The demand for high-quality PCB Iceland manufacturer services continues to grow in Iceland’s electronics industry, driven by the need for precise and durable circuit boards. Choosing the right PCB Iceland manufacturer is critical to ensuring project success, as it directly impacts product performance, production efficiency and overall cost-effectiveness. This blog explores the top Iceland PCB manufacturers, core selection criteria, industry pain points, essential certifications and practical evaluation methods, providing valuable guidance for navigating the PCB Iceland manufacturing landscape.

Top 10 PCB Iceland Manufacturer List

| Company Name | Main Business | Core Advantages | Process Capability | Lead Time |

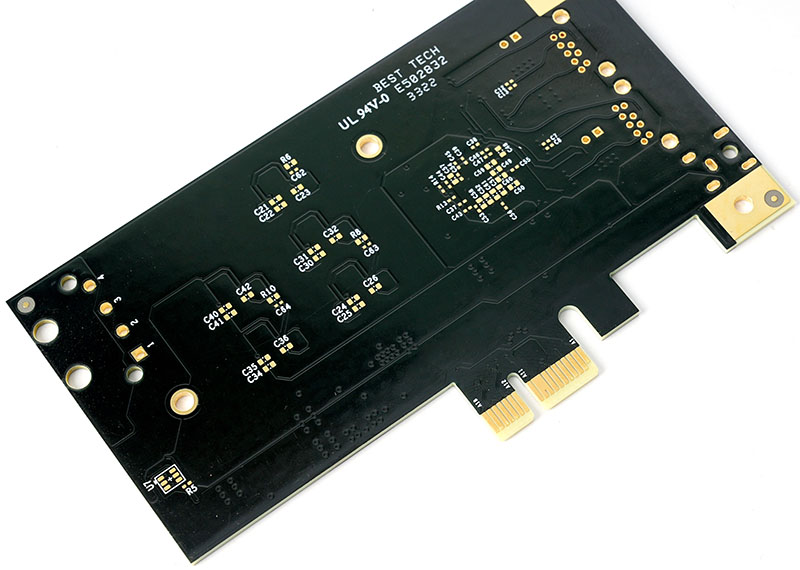

| EBest Circuit(Best Technology) | Custom PCB design, prototyping, mass production, PCB assembly | Global supply chain resources, strict quality control system, professional technical support customized for Icelandic market needs | Supports up to 20-layer HDI PCBs, ¬Ī5% impedance control, 0201-size component assembly | Prototyping 3-5 days, mass production 7-12 days |

| Powersonic | Ultrasonic PCB manufacturing and customization | Specialized in high-frequency ultrasonic PCB technology, compliant with Icelandic safety standards, local after-sales support | Ultrasonic PCB integration, precision drilling, high-reliability soldering | Standard orders 5-8 days, customized ultrasonic products 10-15 days |

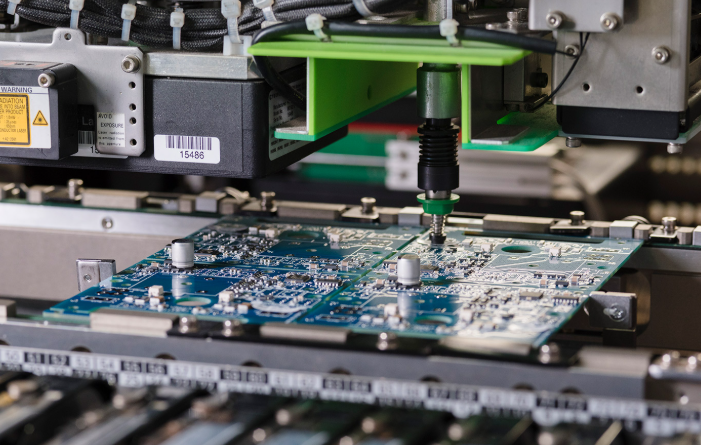

| ABIS Electronics Iceland Branch | PCB fabrication, PCBA assembly, turnkey EMS services | Years of electronic manufacturing experience, ISO-certified quality management, ability to handle complex assembly projects | SMT assembly (25,000 components/hour), BGA/QFP assembly, functional testing | PCB production 6-10 days, PCBA services 8-14 days |

| Opin Kerfi ehf | PCB distribution, custom manufacturing coordination, electronic component sourcing | Local market expertise, HP authorized service partner, reliable supply chain management | Collaborates with local factories for 1-8 layer PCB production, standard/custom solder mask options | 7-14 days depending on order complexity |

| Tölvuland Electronics Division | PCB prototyping, small-batch production, electronic product integration | Local warehouse in Reykjavik, quick response to urgent orders, simplified order process | 1-4 layer PCBs, standard FR-4 substrate, basic assembly services | Prototyping 2-4 days, small-batch production 5-9 days |

| Iceland Circuits Ltd | Industrial-grade PCB manufacturing, environmental-friendly PCB production | Lead-free manufacturing processes, compliance with EU RoHS/REACH regulations, cold environment adaptation design | 2-12 layer PCBs, thermal management optimization, harsh environment testing | Standard orders 8-13 days |

| North Atlantic PCB Solutions | High-reliability PCB fabrication for marine and aerospace applications | Specialized in anti-corrosion PCB design, salt spray testing certification, marine-grade material selection | 4-16 layer PCBs, waterproof solder mask, high-temperature resistant substrates | Custom marine-grade PCBs 10-16 days |

| Reykjavik Electronics Manufacturing | PCB prototyping, low-volume production, design optimization consulting | Local technical team, quick design revision support, on-site quality inspection | 1-6 layer PCBs, flexible PCB options, simple assembly | Prototyping 3-6 days, low-volume production 7-11 days |

