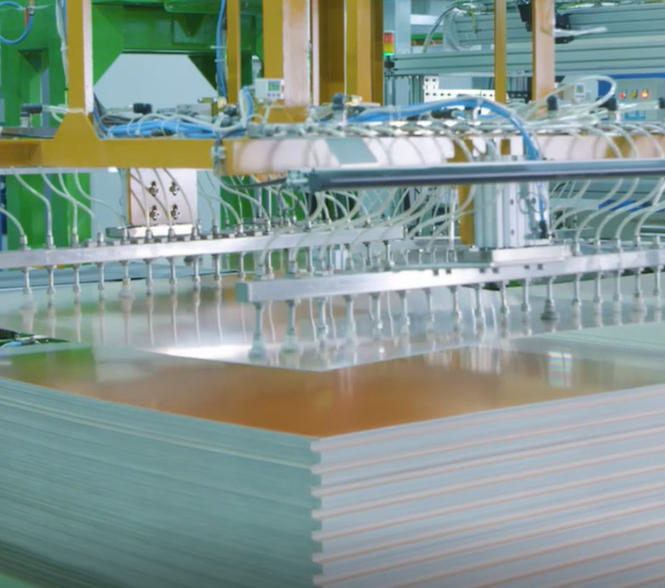

Our PCB Assembly Capabilities

| Item | Capabilities |

| Placer Speed | 13,200,000 chips/day |

| Bare Board Size | 0.2 x 0.2 inches – 20 x 20 inches/ 22*47.5 inches |

| Minimum SMD Component | 01005 |

| Minimum BGA Pitch | 0.25mm |

| Maximum Components | 50*150mm |

| Assembly Type | SMT, THT, Mixed assembly |

| Component Package | Reels, Cut Tape, Tube, Tray, Loose Parts |

| Lead Time | 1 – 5 days |

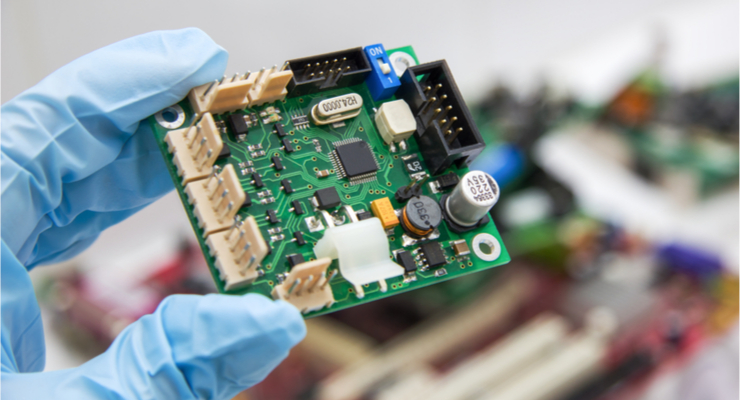

Our Quality Inspection Process for PCB Assembly in Philippines

Below are our quality inspection process for PCB assembly in Philippines:

