You may ever be recommended by some PCB manufacturers to add the fiducial holes on the board edge. Do you know what is fiducial marks and whatâ⏙s the purpose for this kind of holes in a PCB?

Now, let me to show you something for what is the fiducial holes.

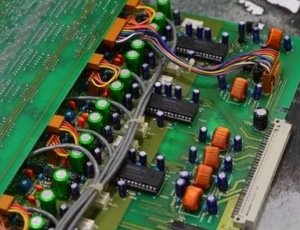

Fiducial holes, we also call it fiducials mark, while we assemble a PCB, it will need to locate the positions for each component, and it is positioned based on the fiducial mark as the reference point.

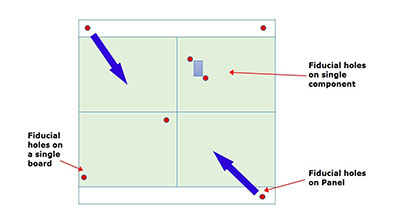

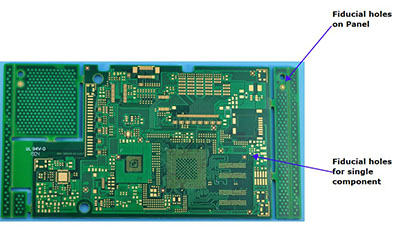

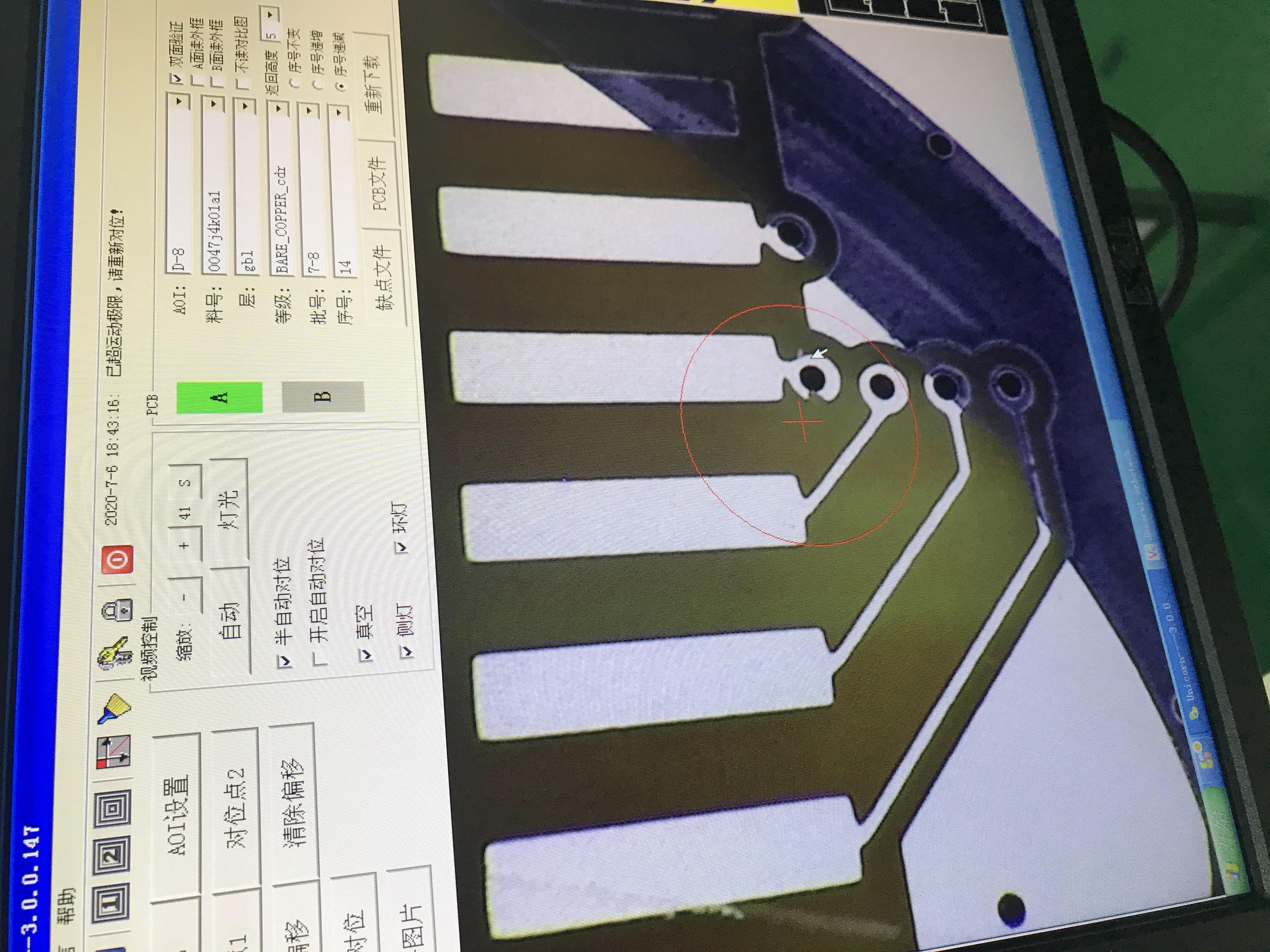

There are 3 types fiducial marks, first type is fiducial marks on a single board, second type is the fiducial marks on a PCB panel, third one is the fiducial marks for some single component on the board.