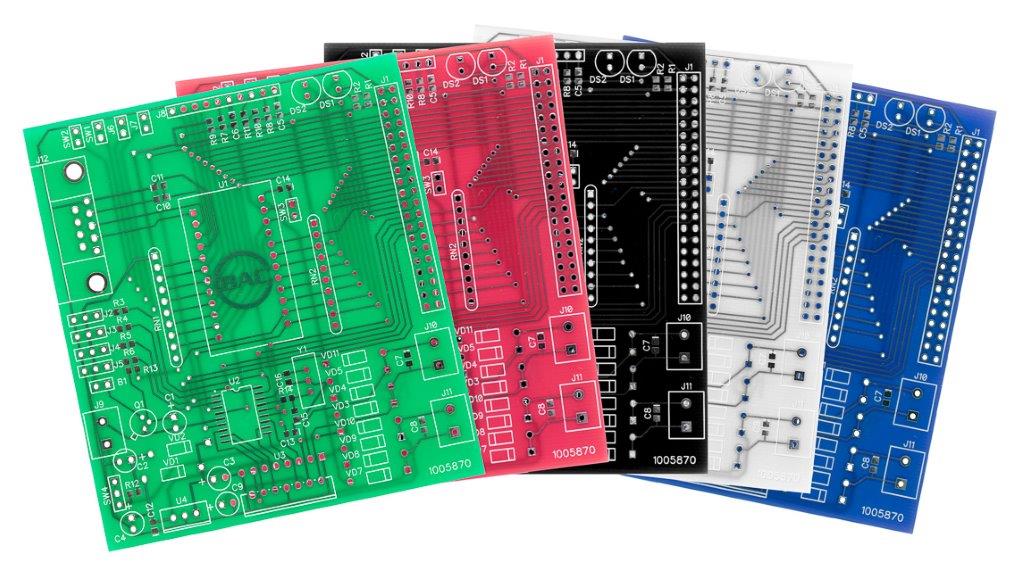

| Arctic PCB Factory | Standard and custom PCB production focusing on consumer electronics | Cost-effective solutions, large production capacity for standard models, local delivery network | 1-8 layer PCBs, FR-4/CEM-1 substrates, standard surface finishes (HASL, ENIG) | Standard orders 5-9 days, custom orders 9-14 days |

| Viking PCB Services | PCB assembly, testing services, post-manufacturing support | Comprehensive testing capabilities (AOI, X-ray), defect analysis services, local repair support | SMT/through-hole assembly, functional testing, burn-in testing | Assembly projects 6-12 days depending on complexity |

How to Choose A Reliable PCB Iceland Manufacturer?

Below is A Detailed Selection Guide to PCB Iceland Manufacturer:

1. Certification & Regulatory Compliance: Select manufacturers with ISO 9001, ISO 14001, UL, and REACH certifications. For example, EU-based suppliers like EBest Circuit( Best Technology) meet RoHS, ensuring compliance with Icelandic and European regulations. Verify certifications via third-party audit reports for transparency.