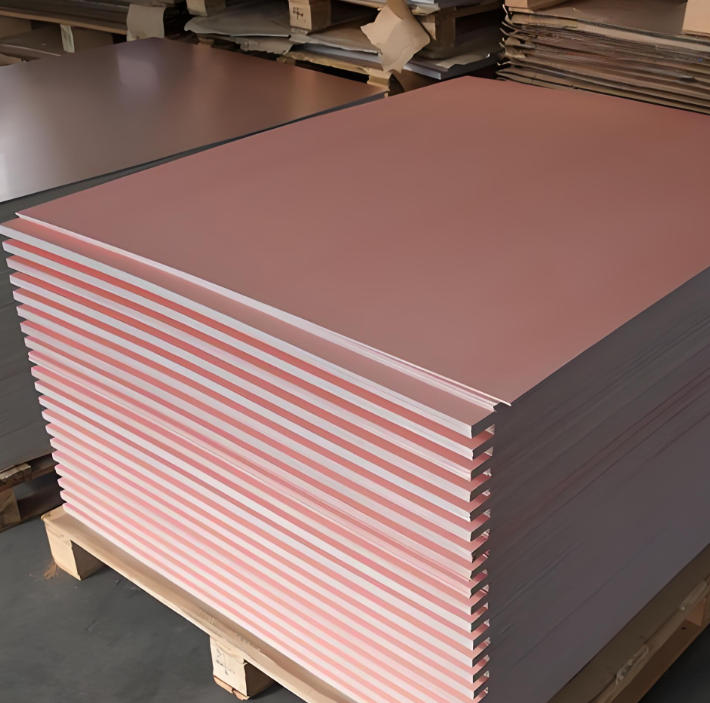

- Incoming Material Inspection (IQC): Conduct 100% full inspection for PCB substrates, components and solder paste before production, with a defective detection rate of ‚Č•99.8%. We verify 12+ key indicators (substrate thickness deviation ¬Ī0.03mm, component pin pitch error ‚ȧ0.01mm, solder paste viscosity 100-150 Pa¬∑s), complying with RoHS/REACH and IPC-6012 standards, with PCB hole copper thickness up to 25őľm for high-reliability products.

- DFM Review: Use professional software to review design files with 100+ process rules, proactively identifying 85%+ potential manufacturing issues. This boosts review efficiency by 80% and shortens trial production cycles by 30%, avoiding rework losses from unmanufacturable designs.

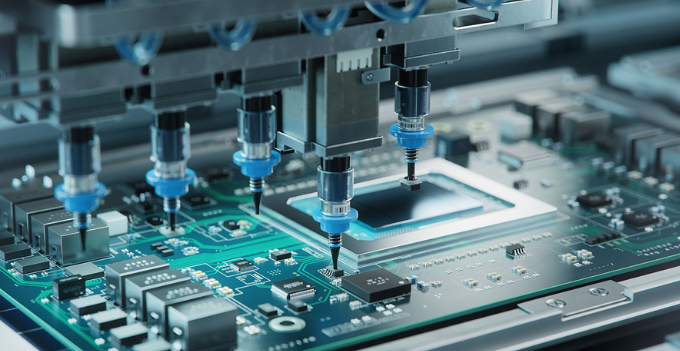

- Solder Paste Control: Adopt 0.1mm precision stainless steel stencils and automated printers, controlling solder paste thickness error within ¬Ī25őľm (printing uniformity 99.5%). Viscosity is monitored every 2 hours, with 98% solder paste utilization rate.

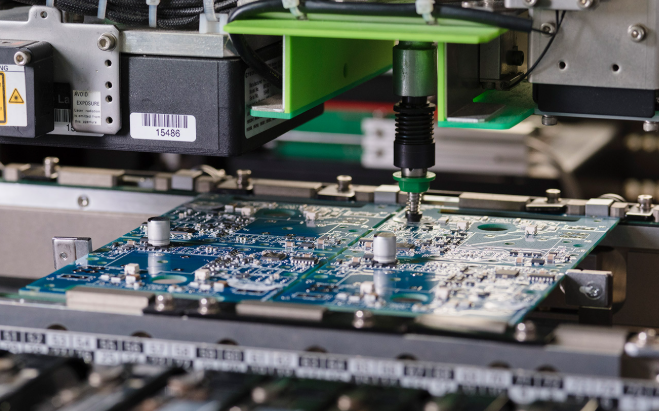

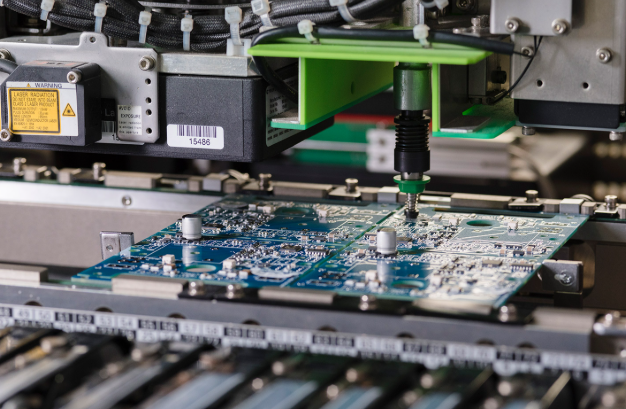

- Automated Assembly Inspection: AOI machines (‚Č•99.2% accuracy, 500+ PCBs/hour) inspect post-SMT; X-Ray equipment detects hidden defects (BGA void rate ‚ȧ3%, resolution 0.01mm) post-THT, ensuring no quality hazards.