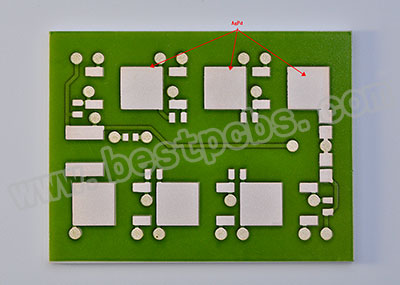

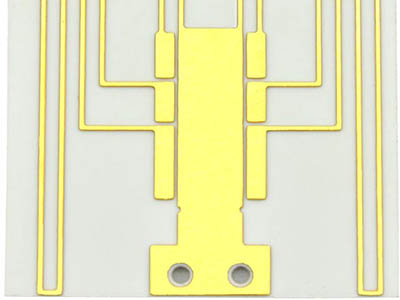

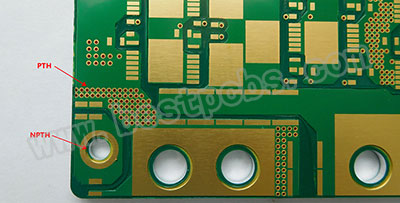

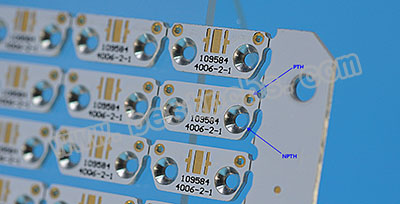

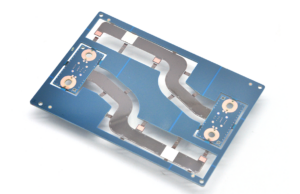

Here are the pictures for you to understand the types of the fiducials.

Fiducial mark on a single board is designed for positioned all circuits features on a single board. It is necessary to have a fiducial mark on a single board.

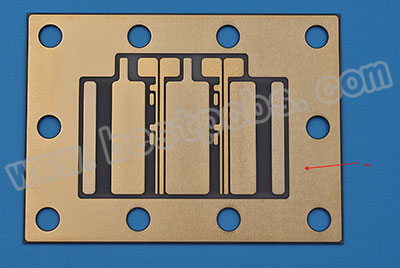

And fiducial marks on a PCB panel is used to assist positioning the circuits.

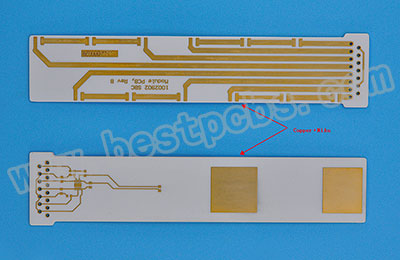

For the fiducial mark of a single component, it is designed to position the fiducial mark of a single component, which can improve the placement progress (For QFP, CSP, BGA and other important components must have the fiducial marks).

So, it is important to add the fiducial holes on a PCB board.

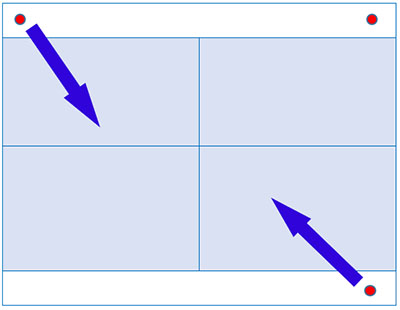

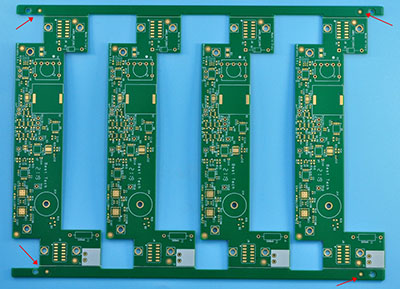

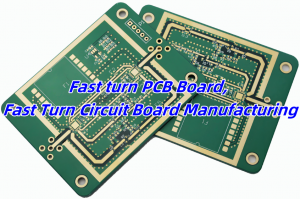

Also, while we make the panel for the PCB board, on the diagonal of the four corners, it is required to have 2 fiducial points at least on 2 diagonal corners. you can also place 4 marks on the four corners, but generally, assembly plant will only need 2 marks for recognize.

See below a PCB panel for reference:

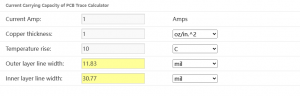

In the other hand, while you design the PCB, please try not to put the silk screens, pads, traces etc. within 2mm of the optical fiducial marks. Otherwise, the SMT machine will not be able to recognize the optical fiducial on the PCB boards.

And if you add the fiducial holes on the area which without any circuits, to avoid the holes being etching while the process, so generally we suggest to add a metal circles around the fiducial holes, to make it more obviously on the boards.

If you have any new PCB design which you also want to add the fiducial marks.

You are welcome to contact Best Technology for a help and we will show our best help for you.