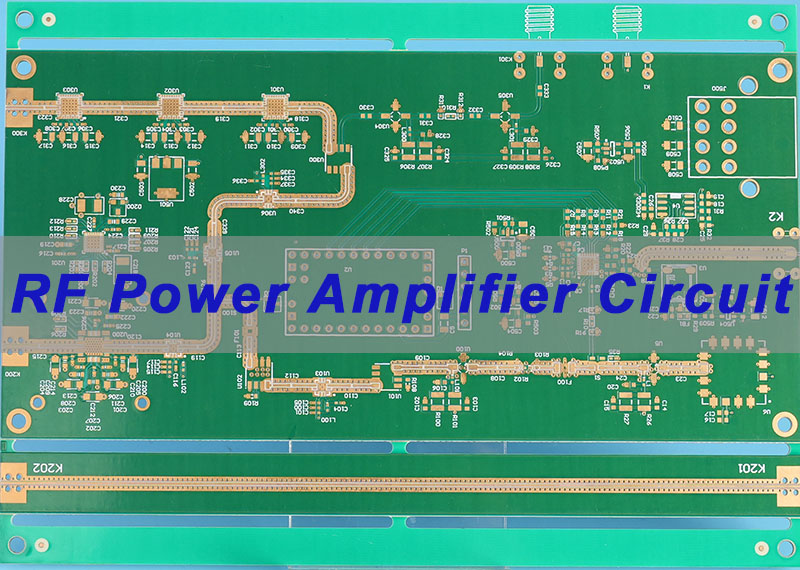

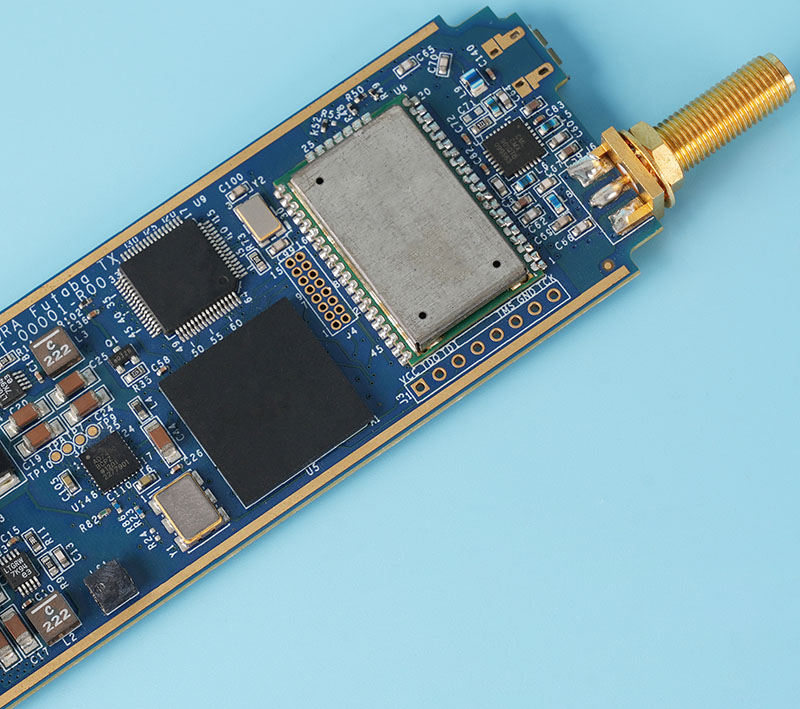

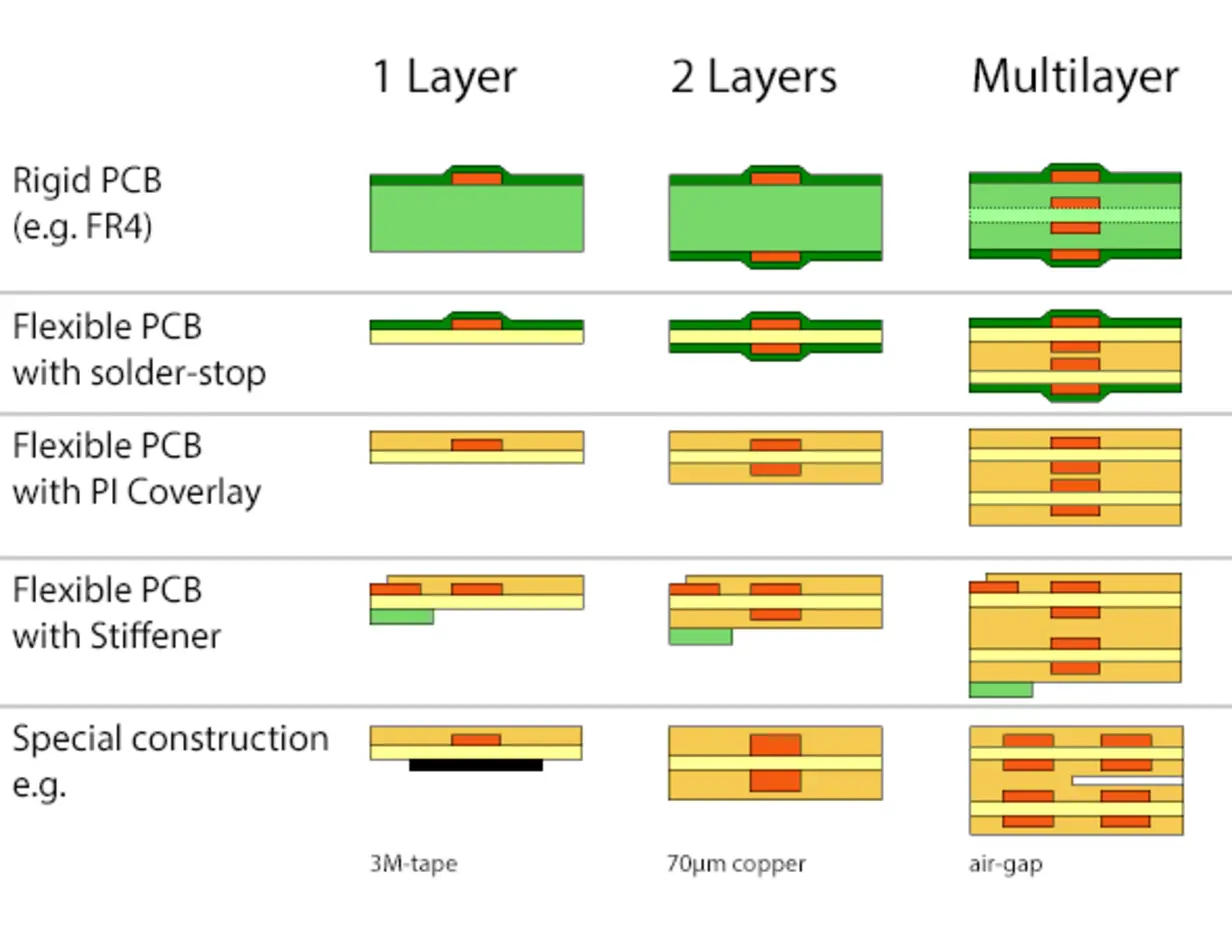

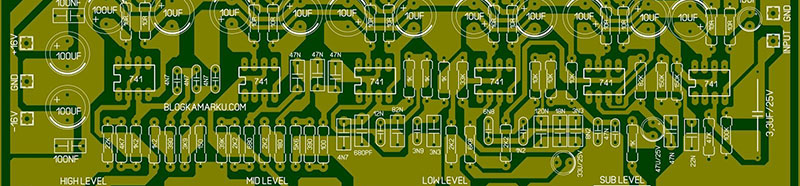

2. Technical Capability & Precision: Prioritize suppliers with line width/spacing capabilities ‚ȧ25őľm, 12+ layer PCB production, and support for advanced processes like HDI, blind/buried vias, and rigid-flex boards. Data from Nordic PCB Association shows 30őľm line/space is standard for high-reliability applications in automotive and telecom sectors.

