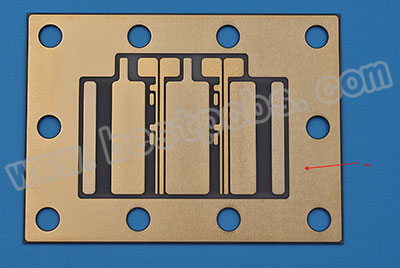

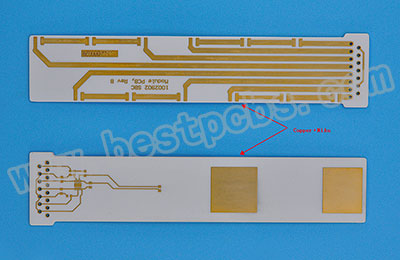

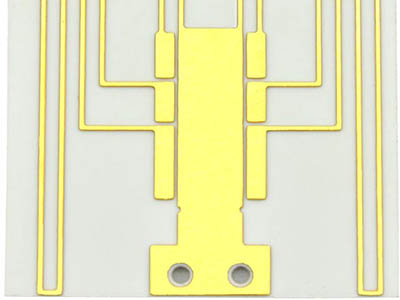

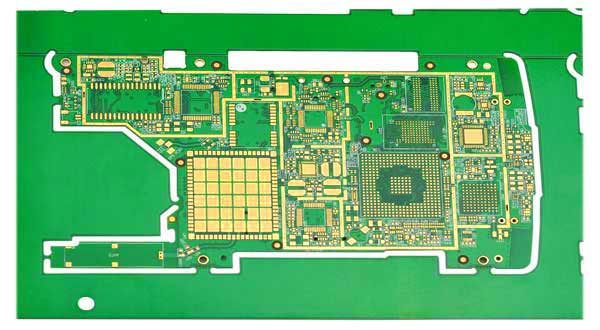

Ceramic PCB including Alumina PCB (Al2O3 PCB), Aluminum Nitride PCB (AlN), Bryllium Oxide PCB(BeO PCB) etc.

There are other differences except the substrate material is different.

- The method of making conductor is different.

The conductor for thick film ceramic is made by printing, but DPC is made by vacuum sputtering and plating.

- The conductor is different.

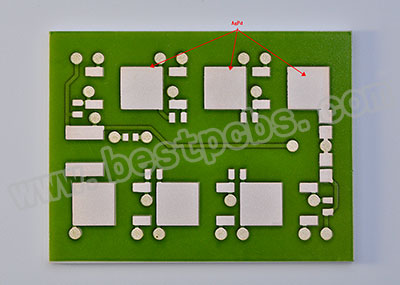

The conductor for thick film ceramic PCB is Au or AgPd, but for DPC ceramic PCB, it is copper.

- The thickness of conductor is different.

Normally, it is 10-20um for thick film ceramic PCB, copper thickness can be 10um-300um for DPC ceramic PCB.

- The solder mask is different.

It is glass glaze for thick film ceramic PCB, the most popular color is greenish and blue. Glass glaze can withstand very high temperature, up to 850C

It is normal solder mask oil for DPC ceramic PCB, the most popular color is white.

The above is only simple introduction for the difference, if you want to know more differences between thick film ceramic PCB and DPC ceramic PCB or other details about ceramic PCB, please contact us