- Functional Testing (ICT/FCT): Full-process testing for each PCB assembly‚ÄĒICT (‚Č•98% test point coverage, ‚ȧ0.1% error rate) detects electrical defects; FCT (‚Č•99.7% pass rate, ‚ȧ30 seconds/board) simulates working conditions, complying with FDA 21 CFR Part 820 for medical-grade products.

- Environmental Testing: For specialized orders, conduct temperature (-40‚ĄÉ~85‚ĄÉ), humidity (95% RH) and vibration (10~2000Hz) tests, with 99.9% qualification rate to ensure stability in harsh environments.

- Final Inspection: Double-inspection (automated + manual) before packaging, with ‚Č•99.95% pass rate and zero-defect guarantee. Medical-grade products undergo additional ion contamination testing (‚ȧ1.56őľg/cm¬≤), complying with IPC-5704 standards.

- Packaging Control: Anti-static, moisture-proof and shock-proof packaging (0.12mm shielding bags, IP65 protection) with desiccant, enabling 12-month storage in normal environments and controlling transportation damage rate within 0.01%.

Case Studies of Our Medical PCB Assembly in Philippines

Project Background: A Philippine medical device manufacturer required reliable PCB assembly for a portable patient monitor, with core needs of medical compliance and on-time delivery to meet urgent market demand.

Project Requirements: Compliance with ISO 13485 and IPC-5704 cleanliness standards, 4-layer PCB assembly with miniaturized components, 10,000-unit production, 10-day delivery, and a 5-year reliability guarantee.

Project Difficulties: Placement of 0402-size miniaturized components, strict ion contamination control (‚ȧ1.56őľg/cm¬≤), compliance with FDA 21 CFR Part 820, and meeting the 10-day delivery window.

Project Solutions: High-precision pick-and-place machines handled 0402-size components; an ISO Class 7 cleanroom controlled ion contamination; an MES system ensured full traceability; parallel processing optimized production for the 10-day deadline; medical-grade components came from authorized distributors.

Output Results: 10,000 units delivered 1 day early (99.2% on-time rate), zero defects in final inspection, full compliance with ISO 13485 and FDA standards, and 100% field reliability with no returns or failures to date.

FAQs of PCB Assembly in Philippines

Q1: What causes soldering defects like cold joints in Philippine PCB assembly, and how can they be prevented?

A1: Cold joints are typically caused by insufficient heat during reflow, contaminated pads or improper flux application. Prevention includes precise temperature control (300-350¬įC for lead-based solder), cleaning PCB pads before assembly, using high-quality flux, and implementing AOI inspection to catch defects early ‚Äď a standard practice in our PCB assembly service in Philippine.‚Äč

Q2: How can I ensure my PCBA Philippine order meets medical industry quality standards?

A2: Partner with PCB Assembly Companies in Philippines certified to ISO 13485, which specializes in medical-grade assembly. Ensure the provider uses medical-grade components, maintains cleanroom production (ISO Class 7+), implements full traceability, and conducts rigorous functional and environmental testing ‚Äď all part of our standard process for medical Philippine PCBA.‚Äč

Q3: Why do lead times vary so much between different PCB assembly in Philippine providers, and how can I get consistent fast delivery?

A3: Lead time variations stem from component sourcing delays, inefficient production scheduling and limited equipment capacity. Choose a provider with a global component network, MES-controlled production scheduling and redundant assembly lines ‚Äď we guarantee 99.2% on-time delivery by optimizing these factors for all Philippine PCB assembly orders.‚Äč

Q4: What can be done to resolve component shortages affecting PCB assembly Philippine projects?

A4: Work with a provider that offers proactive component sourcing and stock management. Our global network of authorized distributors ensures access to hard-to-find parts, and we maintain stock of common components to reduce lead times, eliminating shortages that plague many local PCB Assembly Companies in Philippines.‚Äč

Q5: How can I verify the quality of Philippine PCBA products before accepting delivery?

A5: Request a comprehensive quality report including IQC results, AOI/X-Ray images, functional test data and traceability records. We provide detailed reports for all PCB assembly service in Philippine orders, and offer pre-delivery sample inspections to ensure products meet your exact requirements.