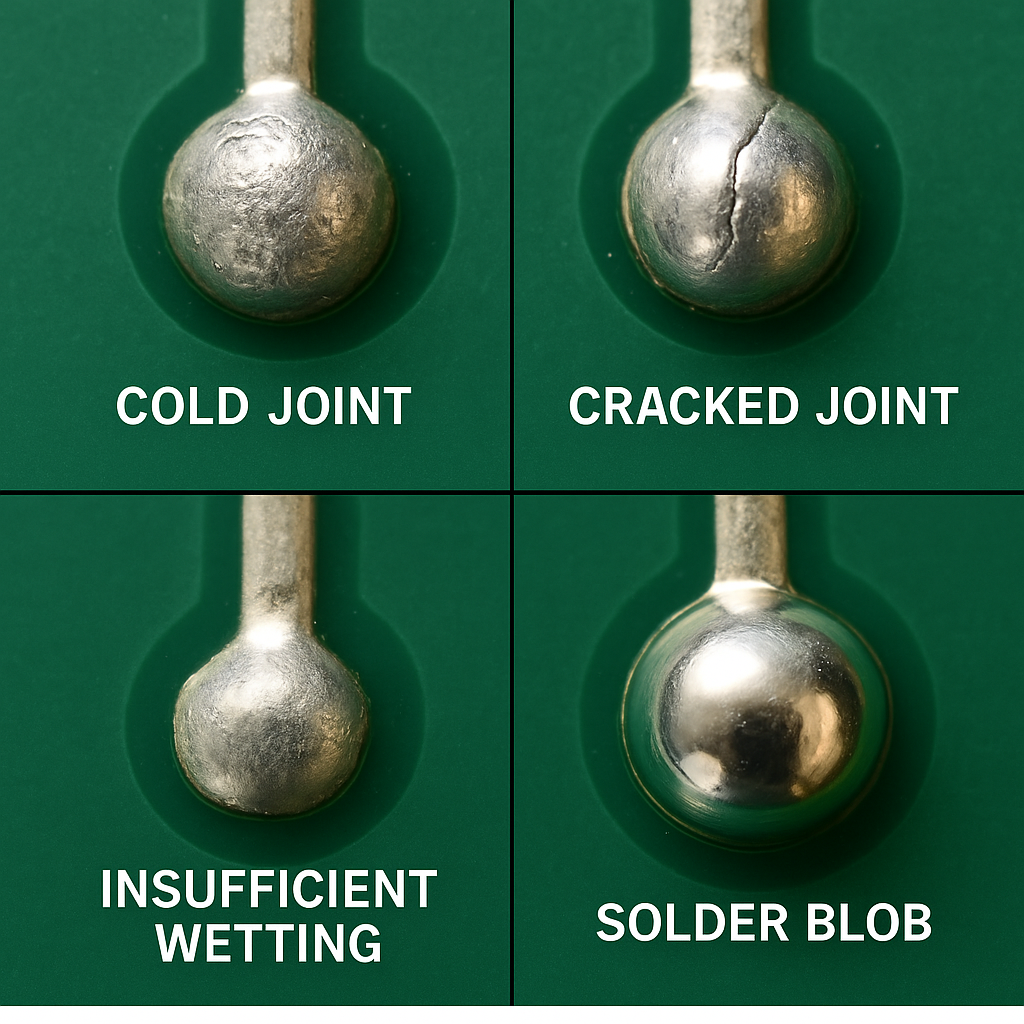

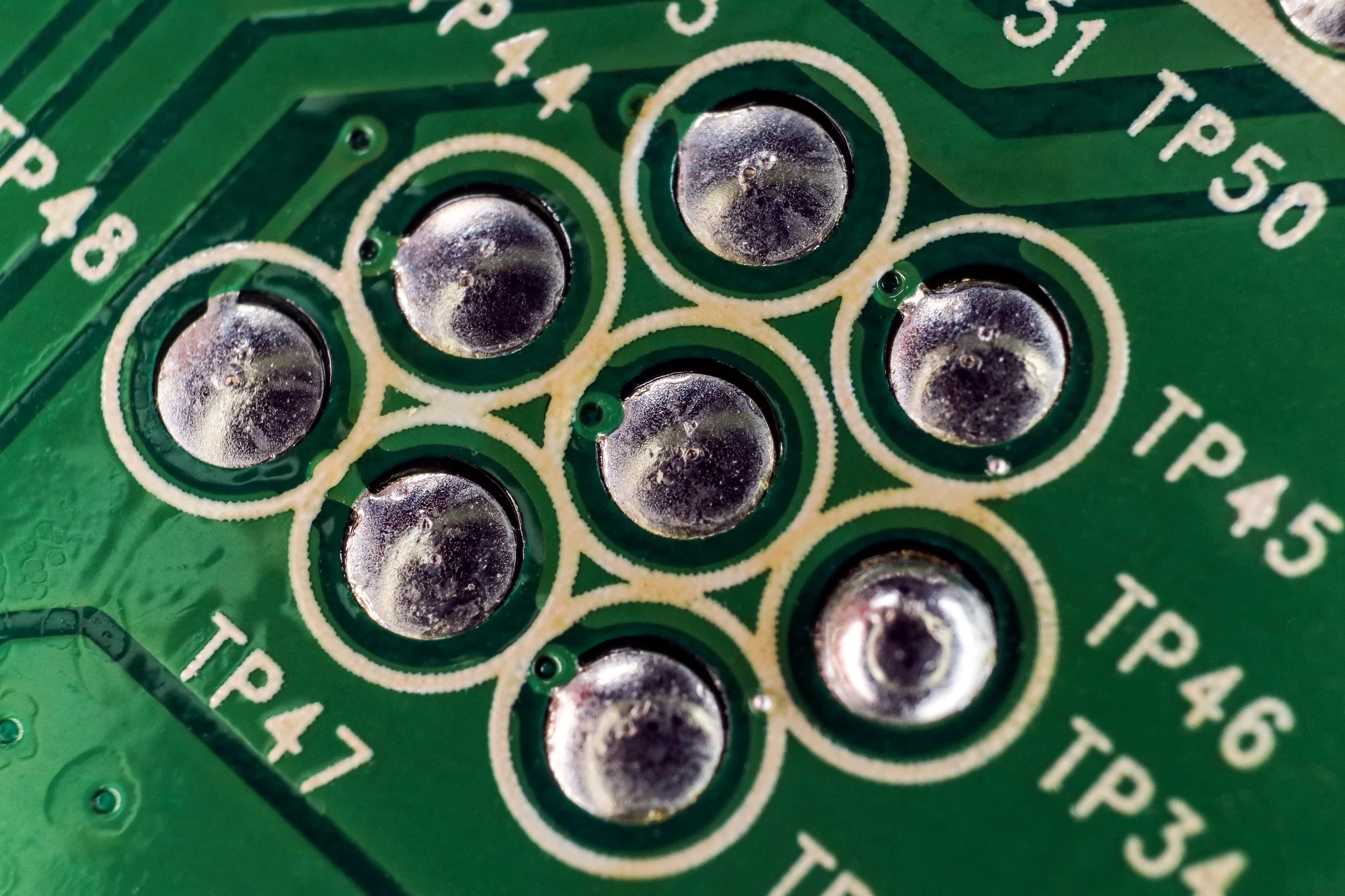

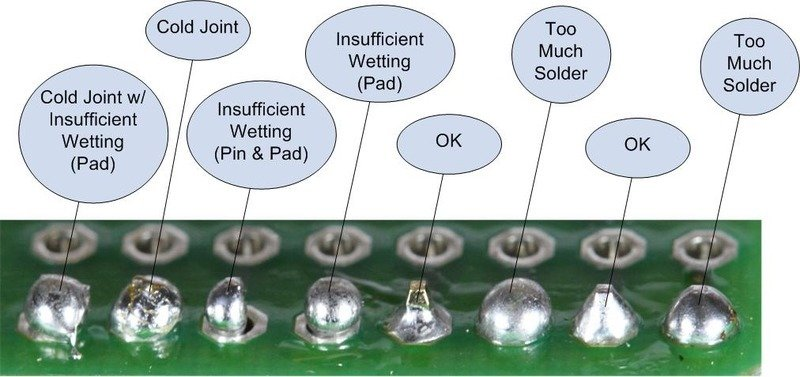

3. Quality Control Systems: Require full-process quality checks using AOI, X-ray, and flying probe testing. Suppliers with IPC-A-610 Class 3 certification achieve 99.2% first-pass yield on multi-layer boards, reducing rework risks. Ask for test data sheets and defect rate metrics for objective assessment.

4. Lead Time & Supply Chain Resilience: Standard prototypes should deliver in 3‚Äď5 days; complex designs in 7‚Äď10 days. Top suppliers offer 24-hour expedited options with 95% on-time delivery rates. Evaluate supply chain redundancy through dual-sourcing of critical materials like copper-clad laminates to avoid delays.

5. Sustainable Materials & Practices: Optimize for manufacturers using lead-free solder (Sn-Ag-Cu), halogen-free substrates, and recyclable packaging. EU Ecolabel-certified suppliers reduce VOC emissions by 40% and achieve 98% waste diversion through closed-loop recycling systems.

6. Technical Support & Responsiveness: Choose suppliers with 7√ó12 technical support and ‚ȧ2-hour response times for DFM feedback. Case studies show teams with local Icelandic representatives reduce communication delays by 50%, accelerating problem resolution.

7. Cost Transparency & Value Engineering: Demand itemized quotes detailing material, fabrication, and testing costs. Suppliers using automated panelization software optimize material usage, reducing costs by 15‚Äď20% without compromising quality. Compare total cost of ownership, including logistics and warranty terms.

8. Industry Experience & References: Select suppliers with proven expertise in 5G infrastructure (e.g., 28GHz RF PCBs), medical implants (IEC 60601 compliance), and automotive electronics (AEC-Q200 qualified). Verify references through independent customer reviews and project portfolios showing similar technical challenges.

9. Localization & Logistics Efficiency: Prioritize EU-based manufacturers with Icelandic distribution hubs to minimize customs delays. Statistics indicate localized logistics reduce shipping times by 3‚Äď5 days and lower carbon footprints by 30% compared to intercontinental transport.

10. R&D Investment & Innovation: Evaluate suppliers investing ‚Č•8% of revenue in R&D for emerging technologies like embedded capacitors or 3D-MID. Patent portfolios in miniaturization or thermal management indicate forward-thinking capabilities, ensuring long-term partnership viability.

Pain Points of Iceland PCB Manufacturing

- High material and manufacturing costs due to limited local raw material supply, leading to increased production expenses for small-batch orders.‚Äč

- Long lead times for specialized components and substrates, as most materials need to be imported to Iceland.‚Äč

- Challenges in meeting strict environmental regulations, including waste disposal requirements for lead-free manufacturing processes.‚Äč

- Limited local capacity for high-complexity PCB production, such as HDI boards and high-frequency circuits, requiring reliance on international partners.‚Äč

- Difficulty in finding manufacturers with expertise in cold environment adaptation, critical for PCB use in Iceland’s harsh climatic conditions.‚Äč

- Inconsistent quality control across smaller local factories, leading to concerns about product reliability and consistency.

Quality Certifications for Iceland PCB Manufacturing Company

- ISO 9001: Quality management system certification, ensuring standardized processes from raw material procurement to final delivery.?

- ISO 14001: Environmental management system certification, covering lead-free manufacturing and waste reduction measures.?

- IS Certification: Iceland’s mandatory safety certification for electronic products, including specific low-temperature and electromagnetic compatibility requirements.?

- UL Certification: Safety certification for flame-retardant materials, essential for consumer electronics and industrial applications.?

- ISO 13485: Quality management certification for medical device PCBs, required for healthcare industry applications.?

- RoHS/REACH Compliance: Compliance with EU regulations restricting hazardous substances in electronic components.

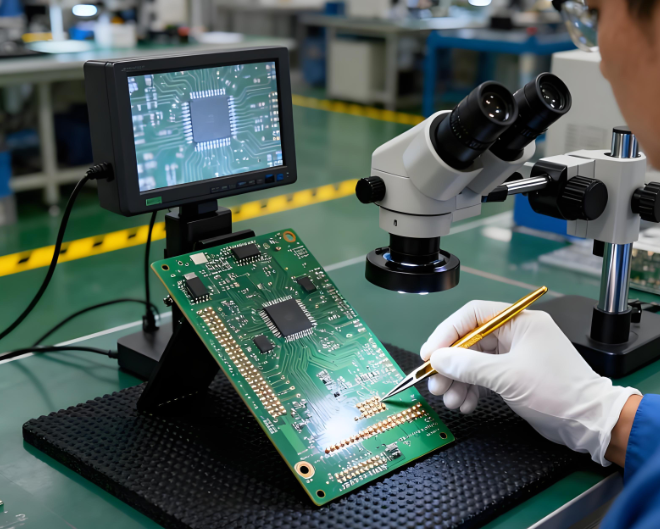

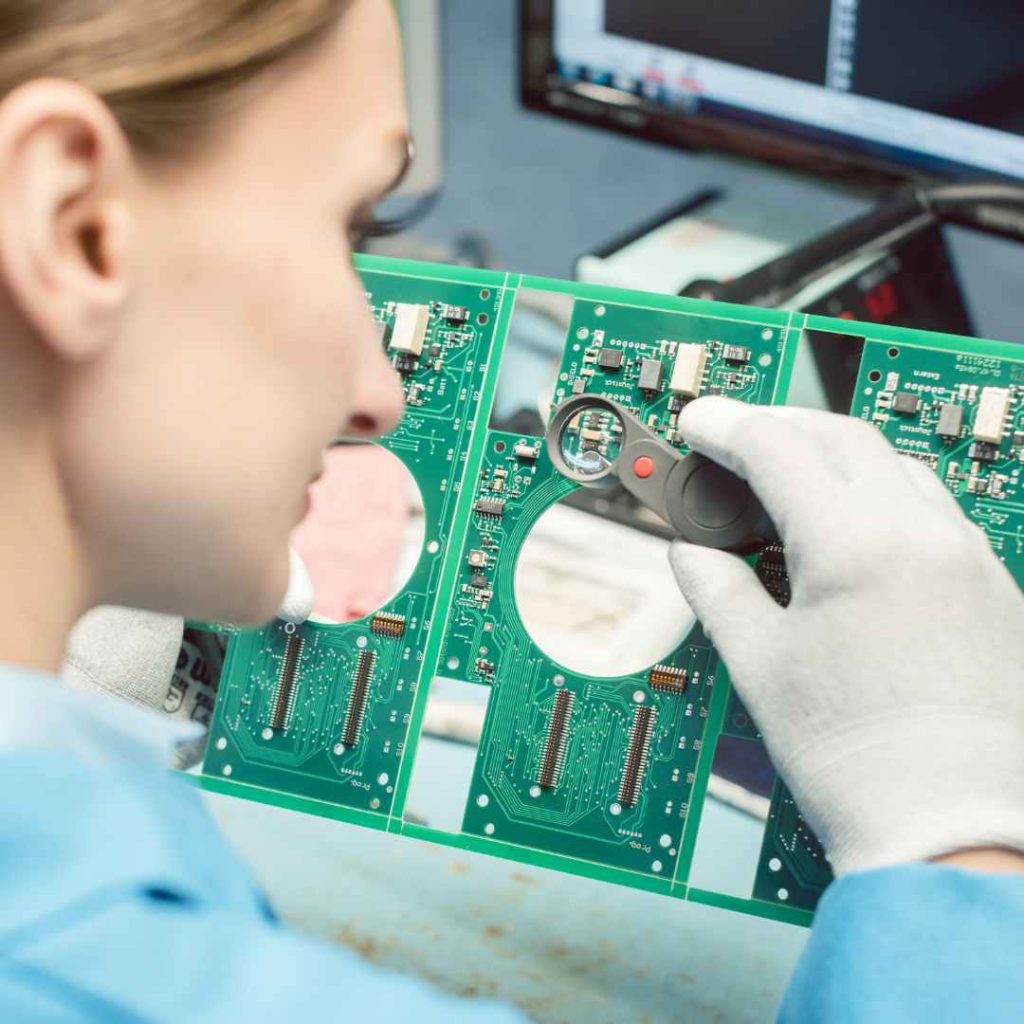

How to Inspect the Quality Management System of Iceland PCB Manufacturer?

Evaluation Guide to the Quality Management System of Iceland PCB Manufacturer:

- ISO Certification Verification: Verify if the manufacturer holds internationally recognized quality management system certifications (e.g., ISO 9001) and confirm the authority of the certifying body and validity period to ensure compliance with international standards.

- Standardized Process Verification: Review whether detailed standard operating procedures (SOPs) are established for each production stage (e.g., drilling accuracy, lamination temperature control, surface treatment) and validate execution consistency through on-site records or sample testing to ensure controllable and traceable process parameters.

- Raw Material Traceability Management: Assess supplier screening mechanisms, require qualification certificates and third-party test reports for key raw materials (e.g., substrates, solder), and inspect warehouse management systems for batch tracking to prevent substandard materials from entering production.

- Equipment Calibration and Maintenance: Check calibration logs and maintenance records for critical equipment such as AOI (Automatic Optical Inspection) and X-ray inspection devices to ensure precision meets industry requirements and prevent quality issues caused by equipment errors.

- Process Data Monitoring and Analysis: Verify if a real-time data collection system (e.g., SPC Statistical Process Control) is implemented to monitor key quality indicators (e.g., line width deviation, solder mask thickness) dynamically and identify potential issues through data analysis to drive continuous improvement.

- Employee Quality Training System: Validate regular quality awareness training and skill assessments for operators, ensure familiarity with quality standards and anomaly handling procedures, and inspect completeness of training archives to match personnel capabilities with job requirements.

- Customer Feedback Closed-Loop Management: Evaluate the customer complaint handling process, require historical case records, confirm root cause analysis methods (e.g., 5Why analysis) for corrective actions, and track verification of improvement effectiveness to form a quality enhancement loop.

- Environmental and Safety Compliance: Check simultaneous implementation of environmental management systems (e.g., ISO 14001) to ensure production environment conditions (e.g., temperature, humidity, cleanliness) meet PCB manufacturing requirements and verify execution of safety protocols to avoid environmental factors affecting product quality stability.

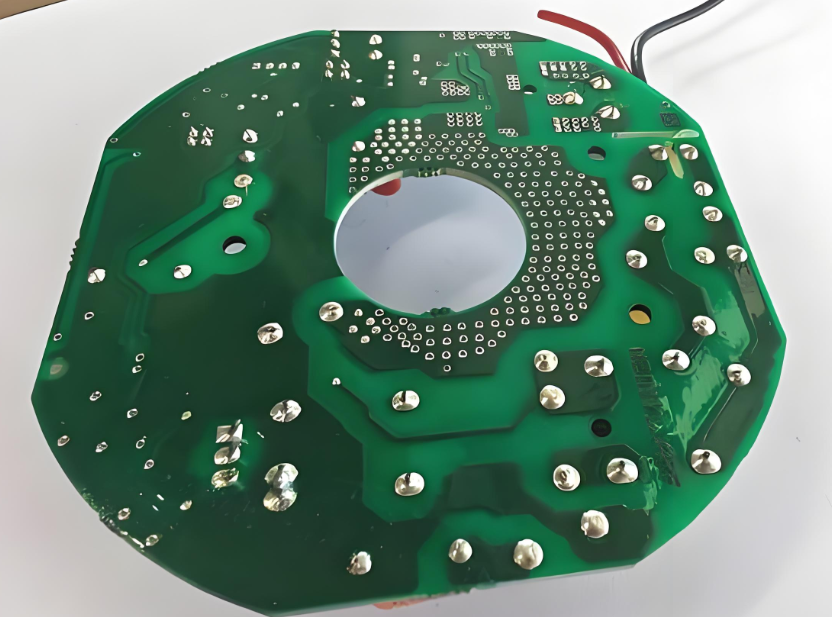

How to Evaluate the Production Capacity of PCB Iceland Manufacturer?

Evaluation Guide to the Production Capacity of PCB Iceland Manufacturer:

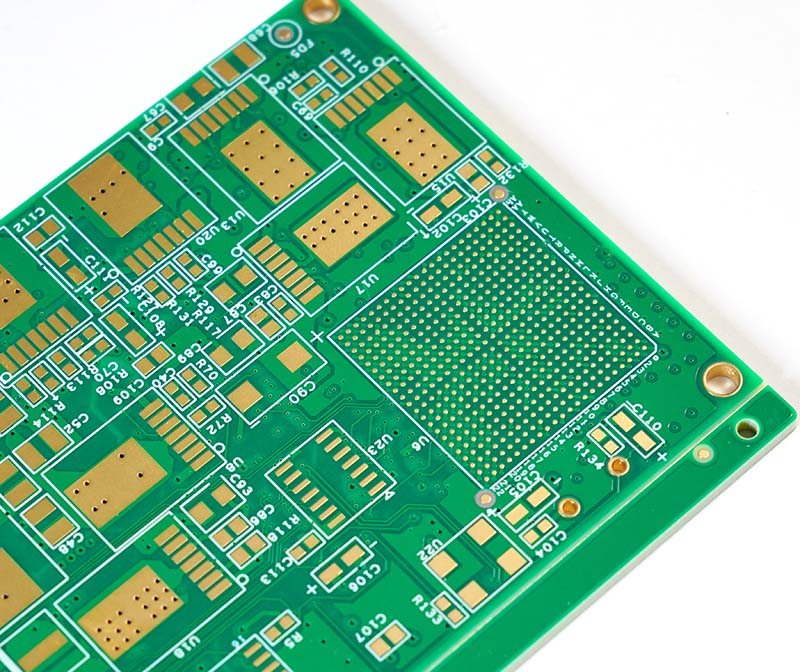

- Check equipment specifications: Confirm availability of advanced equipment with measurable parameters, such as high-precision drilling machines (minimum hole diameter ‚ȧ 0.15mm) and AOI systems (detection accuracy ‚Č• 99.8% for 75őľm line width defects).‚Äč

- Assess production scale and layer capability: Verify maximum monthly output (preferably ‚Č• 10,000„é° for mass production) and layer count range (support for ‚Č• 8-layer standard PCBs or ‚Č• 2-layer HDI boards) to match current and future project demands.‚Äč

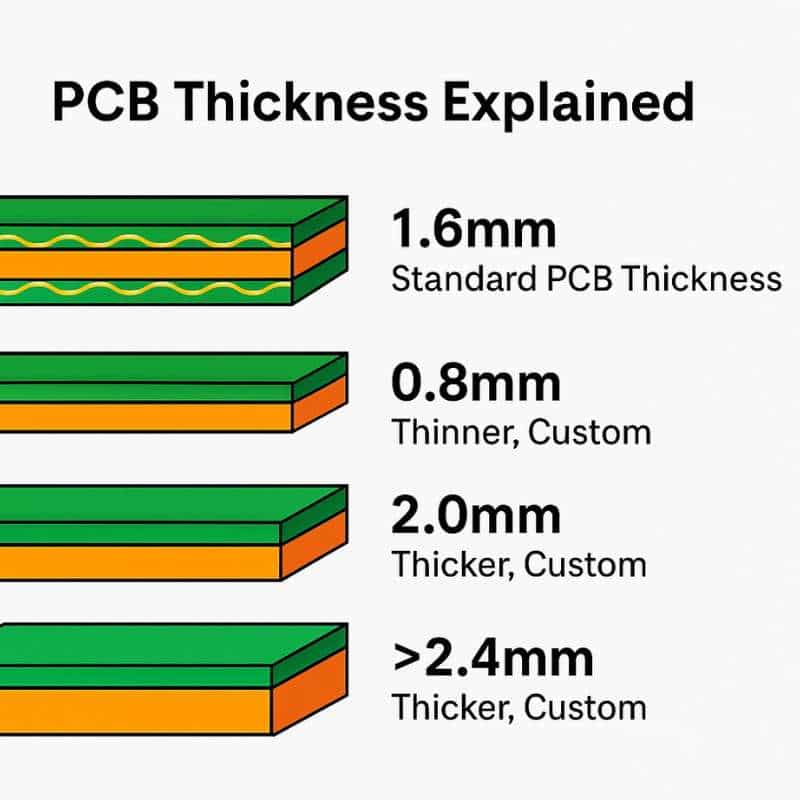

- Validate substrate handling capacity: Confirm proficiency in processing common substrates like FR-4 (Tg 130-140‚ĄÉ) and high-Tg FR-4 (Tg ‚Č• 170‚ĄÉ), as well as flexible substrates with minimum line width/spacing ‚ȧ 50őľm/50őľm.‚Äč

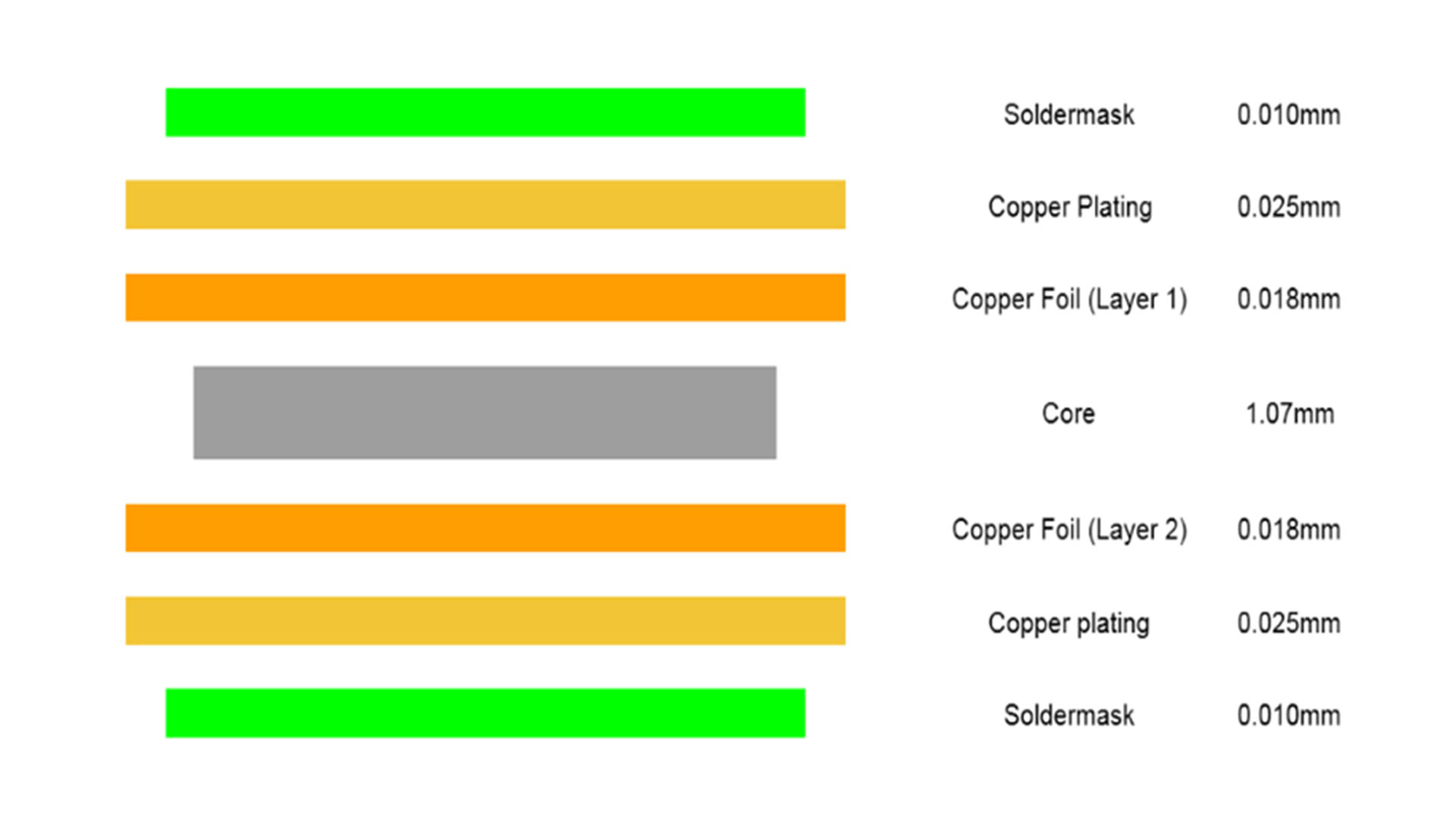

- Evaluate precision performance: Check key precision indicators, including minimum line width/spacing ‚ȧ 75őľm/75őľm, impedance control accuracy ¬Ī5%, and hole diameter tolerance ‚ȧ ¬Ī0.05mm.‚Äč

- Review delivery efficiency data: Confirm lead time benchmarks, prototyping ‚ȧ 5 days, small-batch production (‚ȧ 500 units) ‚ȧ 10 days, and mass production ‚ȧ 15 days with on-time delivery rate ‚Č• 98%.‚Äč

- Assess customization capability: Verify ability to handle non-standard requirements, such as special solder mask colors, custom copper thickness (1-3oz), and thermal management optimization for high-power applications.‚Äč

- Validate assembly capacity (if required): Check SMT assembly speed (‚Č• 25,000 components/hour) and capability to handle BGA/QFP packages with minimum pitch ‚ȧ 0.4mm, supported by X-ray inspection.‚Äč

- Evaluate supply chain resilience: Confirm backup material sources (e.g., 2+ qualified substrate suppliers) and equipment breakdown contingency plans with ‚ȧ 4-hour response time to avoid production delays.

FAQ of Iceland PCB Manufacturing

Q1: What modifications are needed for PCB design to adapt to Iceland’s cold environment?

A1: PCBs used in Iceland’s cold environment require specific material selections, such as high-TG substrates (TG ‚Č• 170¬įC) to prevent brittleness at low temperatures. Additionally, increasing trace width and using flexible solder joints can enhance thermal shock resistance. We provide free design reviews to recommend appropriate modifications, including material selection and layout optimization for cold climate operation.

Q2: How long does PCB prototyping take in Iceland, and can it be expedited?

A2: Standard PCB prototyping in Iceland typically takes 3-7 days. We offer expedited prototyping services with a lead time of 2-3 days by leveraging our global production network and local inventory of key materials. The expedited service includes priority processing and local delivery to meet urgent project timelines.

Q3: What certifications are required for PCB products to be sold legally in Iceland?

A3: Legally sold PCBs in Iceland must have the IS certification issued by the Icelandic Standards Institute (IST). This certification requires compliance with low-voltage directives (LVD) and electromagnetic compatibility (EMC) standards. We ensure all our Iceland-bound PCBs meet these requirements, including providing the necessary technical documentation for customs clearance.

Q4: How to resolve issues with inconsistent plating thickness in PCB production?

A4: Inconsistent plating thickness is often caused by improper bath chemistry or uneven current distribution. Our solution includes strict control of plating process parameters, regular calibration of equipment, and in-process thickness testing using X-ray fluorescence (XRF) technology. We also implement pre-plating cleaning processes to ensure uniform adhesion, reducing plating variations to within ¬Ī5% of the specified thickness.

Q5: Can local Icelandic PCB manufacturers handle high-volume orders, or is it better to work with international partners?

A5: Most local Icelandic PCB manufacturers have limited capacity for high-volume orders. We recommend a hybrid approach: using local manufacturers for small-batch and prototype orders for quick turnaround, and partnering with us for high-volume production. We offer competitive pricing for large orders, global supply chain efficiency, and local delivery to Iceland, ensuring both cost-effectiveness and timely delivery.